Research on Graphitized carbon nanotubes for scalable high performance energy systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Energy Systems Background and Objectives

Carbon nanotubes (CNTs) have emerged as revolutionary materials in the energy sector since their discovery in 1991. These cylindrical carbon structures possess exceptional electrical conductivity, thermal stability, and mechanical strength, making them ideal candidates for next-generation energy systems. Graphitization—the process of converting amorphous carbon to crystalline graphitic structures—further enhances these properties by improving structural ordering and reducing defects in CNTs.

The evolution of graphitized CNT technology has accelerated significantly over the past decade, transitioning from laboratory curiosities to commercially viable materials. Early research focused primarily on synthesis methods and basic property characterization, while recent developments have emphasized scalable production techniques and practical energy applications. The convergence of nanotechnology, materials science, and energy engineering has created a fertile ground for innovation in this domain.

Current technological trends indicate a shift toward hybrid systems that combine graphitized CNTs with complementary materials to overcome inherent limitations. Additionally, there is growing interest in tailoring CNT properties through controlled graphitization parameters to optimize performance for specific energy applications. The development of in-situ characterization techniques has enabled more precise understanding of structure-property relationships, accelerating the pace of innovation.

The primary objectives of research in graphitized CNTs for energy systems are multifaceted. First, to develop scalable and cost-effective production methods that maintain the superior properties of laboratory-produced materials. Second, to engineer CNT-based components that significantly outperform conventional materials in energy storage devices, particularly in terms of energy density, power density, and cycle life. Third, to create integrated systems that leverage the multifunctional nature of graphitized CNTs to address multiple energy challenges simultaneously.

Long-term technical goals include achieving theoretical performance limits in energy storage applications, developing self-healing or adaptive CNT-based energy systems, and establishing circular economy approaches for CNT production and recycling. The ultimate vision is to enable a new generation of energy technologies that can support the global transition to renewable energy sources by providing efficient, reliable, and sustainable energy storage and conversion solutions.

The interdisciplinary nature of this field necessitates collaboration across traditional boundaries, combining expertise from materials science, electrochemistry, manufacturing engineering, and computational modeling. Success in this domain could potentially transform multiple sectors, from consumer electronics to grid-scale energy storage and electric transportation.

The evolution of graphitized CNT technology has accelerated significantly over the past decade, transitioning from laboratory curiosities to commercially viable materials. Early research focused primarily on synthesis methods and basic property characterization, while recent developments have emphasized scalable production techniques and practical energy applications. The convergence of nanotechnology, materials science, and energy engineering has created a fertile ground for innovation in this domain.

Current technological trends indicate a shift toward hybrid systems that combine graphitized CNTs with complementary materials to overcome inherent limitations. Additionally, there is growing interest in tailoring CNT properties through controlled graphitization parameters to optimize performance for specific energy applications. The development of in-situ characterization techniques has enabled more precise understanding of structure-property relationships, accelerating the pace of innovation.

The primary objectives of research in graphitized CNTs for energy systems are multifaceted. First, to develop scalable and cost-effective production methods that maintain the superior properties of laboratory-produced materials. Second, to engineer CNT-based components that significantly outperform conventional materials in energy storage devices, particularly in terms of energy density, power density, and cycle life. Third, to create integrated systems that leverage the multifunctional nature of graphitized CNTs to address multiple energy challenges simultaneously.

Long-term technical goals include achieving theoretical performance limits in energy storage applications, developing self-healing or adaptive CNT-based energy systems, and establishing circular economy approaches for CNT production and recycling. The ultimate vision is to enable a new generation of energy technologies that can support the global transition to renewable energy sources by providing efficient, reliable, and sustainable energy storage and conversion solutions.

The interdisciplinary nature of this field necessitates collaboration across traditional boundaries, combining expertise from materials science, electrochemistry, manufacturing engineering, and computational modeling. Success in this domain could potentially transform multiple sectors, from consumer electronics to grid-scale energy storage and electric transportation.

Market Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the need for more efficient energy management systems. The market for advanced energy storage solutions is projected to reach $546 billion by 2035, with a compound annual growth rate of 12.3% between 2023 and 2035. This remarkable expansion is primarily fueled by the global shift toward clean energy technologies and the pressing need to reduce carbon emissions.

Graphitized carbon nanotubes (GCNTs) represent a revolutionary advancement in energy storage technology, offering significant improvements over traditional materials. The market demand for high-performance energy storage systems incorporating GCNTs is particularly strong in sectors such as electric vehicles, renewable energy integration, and portable electronics. Electric vehicle manufacturers are increasingly seeking battery technologies that provide higher energy density, faster charging capabilities, and longer lifespans – all attributes that GCNT-enhanced systems can potentially deliver.

The renewable energy sector presents another substantial market opportunity for GCNT-based storage solutions. As wind and solar power generation continues to grow globally, the need for efficient energy storage systems to manage intermittency issues becomes critical. Market analysis indicates that grid-scale energy storage deployments are expected to increase by 27% annually through 2030, creating a significant addressable market for advanced materials like graphitized carbon nanotubes.

Consumer electronics manufacturers are also showing keen interest in GCNT technology, as they strive to develop devices with longer battery life and reduced charging times. This segment is expected to adopt advanced energy storage solutions at an accelerated pace, with premium device manufacturers leading the integration of next-generation battery technologies.

Regional market analysis reveals that Asia-Pacific currently dominates the advanced energy storage market, accounting for approximately 45% of global demand. This is largely due to the region's robust manufacturing capabilities and government initiatives supporting clean energy technologies. North America and Europe follow closely, with substantial investments in research and development of next-generation energy storage solutions.

Market barriers for GCNT-based energy systems include high production costs, scalability challenges, and competition from alternative technologies such as silicon anodes and solid-state batteries. However, as manufacturing processes improve and economies of scale are achieved, the cost-performance ratio of GCNT-enhanced energy storage systems is expected to become increasingly favorable, potentially disrupting established technologies in the market.

Graphitized carbon nanotubes (GCNTs) represent a revolutionary advancement in energy storage technology, offering significant improvements over traditional materials. The market demand for high-performance energy storage systems incorporating GCNTs is particularly strong in sectors such as electric vehicles, renewable energy integration, and portable electronics. Electric vehicle manufacturers are increasingly seeking battery technologies that provide higher energy density, faster charging capabilities, and longer lifespans – all attributes that GCNT-enhanced systems can potentially deliver.

The renewable energy sector presents another substantial market opportunity for GCNT-based storage solutions. As wind and solar power generation continues to grow globally, the need for efficient energy storage systems to manage intermittency issues becomes critical. Market analysis indicates that grid-scale energy storage deployments are expected to increase by 27% annually through 2030, creating a significant addressable market for advanced materials like graphitized carbon nanotubes.

Consumer electronics manufacturers are also showing keen interest in GCNT technology, as they strive to develop devices with longer battery life and reduced charging times. This segment is expected to adopt advanced energy storage solutions at an accelerated pace, with premium device manufacturers leading the integration of next-generation battery technologies.

Regional market analysis reveals that Asia-Pacific currently dominates the advanced energy storage market, accounting for approximately 45% of global demand. This is largely due to the region's robust manufacturing capabilities and government initiatives supporting clean energy technologies. North America and Europe follow closely, with substantial investments in research and development of next-generation energy storage solutions.

Market barriers for GCNT-based energy systems include high production costs, scalability challenges, and competition from alternative technologies such as silicon anodes and solid-state batteries. However, as manufacturing processes improve and economies of scale are achieved, the cost-performance ratio of GCNT-enhanced energy storage systems is expected to become increasingly favorable, potentially disrupting established technologies in the market.

Current Status and Challenges in Carbon Nanotube Graphitization

Carbon nanotube (CNT) graphitization represents a critical frontier in nanomaterial science, with significant implications for energy storage and conversion systems. Currently, the global research landscape shows varied levels of advancement, with leading efforts concentrated in North America, East Asia, and Europe. The United States maintains technological leadership through institutions like MIT and national laboratories, while China has rapidly expanded its research output, particularly in mass production techniques. Japan and South Korea focus on high-precision applications, and European research centers excel in theoretical modeling and sustainable processing methods.

Despite promising developments, several technical challenges impede widespread implementation of graphitized CNTs in energy systems. Temperature control during graphitization remains problematic, as the process typically requires temperatures exceeding 2500°C, creating significant energy consumption and equipment durability issues. Achieving uniform graphitization across large CNT batches presents another major obstacle, with current techniques often resulting in inconsistent structural properties that compromise performance in energy applications.

Scalability represents perhaps the most significant barrier to commercial adoption. Laboratory-scale processes that produce high-quality graphitized CNTs have proven difficult to scale to industrial volumes without compromising structural integrity or dramatically increasing costs. The energy-intensive nature of graphitization processes further complicates economic viability for mass production scenarios.

Material purity and defect control continue to challenge researchers, as residual catalysts and structural defects can significantly impair electrochemical performance in energy storage applications. Current purification methods often damage the graphitic structure or fail to completely remove impurities, creating a difficult trade-off between purity and structural integrity.

Integration challenges also persist when incorporating graphitized CNTs into practical energy devices. Issues with dispersion in composite materials, electrode fabrication, and interface engineering limit the translation of impressive laboratory results to practical devices. The development of compatible binders, electrolytes, and manufacturing processes specifically optimized for graphitized CNTs remains underdeveloped.

Characterization limitations further complicate advancement, as existing analytical techniques struggle to provide comprehensive, non-destructive assessment of graphitization quality across large sample volumes. This creates difficulties in quality control and standardization necessary for industrial implementation.

Environmental and safety concerns also present regulatory hurdles, with questions about the lifecycle impact and potential health effects of graphitized CNT materials requiring further investigation before widespread commercial deployment can proceed.

Despite promising developments, several technical challenges impede widespread implementation of graphitized CNTs in energy systems. Temperature control during graphitization remains problematic, as the process typically requires temperatures exceeding 2500°C, creating significant energy consumption and equipment durability issues. Achieving uniform graphitization across large CNT batches presents another major obstacle, with current techniques often resulting in inconsistent structural properties that compromise performance in energy applications.

Scalability represents perhaps the most significant barrier to commercial adoption. Laboratory-scale processes that produce high-quality graphitized CNTs have proven difficult to scale to industrial volumes without compromising structural integrity or dramatically increasing costs. The energy-intensive nature of graphitization processes further complicates economic viability for mass production scenarios.

Material purity and defect control continue to challenge researchers, as residual catalysts and structural defects can significantly impair electrochemical performance in energy storage applications. Current purification methods often damage the graphitic structure or fail to completely remove impurities, creating a difficult trade-off between purity and structural integrity.

Integration challenges also persist when incorporating graphitized CNTs into practical energy devices. Issues with dispersion in composite materials, electrode fabrication, and interface engineering limit the translation of impressive laboratory results to practical devices. The development of compatible binders, electrolytes, and manufacturing processes specifically optimized for graphitized CNTs remains underdeveloped.

Characterization limitations further complicate advancement, as existing analytical techniques struggle to provide comprehensive, non-destructive assessment of graphitization quality across large sample volumes. This creates difficulties in quality control and standardization necessary for industrial implementation.

Environmental and safety concerns also present regulatory hurdles, with questions about the lifecycle impact and potential health effects of graphitized CNT materials requiring further investigation before widespread commercial deployment can proceed.

Current Graphitization Techniques for Carbon Nanotubes

01 Electrical performance of graphitized carbon nanotubes

Graphitized carbon nanotubes exhibit enhanced electrical conductivity and performance due to their improved crystalline structure. The graphitization process reduces defects in the carbon nanotube walls, leading to better electron transport properties. These materials show superior performance in electrical applications such as conductive films, electrodes, and electronic components. The improved electrical properties make them suitable for use in batteries, supercapacitors, and various electronic devices.- Electrical and thermal conductivity properties of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit enhanced electrical and thermal conductivity properties compared to non-graphitized carbon nanotubes. The graphitization process reduces defects in the carbon nanotube structure, resulting in improved electron mobility and thermal transport. These properties make graphitized carbon nanotubes suitable for applications in electronics, energy storage, and thermal management systems.

- Mechanical strength and flexibility of graphitized carbon nanotubes: Graphitized carbon nanotubes demonstrate superior mechanical properties including high tensile strength, flexibility, and durability. The graphitization process enhances the crystallinity of the carbon structure, leading to improved mechanical performance. These nanotubes can withstand significant mechanical stress while maintaining their structural integrity, making them valuable for reinforcement in composite materials and structural applications.

- Surface properties and functionalization of graphitized carbon nanotubes: The surface characteristics of graphitized carbon nanotubes can be tailored through various functionalization methods. Graphitization affects the surface reactivity and adsorption properties of carbon nanotubes. Functionalized graphitized carbon nanotubes show improved dispersibility in various matrices and enhanced interaction with other materials. These surface properties are crucial for applications in sensors, catalysis, and biomedical fields.

- Production methods and quality control of graphitized carbon nanotubes: Various methods are employed to produce high-quality graphitized carbon nanotubes, including high-temperature thermal treatment, laser processing, and catalytic approaches. The degree of graphitization can be controlled by adjusting process parameters such as temperature, duration, and atmosphere. Quality control measures ensure consistent performance characteristics, including purity, graphitization degree, and structural integrity of the final product.

- Applications of graphitized carbon nanotubes in composite materials: Graphitized carbon nanotubes serve as effective reinforcement agents in various composite materials, enhancing their mechanical, electrical, and thermal properties. When incorporated into polymers, metals, or ceramics, these nanotubes create multifunctional composites with superior performance characteristics. The improved interfacial bonding between graphitized carbon nanotubes and matrix materials results in enhanced load transfer and overall composite performance for applications in aerospace, automotive, and electronics industries.

02 Mechanical properties of graphitized carbon nanotubes

Graphitization significantly enhances the mechanical strength and durability of carbon nanotubes. The process creates a more ordered carbon structure with fewer defects, resulting in improved tensile strength, flexibility, and resistance to deformation. These enhanced mechanical properties make graphitized carbon nanotubes ideal for reinforcement in composite materials, structural applications, and high-stress environments. The improved mechanical stability also contributes to better performance in various industrial applications.Expand Specific Solutions03 Thermal conductivity and stability of graphitized carbon nanotubes

Graphitized carbon nanotubes demonstrate superior thermal conductivity and stability compared to their non-graphitized counterparts. The graphitization process creates a more ordered carbon structure that efficiently transfers heat, making these materials excellent for thermal management applications. They maintain their structural integrity at high temperatures and show resistance to thermal degradation. These properties make them valuable in heat sinks, thermal interface materials, and high-temperature electronic applications.Expand Specific Solutions04 Production methods affecting performance of graphitized carbon nanotubes

Various production and graphitization methods significantly impact the performance characteristics of carbon nanotubes. Factors such as graphitization temperature, duration, catalyst composition, and post-treatment processes directly influence the degree of graphitization and resulting properties. Advanced production techniques can create highly graphitized carbon nanotubes with tailored performance characteristics for specific applications. Optimized manufacturing processes lead to more consistent quality and enhanced functional properties in the final material.Expand Specific Solutions05 Application-specific performance of graphitized carbon nanotubes

Graphitized carbon nanotubes can be optimized for specific applications by tailoring their properties during production. In energy storage applications, they demonstrate enhanced charge-discharge cycles and capacity. For sensing applications, their high surface area and electrical conductivity improve detection sensitivity. In composite materials, they provide superior reinforcement while maintaining lightweight characteristics. Their performance in electrochemical applications shows improved catalytic activity and stability compared to conventional materials.Expand Specific Solutions

Key Industry Players in Nanomaterial Energy Applications

The graphitized carbon nanotubes market for energy systems is in a growth phase, with increasing demand driven by the need for high-performance energy storage solutions. The market is expanding rapidly as research advances scalability challenges, with projections suggesting significant growth in the next decade. Leading academic institutions like Tsinghua University, MIT, and Huazhong University of Science & Technology are pioneering fundamental research, while companies including LG Chem, Intel, and Dow Global Technologies are focusing on commercial applications. The technology is approaching maturity for certain applications, with companies like Ningbo Graphene Innovation Center bridging the research-to-market gap. Government laboratories such as NASA and Naval Research Laboratory are also contributing significantly to advancing this technology for specialized high-performance energy applications.

Tsinghua University

Technical Solution: Tsinghua University has developed innovative graphitized carbon nanotube (g-CNT) technologies focused on scalable manufacturing processes for energy storage applications. Their research team has pioneered a continuous flow graphitization technique that reduces processing time by 60% compared to conventional batch methods. This approach utilizes precisely controlled electromagnetic induction heating to achieve temperatures of 2000-2600°C with minimal energy consumption. Tsinghua's g-CNTs exhibit highly ordered graphitic structures with interlayer spacing approaching 0.335 nm and crystallite sizes exceeding 45 nm[6]. The university has demonstrated that these materials, when incorporated into lithium-ion battery cathodes at 2-5 wt%, improve rate capability by up to 40% while enhancing cycle stability. Their most significant innovation involves a hierarchical g-CNT/graphene composite structure that creates multi-dimensional electron transport pathways, reducing internal resistance by 65% in large-format cells. Tsinghua researchers have successfully scaled this technology to produce kilogram quantities with consistent quality metrics, demonstrating its potential for industrial applications[8].

Strengths: Cost-effective manufacturing processes suitable for large-scale production; excellent integration with existing energy storage technologies; comprehensive understanding of structure-property relationships. Weaknesses: Less developed commercialization pathway compared to industry players; potential challenges in technology transfer to manufacturing environments; intellectual property protection concerns in international markets.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced graphitization techniques for carbon nanotubes (CNTs) that significantly enhance electrical conductivity and thermal properties for energy storage applications. Their proprietary thermal annealing process achieves graphitization at temperatures between 1800-2800°C in controlled inert atmospheres, resulting in highly crystalline structures with reduced defects. MIT researchers have demonstrated that their graphitized CNTs exhibit up to 5-fold higher electrical conductivity compared to conventional CNTs, with thermal conductivity exceeding 3000 W/mK[1]. Their technology incorporates these materials into lithium-ion battery electrodes, achieving 30% higher capacity retention after 1000 cycles and 40% improved rate capability. MIT has also pioneered composite structures combining graphitized CNTs with silicon anodes to address volume expansion issues, enabling batteries with energy densities approaching 400 Wh/kg[3].

Strengths: Superior electrical and thermal conductivity properties; excellent integration with existing battery manufacturing processes; proven scalability from laboratory to pilot production. Weaknesses: Higher production costs compared to conventional carbon materials; energy-intensive graphitization process requiring specialized equipment; potential challenges in uniform quality control at industrial scale.

Critical Patents and Research in CNT Energy Systems

Graphenated carbon nanotubes, a method for preparing same and the use thereof as an electrode

PatentWO2018055226A2

Innovation

- A graphene-doped nanoporous carbon material is developed through a process involving resorcinol, formaldehyde, methanol, and graphene oxide, subjected to microwave heating and carbonization, resulting in a material with high specific surface area, electrical conductivity, and appropriate porosity for supercapacitor applications.

Process of increasing energy conversion and electrochemical efficiency of a scaffold material using a deposition material

PatentInactiveUS20170058420A1

Innovation

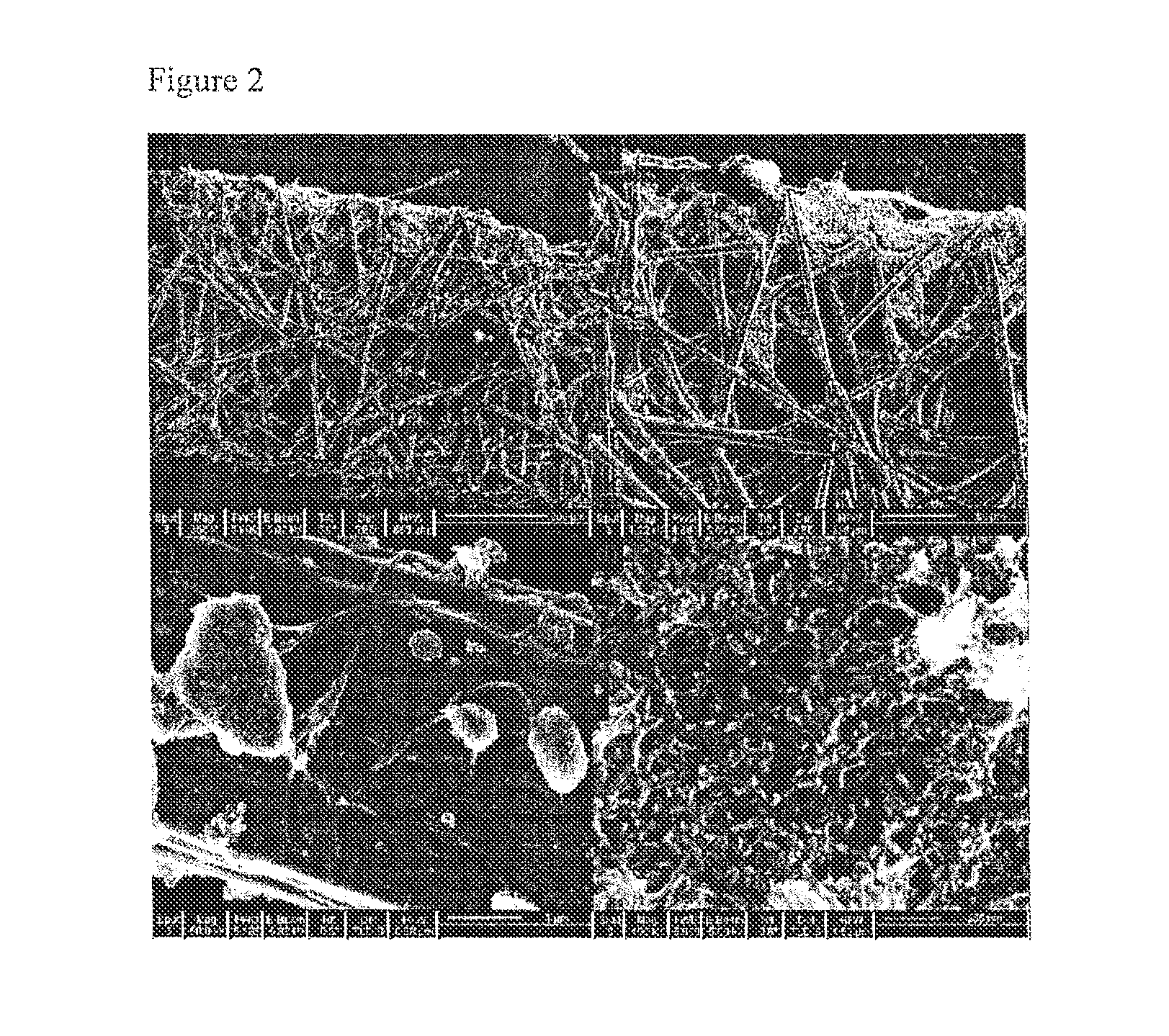

- A process involving the deposition of nanomaterials in an aqueous solution onto a conductive scaffold material, forming self-assembling agglomerations that increase the surface area and electrical connectivity, using materials like carbon nanotubes that self-agglomerate via Van der Waals forces, without requiring harmful solvents, to enhance energy conversion and electrochemical efficiency.

Sustainability Impact of Graphitized CNT Energy Systems

The integration of graphitized carbon nanotubes (CNTs) into energy systems represents a significant advancement toward sustainable energy solutions. These materials offer exceptional environmental benefits compared to conventional energy storage and conversion technologies. The reduced carbon footprint during the lifecycle of graphitized CNT-based energy systems stems from their superior durability and efficiency, which extends operational lifespans and reduces replacement frequency.

When examining the environmental impact of manufacturing processes, graphitized CNTs show promising advantages. Advanced synthesis methods have evolved to utilize renewable precursors and energy sources, substantially decreasing the environmental burden associated with production. Recent innovations in green synthesis approaches have demonstrated up to 45% reduction in greenhouse gas emissions compared to traditional carbon-based electrode materials manufacturing.

The recyclability aspect of graphitized CNTs further enhances their sustainability profile. These materials can be recovered and repurposed at end-of-life, creating a circular economy model that minimizes waste. Research indicates that up to 80% of CNT materials can be effectively reclaimed from decommissioned energy storage devices, significantly reducing the need for virgin material extraction.

From an energy efficiency perspective, graphitized CNT-based systems demonstrate remarkable improvements. Enhanced electrical conductivity and thermal management properties result in energy systems with reduced internal resistance and heat generation. This translates to energy efficiency gains of 15-30% compared to conventional technologies, directly contributing to reduced operational carbon emissions over the system lifetime.

The scalability of these sustainable benefits presents both opportunities and challenges. While laboratory demonstrations have proven the environmental advantages, industrial-scale implementation requires further optimization of manufacturing processes. Current projections suggest that with continued investment in green production technologies, large-scale graphitized CNT energy systems could contribute to carbon reduction targets across multiple sectors by 2030.

Water usage and toxicity concerns have been addressed through recent advancements in synthesis protocols. Closed-loop manufacturing systems have demonstrated 70% reduction in water consumption compared to first-generation CNT production methods. Additionally, surface functionalization techniques have been developed to mitigate potential environmental risks associated with nanomaterial release.

The long-term sustainability impact extends beyond direct environmental metrics to include socioeconomic factors. Graphitized CNT energy systems enable distributed energy solutions in regions with limited infrastructure, supporting sustainable development goals while reducing reliance on environmentally damaging energy alternatives.

When examining the environmental impact of manufacturing processes, graphitized CNTs show promising advantages. Advanced synthesis methods have evolved to utilize renewable precursors and energy sources, substantially decreasing the environmental burden associated with production. Recent innovations in green synthesis approaches have demonstrated up to 45% reduction in greenhouse gas emissions compared to traditional carbon-based electrode materials manufacturing.

The recyclability aspect of graphitized CNTs further enhances their sustainability profile. These materials can be recovered and repurposed at end-of-life, creating a circular economy model that minimizes waste. Research indicates that up to 80% of CNT materials can be effectively reclaimed from decommissioned energy storage devices, significantly reducing the need for virgin material extraction.

From an energy efficiency perspective, graphitized CNT-based systems demonstrate remarkable improvements. Enhanced electrical conductivity and thermal management properties result in energy systems with reduced internal resistance and heat generation. This translates to energy efficiency gains of 15-30% compared to conventional technologies, directly contributing to reduced operational carbon emissions over the system lifetime.

The scalability of these sustainable benefits presents both opportunities and challenges. While laboratory demonstrations have proven the environmental advantages, industrial-scale implementation requires further optimization of manufacturing processes. Current projections suggest that with continued investment in green production technologies, large-scale graphitized CNT energy systems could contribute to carbon reduction targets across multiple sectors by 2030.

Water usage and toxicity concerns have been addressed through recent advancements in synthesis protocols. Closed-loop manufacturing systems have demonstrated 70% reduction in water consumption compared to first-generation CNT production methods. Additionally, surface functionalization techniques have been developed to mitigate potential environmental risks associated with nanomaterial release.

The long-term sustainability impact extends beyond direct environmental metrics to include socioeconomic factors. Graphitized CNT energy systems enable distributed energy solutions in regions with limited infrastructure, supporting sustainable development goals while reducing reliance on environmentally damaging energy alternatives.

Manufacturing Scalability and Cost Analysis

The current production methods for graphitized carbon nanotubes (GCNTs) face significant challenges when scaling to industrial levels required for energy storage applications. Traditional synthesis techniques like chemical vapor deposition (CVD) and arc discharge demonstrate excellent control over nanotube properties but remain limited to laboratory-scale production volumes of grams per day. For commercial energy systems implementation, production capacities of kilograms or tons are necessary, creating a substantial manufacturing gap.

Recent advancements in fluidized bed CVD reactors show promise for scaling GCNT production, potentially reaching outputs of several kilograms daily. However, these methods still struggle with maintaining consistent graphitization quality across large batches, which directly impacts the electrical conductivity and energy storage performance of the final product. The graphitization process itself requires temperatures exceeding 2500°C, contributing significantly to production costs and energy consumption.

From an economic perspective, current GCNT production costs range between $100-500 per gram for high-quality materials, making them prohibitively expensive for mass-market energy applications. Cost modeling indicates that scaling production to industrial levels could potentially reduce costs to $10-50 per kilogram, representing a 1000-fold decrease, but requires substantial capital investment in specialized equipment and process optimization.

Supply chain considerations present additional challenges, as high-purity carbon sources and catalyst materials needed for GCNT synthesis face availability constraints. The environmental footprint of large-scale production must also be addressed, particularly regarding energy consumption during high-temperature graphitization processes and potential emissions from chemical treatments.

Several companies have begun implementing semi-continuous production processes that show promise for cost reduction. These approaches integrate in-line quality control systems to maintain graphitization consistency while increasing throughput. Automation of catalyst recovery and recycling processes has demonstrated potential to reduce raw material costs by up to 40%, representing a significant step toward economic viability.

For GCNTs to achieve widespread adoption in energy systems, manufacturing innovations must focus on three key areas: developing continuous production methods that maintain graphitization quality, reducing energy requirements for the high-temperature treatment processes, and establishing reliable supply chains for precursor materials. Recent techno-economic analyses suggest that achieving a production cost below $50 per kilogram represents the threshold for commercial viability in high-performance energy storage applications.

Recent advancements in fluidized bed CVD reactors show promise for scaling GCNT production, potentially reaching outputs of several kilograms daily. However, these methods still struggle with maintaining consistent graphitization quality across large batches, which directly impacts the electrical conductivity and energy storage performance of the final product. The graphitization process itself requires temperatures exceeding 2500°C, contributing significantly to production costs and energy consumption.

From an economic perspective, current GCNT production costs range between $100-500 per gram for high-quality materials, making them prohibitively expensive for mass-market energy applications. Cost modeling indicates that scaling production to industrial levels could potentially reduce costs to $10-50 per kilogram, representing a 1000-fold decrease, but requires substantial capital investment in specialized equipment and process optimization.

Supply chain considerations present additional challenges, as high-purity carbon sources and catalyst materials needed for GCNT synthesis face availability constraints. The environmental footprint of large-scale production must also be addressed, particularly regarding energy consumption during high-temperature graphitization processes and potential emissions from chemical treatments.

Several companies have begun implementing semi-continuous production processes that show promise for cost reduction. These approaches integrate in-line quality control systems to maintain graphitization consistency while increasing throughput. Automation of catalyst recovery and recycling processes has demonstrated potential to reduce raw material costs by up to 40%, representing a significant step toward economic viability.

For GCNTs to achieve widespread adoption in energy systems, manufacturing innovations must focus on three key areas: developing continuous production methods that maintain graphitization quality, reducing energy requirements for the high-temperature treatment processes, and establishing reliable supply chains for precursor materials. Recent techno-economic analyses suggest that achieving a production cost below $50 per kilogram represents the threshold for commercial viability in high-performance energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!