Graphitized carbon nanotubes for large scale energy storage and renewable integration

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Energy Storage Background & Objectives

Energy storage technologies have evolved significantly over the past decades, with graphitized carbon nanotubes (CNTs) emerging as a promising material for next-generation energy storage systems. The journey began with conventional carbon-based materials in batteries and supercapacitors, but limitations in energy density, charge-discharge rates, and cycle life prompted researchers to explore nanostructured carbon materials. Graphitized CNTs represent a significant advancement in this evolution, offering exceptional electrical conductivity, mechanical strength, and high surface area.

The global transition toward renewable energy sources has intensified the need for efficient, large-scale energy storage solutions. Intermittent renewable sources like solar and wind require robust storage systems to ensure grid stability and reliable power supply. This market demand has accelerated research into advanced materials that can enable higher capacity, faster charging, and longer-lasting energy storage devices.

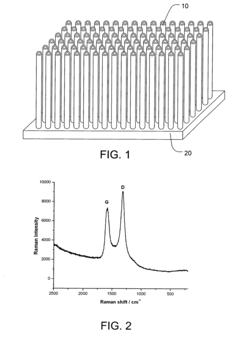

Graphitized CNTs are produced through high-temperature treatment (typically 1800-2800°C) of conventional CNTs, resulting in improved crystallinity, reduced defects, and enhanced sp2 carbon bonding. This process significantly improves their electrical conductivity and thermal stability, making them ideal candidates for energy storage applications. Their unique tubular structure provides channels for ion transport while their high surface area facilitates charge storage mechanisms.

The primary objectives of developing graphitized CNT-based energy storage technologies include achieving energy densities exceeding 500 Wh/kg at the cell level, power densities above 10 kW/kg, and cycle life beyond 10,000 cycles. These targets represent significant improvements over current lithium-ion technologies and would enable more efficient integration of renewable energy sources into existing power grids.

Another critical objective is cost reduction. Current production methods for high-quality graphitized CNTs remain expensive, limiting their commercial viability. Research aims to develop scalable synthesis methods that can reduce production costs below $50 per kilogram while maintaining performance characteristics.

Environmental sustainability constitutes another key goal, with efforts focused on developing eco-friendly synthesis processes and ensuring recyclability of graphitized CNT-based energy storage devices. This aligns with global initiatives to reduce carbon footprints and minimize environmental impact of energy technologies.

The technological roadmap for graphitized CNT energy storage encompasses short-term goals of prototype development and performance optimization, mid-term objectives of pilot-scale production and integration with existing renewable infrastructure, and long-term vision of widespread commercial deployment in grid-scale storage systems, electric vehicles, and portable electronics.

The global transition toward renewable energy sources has intensified the need for efficient, large-scale energy storage solutions. Intermittent renewable sources like solar and wind require robust storage systems to ensure grid stability and reliable power supply. This market demand has accelerated research into advanced materials that can enable higher capacity, faster charging, and longer-lasting energy storage devices.

Graphitized CNTs are produced through high-temperature treatment (typically 1800-2800°C) of conventional CNTs, resulting in improved crystallinity, reduced defects, and enhanced sp2 carbon bonding. This process significantly improves their electrical conductivity and thermal stability, making them ideal candidates for energy storage applications. Their unique tubular structure provides channels for ion transport while their high surface area facilitates charge storage mechanisms.

The primary objectives of developing graphitized CNT-based energy storage technologies include achieving energy densities exceeding 500 Wh/kg at the cell level, power densities above 10 kW/kg, and cycle life beyond 10,000 cycles. These targets represent significant improvements over current lithium-ion technologies and would enable more efficient integration of renewable energy sources into existing power grids.

Another critical objective is cost reduction. Current production methods for high-quality graphitized CNTs remain expensive, limiting their commercial viability. Research aims to develop scalable synthesis methods that can reduce production costs below $50 per kilogram while maintaining performance characteristics.

Environmental sustainability constitutes another key goal, with efforts focused on developing eco-friendly synthesis processes and ensuring recyclability of graphitized CNT-based energy storage devices. This aligns with global initiatives to reduce carbon footprints and minimize environmental impact of energy technologies.

The technological roadmap for graphitized CNT energy storage encompasses short-term goals of prototype development and performance optimization, mid-term objectives of pilot-scale production and integration with existing renewable infrastructure, and long-term vision of widespread commercial deployment in grid-scale storage systems, electric vehicles, and portable electronics.

Market Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources into power grids worldwide. Current market valuations place the advanced energy storage sector at approximately $59 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 8.2% through 2030. Graphitized carbon nanotubes (GCNTs) represent an emerging segment within this expanding market, positioned to address critical challenges in large-scale energy storage applications.

Demand for high-capacity, fast-charging energy storage solutions has intensified as renewable energy penetration increases across major markets. The intermittent nature of solar and wind power generation necessitates advanced storage technologies that can efficiently capture excess energy during peak production periods and release it during high demand or low generation intervals. GCNTs offer promising characteristics to meet these requirements, potentially capturing market share from traditional lithium-ion batteries in grid-scale applications.

Regional market analysis reveals varying adoption patterns and growth trajectories. Asia-Pacific currently dominates the advanced energy storage market with 42% share, led by China's aggressive renewable energy targets and manufacturing capabilities. North America follows at 28%, with particular growth in utility-scale storage projects, while Europe accounts for 23% of the market with strong policy support for renewable integration technologies.

The commercial segment for GCNT-based energy storage solutions remains nascent but demonstrates significant potential. Early adopters include utility companies seeking grid stabilization solutions and renewable energy developers requiring efficient storage integration. Industrial applications in microgrids and backup power systems represent another growing market segment, particularly in regions with unreliable grid infrastructure.

Market barriers for GCNT technology adoption include high initial manufacturing costs, scaling challenges, and competition from established technologies. Current production costs for GCNT-based storage systems exceed lithium-ion alternatives by approximately 30-40%, though this gap is expected to narrow as manufacturing processes mature and economies of scale are achieved.

Consumer willingness to pay premiums for superior performance characteristics varies by market segment. Utility-scale customers demonstrate greater price sensitivity, while specialized applications in aerospace, defense, and premium electric vehicles show higher tolerance for cost premiums in exchange for performance advantages in energy density, charging speed, and operational lifespan.

Market forecasts suggest GCNT-based energy storage solutions could capture 5-7% of the total advanced energy storage market by 2028, representing a potential market value of $4-6 billion. This growth trajectory depends significantly on continued technological advancement, manufacturing scale-up, and favorable regulatory frameworks supporting renewable energy integration.

Demand for high-capacity, fast-charging energy storage solutions has intensified as renewable energy penetration increases across major markets. The intermittent nature of solar and wind power generation necessitates advanced storage technologies that can efficiently capture excess energy during peak production periods and release it during high demand or low generation intervals. GCNTs offer promising characteristics to meet these requirements, potentially capturing market share from traditional lithium-ion batteries in grid-scale applications.

Regional market analysis reveals varying adoption patterns and growth trajectories. Asia-Pacific currently dominates the advanced energy storage market with 42% share, led by China's aggressive renewable energy targets and manufacturing capabilities. North America follows at 28%, with particular growth in utility-scale storage projects, while Europe accounts for 23% of the market with strong policy support for renewable integration technologies.

The commercial segment for GCNT-based energy storage solutions remains nascent but demonstrates significant potential. Early adopters include utility companies seeking grid stabilization solutions and renewable energy developers requiring efficient storage integration. Industrial applications in microgrids and backup power systems represent another growing market segment, particularly in regions with unreliable grid infrastructure.

Market barriers for GCNT technology adoption include high initial manufacturing costs, scaling challenges, and competition from established technologies. Current production costs for GCNT-based storage systems exceed lithium-ion alternatives by approximately 30-40%, though this gap is expected to narrow as manufacturing processes mature and economies of scale are achieved.

Consumer willingness to pay premiums for superior performance characteristics varies by market segment. Utility-scale customers demonstrate greater price sensitivity, while specialized applications in aerospace, defense, and premium electric vehicles show higher tolerance for cost premiums in exchange for performance advantages in energy density, charging speed, and operational lifespan.

Market forecasts suggest GCNT-based energy storage solutions could capture 5-7% of the total advanced energy storage market by 2028, representing a potential market value of $4-6 billion. This growth trajectory depends significantly on continued technological advancement, manufacturing scale-up, and favorable regulatory frameworks supporting renewable energy integration.

Current Status and Challenges in Carbon Nanotube Technology

Carbon nanotube (CNT) technology has evolved significantly since its discovery in 1991, with graphitized carbon nanotubes emerging as a promising material for energy storage applications. Currently, the global market for CNT-based energy storage solutions is experiencing rapid growth, driven by increasing demand for renewable energy integration and grid-scale storage systems. The synthesis of high-quality graphitized CNTs has advanced from laboratory-scale production to semi-industrial processes, though true industrial-scale manufacturing remains challenging.

Major technological breakthroughs have been achieved in controlling CNT structure, purity, and graphitization degree, which directly impact their electrochemical performance. Recent developments in chemical vapor deposition (CVD) techniques have enabled more precise control over nanotube diameter, wall number, and defect density. However, the scalable production of uniform graphitized CNTs with consistent properties continues to be a significant hurdle.

One of the primary challenges facing graphitized CNT technology is the energy-intensive nature of the graphitization process, which typically requires temperatures exceeding 2500°C. This high energy requirement substantially increases production costs and carbon footprint, contradicting the sustainability goals of renewable energy systems. Additionally, the graphitization process can introduce structural defects that may compromise the mechanical integrity and electrical conductivity of the nanotubes.

Material consistency presents another major obstacle. Batch-to-batch variations in graphitization degree, surface functionality, and impurity levels significantly affect performance in energy storage applications. These inconsistencies hinder the standardization necessary for commercial adoption and complicate quality control processes in manufacturing settings.

The geographic distribution of CNT technology development shows concentration in East Asia (particularly Japan, China, and South Korea), North America, and Western Europe. China has emerged as the leading producer of raw CNTs, while advanced graphitization techniques are predominantly developed in Japan and the United States. This geographic disparity creates supply chain vulnerabilities for regions heavily dependent on imports.

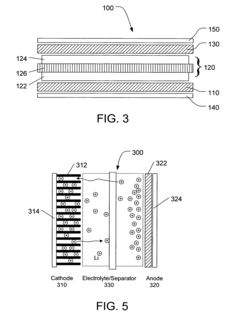

Integration challenges also persist at the system level. Incorporating graphitized CNTs into existing energy storage architectures requires overcoming interface issues between the nanomaterial and other components. Electrolyte compatibility, electrode formulation, and cell design must all be optimized specifically for graphitized CNT materials to fully leverage their enhanced properties.

Environmental and health concerns represent additional challenges. The potential toxicity of CNT particles during manufacturing and the environmental impact of production processes require careful assessment and mitigation strategies. Regulatory frameworks for nanomaterials continue to evolve, creating uncertainty for large-scale implementation.

Major technological breakthroughs have been achieved in controlling CNT structure, purity, and graphitization degree, which directly impact their electrochemical performance. Recent developments in chemical vapor deposition (CVD) techniques have enabled more precise control over nanotube diameter, wall number, and defect density. However, the scalable production of uniform graphitized CNTs with consistent properties continues to be a significant hurdle.

One of the primary challenges facing graphitized CNT technology is the energy-intensive nature of the graphitization process, which typically requires temperatures exceeding 2500°C. This high energy requirement substantially increases production costs and carbon footprint, contradicting the sustainability goals of renewable energy systems. Additionally, the graphitization process can introduce structural defects that may compromise the mechanical integrity and electrical conductivity of the nanotubes.

Material consistency presents another major obstacle. Batch-to-batch variations in graphitization degree, surface functionality, and impurity levels significantly affect performance in energy storage applications. These inconsistencies hinder the standardization necessary for commercial adoption and complicate quality control processes in manufacturing settings.

The geographic distribution of CNT technology development shows concentration in East Asia (particularly Japan, China, and South Korea), North America, and Western Europe. China has emerged as the leading producer of raw CNTs, while advanced graphitization techniques are predominantly developed in Japan and the United States. This geographic disparity creates supply chain vulnerabilities for regions heavily dependent on imports.

Integration challenges also persist at the system level. Incorporating graphitized CNTs into existing energy storage architectures requires overcoming interface issues between the nanomaterial and other components. Electrolyte compatibility, electrode formulation, and cell design must all be optimized specifically for graphitized CNT materials to fully leverage their enhanced properties.

Environmental and health concerns represent additional challenges. The potential toxicity of CNT particles during manufacturing and the environmental impact of production processes require careful assessment and mitigation strategies. Regulatory frameworks for nanomaterials continue to evolve, creating uncertainty for large-scale implementation.

Current Technical Solutions for Large-Scale Energy Storage

01 Graphitized carbon nanotubes for enhanced energy storage

Graphitized carbon nanotubes demonstrate superior energy storage capacity due to their unique structural properties. The graphitization process enhances electrical conductivity and creates a more ordered carbon structure, which facilitates faster electron transport and improves energy storage efficiency. These materials show significant potential for high-performance energy storage applications including batteries and supercapacitors.- Graphitized carbon nanotubes for enhanced energy storage: Graphitized carbon nanotubes demonstrate superior energy storage capacity due to their unique structural properties. The graphitization process improves electrical conductivity and creates a more ordered carbon structure, which enhances electron transfer and energy storage capabilities. These materials show significant improvements in charge/discharge efficiency and overall energy density when used in various energy storage applications.

- Carbon nanotube composites for battery applications: Composite materials incorporating graphitized carbon nanotubes with other materials such as silicon, metal oxides, or polymers can significantly enhance battery performance. These composites leverage the high conductivity of graphitized nanotubes while addressing challenges like volume expansion during cycling. The synergistic effect between the nanotubes and complementary materials results in improved energy density, cycling stability, and rate capability in lithium-ion and other advanced battery systems.

- Structural modification of carbon nanotubes for supercapacitors: Specific structural modifications of graphitized carbon nanotubes, including controlled defect creation, surface functionalization, and pore structure optimization, can dramatically improve supercapacitor performance. These modifications increase the effective surface area and create additional active sites for ion adsorption and charge storage. The resulting materials exhibit enhanced capacitance, improved rate capability, and better cycling stability in supercapacitor applications.

- Manufacturing processes for high-performance graphitized nanotubes: Advanced manufacturing techniques for producing graphitized carbon nanotubes with optimized energy storage properties include high-temperature thermal treatments, catalyst-assisted graphitization, and specialized annealing processes. These methods control the degree of graphitization, remove impurities, and tailor the nanotube structure for specific energy storage applications. The resulting materials show improved crystallinity, reduced defects, and enhanced electrical conductivity, leading to superior energy storage performance.

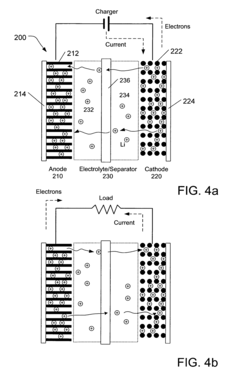

- Hybrid energy storage systems utilizing graphitized nanotubes: Hybrid energy storage systems that combine graphitized carbon nanotubes with complementary energy storage mechanisms offer enhanced performance characteristics. These systems integrate the high power density of supercapacitors with the high energy density of batteries, leveraging the unique properties of graphitized nanotubes as conductive networks and active materials. Such hybrid approaches enable devices with improved energy and power densities, faster charging capabilities, and extended cycle life for applications ranging from portable electronics to electric vehicles.

02 Composite materials with graphitized carbon nanotubes

Composite materials incorporating graphitized carbon nanotubes exhibit enhanced energy storage capabilities. By combining graphitized carbon nanotubes with other materials such as metal oxides, polymers, or other carbon structures, synergistic effects can be achieved. These composites demonstrate improved electrical conductivity, mechanical stability, and higher energy density compared to conventional materials, making them suitable for next-generation energy storage devices.Expand Specific Solutions03 Electrode fabrication using graphitized carbon nanotubes

Specialized electrode fabrication techniques utilizing graphitized carbon nanotubes can significantly enhance energy storage capacity. These methods include surface functionalization, alignment of nanotubes, and controlled deposition processes. The resulting electrodes exhibit larger surface areas, improved electrolyte accessibility, and enhanced charge transfer kinetics, leading to superior performance in batteries and supercapacitors with higher energy and power densities.Expand Specific Solutions04 Structural modifications of graphitized carbon nanotubes

Structural modifications of graphitized carbon nanotubes, such as doping with heteroatoms, creating defects, or adjusting tube diameter and length, can optimize their energy storage properties. These modifications alter the electronic properties, increase active sites for energy storage, and enhance the interaction with electrolytes. The tailored structures demonstrate improved capacity, cycling stability, and rate capability in various energy storage applications.Expand Specific Solutions05 Graphitized carbon nanotubes in advanced energy storage systems

Graphitized carbon nanotubes are being integrated into advanced energy storage systems including lithium-ion batteries, sodium-ion batteries, and hybrid supercapacitors. Their implementation addresses key challenges such as capacity fading, poor rate capability, and limited cycle life. The unique properties of graphitized carbon nanotubes enable the development of energy storage devices with higher energy density, faster charging capabilities, and longer operational lifetimes.Expand Specific Solutions

Leading Companies and Research Institutions in CNT Energy Storage

The graphitized carbon nanotube market for energy storage is in a growth phase, with increasing demand driven by renewable energy integration needs. Market size is expanding rapidly as energy storage applications become critical for grid stability. Technologically, the field shows varying maturity levels across players. Tsinghua University and Rice University lead academic research, while companies like Molecular Rebar Design and Morion NanoTech offer specialized commercial solutions. Applied Materials and LG Chem bring manufacturing expertise to scale production. Intel and Nokia Technologies contribute system integration capabilities. The ecosystem demonstrates a collaborative approach between academic institutions and industrial partners, with most technologies at mid-TRL levels moving toward commercialization.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced graphitized carbon nanotube (GCNT) composites for energy storage applications. Their research focuses on creating hierarchical structures combining GCNTs with other carbon materials to enhance electrochemical performance. They've pioneered a thermal treatment process that optimizes the graphitization degree of carbon nanotubes at temperatures between 1800-2800°C, resulting in improved electrical conductivity while maintaining structural integrity. Their technology incorporates nitrogen-doping of graphitized CNTs to create additional active sites for energy storage. For large-scale applications, they've developed scalable synthesis methods using chemical vapor deposition with precise catalyst control, achieving production rates of several kilograms per day with consistent quality. Their electrode fabrication techniques include direct growth on current collectors to minimize contact resistance and maximize energy density.

Strengths: Superior electrical conductivity (>10^4 S/cm) compared to conventional CNTs; excellent structural stability during charge-discharge cycles; scalable production methods suitable for industrial applications. Weaknesses: Higher production costs compared to traditional carbon materials; energy-intensive graphitization process requiring specialized equipment; potential challenges in uniform quality control during mass production.

William Marsh Rice University

Technical Solution: Rice University has pioneered groundbreaking research in graphitized carbon nanotube (GCNT) technology for energy storage applications. Their approach centers on atomic-level engineering of carbon nanostructures through controlled graphitization processes. Rice's researchers have developed a patented flash Joule heating method that achieves rapid graphitization of carbon nanotubes in seconds rather than hours, dramatically reducing energy requirements and enabling scalable production. Their technology incorporates precise control over defect density and interlayer spacing in multi-walled carbon nanotubes, optimizing ion intercalation kinetics for energy storage applications. For renewable energy integration, Rice has developed GCNT-based composite electrodes that demonstrate exceptional stability under fluctuating charge-discharge conditions typical of solar and wind power generation. Their materials show capacity retention exceeding 90% after 10,000 cycles at high current densities. Additionally, Rice's researchers have pioneered in-situ characterization techniques that provide atomic-level insights into the structural evolution of GCNTs during energy storage processes, enabling continuous refinement of their materials design approach.

Strengths: Cutting-edge fundamental research capabilities; innovative low-energy graphitization processes; strong collaboration network with industry partners for technology transfer. Weaknesses: Primary focus on research rather than commercial-scale manufacturing; technology still requires optimization for cost-effective mass production; limited experience in large-scale system integration compared to industrial players.

Key Patents and Innovations in Graphitized CNT Technology

Process for producing carbon nanostructure on a flexible substrate, and energy storage devices comprising flexible carbon nanostructure electrodes

PatentInactiveUS20100178568A1

Innovation

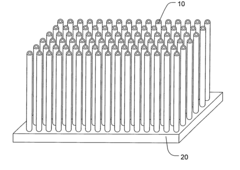

- A process for growing highly packed and vertically aligned carbon nanotubes on flexible metallic substrates, using low temperature evaporation of catalysts and chemical vapor deposition in a hydrocarbon gas atmosphere, to create a high surface area charge collector layer for energy storage units like batteries and supercapacitors.

Process of increasing energy conversion and electrochemical efficiency of a scaffold material using a deposition material

PatentInactiveUS20170058420A1

Innovation

- A process involving the deposition of nanomaterials in an aqueous solution onto a conductive scaffold material, forming self-assembling agglomerations that increase the surface area and electrical connectivity, using materials like carbon nanotubes that self-agglomerate via Van der Waals forces, without requiring harmful solvents, to enhance energy conversion and electrochemical efficiency.

Environmental Impact and Sustainability Assessment

The environmental impact of graphitized carbon nanotubes (GCNTs) for large-scale energy storage systems presents a complex sustainability profile that requires thorough assessment. The production process of GCNTs involves high-temperature graphitization treatments that consume significant energy, potentially generating substantial carbon emissions if powered by fossil fuels. This energy-intensive manufacturing represents a critical environmental consideration when evaluating the lifecycle sustainability of GCNT-based storage technologies.

However, when considering the complete lifecycle, GCNT-based energy storage systems offer considerable environmental advantages. These materials demonstrate exceptional durability and cycling stability, with potential lifespans exceeding conventional battery technologies by several years. This extended operational lifetime significantly reduces waste generation and resource consumption associated with frequent replacements of less durable alternatives.

The raw material sourcing for carbon nanotubes primarily relies on carbon-based feedstocks, which are generally abundant and less environmentally problematic than the rare earth elements and heavy metals required for many competing energy storage technologies. Additionally, carbon-based materials present fewer end-of-life toxicity concerns compared to conventional battery chemistries containing cobalt, nickel, or lead.

When integrated with renewable energy systems, GCNT storage solutions deliver substantial environmental benefits by enabling higher penetration of intermittent renewable sources into the grid. This integration capability directly contributes to reduced greenhouse gas emissions from the power sector by displacing fossil fuel generation during periods of low renewable output.

Water usage represents another important environmental consideration. The production processes for GCNTs typically require less water than competing technologies like lithium extraction, though precise requirements vary by manufacturing method. Emerging green synthesis approaches are further reducing the water and chemical inputs needed for GCNT production.

From a circular economy perspective, research indicates promising recyclability potential for GCNT materials. While industrial-scale recycling processes remain under development, the carbon-based nature of these materials offers inherent advantages for recovery and reuse compared to complex multi-material battery systems.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle environmental performance in energy storage technologies. GCNTs are well-positioned to meet these evolving standards, particularly as manufacturing processes continue to improve in efficiency and as renewable energy increasingly powers production facilities.

However, when considering the complete lifecycle, GCNT-based energy storage systems offer considerable environmental advantages. These materials demonstrate exceptional durability and cycling stability, with potential lifespans exceeding conventional battery technologies by several years. This extended operational lifetime significantly reduces waste generation and resource consumption associated with frequent replacements of less durable alternatives.

The raw material sourcing for carbon nanotubes primarily relies on carbon-based feedstocks, which are generally abundant and less environmentally problematic than the rare earth elements and heavy metals required for many competing energy storage technologies. Additionally, carbon-based materials present fewer end-of-life toxicity concerns compared to conventional battery chemistries containing cobalt, nickel, or lead.

When integrated with renewable energy systems, GCNT storage solutions deliver substantial environmental benefits by enabling higher penetration of intermittent renewable sources into the grid. This integration capability directly contributes to reduced greenhouse gas emissions from the power sector by displacing fossil fuel generation during periods of low renewable output.

Water usage represents another important environmental consideration. The production processes for GCNTs typically require less water than competing technologies like lithium extraction, though precise requirements vary by manufacturing method. Emerging green synthesis approaches are further reducing the water and chemical inputs needed for GCNT production.

From a circular economy perspective, research indicates promising recyclability potential for GCNT materials. While industrial-scale recycling processes remain under development, the carbon-based nature of these materials offers inherent advantages for recovery and reuse compared to complex multi-material battery systems.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle environmental performance in energy storage technologies. GCNTs are well-positioned to meet these evolving standards, particularly as manufacturing processes continue to improve in efficiency and as renewable energy increasingly powers production facilities.

Grid Integration Strategies and Technical Requirements

The integration of graphitized carbon nanotube-based energy storage systems into existing power grids presents significant technical challenges that must be addressed through comprehensive strategies. Grid operators require these advanced storage solutions to meet specific technical requirements to ensure stability, reliability, and efficiency of the overall power system.

Power quality management represents a critical aspect of grid integration, with graphitized carbon nanotube storage systems needing to demonstrate capabilities for voltage regulation, frequency control, and harmonics mitigation. These systems must respond rapidly to fluctuations in the grid, with response times typically required to be under 100 milliseconds for primary frequency regulation applications.

Interoperability standards constitute another essential requirement, as carbon nanotube storage technologies must seamlessly communicate with existing grid infrastructure. This necessitates compliance with protocols such as IEC 61850, IEEE 1547, and region-specific grid codes. The implementation of standardized communication interfaces enables efficient coordination between storage assets and grid management systems.

Scalability considerations are paramount when deploying graphitized carbon nanotube storage at utility scale. Modular design approaches allow for incremental capacity expansion, with power conversion systems typically configured to handle power ratings from 100kW to multiple MW. The physical footprint optimization becomes increasingly important in urban deployment scenarios, where space constraints may limit installation options.

Grid resilience enhancement requires these storage systems to provide black start capabilities and islanding support during outage events. Technical specifications typically mandate the ability to operate autonomously for minimum periods of 4-8 hours during grid disturbances, with seamless transition between grid-connected and islanded modes.

Renewable integration strategies necessitate specific technical capabilities, including ramp rate control to manage the variability of solar and wind generation. Graphitized carbon nanotube storage systems must demonstrate charge/discharge rates sufficient to compensate for renewable intermittency, typically requiring C-rates between 0.5C and 2C depending on the application scenario.

Safety and protection mechanisms represent non-negotiable requirements, with thermal management systems designed to maintain optimal operating temperatures (typically 20-35°C) and prevent thermal runaway events. Advanced battery management systems must incorporate cell-level monitoring with millisecond response times to detect and mitigate potential failure modes.

The economic viability of grid integration depends on achieving round-trip efficiencies exceeding 85%, with degradation rates below 2% annually to ensure acceptable lifetime performance. These technical parameters directly impact the business case for deployment and must be validated through rigorous testing protocols aligned with industry standards.

Power quality management represents a critical aspect of grid integration, with graphitized carbon nanotube storage systems needing to demonstrate capabilities for voltage regulation, frequency control, and harmonics mitigation. These systems must respond rapidly to fluctuations in the grid, with response times typically required to be under 100 milliseconds for primary frequency regulation applications.

Interoperability standards constitute another essential requirement, as carbon nanotube storage technologies must seamlessly communicate with existing grid infrastructure. This necessitates compliance with protocols such as IEC 61850, IEEE 1547, and region-specific grid codes. The implementation of standardized communication interfaces enables efficient coordination between storage assets and grid management systems.

Scalability considerations are paramount when deploying graphitized carbon nanotube storage at utility scale. Modular design approaches allow for incremental capacity expansion, with power conversion systems typically configured to handle power ratings from 100kW to multiple MW. The physical footprint optimization becomes increasingly important in urban deployment scenarios, where space constraints may limit installation options.

Grid resilience enhancement requires these storage systems to provide black start capabilities and islanding support during outage events. Technical specifications typically mandate the ability to operate autonomously for minimum periods of 4-8 hours during grid disturbances, with seamless transition between grid-connected and islanded modes.

Renewable integration strategies necessitate specific technical capabilities, including ramp rate control to manage the variability of solar and wind generation. Graphitized carbon nanotube storage systems must demonstrate charge/discharge rates sufficient to compensate for renewable intermittency, typically requiring C-rates between 0.5C and 2C depending on the application scenario.

Safety and protection mechanisms represent non-negotiable requirements, with thermal management systems designed to maintain optimal operating temperatures (typically 20-35°C) and prevent thermal runaway events. Advanced battery management systems must incorporate cell-level monitoring with millisecond response times to detect and mitigate potential failure modes.

The economic viability of grid integration depends on achieving round-trip efficiencies exceeding 85%, with degradation rates below 2% annually to ensure acceptable lifetime performance. These technical parameters directly impact the business case for deployment and must be validated through rigorous testing protocols aligned with industry standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!