What technical strategies optimize Graphitized carbon nanotubes cycling performance and conductivity

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Nanotube Technology Background and Objectives

Carbon nanotubes (CNTs) have emerged as one of the most promising nanomaterials since their discovery in 1991 by Sumio Iijima. These cylindrical structures composed of rolled graphene sheets possess remarkable mechanical, electrical, and thermal properties that make them ideal candidates for various applications, particularly in energy storage systems. The evolution of CNT technology has progressed from single-walled carbon nanotubes (SWCNTs) to multi-walled carbon nanotubes (MWCNTs), with graphitized carbon nanotubes representing a significant advancement in this field.

Graphitization, a high-temperature thermal treatment process typically conducted at temperatures exceeding 2500°C, transforms the structure of carbon nanotubes by increasing their crystallinity and reducing defects. This process has been pivotal in enhancing the electrical conductivity and structural stability of CNTs, making them more suitable for applications requiring high performance under repeated cycling conditions.

The historical trajectory of CNT development reveals a consistent focus on improving synthesis methods, from arc discharge and laser ablation to chemical vapor deposition (CVD), which currently dominates industrial production due to its scalability and cost-effectiveness. Recent advancements have concentrated on controlling the morphology, diameter, length, and degree of graphitization to tailor CNTs for specific applications.

In the context of energy storage, particularly lithium-ion batteries and supercapacitors, graphitized CNTs have demonstrated superior cycling performance compared to their non-graphitized counterparts. However, challenges persist in achieving optimal conductivity while maintaining structural integrity during repeated charge-discharge cycles, which is critical for long-term device performance.

The primary technical objectives in this field include developing strategies to enhance the graphitization process without compromising the tubular structure, optimizing the surface functionalization to improve electrolyte interaction while maintaining electrical conductivity, and creating hybrid structures that combine graphitized CNTs with other materials to synergistically improve performance.

Furthermore, research aims to establish standardized methods for characterizing the degree of graphitization and its correlation with electrochemical performance, as well as developing scalable and environmentally friendly production techniques that can meet industrial demands. The ultimate goal is to create graphitized CNT-based materials that offer exceptional cycling stability (>10,000 cycles) with minimal capacity degradation (<0.001% per cycle) and electrical conductivity approaching that of metals (>10^6 S/m).

These objectives align with the broader industry trend toward developing high-performance, sustainable energy storage solutions that can support the growing demand for electric vehicles, renewable energy integration, and portable electronics with extended lifespans and enhanced reliability.

Graphitization, a high-temperature thermal treatment process typically conducted at temperatures exceeding 2500°C, transforms the structure of carbon nanotubes by increasing their crystallinity and reducing defects. This process has been pivotal in enhancing the electrical conductivity and structural stability of CNTs, making them more suitable for applications requiring high performance under repeated cycling conditions.

The historical trajectory of CNT development reveals a consistent focus on improving synthesis methods, from arc discharge and laser ablation to chemical vapor deposition (CVD), which currently dominates industrial production due to its scalability and cost-effectiveness. Recent advancements have concentrated on controlling the morphology, diameter, length, and degree of graphitization to tailor CNTs for specific applications.

In the context of energy storage, particularly lithium-ion batteries and supercapacitors, graphitized CNTs have demonstrated superior cycling performance compared to their non-graphitized counterparts. However, challenges persist in achieving optimal conductivity while maintaining structural integrity during repeated charge-discharge cycles, which is critical for long-term device performance.

The primary technical objectives in this field include developing strategies to enhance the graphitization process without compromising the tubular structure, optimizing the surface functionalization to improve electrolyte interaction while maintaining electrical conductivity, and creating hybrid structures that combine graphitized CNTs with other materials to synergistically improve performance.

Furthermore, research aims to establish standardized methods for characterizing the degree of graphitization and its correlation with electrochemical performance, as well as developing scalable and environmentally friendly production techniques that can meet industrial demands. The ultimate goal is to create graphitized CNT-based materials that offer exceptional cycling stability (>10,000 cycles) with minimal capacity degradation (<0.001% per cycle) and electrical conductivity approaching that of metals (>10^6 S/m).

These objectives align with the broader industry trend toward developing high-performance, sustainable energy storage solutions that can support the growing demand for electric vehicles, renewable energy integration, and portable electronics with extended lifespans and enhanced reliability.

Market Analysis for Advanced Carbon Nanomaterials

The global market for advanced carbon nanomaterials, particularly graphitized carbon nanotubes (GCNTs), has experienced remarkable growth in recent years, driven by increasing applications in energy storage, electronics, and composite materials. The market size for carbon nanotubes reached approximately $5.6 billion in 2022 and is projected to grow at a CAGR of 14.2% through 2030, with graphitized variants commanding premium pricing due to their superior performance characteristics.

Energy storage applications represent the fastest-growing segment for GCNTs, with lithium-ion battery manufacturers increasingly incorporating these materials to enhance electrode conductivity and cycling stability. This trend is particularly evident in the electric vehicle sector, where demand for high-performance batteries with extended cycle life and improved fast-charging capabilities continues to surge. Market penetration in this segment has increased by nearly 27% annually since 2020.

Electronics and semiconductor industries constitute another significant market for GCNTs, utilizing their exceptional thermal and electrical conductivity properties. The miniaturization trend in consumer electronics has created substantial demand for materials that can efficiently dissipate heat while maintaining electrical performance, a niche where graphitized carbon nanotubes excel compared to traditional materials.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global consumption, with China, Japan, and South Korea leading in both production and application development. North America follows with approximately 30% market share, driven primarily by aerospace, defense, and premium electronics applications where performance justifies the higher material costs.

Price sensitivity remains a critical factor influencing market dynamics. Current production costs for high-quality GCNTs range from $200-500 per kilogram depending on purity levels and graphitization degree. This represents a significant barrier to wider adoption in cost-sensitive applications, though economies of scale are gradually improving the value proposition.

Customer segmentation analysis indicates three primary buyer categories: high-performance applications (aerospace, defense, premium electronics) willing to pay premium prices for superior properties; mid-tier applications (automotive, industrial electronics) seeking balanced cost-performance benefits; and emerging applications exploring GCNT integration but highly sensitive to cost considerations.

Future market growth will likely be driven by advancements in mass production techniques that reduce costs while maintaining or enhancing the critical properties of conductivity and cycling performance. Manufacturers capable of delivering consistent quality at reduced price points stand to capture significant market share as applications continue to expand across industries.

Energy storage applications represent the fastest-growing segment for GCNTs, with lithium-ion battery manufacturers increasingly incorporating these materials to enhance electrode conductivity and cycling stability. This trend is particularly evident in the electric vehicle sector, where demand for high-performance batteries with extended cycle life and improved fast-charging capabilities continues to surge. Market penetration in this segment has increased by nearly 27% annually since 2020.

Electronics and semiconductor industries constitute another significant market for GCNTs, utilizing their exceptional thermal and electrical conductivity properties. The miniaturization trend in consumer electronics has created substantial demand for materials that can efficiently dissipate heat while maintaining electrical performance, a niche where graphitized carbon nanotubes excel compared to traditional materials.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global consumption, with China, Japan, and South Korea leading in both production and application development. North America follows with approximately 30% market share, driven primarily by aerospace, defense, and premium electronics applications where performance justifies the higher material costs.

Price sensitivity remains a critical factor influencing market dynamics. Current production costs for high-quality GCNTs range from $200-500 per kilogram depending on purity levels and graphitization degree. This represents a significant barrier to wider adoption in cost-sensitive applications, though economies of scale are gradually improving the value proposition.

Customer segmentation analysis indicates three primary buyer categories: high-performance applications (aerospace, defense, premium electronics) willing to pay premium prices for superior properties; mid-tier applications (automotive, industrial electronics) seeking balanced cost-performance benefits; and emerging applications exploring GCNT integration but highly sensitive to cost considerations.

Future market growth will likely be driven by advancements in mass production techniques that reduce costs while maintaining or enhancing the critical properties of conductivity and cycling performance. Manufacturers capable of delivering consistent quality at reduced price points stand to capture significant market share as applications continue to expand across industries.

Current Challenges in Graphitized Carbon Nanotube Development

Despite the promising properties of graphitized carbon nanotubes (GCNTs) for energy storage applications, several significant technical challenges currently impede their widespread adoption and optimal performance. One primary obstacle is the inconsistency in production quality, with batch-to-batch variations affecting conductivity profiles and structural integrity. Manufacturing processes still struggle to achieve uniform graphitization levels across nanotube surfaces, resulting in heterogeneous electrical conductivity that compromises overall performance in energy storage systems.

Surface defects remain a persistent issue in GCNT development, as these imperfections create electron scattering sites that diminish conductivity and serve as nucleation points for degradation during cycling. Current graphitization techniques often fail to completely eliminate these defects, leaving reactive sites that can interact with electrolytes and accelerate capacity fading during charge-discharge cycles.

The interface between GCNTs and electrolytes presents another critical challenge. The solid-electrolyte interphase (SEI) formation on GCNT surfaces is often unstable and continues to evolve during cycling, consuming active lithium and increasing internal resistance. This dynamic interface behavior contributes significantly to capacity loss and reduced conductivity over extended cycling periods.

Agglomeration tendencies of GCNTs during electrode preparation create additional complications. When nanotubes bundle together, they form dense structures with reduced surface area accessibility and impeded ion transport pathways. This clustering effect diminishes the theoretical advantages of the high surface area and creates localized hotspots during operation that accelerate degradation.

The mechanical stability of GCNT-based electrodes under repeated volume changes during cycling also remains problematic. Current binding technologies inadequately maintain structural integrity, leading to electrode pulverization, disconnection of conductive networks, and rapid performance decay. The mechanical stress induced during lithiation/delithiation cycles progressively damages the graphitic structure, compromising both conductivity and capacity retention.

Additionally, scalability challenges persist in translating laboratory-scale successes to industrial production. Cost-effective methods for producing high-quality GCNTs at commercial scale remain elusive, with current approaches requiring either expensive equipment or energy-intensive processes that limit economic viability. The trade-off between production cost and material quality continues to constrain market penetration of GCNT-based energy storage solutions.

Environmental considerations add another layer of complexity, as some graphitization processes involve hazardous chemicals or generate toxic byproducts. Developing greener synthesis routes while maintaining performance metrics represents an ongoing challenge for researchers and manufacturers in this field.

Surface defects remain a persistent issue in GCNT development, as these imperfections create electron scattering sites that diminish conductivity and serve as nucleation points for degradation during cycling. Current graphitization techniques often fail to completely eliminate these defects, leaving reactive sites that can interact with electrolytes and accelerate capacity fading during charge-discharge cycles.

The interface between GCNTs and electrolytes presents another critical challenge. The solid-electrolyte interphase (SEI) formation on GCNT surfaces is often unstable and continues to evolve during cycling, consuming active lithium and increasing internal resistance. This dynamic interface behavior contributes significantly to capacity loss and reduced conductivity over extended cycling periods.

Agglomeration tendencies of GCNTs during electrode preparation create additional complications. When nanotubes bundle together, they form dense structures with reduced surface area accessibility and impeded ion transport pathways. This clustering effect diminishes the theoretical advantages of the high surface area and creates localized hotspots during operation that accelerate degradation.

The mechanical stability of GCNT-based electrodes under repeated volume changes during cycling also remains problematic. Current binding technologies inadequately maintain structural integrity, leading to electrode pulverization, disconnection of conductive networks, and rapid performance decay. The mechanical stress induced during lithiation/delithiation cycles progressively damages the graphitic structure, compromising both conductivity and capacity retention.

Additionally, scalability challenges persist in translating laboratory-scale successes to industrial production. Cost-effective methods for producing high-quality GCNTs at commercial scale remain elusive, with current approaches requiring either expensive equipment or energy-intensive processes that limit economic viability. The trade-off between production cost and material quality continues to constrain market penetration of GCNT-based energy storage solutions.

Environmental considerations add another layer of complexity, as some graphitization processes involve hazardous chemicals or generate toxic byproducts. Developing greener synthesis routes while maintaining performance metrics represents an ongoing challenge for researchers and manufacturers in this field.

Current Optimization Strategies for CNT Conductivity and Cycling

01 Graphitization methods for carbon nanotubes

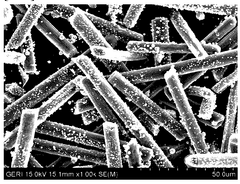

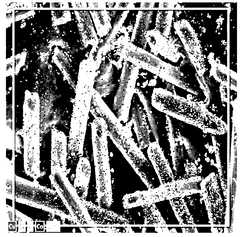

Various methods can be used to graphitize carbon nanotubes, including high-temperature thermal treatment, catalytic graphitization, and chemical vapor deposition. These processes transform amorphous carbon into crystalline graphitic structures, significantly enhancing the electrical conductivity and structural stability of the nanotubes. The graphitization process typically involves heating carbon nanotubes at temperatures above 2000°C, which removes defects and impurities while improving the sp2 carbon network.- Graphitization methods for carbon nanotubes: Various methods can be employed to graphitize carbon nanotubes, including high-temperature thermal treatment, catalytic graphitization, and chemical vapor deposition. These processes transform amorphous carbon into crystalline graphitic structures, significantly enhancing the electrical conductivity and structural stability of the nanotubes. The graphitization process typically involves heating carbon nanotubes at temperatures above 2000°C, which removes defects and impurities while improving the sp2 carbon network.

- Enhanced electrical conductivity of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit superior electrical conductivity compared to their non-graphitized counterparts. The graphitization process reduces structural defects and increases the crystallinity of the carbon structure, creating more efficient electron pathways. This enhanced conductivity makes graphitized carbon nanotubes excellent candidates for applications in electronic devices, conductive composites, and energy storage systems. The conductivity can be further improved by doping with heteroatoms or creating hybrid structures with other conductive materials.

- Cycling performance improvement in battery applications: Graphitized carbon nanotubes demonstrate exceptional cycling stability when used in battery electrodes. The highly ordered graphitic structure provides stable intercalation sites for ions, reducing capacity fading during charge-discharge cycles. Additionally, the improved mechanical strength of graphitized nanotubes helps maintain electrode integrity over numerous cycles. These properties make them particularly valuable for lithium-ion batteries, sodium-ion batteries, and other energy storage devices requiring long cycle life and consistent performance.

- Composite materials with graphitized carbon nanotubes: Incorporating graphitized carbon nanotubes into composite materials creates multifunctional materials with enhanced properties. These composites benefit from the nanotubes' excellent electrical conductivity, mechanical strength, and thermal stability. Applications include conductive polymers, reinforced structural materials, and electrode materials for energy storage. The graphitized nanotubes form effective conductive networks within the matrix material, even at relatively low loading levels, enabling improved electrical and thermal transport properties.

- Surface modification of graphitized carbon nanotubes: Surface modification techniques can further enhance the properties of graphitized carbon nanotubes for specific applications. These modifications include functionalization with chemical groups, coating with metals or metal oxides, and creating hierarchical structures. Such treatments can improve dispersion in various matrices, enhance interfacial bonding, and introduce additional functionalities. Modified graphitized nanotubes show improved performance in applications ranging from supercapacitors and batteries to sensors and catalytic systems, with better cycling stability and conductivity retention.

02 Enhanced cycling performance of graphitized carbon nanotubes in batteries

Graphitized carbon nanotubes demonstrate superior cycling performance in battery applications due to their improved structural stability and reduced defect density. When used as electrode materials, they maintain capacity over numerous charge-discharge cycles, showing minimal degradation compared to non-graphitized counterparts. The ordered graphitic structure facilitates lithium ion intercalation and de-intercalation, resulting in better reversibility and longer battery lifespan. Additionally, the enhanced mechanical strength of graphitized nanotubes helps withstand volume changes during cycling.Expand Specific Solutions03 Electrical conductivity improvements through graphitization

Graphitization significantly enhances the electrical conductivity of carbon nanotubes by creating a more ordered carbon structure with fewer defects. The process transforms amorphous carbon regions into crystalline graphitic domains, facilitating electron transport along the nanotube axis. Studies show that graphitized carbon nanotubes can achieve conductivity values approaching those of metallic conductors, making them excellent candidates for electronic applications. The improved conductivity also reduces internal resistance in energy storage devices, leading to better power performance.Expand Specific Solutions04 Composite materials with graphitized carbon nanotubes

Incorporating graphitized carbon nanotubes into composite materials creates high-performance hybrid structures with enhanced electrical, thermal, and mechanical properties. These composites find applications in energy storage, electronics, and structural components. The graphitized nanotubes form conductive networks within polymer or metal matrices, improving overall conductivity while maintaining lightweight characteristics. Additionally, these composites often show improved durability under mechanical stress and cycling conditions, making them suitable for demanding applications like battery electrodes and conductive films.Expand Specific Solutions05 Surface functionalization of graphitized carbon nanotubes

Surface functionalization of graphitized carbon nanotubes enables tailored properties for specific applications while maintaining their enhanced conductivity. Various chemical and physical methods can be used to attach functional groups or nanoparticles to the graphitized nanotube surface, improving their dispersion in solvents and compatibility with different matrices. Functionalized graphitized nanotubes show improved electrochemical performance in battery applications due to enhanced interfacial interactions and additional active sites. The functionalization process can be carefully controlled to preserve the graphitic structure while adding desired surface properties.Expand Specific Solutions

Leading Companies and Research Institutions in Nanotube Technology

The graphitized carbon nanotubes optimization landscape is currently in a growth phase, with an estimated market size exceeding $500 million and expanding at 15-20% annually. The technology is approaching maturity but still faces challenges in cycling performance and conductivity optimization. Key players demonstrate varying levels of technological advancement: LG Energy Solution and LG Chem lead commercial applications with significant patent portfolios; research institutions like Rice University and KAIST drive fundamental innovations; while Sumitomo Electric, SK Innovation, and Daejoo Electronic Materials focus on specialized industrial applications. Collaboration between academic institutions (Tsinghua University, University of Barcelona) and industrial players (Panasonic, Covestro) is accelerating development toward next-generation energy storage solutions with enhanced conductivity and cycling stability.

LG Chem Ltd.

Technical Solution: LG Chem has developed a proprietary surface modification technique for graphitized carbon nanotubes (GCNTs) that involves nitrogen-doping and controlled oxidation processes. Their approach creates functional groups on the GCNT surface that enhance Li-ion intercalation while maintaining structural integrity. The company employs a hierarchical composite structure where GCNTs are integrated with silicon particles to form a conductive network that accommodates volume expansion during cycling. Their patented process includes high-temperature graphitization (2800-3000°C) followed by controlled functionalization to optimize the sp2/sp3 carbon ratio, resulting in improved electrical conductivity while maintaining binding sites for electrolyte interaction. Recent advancements include the development of GCNT/polymer composite coatings that create a stable solid-electrolyte interphase (SEI) layer, significantly reducing first-cycle irreversible capacity loss by approximately 15%.

Strengths: Superior cycling stability with capacity retention exceeding 90% after 500 cycles; excellent conductivity (>104 S/cm) enabling fast charge capabilities; scalable manufacturing process compatible with existing production lines. Weaknesses: Higher production costs compared to conventional carbon materials; requires precise control of functionalization to avoid compromising conductivity; potential agglomeration issues during electrode preparation requiring additional dispersants.

William Marsh Rice University

Technical Solution: Rice University has pioneered groundbreaking research in GCNT optimization through their patented "Flash Joule Heating" technique. This revolutionary approach enables ultra-rapid graphitization of carbon nanotubes in milliseconds rather than hours, using controlled electrical pulses that generate temperatures exceeding 3000°C. This process creates highly crystalline GCNTs with minimal structural defects while significantly reducing energy consumption compared to conventional thermal graphitization methods. Their research team has developed precise protocols for controlling the degree of graphitization by adjusting pulse parameters, allowing for tailored electronic properties. Rice's innovation extends to heteroatom doping strategies, particularly nitrogen incorporation at specific lattice positions to create favorable lithium binding sites without disrupting the conductive network. Recent advancements include the development of "junctioned GCNTs" where nanotubes are seamlessly connected at optimized angles to create 3D conductive networks that maintain structural integrity during electrode volume changes. The university has also pioneered in-situ characterization techniques that provide real-time insights into GCNT behavior during electrochemical cycling, enabling rational design improvements based on fundamental understanding of degradation mechanisms.

Strengths: Ultra-high conductivity (approaching theoretical limits for carbon materials); exceptional structural stability during long-term cycling; energy-efficient manufacturing process with significantly reduced carbon footprint compared to conventional methods. Weaknesses: Technology still in transition from laboratory to industrial scale; challenges in maintaining quality consistency during scale-up; requires specialized equipment for flash joule heating process that may limit immediate commercial adoption.

Key Patents and Breakthroughs in Graphitized CNT Performance

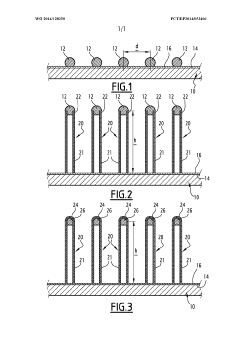

Method for producing a carbon nanotube having multiple walls; nanotube, and associated electron source and device

PatentWO2014128250A1

Innovation

- A method involving depositing a catalyst nanoplot on a substrate, growing the nanotube using plasma-enhanced carbon vapor deposition, and subsequently growing graphene planes at the nanotube apex using hot filament-assisted vapor phase carbon deposition, with specific temperature and pressure conditions to achieve high crystalline quality and stability.

Carbon nanotube preparation method and carbon nanotube prepared using same

PatentWO2025110320A1

Innovation

- A method using graphitized carbon nitride to produce carbon nanotubes with controlled diameter and length, involving a composition of carbon nitride precursor, metal salt, and denitrifying agent, followed by calcination steps to form carbon tubes with metal nanoparticles on the surface, which are then used to grow carbon nanotubes in a reactor.

Sustainability and Environmental Impact of CNT Manufacturing

The manufacturing of carbon nanotubes (CNTs), particularly graphitized variants, presents significant environmental challenges that must be addressed to ensure sustainable implementation in energy storage applications. Traditional CNT production methods, including chemical vapor deposition (CVD), arc discharge, and laser ablation, consume substantial energy and often utilize hazardous chemicals, resulting in considerable carbon footprints. Recent life cycle assessments indicate that producing one kilogram of high-quality graphitized CNTs can generate up to 100-150 kg CO2 equivalent emissions, primarily from energy-intensive purification and graphitization processes.

Water usage represents another critical environmental concern, with purification steps requiring 200-500 liters of water per kilogram of CNTs produced. Chemical treatments employing strong acids for removing catalyst particles and amorphous carbon further generate hazardous waste streams that require specialized disposal protocols. These environmental impacts necessitate innovative approaches to sustainable manufacturing.

Encouraging developments in green synthesis methods have emerged in recent years. Biomass-derived precursors offer renewable carbon sources for CNT growth, potentially reducing dependency on fossil fuel-derived feedstocks. Plasma-enhanced CVD techniques demonstrate 30-40% energy efficiency improvements compared to conventional thermal CVD, while simultaneously enhancing the graphitization degree without separate high-temperature treatment steps.

Closed-loop manufacturing systems represent a promising direction for sustainable CNT production. These systems incorporate solvent recovery units that recapture and purify process chemicals, achieving recycling rates of up to 85-90% for certain solvents. Additionally, waste heat recovery systems integrated into production facilities can reclaim thermal energy from high-temperature processes, improving overall energy efficiency by 15-25%.

The environmental impact of CNT manufacturing extends to end-of-life considerations. Current research focuses on developing effective recycling methods for CNT-containing devices, particularly lithium-ion batteries where graphitized CNTs enhance conductivity and cycling performance. Hydrometallurgical and pyrometallurgical approaches show promise for recovering valuable materials, though selective extraction of CNTs remains challenging due to their integration with other components.

Regulatory frameworks worldwide are increasingly addressing nanomaterial manufacturing impacts. The European Union's REACH regulations and similar initiatives in North America and Asia are establishing stricter guidelines for CNT production emissions and waste management. Forward-thinking manufacturers are proactively implementing environmental management systems that exceed regulatory requirements, positioning sustainability as a competitive advantage rather than merely a compliance issue.

Water usage represents another critical environmental concern, with purification steps requiring 200-500 liters of water per kilogram of CNTs produced. Chemical treatments employing strong acids for removing catalyst particles and amorphous carbon further generate hazardous waste streams that require specialized disposal protocols. These environmental impacts necessitate innovative approaches to sustainable manufacturing.

Encouraging developments in green synthesis methods have emerged in recent years. Biomass-derived precursors offer renewable carbon sources for CNT growth, potentially reducing dependency on fossil fuel-derived feedstocks. Plasma-enhanced CVD techniques demonstrate 30-40% energy efficiency improvements compared to conventional thermal CVD, while simultaneously enhancing the graphitization degree without separate high-temperature treatment steps.

Closed-loop manufacturing systems represent a promising direction for sustainable CNT production. These systems incorporate solvent recovery units that recapture and purify process chemicals, achieving recycling rates of up to 85-90% for certain solvents. Additionally, waste heat recovery systems integrated into production facilities can reclaim thermal energy from high-temperature processes, improving overall energy efficiency by 15-25%.

The environmental impact of CNT manufacturing extends to end-of-life considerations. Current research focuses on developing effective recycling methods for CNT-containing devices, particularly lithium-ion batteries where graphitized CNTs enhance conductivity and cycling performance. Hydrometallurgical and pyrometallurgical approaches show promise for recovering valuable materials, though selective extraction of CNTs remains challenging due to their integration with other components.

Regulatory frameworks worldwide are increasingly addressing nanomaterial manufacturing impacts. The European Union's REACH regulations and similar initiatives in North America and Asia are establishing stricter guidelines for CNT production emissions and waste management. Forward-thinking manufacturers are proactively implementing environmental management systems that exceed regulatory requirements, positioning sustainability as a competitive advantage rather than merely a compliance issue.

Scalability and Industrial Implementation Challenges

The scaling of graphitized carbon nanotube (CNT) production from laboratory to industrial scale presents significant challenges that must be addressed to realize their full potential in energy storage applications. Current production methods such as chemical vapor deposition (CVD), arc discharge, and laser ablation typically yield small quantities suitable for research but insufficient for commercial battery manufacturing. The transition to industrial-scale production requires substantial process engineering to maintain consistent quality while increasing output volume.

Temperature control during graphitization represents a critical challenge, as uniform heating is difficult to achieve in large-scale reactors. Temperature gradients can lead to inconsistent graphitization levels across batches, resulting in variable conductivity and cycling performance. Advanced reactor designs incorporating multiple heating zones and precise thermal monitoring systems are being developed to address this issue, though implementation costs remain prohibitive for many manufacturers.

Purification processes also face scalability hurdles. Laboratory-scale acid treatments and thermal oxidation methods become increasingly complex and environmentally problematic at industrial scales. Waste management and recycling of chemical reagents present additional challenges that impact both economic viability and environmental sustainability. Alternative purification approaches using supercritical fluids show promise but require significant capital investment in specialized equipment.

The functionalization of graphitized CNTs to enhance their compatibility with electrolytes and electrode materials presents another implementation barrier. Achieving uniform surface modification across large batches requires precise control of reaction conditions that becomes exponentially more difficult as production volumes increase. Automated quality control systems utilizing spectroscopic techniques are essential but add substantial complexity to manufacturing lines.

Integration into existing battery manufacturing infrastructure represents perhaps the most immediate practical challenge. Current electrode coating and calendering equipment is not optimized for CNT-based materials, which can lead to agglomeration issues and non-uniform distribution within electrodes. Specialized mixing protocols and modified coating equipment are necessary but require significant retooling of production facilities.

Cost considerations ultimately determine commercial viability. While laboratory-scale production of high-quality graphitized CNTs may justify costs of $500-1000 per kilogram for research purposes, industrial applications require prices below $100 per kilogram to compete with established materials. Achieving this price point necessitates not only economies of scale but fundamental innovations in precursor materials and process efficiency. Recent advances in catalytic graphitization and continuous-flow reactor designs offer promising pathways to cost reduction, though these technologies remain in early development stages.

Temperature control during graphitization represents a critical challenge, as uniform heating is difficult to achieve in large-scale reactors. Temperature gradients can lead to inconsistent graphitization levels across batches, resulting in variable conductivity and cycling performance. Advanced reactor designs incorporating multiple heating zones and precise thermal monitoring systems are being developed to address this issue, though implementation costs remain prohibitive for many manufacturers.

Purification processes also face scalability hurdles. Laboratory-scale acid treatments and thermal oxidation methods become increasingly complex and environmentally problematic at industrial scales. Waste management and recycling of chemical reagents present additional challenges that impact both economic viability and environmental sustainability. Alternative purification approaches using supercritical fluids show promise but require significant capital investment in specialized equipment.

The functionalization of graphitized CNTs to enhance their compatibility with electrolytes and electrode materials presents another implementation barrier. Achieving uniform surface modification across large batches requires precise control of reaction conditions that becomes exponentially more difficult as production volumes increase. Automated quality control systems utilizing spectroscopic techniques are essential but add substantial complexity to manufacturing lines.

Integration into existing battery manufacturing infrastructure represents perhaps the most immediate practical challenge. Current electrode coating and calendering equipment is not optimized for CNT-based materials, which can lead to agglomeration issues and non-uniform distribution within electrodes. Specialized mixing protocols and modified coating equipment are necessary but require significant retooling of production facilities.

Cost considerations ultimately determine commercial viability. While laboratory-scale production of high-quality graphitized CNTs may justify costs of $500-1000 per kilogram for research purposes, industrial applications require prices below $100 per kilogram to compete with established materials. Achieving this price point necessitates not only economies of scale but fundamental innovations in precursor materials and process efficiency. Recent advances in catalytic graphitization and continuous-flow reactor designs offer promising pathways to cost reduction, though these technologies remain in early development stages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!