Graphitized carbon nanotubes for grid storage and industrial energy applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Energy Storage Background & Objectives

Energy storage technologies have undergone significant evolution over the past decades, with graphitized carbon nanotubes (CNTs) emerging as a promising frontier for grid-scale and industrial energy applications. The journey of carbon-based energy storage began with traditional activated carbons, progressing through graphite intercalation compounds, and now advancing into the realm of nanostructured carbon materials. Graphitized CNTs represent a critical advancement in this progression, offering unique properties that address limitations of conventional storage technologies.

The global energy landscape is rapidly shifting toward renewable sources, creating an unprecedented demand for efficient, high-capacity energy storage solutions. Traditional lithium-ion batteries face challenges in grid-scale applications due to resource limitations, safety concerns, and insufficient cycle life. Graphitized CNTs offer potential solutions through their exceptional electrical conductivity, mechanical strength, and electrochemical stability – properties that can be harnessed for next-generation energy storage systems.

Current technical objectives in this field focus on optimizing the graphitization process of CNTs to enhance their performance characteristics. Specifically, researchers aim to achieve precise control over the degree of graphitization, which directly influences the electrical conductivity and energy storage capacity. The temperature range of 1800-2800°C during thermal treatment represents a critical parameter that determines the final structure and properties of these materials.

Another key objective involves developing scalable manufacturing processes that maintain the superior properties of laboratory-produced graphitized CNTs while enabling industrial-scale production. This includes innovations in continuous graphitization techniques, quality control methodologies, and integration strategies with existing energy storage architectures.

The environmental sustainability of graphitized CNT production also represents a significant objective. Current research aims to reduce energy consumption during the graphitization process, minimize the use of hazardous chemicals, and explore environmentally friendly precursors for CNT synthesis. These efforts align with global sustainability goals and regulatory requirements for clean energy technologies.

From an application perspective, technical objectives extend to demonstrating the viability of graphitized CNTs in various energy storage configurations, including supercapacitors, hybrid capacitors, and advanced battery systems. Particular emphasis is placed on applications requiring rapid charge-discharge cycles, high power density, and long operational lifetimes – characteristics essential for grid stabilization and industrial energy management.

The ultimate goal of current research and development efforts is to position graphitized CNTs as a transformative technology that can address the growing gap between renewable energy generation and consumption patterns, thereby facilitating the global transition to sustainable energy systems while supporting industrial energy efficiency improvements.

The global energy landscape is rapidly shifting toward renewable sources, creating an unprecedented demand for efficient, high-capacity energy storage solutions. Traditional lithium-ion batteries face challenges in grid-scale applications due to resource limitations, safety concerns, and insufficient cycle life. Graphitized CNTs offer potential solutions through their exceptional electrical conductivity, mechanical strength, and electrochemical stability – properties that can be harnessed for next-generation energy storage systems.

Current technical objectives in this field focus on optimizing the graphitization process of CNTs to enhance their performance characteristics. Specifically, researchers aim to achieve precise control over the degree of graphitization, which directly influences the electrical conductivity and energy storage capacity. The temperature range of 1800-2800°C during thermal treatment represents a critical parameter that determines the final structure and properties of these materials.

Another key objective involves developing scalable manufacturing processes that maintain the superior properties of laboratory-produced graphitized CNTs while enabling industrial-scale production. This includes innovations in continuous graphitization techniques, quality control methodologies, and integration strategies with existing energy storage architectures.

The environmental sustainability of graphitized CNT production also represents a significant objective. Current research aims to reduce energy consumption during the graphitization process, minimize the use of hazardous chemicals, and explore environmentally friendly precursors for CNT synthesis. These efforts align with global sustainability goals and regulatory requirements for clean energy technologies.

From an application perspective, technical objectives extend to demonstrating the viability of graphitized CNTs in various energy storage configurations, including supercapacitors, hybrid capacitors, and advanced battery systems. Particular emphasis is placed on applications requiring rapid charge-discharge cycles, high power density, and long operational lifetimes – characteristics essential for grid stabilization and industrial energy management.

The ultimate goal of current research and development efforts is to position graphitized CNTs as a transformative technology that can address the growing gap between renewable energy generation and consumption patterns, thereby facilitating the global transition to sustainable energy systems while supporting industrial energy efficiency improvements.

Grid Storage Market Analysis and Energy Demand Trends

The global grid storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the grid energy storage market was valued at approximately $27 billion and is projected to reach $51 billion by 2028, representing a compound annual growth rate (CAGR) of 13.5%. This remarkable expansion reflects the critical role that energy storage technologies play in modern power infrastructure.

Lithium-ion batteries currently dominate the market with over 70% share, but emerging technologies like graphitized carbon nanotubes (GCNTs) are gaining attention due to their superior electrical conductivity, thermal stability, and potential for cost reduction in large-scale applications. The demand for grid-scale storage solutions is particularly strong in regions with high renewable energy penetration, including North America, Europe, and parts of Asia-Pacific.

Industrial energy applications represent another significant market segment for advanced storage technologies. Manufacturing sectors, particularly those with energy-intensive processes, are increasingly seeking solutions to manage peak demand charges and improve energy resilience. The industrial energy storage market is expected to grow at a CAGR of 11.8% through 2030, with particular emphasis on technologies that offer long duration storage capabilities.

Key demand drivers include the global push for decarbonization, with over 70 countries having set net-zero emissions targets. This transition necessitates substantial investments in energy storage to accommodate the intermittent nature of renewable generation. Additionally, aging grid infrastructure in developed economies is creating opportunities for modernization projects that incorporate advanced storage solutions.

Regulatory frameworks are evolving to support grid storage deployment. For instance, FERC Order 841 in the United States has opened wholesale markets to energy storage participation, while the European Union's Green Deal includes provisions for accelerating storage adoption. These policy developments are expected to unlock approximately $35 billion in new investments over the next decade.

Price trends are also favorable for emerging technologies like GCNTs. While traditional lithium-ion storage costs have decreased by approximately 87% since 2010, they still face challenges related to raw material supply chains. This creates an opportunity for alternative technologies that utilize more abundant materials, such as carbon-based solutions.

The convergence of declining costs, supportive policies, and increasing renewable penetration indicates that the market for advanced grid storage technologies, including those utilizing graphitized carbon nanotubes, is poised for substantial growth in the coming years, with particular strength in utility-scale applications and industrial energy management systems.

Lithium-ion batteries currently dominate the market with over 70% share, but emerging technologies like graphitized carbon nanotubes (GCNTs) are gaining attention due to their superior electrical conductivity, thermal stability, and potential for cost reduction in large-scale applications. The demand for grid-scale storage solutions is particularly strong in regions with high renewable energy penetration, including North America, Europe, and parts of Asia-Pacific.

Industrial energy applications represent another significant market segment for advanced storage technologies. Manufacturing sectors, particularly those with energy-intensive processes, are increasingly seeking solutions to manage peak demand charges and improve energy resilience. The industrial energy storage market is expected to grow at a CAGR of 11.8% through 2030, with particular emphasis on technologies that offer long duration storage capabilities.

Key demand drivers include the global push for decarbonization, with over 70 countries having set net-zero emissions targets. This transition necessitates substantial investments in energy storage to accommodate the intermittent nature of renewable generation. Additionally, aging grid infrastructure in developed economies is creating opportunities for modernization projects that incorporate advanced storage solutions.

Regulatory frameworks are evolving to support grid storage deployment. For instance, FERC Order 841 in the United States has opened wholesale markets to energy storage participation, while the European Union's Green Deal includes provisions for accelerating storage adoption. These policy developments are expected to unlock approximately $35 billion in new investments over the next decade.

Price trends are also favorable for emerging technologies like GCNTs. While traditional lithium-ion storage costs have decreased by approximately 87% since 2010, they still face challenges related to raw material supply chains. This creates an opportunity for alternative technologies that utilize more abundant materials, such as carbon-based solutions.

The convergence of declining costs, supportive policies, and increasing renewable penetration indicates that the market for advanced grid storage technologies, including those utilizing graphitized carbon nanotubes, is poised for substantial growth in the coming years, with particular strength in utility-scale applications and industrial energy management systems.

Current Challenges in Carbon Nanotube Graphitization

Despite significant advancements in carbon nanotube (CNT) graphitization techniques, several critical challenges continue to impede widespread industrial adoption for grid storage and energy applications. The primary obstacle remains the scalability of high-quality graphitization processes. Laboratory-scale methods that produce well-graphitized CNTs with excellent electrical conductivity and structural integrity often fail to translate effectively to industrial-scale production, creating a significant bottleneck for commercial viability.

Temperature control during graphitization presents another substantial challenge. The process typically requires temperatures exceeding 2500°C, which demands specialized equipment and significant energy input. Maintaining uniform temperature distribution throughout large batches of CNTs is particularly problematic, often resulting in inconsistent graphitization quality across production batches.

Structural defects and impurities represent persistent issues in the graphitization process. Even minor structural imperfections can significantly compromise the electrical conductivity and energy storage capacity of graphitized CNTs. Current purification techniques often damage the nanotube structure or fail to completely remove catalytic particles and amorphous carbon, negatively affecting performance in energy storage applications.

Cost-effectiveness remains a significant barrier to commercial implementation. The high-temperature treatments and specialized equipment required for graphitization substantially increase production costs. Additionally, the energy-intensive nature of the process contradicts the sustainability goals that many grid storage solutions aim to address, creating a paradoxical situation where environmentally beneficial technology requires environmentally costly manufacturing processes.

Quality control and standardization present ongoing challenges. The lack of universally accepted metrics for evaluating graphitization quality hampers industrial adoption, as manufacturers struggle to guarantee consistent performance specifications to potential customers in the energy sector. This uncertainty increases perceived risk and slows market acceptance.

Material compatibility issues also arise when integrating graphitized CNTs with other components in energy storage systems. Interface engineering between graphitized CNTs and electrolytes, current collectors, or binding materials remains problematic, often resulting in suboptimal system performance despite excellent properties of the individual graphitized CNTs.

Environmental and safety concerns associated with high-temperature processing and potential nanoparticle release during manufacturing further complicate industrial scale-up. Regulatory uncertainties regarding nanomaterial handling and disposal add additional layers of complexity to commercial implementation efforts in the sensitive energy infrastructure sector.

Temperature control during graphitization presents another substantial challenge. The process typically requires temperatures exceeding 2500°C, which demands specialized equipment and significant energy input. Maintaining uniform temperature distribution throughout large batches of CNTs is particularly problematic, often resulting in inconsistent graphitization quality across production batches.

Structural defects and impurities represent persistent issues in the graphitization process. Even minor structural imperfections can significantly compromise the electrical conductivity and energy storage capacity of graphitized CNTs. Current purification techniques often damage the nanotube structure or fail to completely remove catalytic particles and amorphous carbon, negatively affecting performance in energy storage applications.

Cost-effectiveness remains a significant barrier to commercial implementation. The high-temperature treatments and specialized equipment required for graphitization substantially increase production costs. Additionally, the energy-intensive nature of the process contradicts the sustainability goals that many grid storage solutions aim to address, creating a paradoxical situation where environmentally beneficial technology requires environmentally costly manufacturing processes.

Quality control and standardization present ongoing challenges. The lack of universally accepted metrics for evaluating graphitization quality hampers industrial adoption, as manufacturers struggle to guarantee consistent performance specifications to potential customers in the energy sector. This uncertainty increases perceived risk and slows market acceptance.

Material compatibility issues also arise when integrating graphitized CNTs with other components in energy storage systems. Interface engineering between graphitized CNTs and electrolytes, current collectors, or binding materials remains problematic, often resulting in suboptimal system performance despite excellent properties of the individual graphitized CNTs.

Environmental and safety concerns associated with high-temperature processing and potential nanoparticle release during manufacturing further complicate industrial scale-up. Regulatory uncertainties regarding nanomaterial handling and disposal add additional layers of complexity to commercial implementation efforts in the sensitive energy infrastructure sector.

Current Graphitized CNT Implementation Approaches

01 Manufacturing methods of graphitized carbon nanotubes

Various techniques are employed to produce graphitized carbon nanotubes, including high-temperature thermal treatment processes that convert amorphous carbon structures into more ordered graphitic structures. These methods often involve heating carbon nanotubes at temperatures exceeding 2000°C under controlled atmospheres to enhance graphitization. The resulting graphitized nanotubes exhibit improved electrical conductivity, thermal stability, and mechanical properties compared to non-graphitized variants.- Synthesis and production methods of graphitized carbon nanotubes: Various methods for synthesizing and producing graphitized carbon nanotubes are disclosed, including high-temperature thermal treatments that transform amorphous carbon into crystalline graphitic structures. These processes typically involve heating carbon nanotubes at temperatures ranging from 1500°C to 3000°C under controlled atmospheres to improve their structural integrity, electrical conductivity, and mechanical properties. The graphitization process removes structural defects and impurities, resulting in nanotubes with enhanced performance characteristics for various applications.

- Applications in energy storage and electronic devices: Graphitized carbon nanotubes demonstrate exceptional performance in energy storage applications and electronic devices. Their highly ordered graphitic structure provides superior electrical conductivity, making them ideal for use in lithium-ion batteries, supercapacitors, and various electronic components. When incorporated into electrode materials, they enhance charge transfer, increase energy density, and improve cycling stability. Their unique combination of high surface area, excellent electrical properties, and mechanical strength makes them valuable additives for next-generation energy storage solutions and electronic applications.

- Composite materials incorporating graphitized carbon nanotubes: Graphitized carbon nanotubes can be incorporated into various composite materials to enhance their mechanical, thermal, and electrical properties. These composites find applications in aerospace, automotive, and construction industries due to their improved strength-to-weight ratio, thermal stability, and conductivity. The graphitization process enhances the interfacial bonding between the nanotubes and matrix materials, resulting in more effective load transfer and reinforcement. Methods for uniform dispersion and functionalization of graphitized nanotubes within polymer, metal, or ceramic matrices are described to optimize composite performance.

- Surface modification and functionalization techniques: Various techniques for surface modification and functionalization of graphitized carbon nanotubes are presented to enhance their compatibility with different matrices and to impart specific properties. These methods include chemical treatments, plasma processing, and coating with functional groups or other nanomaterials. Surface functionalization improves dispersion characteristics, reduces agglomeration, and enables tailored interactions with surrounding materials. Modified graphitized carbon nanotubes show enhanced performance in specific applications such as sensors, catalysts, and biomedical devices where surface chemistry plays a crucial role.

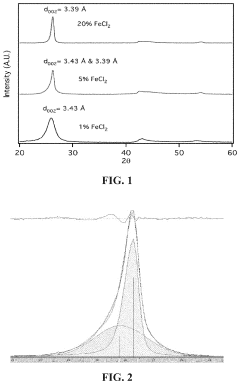

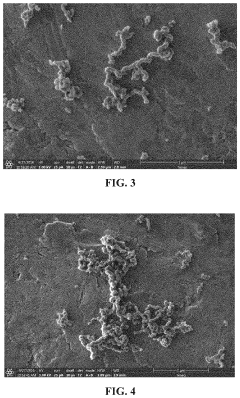

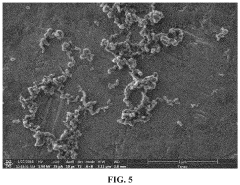

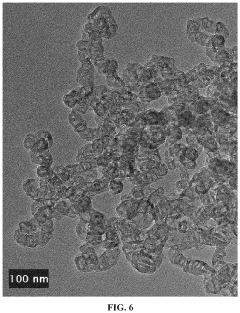

- Characterization and quality control methods: Various analytical techniques and quality control methods for characterizing graphitized carbon nanotubes are described. These include Raman spectroscopy, X-ray diffraction, transmission electron microscopy, and thermogravimetric analysis to evaluate the degree of graphitization, structural integrity, and purity. The characterization methods help in determining key parameters such as crystallinity, defect density, and thermal stability, which are critical for ensuring consistent performance in applications. Standardized testing protocols and quality metrics are established to facilitate the industrial-scale production and application of graphitized carbon nanotubes with predictable properties.

02 Composite materials incorporating graphitized carbon nanotubes

Graphitized carbon nanotubes are integrated into various composite materials to enhance their properties. These composites benefit from the superior electrical conductivity, thermal stability, and mechanical strength of graphitized nanotubes. Applications include polymer composites with improved electrical conductivity, metal matrix composites with enhanced mechanical properties, and ceramic composites with better thermal management capabilities. The graphitization process optimizes the interface between nanotubes and matrix materials.Expand Specific Solutions03 Electrode applications of graphitized carbon nanotubes

Graphitized carbon nanotubes serve as excellent electrode materials in various energy storage and conversion devices. Their highly ordered graphitic structure provides superior electrical conductivity and electrochemical stability. These materials are utilized in lithium-ion batteries, supercapacitors, fuel cells, and other electrochemical systems. The graphitization process reduces defects and impurities, resulting in improved charge transfer kinetics and cycling stability in electrochemical applications.Expand Specific Solutions04 Surface functionalization of graphitized carbon nanotubes

Surface modification techniques are applied to graphitized carbon nanotubes to enhance their compatibility with various matrices and to impart specific properties. These functionalization methods include chemical treatments, plasma processing, and coating with functional groups or polymers. Modified graphitized nanotubes show improved dispersion in solvents and matrices, enhanced interfacial bonding, and can be tailored for specific applications such as sensing, catalysis, or biomedical uses.Expand Specific Solutions05 Thermal and electrical applications of graphitized carbon nanotubes

Graphitized carbon nanotubes exhibit exceptional thermal and electrical properties, making them valuable for specialized applications. Their high thermal conductivity enables efficient heat dissipation in electronic devices and thermal interface materials. The superior electrical conductivity makes them ideal for transparent conductive films, electromagnetic shielding, and conductive additives. These properties are particularly beneficial in aerospace, electronics, and energy sectors where high performance under extreme conditions is required.Expand Specific Solutions

Leading Companies in Advanced Carbon Materials Industry

The graphitized carbon nanotube market for grid storage and industrial energy applications is in a growth phase, with increasing demand driven by the need for advanced energy storage solutions. The market size is expanding as these materials demonstrate superior performance in high-capacity storage systems. Technologically, the field shows varying maturity levels across players. Applied Materials and Intel lead with established manufacturing capabilities, while Molecular Rebar Design offers specialized surface-tailored nanotubes. Academic institutions like Rice University and University of California contribute fundamental research advancements. Asian companies including Hangzhou Highene Technology and Panasonic are rapidly developing commercial applications. The ecosystem includes both specialized nanotechnology firms and diversified industrial giants like Dow and Infineon, creating a competitive landscape where technical differentiation and application-specific solutions are key competitive advantages.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced manufacturing technologies for graphitized carbon nanotube (g-CNT) production aimed at grid storage and industrial energy applications. Their approach leverages precision engineering and semiconductor manufacturing expertise to create highly controlled g-CNT structures with optimized properties for energy storage. Their proprietary Chemical Vapor Deposition (CVD) systems enable large-scale production of vertically aligned carbon nanotube arrays with precise control over diameter, length, and density. These arrays undergo a specialized graphitization process at temperatures exceeding 2700°C in custom-designed furnaces that ensure uniform heat distribution and precise atmosphere control. The resulting g-CNTs exhibit exceptional electrical conductivity (>10^5 S/m) and thermal stability, making them ideal for high-power grid storage applications. Applied Materials has also developed specialized equipment for integrating these g-CNTs into electrode structures, including roll-to-roll processing systems that enable continuous production of g-CNT-enhanced battery electrodes with consistent quality and performance characteristics.

Strengths: Unparalleled expertise in scaling advanced materials production; established global supply chain and customer relationships; comprehensive equipment portfolio spanning material synthesis to device integration. Weaknesses: Higher capital investment requirements compared to conventional carbon material production; complex process control requirements; competition from specialized nanomaterial manufacturers.

The Regents of the University of California

Technical Solution: The University of California has developed advanced graphitized carbon nanotube (g-CNT) composite materials for next-generation grid storage applications. Their research teams have pioneered multi-functional g-CNT architectures that combine high electrical conductivity with exceptional mechanical properties. Their approach involves controlled graphitization of carbon nanotubes at temperatures exceeding 2500°C, resulting in highly ordered carbon structures with enhanced electron transport capabilities. A key innovation is their development of 3D interconnected g-CNT networks that serve as conductive scaffolds in high-capacity electrodes for grid-scale energy storage. These structures have demonstrated remarkable stability during rapid charge-discharge cycles, with capacity retention exceeding 90% after 10,000 cycles. Additionally, their research has yielded g-CNT/silicon composite anodes that address volume expansion issues in high-capacity battery systems, enabling energy densities approaching 400 Wh/kg while maintaining structural integrity.

Strengths: Cutting-edge research capabilities with access to advanced characterization techniques; strong intellectual property portfolio; demonstrated scale-up potential for industrial applications. Weaknesses: Technology still primarily at research/prototype stage; higher production costs compared to conventional materials; challenges in standardizing manufacturing processes across different applications.

Key Patents and Research on CNT Graphitization Processes

Production of carbon nanochains and nanotubes from biomass

PatentActiveUS20220089445A1

Innovation

- The synthesis of high purity carbon nanochains and carbon nanotubes is achieved through laser irradiation of low-cost biomass or carbonaceous materials in the presence of catalysts, such as transition metal salts or elemental metals, which convert biomass into pyrolysis-oil, pyrolysis-gas, and char, and subsequently into carbon nanostructures.

An energy storage electrode

PatentWO2017093596A1

Innovation

- The use of a graphene/carbon nanoflower composite (G/CNF) material in energy storage electrodes, comprising multi-layered graphene sheets and carbon nanoflowers, which enhances lithium ion transport properties and prevents structural degradation through rotational disorder and flexibility, and can be optimized with ultrafine metal nanoparticles for improved conductivity and capacity.

Environmental Impact and Sustainability Assessment

The environmental footprint of graphitized carbon nanotubes (GCNTs) must be thoroughly assessed across their entire lifecycle to ensure sustainable implementation in grid storage and industrial energy applications. Production of GCNTs typically involves energy-intensive processes including high-temperature graphitization treatments, which can generate significant carbon emissions if powered by fossil fuels. Current manufacturing methods require temperatures exceeding 2500°C, resulting in considerable energy consumption that may partially offset the environmental benefits these materials provide in energy storage applications.

Raw material sourcing for carbon nanotube production presents additional environmental considerations. While carbon is abundant, the extraction and processing of catalyst materials like nickel, cobalt, and iron used in CNT synthesis can lead to habitat disruption, water pollution, and energy-intensive mining operations. Sustainable sourcing practices and recycling of catalyst materials are becoming increasingly important as production scales up to meet growing energy storage demands.

Water usage during manufacturing and purification processes represents another significant environmental concern. Conventional CNT production methods often require substantial water resources for cooling and purification steps. Advanced closed-loop water systems and dry processing techniques are being developed to minimize this impact, though implementation remains limited in large-scale production facilities.

End-of-life management for GCNT-based energy storage systems presents both challenges and opportunities. These materials have potential for recycling and recovery, which could significantly reduce their overall environmental impact. However, current recycling infrastructure for nanomaterials remains underdeveloped, creating a risk of improper disposal and potential environmental contamination if not addressed proactively.

The positive environmental contributions of GCNTs must also be quantified when assessing overall sustainability. Their application in grid storage can enable greater renewable energy integration, potentially reducing reliance on fossil fuels and associated emissions. Preliminary lifecycle assessments suggest that despite energy-intensive production, GCNT-based storage systems could achieve net environmental benefits through extended lifespans, improved efficiency, and enabling higher renewable energy penetration.

Regulatory frameworks for nanomaterial environmental safety continue to evolve globally. Comprehensive risk assessment protocols are being developed to evaluate potential environmental exposure pathways and ecological impacts of GCNTs throughout their lifecycle. Industry stakeholders are increasingly adopting voluntary environmental stewardship programs while formal regulations are being established.

Raw material sourcing for carbon nanotube production presents additional environmental considerations. While carbon is abundant, the extraction and processing of catalyst materials like nickel, cobalt, and iron used in CNT synthesis can lead to habitat disruption, water pollution, and energy-intensive mining operations. Sustainable sourcing practices and recycling of catalyst materials are becoming increasingly important as production scales up to meet growing energy storage demands.

Water usage during manufacturing and purification processes represents another significant environmental concern. Conventional CNT production methods often require substantial water resources for cooling and purification steps. Advanced closed-loop water systems and dry processing techniques are being developed to minimize this impact, though implementation remains limited in large-scale production facilities.

End-of-life management for GCNT-based energy storage systems presents both challenges and opportunities. These materials have potential for recycling and recovery, which could significantly reduce their overall environmental impact. However, current recycling infrastructure for nanomaterials remains underdeveloped, creating a risk of improper disposal and potential environmental contamination if not addressed proactively.

The positive environmental contributions of GCNTs must also be quantified when assessing overall sustainability. Their application in grid storage can enable greater renewable energy integration, potentially reducing reliance on fossil fuels and associated emissions. Preliminary lifecycle assessments suggest that despite energy-intensive production, GCNT-based storage systems could achieve net environmental benefits through extended lifespans, improved efficiency, and enabling higher renewable energy penetration.

Regulatory frameworks for nanomaterial environmental safety continue to evolve globally. Comprehensive risk assessment protocols are being developed to evaluate potential environmental exposure pathways and ecological impacts of GCNTs throughout their lifecycle. Industry stakeholders are increasingly adopting voluntary environmental stewardship programs while formal regulations are being established.

Scalability and Cost Analysis for Industrial Adoption

The scalability of graphitized carbon nanotube (GCNT) technology represents a critical factor in determining its viability for widespread industrial adoption in grid storage and energy applications. Current production methods primarily operate at laboratory or small pilot scales, with annual global production capacity estimated at less than 500 metric tons. This limited scale presents significant challenges for industries requiring thousands of tons of material for grid-scale energy storage implementations.

Production scaling faces several technical hurdles that directly impact cost structures. The high-temperature graphitization process (typically 2500-3000°C) requires specialized equipment and substantial energy inputs, contributing approximately 35-40% of total production costs. Purification processes to achieve the 99.9% carbon content necessary for optimal electrical conductivity add another 20-25% to production expenses. These factors currently position GCNT materials at $80-120 per kilogram, significantly higher than competing energy storage materials.

Economic modeling suggests that achieving price points below $50/kg would be necessary to enable competitive large-scale industrial applications. This would require production facilities capable of processing at least 1,000 tons annually to achieve economies of scale. Industry analysts project that with optimized continuous production methods and increased automation, such price targets could be achievable within 5-7 years, potentially reducing costs by 60-70%.

Infrastructure requirements present additional scaling challenges. GCNT manufacturing demands specialized facilities with precise temperature control systems, inert gas handling capabilities, and advanced quality control instrumentation. Capital expenditure for a mid-scale production facility (100-500 tons/year) is estimated at $50-80 million, with larger facilities requiring proportionally greater investment but offering improved unit economics.

Supply chain considerations further complicate industrial adoption. The production process requires high-purity carbon precursors and specialized catalysts, both subject to market volatility. Vertical integration strategies being explored by leading manufacturers could potentially stabilize these inputs and reduce costs by 15-20%.

From an adoption perspective, industries must also factor in integration costs beyond raw material expenses. Retrofitting existing energy storage systems to incorporate GCNT technology typically adds 30-45% to initial implementation costs, though these are potentially offset by improved performance and longevity. Complete system lifecycle analysis indicates that despite higher upfront costs, GCNT-based solutions could achieve cost parity with conventional technologies within 3-5 years of operation due to efficiency gains and reduced maintenance requirements.

Production scaling faces several technical hurdles that directly impact cost structures. The high-temperature graphitization process (typically 2500-3000°C) requires specialized equipment and substantial energy inputs, contributing approximately 35-40% of total production costs. Purification processes to achieve the 99.9% carbon content necessary for optimal electrical conductivity add another 20-25% to production expenses. These factors currently position GCNT materials at $80-120 per kilogram, significantly higher than competing energy storage materials.

Economic modeling suggests that achieving price points below $50/kg would be necessary to enable competitive large-scale industrial applications. This would require production facilities capable of processing at least 1,000 tons annually to achieve economies of scale. Industry analysts project that with optimized continuous production methods and increased automation, such price targets could be achievable within 5-7 years, potentially reducing costs by 60-70%.

Infrastructure requirements present additional scaling challenges. GCNT manufacturing demands specialized facilities with precise temperature control systems, inert gas handling capabilities, and advanced quality control instrumentation. Capital expenditure for a mid-scale production facility (100-500 tons/year) is estimated at $50-80 million, with larger facilities requiring proportionally greater investment but offering improved unit economics.

Supply chain considerations further complicate industrial adoption. The production process requires high-purity carbon precursors and specialized catalysts, both subject to market volatility. Vertical integration strategies being explored by leading manufacturers could potentially stabilize these inputs and reduce costs by 15-20%.

From an adoption perspective, industries must also factor in integration costs beyond raw material expenses. Retrofitting existing energy storage systems to incorporate GCNT technology typically adds 30-45% to initial implementation costs, though these are potentially offset by improved performance and longevity. Complete system lifecycle analysis indicates that despite higher upfront costs, GCNT-based solutions could achieve cost parity with conventional technologies within 3-5 years of operation due to efficiency gains and reduced maintenance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!