How nanotube length and diameter influence Graphitized carbon nanotubes performance

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Dimensional Effects Background

Graphitized carbon nanotubes (GCNTs) represent a significant advancement in nanomaterial science, emerging from the thermal treatment of conventional carbon nanotubes (CNTs) at temperatures exceeding 2000°C. This graphitization process transforms the structure of CNTs by enhancing crystallinity, reducing defects, and improving overall electrical and thermal conductivity properties. The dimensional characteristics of GCNTs—specifically their length and diameter—play crucial roles in determining their performance across various applications.

The evolution of GCNT research began in the late 1990s, following the discovery of multi-walled carbon nanotubes by Iijima in 1991. Early studies focused primarily on synthesis methods and basic characterization, with limited attention to dimensional effects. By the mid-2000s, researchers began systematically investigating how the physical dimensions of GCNTs influence their properties, marking a significant shift in research focus.

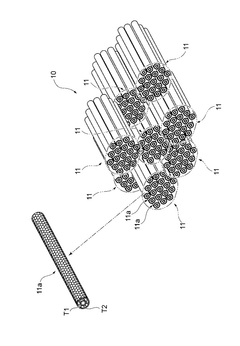

Dimensional parameters directly impact the fundamental properties of GCNTs. Longer nanotubes typically provide enhanced electrical conductivity along their axis due to reduced inter-tube junction resistance in composite materials. However, this advantage comes with processing challenges, as longer tubes tend to entangle and form aggregates. Diameter variations similarly affect performance characteristics—smaller-diameter GCNTs exhibit higher surface-to-volume ratios beneficial for catalytic applications, while larger-diameter tubes often demonstrate superior mechanical strength and thermal stability.

The graphitization process itself interacts with dimensional factors in complex ways. Research indicates that thinner CNTs graphitize more readily than thicker ones under identical thermal conditions, resulting in varying degrees of graphitic perfection depending on initial dimensions. This differential graphitization creates a spectrum of performance characteristics even within seemingly similar GCNT batches.

Current technological trends point toward precise dimensional control during both initial CNT synthesis and subsequent graphitization processes. Advanced techniques such as controlled chemical vapor deposition (CVD) and template-assisted growth now enable more precise tailoring of GCNT dimensions to specific application requirements. This dimensional engineering represents a critical frontier in maximizing GCNT performance.

The relationship between GCNT dimensions and performance properties follows certain scaling laws that researchers are still working to fully quantify. Electrical conductivity, thermal transport, mechanical strength, and surface reactivity all demonstrate distinct dimensional dependencies that must be understood to optimize GCNTs for specific applications.

As research progresses, the field is moving toward establishing standardized methods for dimensional characterization and classification of GCNTs, which will facilitate more systematic studies of dimension-property relationships and accelerate commercial adoption of these advanced materials.

The evolution of GCNT research began in the late 1990s, following the discovery of multi-walled carbon nanotubes by Iijima in 1991. Early studies focused primarily on synthesis methods and basic characterization, with limited attention to dimensional effects. By the mid-2000s, researchers began systematically investigating how the physical dimensions of GCNTs influence their properties, marking a significant shift in research focus.

Dimensional parameters directly impact the fundamental properties of GCNTs. Longer nanotubes typically provide enhanced electrical conductivity along their axis due to reduced inter-tube junction resistance in composite materials. However, this advantage comes with processing challenges, as longer tubes tend to entangle and form aggregates. Diameter variations similarly affect performance characteristics—smaller-diameter GCNTs exhibit higher surface-to-volume ratios beneficial for catalytic applications, while larger-diameter tubes often demonstrate superior mechanical strength and thermal stability.

The graphitization process itself interacts with dimensional factors in complex ways. Research indicates that thinner CNTs graphitize more readily than thicker ones under identical thermal conditions, resulting in varying degrees of graphitic perfection depending on initial dimensions. This differential graphitization creates a spectrum of performance characteristics even within seemingly similar GCNT batches.

Current technological trends point toward precise dimensional control during both initial CNT synthesis and subsequent graphitization processes. Advanced techniques such as controlled chemical vapor deposition (CVD) and template-assisted growth now enable more precise tailoring of GCNT dimensions to specific application requirements. This dimensional engineering represents a critical frontier in maximizing GCNT performance.

The relationship between GCNT dimensions and performance properties follows certain scaling laws that researchers are still working to fully quantify. Electrical conductivity, thermal transport, mechanical strength, and surface reactivity all demonstrate distinct dimensional dependencies that must be understood to optimize GCNTs for specific applications.

As research progresses, the field is moving toward establishing standardized methods for dimensional characterization and classification of GCNTs, which will facilitate more systematic studies of dimension-property relationships and accelerate commercial adoption of these advanced materials.

Market Applications of Size-Optimized Carbon Nanotubes

The market for carbon nanotubes (CNTs) has expanded significantly across various industries, with size-optimized graphitized carbon nanotubes playing a crucial role in numerous applications. The length and diameter of these nanotubes directly influence their performance characteristics, creating distinct market opportunities based on specific dimensional requirements.

In the electronics sector, shorter CNTs (typically <1 μm) with smaller diameters (1-2 nm) have found extensive applications in transistors and integrated circuits. These dimensions allow for higher packing density and improved electron mobility, critical for next-generation semiconductor devices. The market for these precision-engineered nanotubes is growing at a substantial rate as electronics continue to miniaturize.

Longer nanotubes (10-100 μm) with moderate diameters are increasingly utilized in composite materials for aerospace and automotive industries. These size-optimized CNTs provide exceptional mechanical reinforcement while maintaining processability. Boeing and Airbus have incorporated such nanotubes into structural components, achieving weight reductions of up to 30% compared to conventional materials while maintaining or improving strength properties.

The energy storage sector represents another significant market application, where CNT length and diameter optimization directly impacts performance. Medium-length nanotubes (2-10 μm) with tailored diameters have enhanced the capacity and charging rates of lithium-ion batteries. Companies like Samsung and Panasonic have invested heavily in this technology, recognizing the potential for next-generation energy storage solutions.

In medical applications, precisely controlled nanotube dimensions enable targeted drug delivery systems. Ultra-small diameter nanotubes (0.8-1.5 nm) can encapsulate pharmaceutical compounds, while their length determines circulation time in the bloodstream. This application segment is expected to grow substantially as personalized medicine advances.

Environmental remediation represents an emerging market for size-optimized CNTs. Longer nanotubes with specific diameter ranges have demonstrated superior adsorption capabilities for contaminant removal from water and air. Their high surface area-to-volume ratio, directly related to their dimensions, makes them excellent filtration materials.

The sporting goods industry has also embraced size-optimized CNTs, incorporating them into high-performance equipment. Tennis rackets, bicycle frames, and golf clubs utilizing specific length-to-diameter ratio nanotubes have shown improved strength-to-weight characteristics and vibration dampening properties.

As manufacturing techniques continue to advance, allowing for more precise control over nanotube dimensions, these market applications are expected to expand further. The ability to tailor CNT length and diameter to specific application requirements will remain a key driver of market growth across these diverse sectors.

In the electronics sector, shorter CNTs (typically <1 μm) with smaller diameters (1-2 nm) have found extensive applications in transistors and integrated circuits. These dimensions allow for higher packing density and improved electron mobility, critical for next-generation semiconductor devices. The market for these precision-engineered nanotubes is growing at a substantial rate as electronics continue to miniaturize.

Longer nanotubes (10-100 μm) with moderate diameters are increasingly utilized in composite materials for aerospace and automotive industries. These size-optimized CNTs provide exceptional mechanical reinforcement while maintaining processability. Boeing and Airbus have incorporated such nanotubes into structural components, achieving weight reductions of up to 30% compared to conventional materials while maintaining or improving strength properties.

The energy storage sector represents another significant market application, where CNT length and diameter optimization directly impacts performance. Medium-length nanotubes (2-10 μm) with tailored diameters have enhanced the capacity and charging rates of lithium-ion batteries. Companies like Samsung and Panasonic have invested heavily in this technology, recognizing the potential for next-generation energy storage solutions.

In medical applications, precisely controlled nanotube dimensions enable targeted drug delivery systems. Ultra-small diameter nanotubes (0.8-1.5 nm) can encapsulate pharmaceutical compounds, while their length determines circulation time in the bloodstream. This application segment is expected to grow substantially as personalized medicine advances.

Environmental remediation represents an emerging market for size-optimized CNTs. Longer nanotubes with specific diameter ranges have demonstrated superior adsorption capabilities for contaminant removal from water and air. Their high surface area-to-volume ratio, directly related to their dimensions, makes them excellent filtration materials.

The sporting goods industry has also embraced size-optimized CNTs, incorporating them into high-performance equipment. Tennis rackets, bicycle frames, and golf clubs utilizing specific length-to-diameter ratio nanotubes have shown improved strength-to-weight characteristics and vibration dampening properties.

As manufacturing techniques continue to advance, allowing for more precise control over nanotube dimensions, these market applications are expected to expand further. The ability to tailor CNT length and diameter to specific application requirements will remain a key driver of market growth across these diverse sectors.

Current Challenges in Nanotube Dimensional Control

Despite significant advancements in carbon nanotube synthesis over the past decades, achieving precise control over nanotube dimensions remains one of the most persistent challenges in the field. The performance of graphitized carbon nanotubes (GCNTs) is heavily dependent on their length and diameter, yet manufacturing processes that can reliably produce nanotubes with uniform dimensions at scale continue to elude researchers and manufacturers alike.

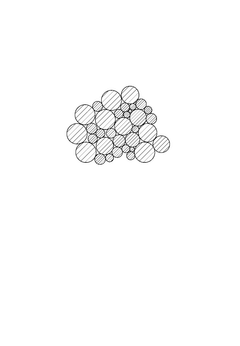

Current synthesis methods, including chemical vapor deposition (CVD), arc discharge, and laser ablation, all suffer from inherent limitations in dimensional control. CVD processes, while offering better scalability, typically produce nanotubes with wide diameter distributions ranging from 0.4 to 5 nm. This variability significantly impacts electrical conductivity, mechanical strength, and thermal properties of the resulting materials.

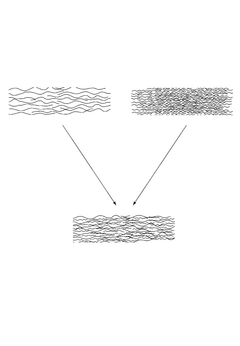

Length control presents an even greater challenge. Post-synthesis processing techniques such as ultrasonication and acid treatment are commonly employed to achieve desired lengths, but these methods often introduce structural defects that compromise the intrinsic properties of GCNTs. The trade-off between achieving target dimensions and maintaining structural integrity represents a fundamental dilemma in nanotube engineering.

Another critical issue is the lack of real-time monitoring techniques during synthesis. Current characterization methods, including transmission electron microscopy (TEM) and Raman spectroscopy, are primarily post-production analytical tools rather than in-process control mechanisms. This gap severely limits the ability to make dynamic adjustments during manufacturing to achieve dimensional uniformity.

The chirality control problem further complicates dimensional precision. The specific arrangement of carbon atoms along the nanotube wall (chirality) directly influences diameter and electronic properties. Despite theoretical advances in understanding chirality-controlled growth, practical methods for selective chirality synthesis remain elusive in industrial settings.

Catalyst design represents another frontier challenge. The size, composition, and surface properties of catalyst particles directly determine nanotube diameter, but achieving uniform catalyst particles at nanoscale dimensions involves overcoming significant thermodynamic barriers related to particle aggregation and Ostwald ripening during high-temperature synthesis.

Scaling production while maintaining dimensional control introduces additional complexities. Laboratory-scale processes that demonstrate promising dimensional uniformity often fail to translate to industrial volumes due to heat and mass transfer limitations in larger reactors. This scaling challenge has significantly hindered the commercial viability of applications requiring precise nanotube dimensions.

The economic implications of these technical challenges are substantial. The cost premium for dimensionally controlled GCNTs can be 5-10 times higher than standard grades, limiting their adoption in cost-sensitive applications despite their superior performance potential.

Current synthesis methods, including chemical vapor deposition (CVD), arc discharge, and laser ablation, all suffer from inherent limitations in dimensional control. CVD processes, while offering better scalability, typically produce nanotubes with wide diameter distributions ranging from 0.4 to 5 nm. This variability significantly impacts electrical conductivity, mechanical strength, and thermal properties of the resulting materials.

Length control presents an even greater challenge. Post-synthesis processing techniques such as ultrasonication and acid treatment are commonly employed to achieve desired lengths, but these methods often introduce structural defects that compromise the intrinsic properties of GCNTs. The trade-off between achieving target dimensions and maintaining structural integrity represents a fundamental dilemma in nanotube engineering.

Another critical issue is the lack of real-time monitoring techniques during synthesis. Current characterization methods, including transmission electron microscopy (TEM) and Raman spectroscopy, are primarily post-production analytical tools rather than in-process control mechanisms. This gap severely limits the ability to make dynamic adjustments during manufacturing to achieve dimensional uniformity.

The chirality control problem further complicates dimensional precision. The specific arrangement of carbon atoms along the nanotube wall (chirality) directly influences diameter and electronic properties. Despite theoretical advances in understanding chirality-controlled growth, practical methods for selective chirality synthesis remain elusive in industrial settings.

Catalyst design represents another frontier challenge. The size, composition, and surface properties of catalyst particles directly determine nanotube diameter, but achieving uniform catalyst particles at nanoscale dimensions involves overcoming significant thermodynamic barriers related to particle aggregation and Ostwald ripening during high-temperature synthesis.

Scaling production while maintaining dimensional control introduces additional complexities. Laboratory-scale processes that demonstrate promising dimensional uniformity often fail to translate to industrial volumes due to heat and mass transfer limitations in larger reactors. This scaling challenge has significantly hindered the commercial viability of applications requiring precise nanotube dimensions.

The economic implications of these technical challenges are substantial. The cost premium for dimensionally controlled GCNTs can be 5-10 times higher than standard grades, limiting their adoption in cost-sensitive applications despite their superior performance potential.

Current Methodologies for CNT Length-Diameter Optimization

01 Electrical and thermal conductivity properties

Graphitized carbon nanotubes exhibit superior electrical and thermal conductivity compared to non-graphitized counterparts. The graphitization process reduces defects in the carbon nanotube structure, resulting in enhanced electron mobility and improved conductivity. These properties make graphitized carbon nanotubes ideal for applications in electronics, energy storage devices, and thermal management systems.- Electrical and thermal conductivity properties of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit enhanced electrical and thermal conductivity properties compared to non-graphitized carbon nanotubes. The graphitization process reduces defects in the carbon nanotube structure, resulting in improved electron mobility and thermal transport. These properties make graphitized carbon nanotubes suitable for applications in electronics, energy storage, and thermal management systems.

- Mechanical strength and structural integrity of graphitized carbon nanotubes: Graphitized carbon nanotubes demonstrate superior mechanical strength and structural integrity. The graphitization process enhances the crystallinity of the carbon structure, resulting in improved tensile strength, flexibility, and durability. These mechanical properties make graphitized carbon nanotubes valuable for reinforcement in composite materials and structural applications where high strength-to-weight ratio is required.

- Surface properties and functionalization of graphitized carbon nanotubes: Graphitized carbon nanotubes have unique surface properties that can be further enhanced through functionalization. The graphitization process affects the surface chemistry, making it more suitable for specific applications. Functionalized graphitized carbon nanotubes show improved dispersibility in various matrices, enhanced interaction with other materials, and can be tailored for specific applications in sensors, catalysts, and biomedical devices.

- Production methods and quality control of graphitized carbon nanotubes: Various production methods for graphitized carbon nanotubes significantly impact their performance characteristics. High-temperature thermal treatment, catalytic graphitization, and laser-assisted processes are among the techniques used to produce graphitized carbon nanotubes with controlled properties. Quality control measures, including precise temperature control, catalyst selection, and post-processing treatments, are essential for achieving consistent performance in the final product.

- Applications of graphitized carbon nanotubes in composite materials: Graphitized carbon nanotubes serve as excellent reinforcement agents in composite materials, enhancing their overall performance. When incorporated into polymers, metals, or ceramics, they significantly improve mechanical strength, electrical conductivity, thermal stability, and other functional properties of the resulting composites. These enhanced composites find applications in aerospace, automotive, electronics, and energy storage industries where high-performance materials are required.

02 Mechanical strength and structural integrity

Graphitized carbon nanotubes demonstrate exceptional mechanical properties including high tensile strength, flexibility, and durability. The graphitization process enhances the crystallinity of the carbon structure, resulting in improved mechanical performance. These nanotubes can withstand significant mechanical stress while maintaining their structural integrity, making them suitable for reinforcement in composite materials and structural applications.Expand Specific Solutions03 Surface properties and functionalization

The surface characteristics of graphitized carbon nanotubes can be tailored through various functionalization methods. Graphitization affects the surface reactivity and adsorption properties of carbon nanotubes, which can be further modified to enhance compatibility with different matrices. These surface modifications improve dispersion in solvents and polymers, enabling better integration into composite materials and expanding their application range.Expand Specific Solutions04 Electrochemical performance and energy storage applications

Graphitized carbon nanotubes demonstrate enhanced electrochemical performance, making them valuable for energy storage applications. Their high surface area, improved conductivity, and stable structure contribute to superior performance in batteries, supercapacitors, and fuel cells. The graphitization process optimizes the electron transfer capabilities and increases the energy density of storage devices incorporating these materials.Expand Specific Solutions05 Thermal stability and high-temperature applications

Graphitized carbon nanotubes exhibit exceptional thermal stability and resistance to degradation at elevated temperatures. The graphitization process removes structural defects and amorphous carbon, resulting in materials that can withstand extreme thermal conditions. This thermal resilience makes them suitable for high-temperature applications in aerospace, industrial processing, and thermal interface materials.Expand Specific Solutions

Leading Research Groups and Manufacturers in CNT Field

The graphitized carbon nanotubes (GCNTs) market is in a growth phase, with increasing applications across electronics, energy storage, and composite materials sectors. Market size is expanding rapidly, projected to reach significant value by 2030 due to superior mechanical, electrical, and thermal properties of GCNTs. Technical maturity varies by application, with companies at different development stages. Intel, Samsung, and Applied Materials lead in electronics integration, while BASF and Nanotech Energy focus on energy storage applications. Specialized manufacturers like Hyperion Catalysis and Wuxi Dongheng have developed proprietary nanotube length and diameter control technologies. Research institutions including Tsinghua University and Clemson University are advancing fundamental understanding of how nanotube dimensions affect performance characteristics, creating a competitive landscape balanced between established corporations and innovative startups.

BASF Corp.

Technical Solution: BASF has developed comprehensive research programs investigating how carbon nanotube dimensions affect performance in various applications. Their studies show that longer CNTs (20-100μm) create more efficient conductive networks in polymer composites, reducing the percolation threshold by up to 75% compared to shorter tubes. For thermal management applications, they've determined that medium-diameter CNTs (15-25nm) provide the optimal balance between surface area and thermal conductivity after graphitization. BASF's proprietary graphitization process involves carefully controlled temperature ramping (5-10°C/min) to temperatures between 2300-2800°C, with the specific protocol tailored to the initial CNT dimensions. Their research demonstrates that graphitization increases the elastic modulus of CNTs more significantly for smaller diameter tubes (8-15nm) than larger ones (>30nm), with improvements of up to 40% observed. BASF has developed specialized dispersion technologies that maintain the length advantage of longer CNTs during processing, addressing a key challenge in industrial applications. Their work also shows that the degree of graphitization (measured by Raman spectroscopy ID/IG ratios) correlates strongly with both diameter and chirality, with certain chiralities showing up to 30% better graphitization under identical conditions.

Strengths: Extensive application-focused research across multiple industries; strong capabilities in scaling laboratory findings to industrial production; comprehensive understanding of structure-property relationships. Weaknesses: Proprietary nature of research may limit published details; focus may be more on application performance than fundamental understanding of graphitization mechanisms.

Nanotech Energy, Inc.

Technical Solution: Nanotech Energy has developed proprietary methods for controlling carbon nanotube (CNT) dimensions to optimize performance in energy storage applications. Their research demonstrates that longer CNTs (>10μm) create more efficient conductive networks with fewer junction points, reducing electrical resistance by up to 40% compared to shorter tubes. They've established that CNTs with diameters between 10-30nm provide optimal surface area-to-volume ratios for energy storage applications. Their graphitized CNTs undergo high-temperature treatment (2500-3000°C) to remove defects and increase crystallinity, resulting in enhanced electrical conductivity (up to 104 S/cm) and thermal stability. Their proprietary functionalization techniques maintain CNT length while improving dispersibility in various matrices, addressing a common challenge in nanotube processing. Nanotech's graphene-CNT hybrid materials leverage the dimensional advantages of both materials to create superior conductive networks for energy storage applications.

Strengths: Exceptional expertise in controlling CNT dimensions for specific applications; proprietary graphitization processes that preserve nanotube integrity; advanced hybridization techniques combining CNTs with graphene. Weaknesses: Manufacturing processes for precisely controlled CNT dimensions may face scalability challenges; high-temperature graphitization processes are energy-intensive and costly.

Key Scientific Findings on Dimensional-Performance Relationships

Carbon nanotube wire

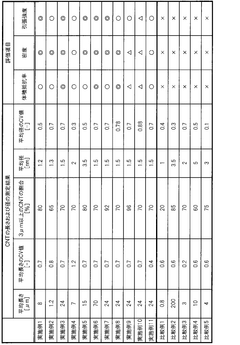

PatentWO2019189831A1

Innovation

- A carbon nanotube wire composed of a plurality of nanotubes with predetermined variations in diameter and length, where the average length is 150 μm or less, the coefficient of variation (CV) of the average length is 0.40 or more, and the average diameter is less than 4 nm, with a CV value of 0.18 or more, and a proportion of nanotubes with a length of 3 μm or more is 60% or more, to ensure dense packing and alignment.

carbon nanotubes and a method for their growth

PatentUndeterminedRU2006111408A

Innovation

- Single-layer carbon nanotubes coated with a shell of pyrolytic carbon, where graphene layers forming the shell are located concentrically and parallel to the fiber axis.

- Carbon nanotubes with extremely high aspect ratio (length to diameter ratio > 10000) and constant diameter (30-150 nm) along the entire length.

- Catalyst-free growth method where nanotube nucleation is initiated by a catalyst, but further growth occurs without catalyst participation from a carbon-containing gaseous medium maintained below the soot formation threshold.

Characterization Techniques for CNT Dimensional Analysis

Accurate characterization of carbon nanotube (CNT) dimensions is critical for understanding the relationship between structural parameters and performance in graphitized carbon nanotubes. Several advanced analytical techniques have been developed and refined specifically for measuring CNT length and diameter with high precision.

Transmission Electron Microscopy (TEM) remains the gold standard for CNT dimensional analysis, offering nanometer-scale resolution that allows direct visualization of both the external diameter and internal cavity of nanotubes. High-resolution TEM (HR-TEM) can further reveal the graphitic wall structure, enabling precise counting of graphene layers and assessment of graphitization quality. For large-scale statistical analysis, automated TEM image processing algorithms have been developed to measure thousands of nanotubes efficiently.

Scanning Electron Microscopy (SEM) provides complementary information, particularly valuable for length measurements of longer CNTs and for analyzing CNT alignment and dispersion. While offering lower resolution than TEM, modern field-emission SEM systems can achieve sub-nanometer resolution suitable for diameter estimation of CNT bundles.

Atomic Force Microscopy (AFM) offers three-dimensional topographical imaging with sub-nanometer vertical resolution, making it particularly useful for precise height (diameter) measurements of individual nanotubes deposited on flat substrates. AFM can also provide information about CNT mechanical properties through force-distance measurements.

Raman spectroscopy serves as a non-destructive technique that indirectly correlates spectral features with CNT dimensions. The radial breathing mode (RBM) frequencies in single-walled CNTs are inversely proportional to tube diameter, while G-band and D-band ratios provide insights into graphitization degree and defect density.

Dynamic Light Scattering (DLS) and Small-Angle X-ray Scattering (SAXS) enable solution-phase analysis of CNT dimensions, offering statistical distribution data without the sampling limitations of microscopy techniques. These methods are particularly valuable for quality control in large-scale production environments.

X-ray Diffraction (XRD) analysis provides information about the crystalline structure of graphitized CNTs, with peak widths correlating to crystallite sizes and graphitization degree. This technique is especially useful for monitoring structural changes during thermal graphitization processes.

Advanced characterization often combines multiple techniques to overcome the limitations of individual methods. For instance, correlative microscopy approaches linking TEM with Raman mapping can provide both structural and spectroscopic information from identical nanotube regions, establishing more robust structure-property relationships.

Transmission Electron Microscopy (TEM) remains the gold standard for CNT dimensional analysis, offering nanometer-scale resolution that allows direct visualization of both the external diameter and internal cavity of nanotubes. High-resolution TEM (HR-TEM) can further reveal the graphitic wall structure, enabling precise counting of graphene layers and assessment of graphitization quality. For large-scale statistical analysis, automated TEM image processing algorithms have been developed to measure thousands of nanotubes efficiently.

Scanning Electron Microscopy (SEM) provides complementary information, particularly valuable for length measurements of longer CNTs and for analyzing CNT alignment and dispersion. While offering lower resolution than TEM, modern field-emission SEM systems can achieve sub-nanometer resolution suitable for diameter estimation of CNT bundles.

Atomic Force Microscopy (AFM) offers three-dimensional topographical imaging with sub-nanometer vertical resolution, making it particularly useful for precise height (diameter) measurements of individual nanotubes deposited on flat substrates. AFM can also provide information about CNT mechanical properties through force-distance measurements.

Raman spectroscopy serves as a non-destructive technique that indirectly correlates spectral features with CNT dimensions. The radial breathing mode (RBM) frequencies in single-walled CNTs are inversely proportional to tube diameter, while G-band and D-band ratios provide insights into graphitization degree and defect density.

Dynamic Light Scattering (DLS) and Small-Angle X-ray Scattering (SAXS) enable solution-phase analysis of CNT dimensions, offering statistical distribution data without the sampling limitations of microscopy techniques. These methods are particularly valuable for quality control in large-scale production environments.

X-ray Diffraction (XRD) analysis provides information about the crystalline structure of graphitized CNTs, with peak widths correlating to crystallite sizes and graphitization degree. This technique is especially useful for monitoring structural changes during thermal graphitization processes.

Advanced characterization often combines multiple techniques to overcome the limitations of individual methods. For instance, correlative microscopy approaches linking TEM with Raman mapping can provide both structural and spectroscopic information from identical nanotube regions, establishing more robust structure-property relationships.

Environmental and Safety Considerations of Engineered CNTs

The environmental and safety implications of graphitized carbon nanotubes (GCNTs) are significantly influenced by their physical dimensions, particularly length and diameter. These structural parameters directly affect how these nanomaterials interact with biological systems and the environment throughout their lifecycle.

Nanotube length plays a critical role in determining toxicity profiles. Longer carbon nanotubes (exceeding 10-15 μm) have been associated with asbestos-like pathogenicity due to their inability to be effectively cleared by macrophages, potentially leading to granuloma formation and inflammatory responses. Conversely, shorter GCNTs demonstrate reduced biopersistence and improved clearance rates from biological systems, suggesting lower long-term toxicity concerns.

Diameter variations similarly impact safety considerations. Thinner nanotubes (particularly those under 50 nm) demonstrate enhanced ability to penetrate cellular membranes and biological barriers, potentially increasing cytotoxicity risks. Wider diameter GCNTs typically exhibit reduced cellular uptake and consequently lower direct cytotoxicity, though they may present different environmental transport behaviors.

The surface-to-volume ratio, directly determined by length and diameter dimensions, affects reactivity with biological molecules and environmental media. Smaller diameter GCNTs possess larger relative surface areas, potentially increasing their capacity to adsorb environmental contaminants or biological molecules, which may alter their toxicological profile and environmental fate.

Manufacturing processes for controlling GCNT dimensions may introduce additional environmental considerations. Production methods targeting specific length and diameter distributions often require more intensive chemical processing, potentially generating hazardous waste streams that require specialized management protocols.

Regulatory frameworks increasingly recognize the importance of physical dimensions in nanomaterial risk assessment. Several jurisdictions now require specific safety documentation for high-aspect-ratio nanomaterials, with particular attention to those resembling asbestos-like dimensions. This dimensional-based regulatory approach necessitates precise control and characterization of GCNT length and diameter during production.

Disposal and environmental release scenarios must account for how different GCNT dimensions affect environmental transport, degradation, and bioaccumulation potential. Shorter, wider GCNTs typically demonstrate reduced mobility in environmental matrices compared to their longer, thinner counterparts, potentially limiting their environmental distribution following release events.

Occupational safety protocols for handling engineered GCNTs should be tailored according to dimensional characteristics, with stricter containment measures implemented for those dimensions associated with higher biological activity and respiratory concerns.

Nanotube length plays a critical role in determining toxicity profiles. Longer carbon nanotubes (exceeding 10-15 μm) have been associated with asbestos-like pathogenicity due to their inability to be effectively cleared by macrophages, potentially leading to granuloma formation and inflammatory responses. Conversely, shorter GCNTs demonstrate reduced biopersistence and improved clearance rates from biological systems, suggesting lower long-term toxicity concerns.

Diameter variations similarly impact safety considerations. Thinner nanotubes (particularly those under 50 nm) demonstrate enhanced ability to penetrate cellular membranes and biological barriers, potentially increasing cytotoxicity risks. Wider diameter GCNTs typically exhibit reduced cellular uptake and consequently lower direct cytotoxicity, though they may present different environmental transport behaviors.

The surface-to-volume ratio, directly determined by length and diameter dimensions, affects reactivity with biological molecules and environmental media. Smaller diameter GCNTs possess larger relative surface areas, potentially increasing their capacity to adsorb environmental contaminants or biological molecules, which may alter their toxicological profile and environmental fate.

Manufacturing processes for controlling GCNT dimensions may introduce additional environmental considerations. Production methods targeting specific length and diameter distributions often require more intensive chemical processing, potentially generating hazardous waste streams that require specialized management protocols.

Regulatory frameworks increasingly recognize the importance of physical dimensions in nanomaterial risk assessment. Several jurisdictions now require specific safety documentation for high-aspect-ratio nanomaterials, with particular attention to those resembling asbestos-like dimensions. This dimensional-based regulatory approach necessitates precise control and characterization of GCNT length and diameter during production.

Disposal and environmental release scenarios must account for how different GCNT dimensions affect environmental transport, degradation, and bioaccumulation potential. Shorter, wider GCNTs typically demonstrate reduced mobility in environmental matrices compared to their longer, thinner counterparts, potentially limiting their environmental distribution following release events.

Occupational safety protocols for handling engineered GCNTs should be tailored according to dimensional characteristics, with stricter containment measures implemented for those dimensions associated with higher biological activity and respiratory concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!