Evaluation of Graphitized carbon nanotubes for automotive and grid energy storage applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Energy Storage Background & Objectives

Carbon nanotubes (CNTs) have emerged as a revolutionary material in energy storage technology since their discovery in 1991. These cylindrical carbon structures possess exceptional electrical conductivity, mechanical strength, and thermal stability, making them ideal candidates for next-generation energy storage applications. Graphitized carbon nanotubes, specifically, represent an advanced form where the carbon structure undergoes high-temperature treatment to enhance crystallinity and reduce defects, resulting in superior electrical and thermal properties compared to conventional CNTs.

The evolution of energy storage technologies has been driven by increasing demands for higher energy density, faster charging capabilities, and longer cycle life in both automotive and grid applications. Traditional lithium-ion batteries, while commercially successful, face limitations in power density and cycle stability that restrict their performance in these demanding sectors. Graphitized CNTs offer a promising pathway to overcome these constraints through their unique structural and electrical properties.

In the automotive sector, the transition toward electric vehicles (EVs) necessitates energy storage solutions that deliver high power density for acceleration, rapid charging capabilities, and sufficient energy density for extended range. Current EV batteries struggle to simultaneously meet all these requirements, creating a technological gap that graphitized CNTs could potentially address.

For grid energy storage, the integration of renewable energy sources introduces challenges related to intermittency and peak demand management. Energy storage systems must provide rapid response times, high efficiency, and long-term durability under frequent charge-discharge cycles. The exceptional conductivity and stability of graphitized CNTs present opportunities for significant improvements in these critical areas.

The primary objective of this technical evaluation is to comprehensively assess the potential of graphitized carbon nanotubes as a transformative material in automotive and grid energy storage applications. This includes analyzing their fundamental properties, current manufacturing capabilities, integration challenges, and performance characteristics compared to existing solutions.

Additionally, this research aims to identify the technological barriers that must be overcome to enable widespread commercial adoption of graphitized CNT-based energy storage systems. These include scalable production methods, cost-effective integration techniques, and performance optimization strategies that align with industry requirements and standards.

The evaluation will also establish quantifiable performance targets for graphitized CNT energy storage systems, including specific energy and power densities, cycle life expectations, temperature tolerance ranges, and safety parameters that would position this technology as a viable alternative to current solutions in both automotive and grid applications.

The evolution of energy storage technologies has been driven by increasing demands for higher energy density, faster charging capabilities, and longer cycle life in both automotive and grid applications. Traditional lithium-ion batteries, while commercially successful, face limitations in power density and cycle stability that restrict their performance in these demanding sectors. Graphitized CNTs offer a promising pathway to overcome these constraints through their unique structural and electrical properties.

In the automotive sector, the transition toward electric vehicles (EVs) necessitates energy storage solutions that deliver high power density for acceleration, rapid charging capabilities, and sufficient energy density for extended range. Current EV batteries struggle to simultaneously meet all these requirements, creating a technological gap that graphitized CNTs could potentially address.

For grid energy storage, the integration of renewable energy sources introduces challenges related to intermittency and peak demand management. Energy storage systems must provide rapid response times, high efficiency, and long-term durability under frequent charge-discharge cycles. The exceptional conductivity and stability of graphitized CNTs present opportunities for significant improvements in these critical areas.

The primary objective of this technical evaluation is to comprehensively assess the potential of graphitized carbon nanotubes as a transformative material in automotive and grid energy storage applications. This includes analyzing their fundamental properties, current manufacturing capabilities, integration challenges, and performance characteristics compared to existing solutions.

Additionally, this research aims to identify the technological barriers that must be overcome to enable widespread commercial adoption of graphitized CNT-based energy storage systems. These include scalable production methods, cost-effective integration techniques, and performance optimization strategies that align with industry requirements and standards.

The evaluation will also establish quantifiable performance targets for graphitized CNT energy storage systems, including specific energy and power densities, cycle life expectations, temperature tolerance ranges, and safety parameters that would position this technology as a viable alternative to current solutions in both automotive and grid applications.

Automotive & Grid Storage Market Analysis

The global energy storage market is experiencing unprecedented growth, driven by the dual imperatives of vehicle electrification and renewable energy integration. The automotive energy storage sector is projected to reach $209 billion by 2030, with a compound annual growth rate of 17.2% from 2023. This growth is primarily fueled by the rapid adoption of electric vehicles (EVs), with major markets including China, Europe, and North America leading the transition away from internal combustion engines.

Consumer demand for EVs with longer ranges, faster charging capabilities, and improved safety profiles is reshaping the automotive battery landscape. Current lithium-ion technologies face limitations in energy density, charging speed, and thermal management that graphitized carbon nanotubes could potentially address. The market increasingly values batteries that can deliver 300+ miles of range while charging to 80% capacity in under 20 minutes.

In parallel, the grid energy storage market is projected to reach $31.2 billion by 2029, growing at 18.7% annually. This sector's expansion is driven by the increasing penetration of intermittent renewable energy sources like solar and wind, which require robust storage solutions to ensure grid stability and reliability. Utility-scale storage deployments are accelerating globally, with particular momentum in regions with aggressive renewable energy targets.

The grid storage market demands solutions with specific performance characteristics: long cycle life (10,000+ cycles), high round-trip efficiency (>85%), scalability, and increasingly, duration flexibility ranging from short-term frequency regulation to multi-day backup capacity. Cost remains a critical factor, with the industry targeting system costs below $100/kWh for widespread adoption.

Both automotive and grid storage applications face similar technical challenges that advanced materials like graphitized carbon nanotubes could potentially address. These include improving energy density, enhancing charge/discharge rates, extending operational lifespans, and maintaining performance across wider temperature ranges.

Regional market dynamics vary significantly. Asia-Pacific, particularly China, dominates manufacturing capacity for current battery technologies, while North America and Europe are investing heavily in next-generation solutions. Government policies, including subsidies, mandates, and infrastructure investments, continue to shape market development across regions.

The convergence of automotive and grid storage markets is creating new opportunities for technology crossover, with vehicle-to-grid (V2G) applications emerging as a potential value stream that could benefit from advanced materials with superior cycling capabilities and power characteristics.

Consumer demand for EVs with longer ranges, faster charging capabilities, and improved safety profiles is reshaping the automotive battery landscape. Current lithium-ion technologies face limitations in energy density, charging speed, and thermal management that graphitized carbon nanotubes could potentially address. The market increasingly values batteries that can deliver 300+ miles of range while charging to 80% capacity in under 20 minutes.

In parallel, the grid energy storage market is projected to reach $31.2 billion by 2029, growing at 18.7% annually. This sector's expansion is driven by the increasing penetration of intermittent renewable energy sources like solar and wind, which require robust storage solutions to ensure grid stability and reliability. Utility-scale storage deployments are accelerating globally, with particular momentum in regions with aggressive renewable energy targets.

The grid storage market demands solutions with specific performance characteristics: long cycle life (10,000+ cycles), high round-trip efficiency (>85%), scalability, and increasingly, duration flexibility ranging from short-term frequency regulation to multi-day backup capacity. Cost remains a critical factor, with the industry targeting system costs below $100/kWh for widespread adoption.

Both automotive and grid storage applications face similar technical challenges that advanced materials like graphitized carbon nanotubes could potentially address. These include improving energy density, enhancing charge/discharge rates, extending operational lifespans, and maintaining performance across wider temperature ranges.

Regional market dynamics vary significantly. Asia-Pacific, particularly China, dominates manufacturing capacity for current battery technologies, while North America and Europe are investing heavily in next-generation solutions. Government policies, including subsidies, mandates, and infrastructure investments, continue to shape market development across regions.

The convergence of automotive and grid storage markets is creating new opportunities for technology crossover, with vehicle-to-grid (V2G) applications emerging as a potential value stream that could benefit from advanced materials with superior cycling capabilities and power characteristics.

Technical Challenges in Carbon Nanotube Graphitization

Despite significant advancements in carbon nanotube (CNT) graphitization techniques, several technical challenges persist that hinder the widespread adoption of graphitized CNTs in automotive and grid energy storage applications. The primary challenge lies in achieving uniform and complete graphitization across large batches of carbon nanotubes. Current high-temperature thermal treatment methods (typically 1800-3000°C) often result in inconsistent graphitization levels, with some CNTs exhibiting perfect graphitic structures while others remain partially graphitized, leading to performance variability in energy storage devices.

Scale-up of graphitization processes presents another significant hurdle. Laboratory-scale graphitization techniques that produce high-quality materials often face difficulties when translated to industrial production volumes required for automotive and grid applications. The energy-intensive nature of graphitization processes, particularly those requiring temperatures above 2500°C, contributes substantially to production costs and environmental impact, making commercial viability challenging.

Structural integrity maintenance during graphitization represents a critical technical barrier. The high temperatures necessary for effective graphitization can cause structural deformations, tube shortening, and wall damage in CNTs. These structural changes can negatively impact the electrical conductivity, mechanical strength, and electrochemical performance of the resulting materials, compromising their effectiveness in energy storage applications.

Controlling defect formation and elimination during the graphitization process remains technically demanding. While graphitization aims to reduce structural defects, the process itself can introduce new types of defects or fail to eliminate existing ones completely. The presence of residual defects significantly affects electron transport properties and electrochemical performance in energy storage applications.

Purification challenges also persist throughout the graphitization workflow. Catalyst particles and amorphous carbon impurities can interfere with uniform graphitization and subsequently degrade performance in energy storage devices. Current purification methods often involve aggressive chemical treatments that may damage the CNT structure or introduce functional groups that interfere with graphitization.

The characterization and quality control of graphitized CNTs present additional technical difficulties. Existing analytical techniques struggle to provide comprehensive, high-throughput assessment of graphitization degree, defect density, and electrochemical performance parameters across large production batches. This limitation hampers quality assurance processes necessary for automotive and grid applications where reliability and consistency are paramount.

Lastly, integration challenges exist when incorporating graphitized CNTs into practical electrode architectures. Issues with dispersion, agglomeration, and interfacial compatibility with binders and current collectors can significantly reduce the theoretical performance advantages of graphitized CNTs in actual energy storage devices.

Scale-up of graphitization processes presents another significant hurdle. Laboratory-scale graphitization techniques that produce high-quality materials often face difficulties when translated to industrial production volumes required for automotive and grid applications. The energy-intensive nature of graphitization processes, particularly those requiring temperatures above 2500°C, contributes substantially to production costs and environmental impact, making commercial viability challenging.

Structural integrity maintenance during graphitization represents a critical technical barrier. The high temperatures necessary for effective graphitization can cause structural deformations, tube shortening, and wall damage in CNTs. These structural changes can negatively impact the electrical conductivity, mechanical strength, and electrochemical performance of the resulting materials, compromising their effectiveness in energy storage applications.

Controlling defect formation and elimination during the graphitization process remains technically demanding. While graphitization aims to reduce structural defects, the process itself can introduce new types of defects or fail to eliminate existing ones completely. The presence of residual defects significantly affects electron transport properties and electrochemical performance in energy storage applications.

Purification challenges also persist throughout the graphitization workflow. Catalyst particles and amorphous carbon impurities can interfere with uniform graphitization and subsequently degrade performance in energy storage devices. Current purification methods often involve aggressive chemical treatments that may damage the CNT structure or introduce functional groups that interfere with graphitization.

The characterization and quality control of graphitized CNTs present additional technical difficulties. Existing analytical techniques struggle to provide comprehensive, high-throughput assessment of graphitization degree, defect density, and electrochemical performance parameters across large production batches. This limitation hampers quality assurance processes necessary for automotive and grid applications where reliability and consistency are paramount.

Lastly, integration challenges exist when incorporating graphitized CNTs into practical electrode architectures. Issues with dispersion, agglomeration, and interfacial compatibility with binders and current collectors can significantly reduce the theoretical performance advantages of graphitized CNTs in actual energy storage devices.

Current Graphitized CNT Implementation Methods

01 Synthesis methods for graphitized carbon nanotubes

Various methods can be employed to synthesize graphitized carbon nanotubes, including high-temperature thermal treatment processes that transform amorphous carbon into crystalline graphitic structures. These methods often involve heating carbon nanotubes at temperatures above 2000°C in controlled environments to improve their crystallinity and electrical properties. The graphitization process can be optimized by adjusting parameters such as temperature, duration, and atmosphere to achieve desired structural characteristics.- Manufacturing methods of graphitized carbon nanotubes: Various methods are employed to produce graphitized carbon nanotubes, including high-temperature thermal treatment processes that convert amorphous carbon structures into more ordered graphitic structures. These manufacturing techniques often involve heating carbon nanotubes at temperatures exceeding 2000°C in controlled environments to achieve graphitization. The process parameters such as temperature, duration, and atmosphere significantly influence the degree of graphitization and the resulting properties of the nanotubes.

- Electrical and thermal properties of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit enhanced electrical conductivity and thermal properties compared to their non-graphitized counterparts. The graphitization process reduces defects in the carbon structure, resulting in improved electron mobility and electrical performance. These materials show superior thermal conductivity due to the more ordered graphitic structure, making them valuable for applications in electronics, energy storage, and thermal management systems.

- Composite materials incorporating graphitized carbon nanotubes: Graphitized carbon nanotubes are used as reinforcement in various composite materials to enhance mechanical, electrical, and thermal properties. When incorporated into polymer, metal, or ceramic matrices, these nanotubes significantly improve strength, stiffness, and conductivity of the resulting composites. The superior interfacial bonding between graphitized nanotubes and matrix materials leads to more effective load transfer and property enhancement compared to non-graphitized variants.

- Surface functionalization of graphitized carbon nanotubes: Surface modification and functionalization techniques are applied to graphitized carbon nanotubes to improve their compatibility with various matrices and to tailor their properties for specific applications. These processes involve attaching functional groups to the nanotube surface through chemical treatments while preserving the beneficial graphitic structure. Functionalized graphitized nanotubes show enhanced dispersibility in solvents and polymers, enabling better processing and integration into advanced materials.

- Energy storage applications of graphitized carbon nanotubes: Graphitized carbon nanotubes are extensively utilized in energy storage devices such as lithium-ion batteries, supercapacitors, and fuel cells. Their highly ordered graphitic structure provides excellent electron transport pathways and electrochemical stability. These materials serve as conductive additives in electrodes, enhancing charge transfer and cycling performance. The high surface area combined with superior electrical conductivity makes graphitized carbon nanotubes particularly valuable for improving energy density and power capability in storage devices.

02 Applications in energy storage and electronic devices

Graphitized carbon nanotubes exhibit excellent electrical conductivity and thermal stability, making them ideal for energy storage applications such as lithium-ion batteries, supercapacitors, and fuel cells. Their highly ordered graphitic structure facilitates electron transport and ion diffusion, enhancing device performance. Additionally, these materials are utilized in electronic components, field emission displays, and conductive composites where their superior electrical properties provide advantages over conventional materials.Expand Specific Solutions03 Composite materials incorporating graphitized carbon nanotubes

Graphitized carbon nanotubes can be incorporated into various matrices to form advanced composite materials with enhanced mechanical, electrical, and thermal properties. These composites find applications in aerospace, automotive, and construction industries. The graphitization process improves the interfacial bonding between nanotubes and matrix materials, resulting in better load transfer and overall performance. Methods for uniform dispersion and functionalization of graphitized nanotubes within composite matrices are critical for optimizing material properties.Expand Specific Solutions04 Surface modification and functionalization techniques

Various techniques can be employed to modify the surface of graphitized carbon nanotubes, including chemical functionalization, plasma treatment, and coating with metallic or polymeric materials. These modifications enhance compatibility with specific matrices, improve dispersibility, and introduce additional functionalities. Surface-modified graphitized carbon nanotubes can be tailored for specific applications such as sensing, catalysis, or biomedical uses while maintaining their core graphitic structure and beneficial properties.Expand Specific Solutions05 Characterization and quality control methods

Specialized techniques are employed to characterize graphitized carbon nanotubes and assess their quality, including Raman spectroscopy, X-ray diffraction, transmission electron microscopy, and electrical conductivity measurements. These methods help determine the degree of graphitization, structural integrity, and performance characteristics. Quality control protocols ensure consistency in production and help correlate processing parameters with final material properties, enabling the optimization of graphitized carbon nanotubes for specific applications.Expand Specific Solutions

Leading Companies in CNT Energy Storage

The graphitized carbon nanotube market for energy storage applications is in a growth phase, with increasing demand driven by automotive and grid storage needs. The market is expected to expand significantly as battery technology advances, with projections showing substantial growth over the next decade. Technologically, the field is maturing rapidly with key players demonstrating varied levels of development. Research institutions like University of Tsukuba, Rice University, and National Taiwan University of Science & Technology are advancing fundamental science, while commercial entities including Sumitomo Electric Industries, Nikkiso Co., and Hangzhou Highene Technology are scaling manufacturing processes. Intel and NASA are exploring high-performance applications, while automotive-focused companies are developing integration solutions for electric vehicles. The ecosystem shows a healthy balance between academic research and industrial commercialization efforts.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric Industries has developed an advanced manufacturing process for graphitized carbon nanotubes (GCNTs) specifically optimized for energy storage applications. Their proprietary technique involves a continuous high-temperature (>2700°C) graphitization process combined with precise catalyst control to produce highly crystalline nanotubes with exceptional electrical and thermal properties. For automotive applications, Sumitomo has created GCNT-enhanced electrode materials that demonstrate superior fast-charging capabilities, achieving 80% charge in under 15 minutes while maintaining thermal stability. Their automotive battery systems incorporate GCNT-based thermal management components that improve heat distribution and reduce hotspot formation, extending battery life by approximately 30% under extreme operating conditions. For grid storage applications, Sumitomo has developed large-format GCNT-enhanced electrodes with remarkable cycling stability (>8,000 cycles at 80% capacity retention) and improved power handling capabilities. Their grid storage systems utilize a hierarchical electrode architecture where GCNTs create conductive networks throughout the electrode structure, significantly reducing internal resistance and enabling high-power response for grid stabilization applications.

Strengths: Established industrial-scale manufacturing capabilities and extensive experience in materials commercialization provide advantages for market deployment. Their integrated approach addressing both energy storage and thermal management offers comprehensive solutions. Weaknesses: Higher production costs compared to conventional materials may limit adoption in price-sensitive markets, and their technology may face competition from alternative carbon nanomaterials.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed advanced graphitized carbon nanotube (GCNT) composites specifically engineered for automotive and grid energy storage applications. Their proprietary process involves controlled graphitization of carbon nanotubes at temperatures exceeding 2500°C, resulting in highly crystalline structures with enhanced electrical conductivity (>10^6 S/m) and thermal stability. These GCNTs are incorporated into electrode materials using a patented dispersion technique that ensures uniform distribution within the electrode matrix. For automotive applications, Dow has created GCNT-enhanced lithium-ion battery electrodes that demonstrate up to 40% higher energy density compared to conventional graphite electrodes, while maintaining structural integrity over extended charge-discharge cycles. Their grid storage solution utilizes GCNT-infused flow battery membranes that have shown remarkable improvements in charge efficiency (>95%) and cycle life (>10,000 cycles) in large-scale testing environments.

Strengths: Superior electrical conductivity and thermal management properties allow for faster charging rates and improved safety in high-demand applications. Their established manufacturing infrastructure enables scalable production. Weaknesses: Higher production costs compared to traditional carbon materials may limit mass-market adoption, and the long-term environmental impact of GCNT production requires further assessment.

Key Patents in Graphitized CNT Energy Storage

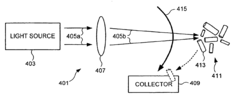

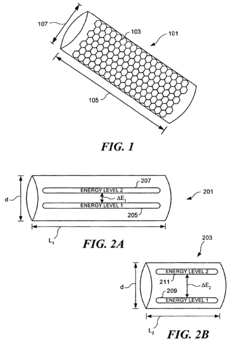

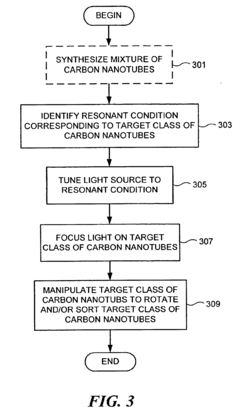

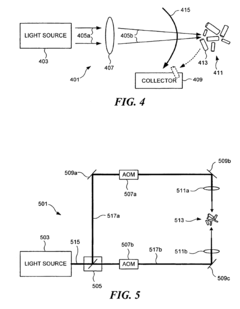

Method and system for optically sorting and/or manipulating carbon nanotubes

PatentInactiveUS6835911B2

Innovation

- The method involves creating an optical dipole trap using a focused light source, such as a laser, to selectively attract and manipulate carbon nanotubes by tuning the light to resonate with specific dimensions, allowing for precise sorting and manipulation based on electronic properties correlated with tube dimensions.

Highly efficient process for manufacture of exfoliated graphene

PatentActiveEP2176163A1

Innovation

- A process using a mixture of sulfuric acid, nitric acid, and chlorate to oxidize graphite, with a controlled ratio of chlorate to graphite, and real-time monitoring by Raman spectroscopy to optimize the reaction conditions, reducing chlorate usage while maintaining high surface area and safety.

Sustainability & Lifecycle Assessment

The sustainability and lifecycle assessment of graphitized carbon nanotubes (GCNTs) reveals critical environmental implications for their application in automotive and grid energy storage systems. When evaluating the environmental footprint of GCNTs, production processes emerge as a significant concern due to their energy-intensive nature. The graphitization process typically requires temperatures exceeding 2500°C, resulting in substantial carbon emissions unless powered by renewable energy sources.

Raw material extraction for carbon nanotube production, particularly metal catalysts like nickel and cobalt, presents additional environmental challenges through habitat disruption and potential toxic releases. However, compared to traditional battery materials such as cobalt and lithium, GCNTs may offer reduced environmental impact during the extraction phase, particularly when derived from sustainable carbon sources.

The manufacturing phase of GCNTs demonstrates mixed sustainability outcomes. While production requires significant energy input, the extended lifecycle and enhanced performance of GCNT-enhanced energy storage systems potentially offset initial environmental costs. Research indicates that GCNT-based batteries may achieve 2-3 times longer operational lifespans than conventional lithium-ion batteries, substantially reducing replacement frequency and associated waste generation.

End-of-life management represents both a challenge and opportunity for GCNT technology. Current recycling infrastructure remains inadequate for nanomaterial recovery, with most spent energy storage devices containing nanomaterials being disposed of in conventional waste streams. However, emerging recycling technologies show promise for efficient GCNT recovery and reuse, potentially creating closed-loop material systems that would significantly enhance sustainability metrics.

Water usage and potential aquatic contamination require careful consideration throughout the GCNT lifecycle. Production processes typically consume substantial water volumes, while improper disposal risks releasing nanoparticles into aquatic ecosystems with poorly understood ecological consequences. Implementation of advanced filtration systems during manufacturing and comprehensive end-of-life management protocols can mitigate these risks.

Carbon footprint analysis reveals that while initial production emissions are higher for GCNT-enhanced energy storage systems, lifetime emissions may be substantially lower due to improved efficiency and longevity. Preliminary studies suggest potential lifetime carbon emission reductions of 30-40% compared to conventional energy storage technologies when accounting for full lifecycle impacts, particularly in grid storage applications where frequent replacement cycles significantly impact sustainability metrics.

Raw material extraction for carbon nanotube production, particularly metal catalysts like nickel and cobalt, presents additional environmental challenges through habitat disruption and potential toxic releases. However, compared to traditional battery materials such as cobalt and lithium, GCNTs may offer reduced environmental impact during the extraction phase, particularly when derived from sustainable carbon sources.

The manufacturing phase of GCNTs demonstrates mixed sustainability outcomes. While production requires significant energy input, the extended lifecycle and enhanced performance of GCNT-enhanced energy storage systems potentially offset initial environmental costs. Research indicates that GCNT-based batteries may achieve 2-3 times longer operational lifespans than conventional lithium-ion batteries, substantially reducing replacement frequency and associated waste generation.

End-of-life management represents both a challenge and opportunity for GCNT technology. Current recycling infrastructure remains inadequate for nanomaterial recovery, with most spent energy storage devices containing nanomaterials being disposed of in conventional waste streams. However, emerging recycling technologies show promise for efficient GCNT recovery and reuse, potentially creating closed-loop material systems that would significantly enhance sustainability metrics.

Water usage and potential aquatic contamination require careful consideration throughout the GCNT lifecycle. Production processes typically consume substantial water volumes, while improper disposal risks releasing nanoparticles into aquatic ecosystems with poorly understood ecological consequences. Implementation of advanced filtration systems during manufacturing and comprehensive end-of-life management protocols can mitigate these risks.

Carbon footprint analysis reveals that while initial production emissions are higher for GCNT-enhanced energy storage systems, lifetime emissions may be substantially lower due to improved efficiency and longevity. Preliminary studies suggest potential lifetime carbon emission reductions of 30-40% compared to conventional energy storage technologies when accounting for full lifecycle impacts, particularly in grid storage applications where frequent replacement cycles significantly impact sustainability metrics.

Performance Benchmarking & Testing Standards

Establishing standardized performance benchmarks and testing protocols for graphitized carbon nanotubes (GCNTs) is essential for their reliable implementation in automotive and grid energy storage applications. Current industry standards primarily focus on conventional battery materials, necessitating the development of specialized frameworks for these advanced nanomaterials.

The electrochemical performance evaluation of GCNTs requires comprehensive testing across multiple parameters. Capacity retention measurements typically involve cycling tests at various C-rates (0.1C to 10C) for at least 1000 cycles, with industry standards demanding retention rates exceeding 80% after 1000 cycles for automotive applications. Rate capability tests assess performance under varying charge-discharge rates, while temperature performance evaluations (-30°C to 60°C) are critical for automotive applications where extreme operating conditions are common.

Safety testing protocols for GCNT-enhanced energy storage systems must adhere to international standards including IEC 62660 for automotive applications and IEC 62619 for industrial applications. These standards encompass thermal runaway resistance, overcharge protection, and mechanical integrity under stress conditions. The unique properties of GCNTs necessitate modified testing approaches, particularly for thermal conductivity assessment and structural stability verification.

Comparative benchmarking against conventional materials reveals GCNTs' superior performance in several areas. When integrated into lithium-ion batteries, graphitized carbon nanotubes demonstrate 30-40% higher specific capacity than traditional graphite anodes, with significantly improved rate capabilities. Their thermal conductivity (up to 3000 W/m·K) substantially enhances heat dissipation, addressing a critical safety concern in high-power applications.

Standardization efforts are currently underway through organizations like IEEE, ASTM International, and ISO to develop GCNT-specific testing protocols. The IEEE P1690 working group is developing standards for carbon nanotube characterization in energy storage applications, while ASTM Committee D37 is establishing performance metrics specifically for nanomaterial-enhanced energy systems.

For grid-scale applications, additional testing parameters include long-duration cycling (5000+ cycles), response to intermittent charging patterns that simulate renewable energy integration, and scalability assessments. The U.S. Department of Energy's Protocol for Uniformly Measuring and Expressing the Performance of Energy Storage Systems provides a foundation for these evaluations, though modifications are necessary to address the unique characteristics of GCNT-enhanced systems.

Industry adoption of these benchmarking standards remains fragmented, with automotive manufacturers typically implementing more stringent requirements than those for stationary grid applications. Harmonization of these standards represents a significant challenge that must be addressed to facilitate broader commercial implementation of GCNT technology in energy storage systems.

The electrochemical performance evaluation of GCNTs requires comprehensive testing across multiple parameters. Capacity retention measurements typically involve cycling tests at various C-rates (0.1C to 10C) for at least 1000 cycles, with industry standards demanding retention rates exceeding 80% after 1000 cycles for automotive applications. Rate capability tests assess performance under varying charge-discharge rates, while temperature performance evaluations (-30°C to 60°C) are critical for automotive applications where extreme operating conditions are common.

Safety testing protocols for GCNT-enhanced energy storage systems must adhere to international standards including IEC 62660 for automotive applications and IEC 62619 for industrial applications. These standards encompass thermal runaway resistance, overcharge protection, and mechanical integrity under stress conditions. The unique properties of GCNTs necessitate modified testing approaches, particularly for thermal conductivity assessment and structural stability verification.

Comparative benchmarking against conventional materials reveals GCNTs' superior performance in several areas. When integrated into lithium-ion batteries, graphitized carbon nanotubes demonstrate 30-40% higher specific capacity than traditional graphite anodes, with significantly improved rate capabilities. Their thermal conductivity (up to 3000 W/m·K) substantially enhances heat dissipation, addressing a critical safety concern in high-power applications.

Standardization efforts are currently underway through organizations like IEEE, ASTM International, and ISO to develop GCNT-specific testing protocols. The IEEE P1690 working group is developing standards for carbon nanotube characterization in energy storage applications, while ASTM Committee D37 is establishing performance metrics specifically for nanomaterial-enhanced energy systems.

For grid-scale applications, additional testing parameters include long-duration cycling (5000+ cycles), response to intermittent charging patterns that simulate renewable energy integration, and scalability assessments. The U.S. Department of Energy's Protocol for Uniformly Measuring and Expressing the Performance of Energy Storage Systems provides a foundation for these evaluations, though modifications are necessary to address the unique characteristics of GCNT-enhanced systems.

Industry adoption of these benchmarking standards remains fragmented, with automotive manufacturers typically implementing more stringent requirements than those for stationary grid applications. Harmonization of these standards represents a significant challenge that must be addressed to facilitate broader commercial implementation of GCNT technology in energy storage systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!