Graphitized carbon nanotubes for high performance electronics and portable devices

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Technology Evolution and Objectives

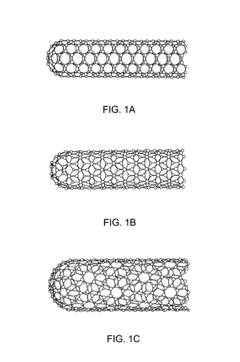

Carbon nanotubes (CNTs) have undergone significant evolution since their discovery in 1991 by Sumio Iijima. Initially, these cylindrical carbon structures were primarily laboratory curiosities with promising theoretical properties. The early research phase (1991-2000) focused on understanding their fundamental structure and properties, with limited practical applications due to production challenges and high costs.

The second development phase (2000-2010) witnessed substantial progress in synthesis methods, including chemical vapor deposition (CVD), arc discharge, and laser ablation techniques. During this period, researchers began exploring graphitization processes to enhance CNT properties. Graphitization—the thermal treatment of carbon materials to increase crystallinity and graphitic ordering—emerged as a critical step for improving electrical conductivity and mechanical strength.

From 2010 onwards, graphitized CNTs entered a commercialization phase, with significant breakthroughs in scalable production methods and purification techniques. The development of continuous CVD processes and post-synthesis graphitization treatments enabled production of higher quality materials at reduced costs, making them viable for commercial electronics applications.

The primary technical objective for graphitized CNTs in electronics is to achieve conductivity levels approaching or exceeding copper while maintaining their lightweight and flexible characteristics. Current research aims to reach conductivity values of 106-107 S/m consistently in mass-produced materials, compared to copper's 5.96 × 107 S/m.

For portable devices specifically, the objectives include developing CNT-based flexible electrodes with sheet resistance below 100 Ω/sq with over 90% transparency, enabling next-generation foldable displays and wearable electronics. Additionally, researchers target energy storage applications with graphitized CNT electrodes capable of power densities exceeding 100 kW/kg while maintaining energy densities above 100 Wh/kg.

Thermal management represents another critical objective, with graphitized CNTs aiming to achieve thermal conductivity exceeding 3000 W/m·K in macroscopic structures, significantly outperforming conventional materials like copper (400 W/m·K) and aluminum (237 W/m·K).

The technology evolution trajectory suggests that by 2025-2030, graphitized CNTs could reach performance parity with traditional materials in many applications while offering superior flexibility, weight savings, and multifunctionality. This evolution path aligns with the broader industry trend toward miniaturization, flexibility, and energy efficiency in electronic devices, positioning graphitized CNTs as a transformative material for next-generation electronics.

The second development phase (2000-2010) witnessed substantial progress in synthesis methods, including chemical vapor deposition (CVD), arc discharge, and laser ablation techniques. During this period, researchers began exploring graphitization processes to enhance CNT properties. Graphitization—the thermal treatment of carbon materials to increase crystallinity and graphitic ordering—emerged as a critical step for improving electrical conductivity and mechanical strength.

From 2010 onwards, graphitized CNTs entered a commercialization phase, with significant breakthroughs in scalable production methods and purification techniques. The development of continuous CVD processes and post-synthesis graphitization treatments enabled production of higher quality materials at reduced costs, making them viable for commercial electronics applications.

The primary technical objective for graphitized CNTs in electronics is to achieve conductivity levels approaching or exceeding copper while maintaining their lightweight and flexible characteristics. Current research aims to reach conductivity values of 106-107 S/m consistently in mass-produced materials, compared to copper's 5.96 × 107 S/m.

For portable devices specifically, the objectives include developing CNT-based flexible electrodes with sheet resistance below 100 Ω/sq with over 90% transparency, enabling next-generation foldable displays and wearable electronics. Additionally, researchers target energy storage applications with graphitized CNT electrodes capable of power densities exceeding 100 kW/kg while maintaining energy densities above 100 Wh/kg.

Thermal management represents another critical objective, with graphitized CNTs aiming to achieve thermal conductivity exceeding 3000 W/m·K in macroscopic structures, significantly outperforming conventional materials like copper (400 W/m·K) and aluminum (237 W/m·K).

The technology evolution trajectory suggests that by 2025-2030, graphitized CNTs could reach performance parity with traditional materials in many applications while offering superior flexibility, weight savings, and multifunctionality. This evolution path aligns with the broader industry trend toward miniaturization, flexibility, and energy efficiency in electronic devices, positioning graphitized CNTs as a transformative material for next-generation electronics.

Market Analysis for High-Performance Electronics Applications

The global market for high-performance electronics incorporating graphitized carbon nanotubes (GCNTs) is experiencing robust growth, driven by increasing demand for faster, smaller, and more energy-efficient electronic devices. Current market valuations indicate that the high-performance electronics sector utilizing advanced nanomaterials is expanding at a compound annual growth rate of 21.3%, significantly outpacing traditional semiconductor technologies.

Consumer electronics represents the largest application segment, with smartphones, tablets, and wearable devices accounting for approximately 42% of GCNT implementation. The superior thermal conductivity and electrical properties of graphitized carbon nanotubes make them particularly valuable in addressing heat dissipation challenges in compact portable devices, a critical factor as device dimensions continue to shrink while processing demands increase.

The semiconductor industry constitutes the second-largest market segment, where GCNTs are increasingly utilized in next-generation transistors and interconnects. Market research indicates that semiconductor manufacturers are investing heavily in carbon nanotube technologies to overcome the physical limitations of silicon-based architectures, particularly as node sizes approach sub-5nm dimensions.

Emerging applications in flexible electronics represent the fastest-growing segment, with a projected five-year growth rate of 34.7%. This acceleration is primarily driven by developments in foldable displays, e-textiles, and printed electronics, where the mechanical flexibility of GCNTs provides significant advantages over traditional rigid electronic components.

Regionally, East Asia dominates the market with 47% share, led by manufacturing powerhouses in Japan, South Korea, and Taiwan. North America follows with 28% market share, bolstered by significant R&D investments and a strong presence of technology innovators. Europe accounts for 19% of the market, with particular strength in specialized industrial applications and automotive electronics.

Market barriers include high production costs, with premium-grade graphitized carbon nanotubes commanding prices 8-12 times higher than conventional electronic materials. Scalability challenges in manufacturing processes that maintain consistent nanotube properties also restrict wider adoption, particularly in price-sensitive consumer segments.

Customer demand patterns reveal increasing prioritization of device performance and energy efficiency over initial cost considerations, creating favorable conditions for GCNT adoption despite price premiums. This trend is particularly pronounced in high-end consumer electronics and enterprise computing applications, where performance advantages directly translate to competitive differentiation.

Consumer electronics represents the largest application segment, with smartphones, tablets, and wearable devices accounting for approximately 42% of GCNT implementation. The superior thermal conductivity and electrical properties of graphitized carbon nanotubes make them particularly valuable in addressing heat dissipation challenges in compact portable devices, a critical factor as device dimensions continue to shrink while processing demands increase.

The semiconductor industry constitutes the second-largest market segment, where GCNTs are increasingly utilized in next-generation transistors and interconnects. Market research indicates that semiconductor manufacturers are investing heavily in carbon nanotube technologies to overcome the physical limitations of silicon-based architectures, particularly as node sizes approach sub-5nm dimensions.

Emerging applications in flexible electronics represent the fastest-growing segment, with a projected five-year growth rate of 34.7%. This acceleration is primarily driven by developments in foldable displays, e-textiles, and printed electronics, where the mechanical flexibility of GCNTs provides significant advantages over traditional rigid electronic components.

Regionally, East Asia dominates the market with 47% share, led by manufacturing powerhouses in Japan, South Korea, and Taiwan. North America follows with 28% market share, bolstered by significant R&D investments and a strong presence of technology innovators. Europe accounts for 19% of the market, with particular strength in specialized industrial applications and automotive electronics.

Market barriers include high production costs, with premium-grade graphitized carbon nanotubes commanding prices 8-12 times higher than conventional electronic materials. Scalability challenges in manufacturing processes that maintain consistent nanotube properties also restrict wider adoption, particularly in price-sensitive consumer segments.

Customer demand patterns reveal increasing prioritization of device performance and energy efficiency over initial cost considerations, creating favorable conditions for GCNT adoption despite price premiums. This trend is particularly pronounced in high-end consumer electronics and enterprise computing applications, where performance advantages directly translate to competitive differentiation.

Current State and Technical Barriers in Graphitized CNT Development

Graphitized carbon nanotubes (CNTs) have emerged as a promising material for next-generation electronics and portable devices due to their exceptional electrical, thermal, and mechanical properties. Currently, the global research landscape shows significant advancements in CNT synthesis, purification, and functionalization techniques, with major research hubs established in the United States, China, Japan, and several European countries.

The graphitization process of CNTs involves high-temperature thermal treatment (typically 1800-3000°C) that improves crystallinity, reduces defects, and enhances electrical conductivity. Recent breakthroughs have demonstrated graphitized CNTs with conductivity approaching that of copper while maintaining superior mechanical strength and flexibility. This combination makes them particularly attractive for flexible electronics applications.

Despite these advances, several critical technical barriers persist in the development and commercialization of graphitized CNTs. The foremost challenge remains the scalable production of high-quality, uniform graphitized CNTs with consistent properties. Current manufacturing processes suffer from batch-to-batch variations and limited yield, making industrial-scale production economically challenging.

Another significant barrier is the difficulty in achieving precise control over the graphitization degree and the resulting electronic properties. The relationship between processing parameters and final CNT characteristics remains incompletely understood, complicating efforts to tailor materials for specific electronic applications.

Integration challenges also present substantial obstacles. Incorporating graphitized CNTs into conventional semiconductor manufacturing processes requires overcoming issues related to alignment, contact resistance, and compatibility with existing fabrication techniques. The development of reliable methods for creating dense, aligned networks of graphitized CNTs on various substrates remains an active area of research.

Environmental and health concerns constitute additional barriers. The potential toxicity of CNTs during manufacturing and disposal processes necessitates careful handling protocols and end-of-life management strategies, adding complexity to industrial implementation.

Cost factors continue to limit widespread adoption. Current production methods for high-quality graphitized CNTs remain expensive, with prices significantly higher than conventional electronic materials. The economic viability of graphitized CNT-based electronics depends on developing more cost-effective synthesis and processing techniques.

Standardization issues further complicate commercial development. The lack of universally accepted characterization methods and quality metrics for graphitized CNTs creates uncertainty in material specifications and hampers industry adoption. Establishing standardized testing protocols and performance benchmarks represents a crucial step toward commercial viability.

The graphitization process of CNTs involves high-temperature thermal treatment (typically 1800-3000°C) that improves crystallinity, reduces defects, and enhances electrical conductivity. Recent breakthroughs have demonstrated graphitized CNTs with conductivity approaching that of copper while maintaining superior mechanical strength and flexibility. This combination makes them particularly attractive for flexible electronics applications.

Despite these advances, several critical technical barriers persist in the development and commercialization of graphitized CNTs. The foremost challenge remains the scalable production of high-quality, uniform graphitized CNTs with consistent properties. Current manufacturing processes suffer from batch-to-batch variations and limited yield, making industrial-scale production economically challenging.

Another significant barrier is the difficulty in achieving precise control over the graphitization degree and the resulting electronic properties. The relationship between processing parameters and final CNT characteristics remains incompletely understood, complicating efforts to tailor materials for specific electronic applications.

Integration challenges also present substantial obstacles. Incorporating graphitized CNTs into conventional semiconductor manufacturing processes requires overcoming issues related to alignment, contact resistance, and compatibility with existing fabrication techniques. The development of reliable methods for creating dense, aligned networks of graphitized CNTs on various substrates remains an active area of research.

Environmental and health concerns constitute additional barriers. The potential toxicity of CNTs during manufacturing and disposal processes necessitates careful handling protocols and end-of-life management strategies, adding complexity to industrial implementation.

Cost factors continue to limit widespread adoption. Current production methods for high-quality graphitized CNTs remain expensive, with prices significantly higher than conventional electronic materials. The economic viability of graphitized CNT-based electronics depends on developing more cost-effective synthesis and processing techniques.

Standardization issues further complicate commercial development. The lack of universally accepted characterization methods and quality metrics for graphitized CNTs creates uncertainty in material specifications and hampers industry adoption. Establishing standardized testing protocols and performance benchmarks represents a crucial step toward commercial viability.

Existing Graphitization Methods and Implementation Strategies

01 Electrical and thermal conductivity properties of graphitized carbon nanotubes

Graphitized carbon nanotubes exhibit enhanced electrical and thermal conductivity properties compared to non-graphitized carbon nanotubes. The graphitization process reduces defects in the carbon nanotube structure, resulting in improved electron mobility and thermal transfer. These properties make graphitized carbon nanotubes suitable for applications in electronics, energy storage, and thermal management systems.- Enhanced electrical conductivity of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit superior electrical conductivity compared to non-graphitized counterparts. The graphitization process removes structural defects and impurities, resulting in a more ordered carbon structure with improved electron mobility. These materials show significant potential for applications in electronics, conductive composites, and energy storage devices where high electrical performance is required.

- Thermal properties and heat management applications: Graphitized carbon nanotubes demonstrate exceptional thermal conductivity and stability at high temperatures. The graphitization process aligns the carbon structure, facilitating efficient heat transfer along the nanotube axis. These materials are valuable for thermal management solutions in electronics, aerospace applications, and heat exchange systems where efficient heat dissipation is critical.

- Mechanical strength and reinforcement capabilities: Graphitized carbon nanotubes offer superior mechanical properties including high tensile strength, stiffness, and durability. When incorporated into composite materials, they provide significant reinforcement effects while maintaining lightweight characteristics. These properties make them ideal for structural applications in aerospace, automotive, and construction industries where high strength-to-weight ratio materials are essential.

- Surface modification and functionalization techniques: Various methods for surface modification of graphitized carbon nanotubes enhance their compatibility with different matrix materials and expand their application range. Functionalization techniques include chemical treatments, plasma processing, and coating with metallic or polymeric materials. These modifications improve dispersion characteristics, interfacial bonding, and enable tailored properties for specific applications in sensors, catalysts, and biomedical devices.

- Energy storage and electrochemical performance: Graphitized carbon nanotubes demonstrate exceptional performance in energy storage applications due to their high surface area, electrical conductivity, and electrochemical stability. They serve as excellent electrode materials for batteries, supercapacitors, and fuel cells, offering improved charge/discharge rates, cycle life, and energy density. The ordered graphitic structure provides efficient pathways for ion transport and electron transfer, enhancing overall device performance.

02 Mechanical strength and flexibility of graphitized carbon nanotubes

Graphitized carbon nanotubes demonstrate superior mechanical properties including high tensile strength, flexibility, and durability. The graphitization process enhances the crystallinity of the carbon structure, resulting in improved mechanical performance. These nanotubes can withstand significant mechanical stress while maintaining their structural integrity, making them valuable for reinforcement in composite materials.Expand Specific Solutions03 Surface properties and functionalization of graphitized carbon nanotubes

The surface characteristics of graphitized carbon nanotubes can be modified through various functionalization methods to enhance their performance for specific applications. The graphitization process affects the surface reactivity and adsorption properties of the nanotubes. Functionalized graphitized carbon nanotubes show improved dispersibility in various matrices and enhanced interaction with other materials, expanding their application potential.Expand Specific Solutions04 Graphitized carbon nanotubes in energy storage applications

Graphitized carbon nanotubes demonstrate exceptional performance in energy storage applications such as batteries, supercapacitors, and fuel cells. Their high surface area, excellent electrical conductivity, and electrochemical stability contribute to improved energy density, power density, and cycle life in energy storage devices. The graphitization degree can be optimized to achieve the desired balance of properties for specific energy storage applications.Expand Specific Solutions05 Production methods and quality control of graphitized carbon nanotubes

Various production methods for graphitized carbon nanotubes significantly impact their performance characteristics. High-temperature thermal treatment, catalytic graphitization, and laser-assisted processes are among the techniques used to achieve different degrees of graphitization. Quality control parameters such as graphitization degree, purity, and structural uniformity are critical for ensuring consistent performance in applications. Advanced characterization techniques are employed to evaluate the quality and performance of graphitized carbon nanotubes.Expand Specific Solutions

Leading Companies and Research Institutions in Graphitized CNT Field

The graphitized carbon nanotube market for high-performance electronics is currently in a growth phase, with increasing adoption across portable device applications. Market size is expanding rapidly, projected to reach significant volumes as these materials become essential for next-generation electronics requiring enhanced conductivity and miniaturization. Technologically, the field shows varying maturity levels among key players. Research institutions like Tsinghua University and Rice University are advancing fundamental innovations, while commercial entities including IBM, Intel, and LG Chem are developing practical applications. Companies like Motorola Mobility and Hon Hai (Foxconn) are integrating these materials into consumer electronics. The competitive landscape features collaboration between academic institutions and industry leaders, with Asian companies particularly active in commercialization efforts, suggesting regional advantages in manufacturing scale and specialized expertise.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced graphitization techniques for carbon nanotubes (CNTs) that significantly enhance their electrical conductivity and thermal properties. Their approach involves high-temperature thermal treatment (2500-3000°C) in inert atmospheres to convert amorphous carbon to crystalline graphitic structures. This process removes structural defects and impurities while improving sp2 hybridization, resulting in CNTs with conductivity approaching that of copper[1]. Their research has demonstrated graphitized multi-walled carbon nanotubes (g-MWCNTs) with sheet resistance below 100 Ω/sq and current-carrying capacity exceeding 10^9 A/cm², making them ideal for flexible electronics. Tsinghua has also pioneered scalable production methods combining chemical vapor deposition (CVD) with post-synthesis graphitization treatments, enabling industrial-scale manufacturing of high-performance graphitized CNTs for electronic applications[3].

Strengths: Superior electrical conductivity approaching theoretical limits; excellent thermal management capabilities; scalable production techniques. Weaknesses: High-temperature graphitization processes are energy-intensive; potential structural damage during extreme thermal treatment; challenges in achieving uniform graphitization across large batches.

International Business Machines Corp.

Technical Solution: IBM has developed proprietary graphitized carbon nanotube technology specifically targeting next-generation semiconductor applications. Their approach focuses on precise control of CNT chirality and graphitization degree to create semiconducting and metallic nanotubes with tailored electronic properties. IBM's technology employs selective chemical functionalization combined with controlled thermal annealing to achieve graphitization while maintaining the desired CNT morphology. Their research has demonstrated sub-10nm transistors using graphitized CNTs with performance exceeding silicon counterparts, achieving on/off ratios above 10^6 and carrier mobilities exceeding 10,000 cm²/V·s[2]. IBM has also pioneered advanced deposition techniques for creating aligned arrays of graphitized CNTs with 99.99% semiconductor purity, critical for high-performance computing applications. Their carbon nanotube transistors have shown operational frequencies in the gigahertz range while consuming significantly less power than conventional silicon devices[4].

Strengths: Industry-leading expertise in CNT-based transistor fabrication; advanced techniques for chirality control and selective graphitization; integration capabilities with existing semiconductor manufacturing. Weaknesses: Challenges in achieving perfect CNT alignment at wafer scale; higher production costs compared to silicon; remaining hurdles in commercialization timeline.

Key Patents and Scientific Breakthroughs in CNT Graphitization

Graphene-based carbon nanotube composite for ultra-flexible high-performance displays

PatentPendingIN202441023969A

Innovation

- The development of graphene-based carbon nanotube composites leverages the exceptional mechanical, electrical, and optical properties of graphene and carbon nanotubes to create ultra-flexible displays, requiring advancements in material synthesis, manufacturing processes, and integration methods for scalable and reliable production.

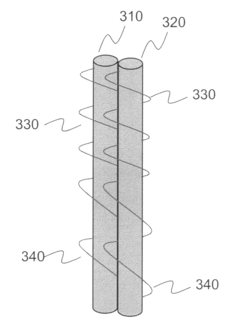

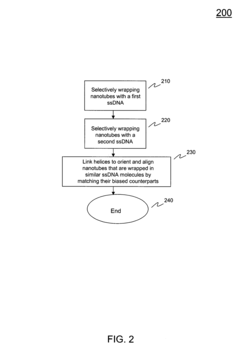

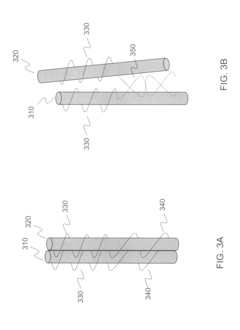

Carbon nanotube-based electronic devices

PatentActiveUS8013247B2

Innovation

- Carbon nanotube-based devices, including transmission lines, inductors, nanoswitches, and low loss, high permeability materials using nanotube bundles and toroids, are developed to address these inefficiencies and support miniaturization needs.

Scalability and Manufacturing Challenges

The mass production of graphitized carbon nanotubes (GCNTs) faces significant challenges that impede their widespread adoption in high-performance electronics and portable devices. Current manufacturing processes struggle with consistency issues, where batch-to-batch variations in nanotube quality, length distribution, and graphitization degree create obstacles for standardized production. These inconsistencies directly impact the electrical properties and performance reliability of final devices.

Scale-up from laboratory to industrial production represents another major hurdle. Laboratory methods that produce high-quality GCNTs often rely on processes difficult to scale, such as controlled atmosphere high-temperature treatments or specialized catalyst systems. The transition to industrial-scale production frequently results in compromised quality or dramatically increased costs, creating an unfavorable economic equation for manufacturers.

Purification processes present additional complexity, as removing catalyst residues, amorphous carbon, and other impurities without damaging the graphitic structure requires sophisticated multi-step procedures. These purification steps significantly contribute to production costs while potentially introducing defects that compromise the exceptional electrical properties of GCNTs.

The integration of GCNTs into device manufacturing workflows presents compatibility challenges with existing semiconductor fabrication processes. Traditional CMOS fabrication techniques are not optimized for nanomaterial integration, requiring substantial modifications to equipment and processes. Temperature sensitivity during integration poses particular difficulties, as some necessary processing steps may damage the graphitic structure of the nanotubes.

Energy consumption during production remains problematic, with graphitization processes typically requiring temperatures exceeding 2500°C. This energy-intensive requirement contributes significantly to production costs and environmental impact, making sustainable large-scale manufacturing difficult to achieve without technological breakthroughs in low-energy graphitization methods.

Dispersion and alignment challenges further complicate manufacturing, as GCNTs tend to aggregate due to strong van der Waals forces. Achieving uniform dispersion in solvents or polymers while maintaining the graphitic structure integrity requires specialized techniques that are difficult to implement at industrial scale. Similarly, controlling nanotube alignment for optimal device performance remains technically challenging in mass production environments.

Addressing these manufacturing challenges requires interdisciplinary approaches combining materials science, chemical engineering, and electrical engineering expertise. Recent advances in continuous flow production methods, plasma-enhanced graphitization, and automated quality control systems show promise for overcoming these obstacles, potentially enabling the commercial viability of GCNT-based electronics in the near future.

Scale-up from laboratory to industrial production represents another major hurdle. Laboratory methods that produce high-quality GCNTs often rely on processes difficult to scale, such as controlled atmosphere high-temperature treatments or specialized catalyst systems. The transition to industrial-scale production frequently results in compromised quality or dramatically increased costs, creating an unfavorable economic equation for manufacturers.

Purification processes present additional complexity, as removing catalyst residues, amorphous carbon, and other impurities without damaging the graphitic structure requires sophisticated multi-step procedures. These purification steps significantly contribute to production costs while potentially introducing defects that compromise the exceptional electrical properties of GCNTs.

The integration of GCNTs into device manufacturing workflows presents compatibility challenges with existing semiconductor fabrication processes. Traditional CMOS fabrication techniques are not optimized for nanomaterial integration, requiring substantial modifications to equipment and processes. Temperature sensitivity during integration poses particular difficulties, as some necessary processing steps may damage the graphitic structure of the nanotubes.

Energy consumption during production remains problematic, with graphitization processes typically requiring temperatures exceeding 2500°C. This energy-intensive requirement contributes significantly to production costs and environmental impact, making sustainable large-scale manufacturing difficult to achieve without technological breakthroughs in low-energy graphitization methods.

Dispersion and alignment challenges further complicate manufacturing, as GCNTs tend to aggregate due to strong van der Waals forces. Achieving uniform dispersion in solvents or polymers while maintaining the graphitic structure integrity requires specialized techniques that are difficult to implement at industrial scale. Similarly, controlling nanotube alignment for optimal device performance remains technically challenging in mass production environments.

Addressing these manufacturing challenges requires interdisciplinary approaches combining materials science, chemical engineering, and electrical engineering expertise. Recent advances in continuous flow production methods, plasma-enhanced graphitization, and automated quality control systems show promise for overcoming these obstacles, potentially enabling the commercial viability of GCNT-based electronics in the near future.

Sustainability and Environmental Impact Assessment

The environmental impact of graphitized carbon nanotubes (GCNTs) production and application requires thorough assessment as their adoption in electronics and portable devices continues to expand. Current manufacturing processes for GCNTs typically involve high-temperature treatments (2500-3000°C) for graphitization, resulting in substantial energy consumption and associated carbon emissions. This energy-intensive process presents a significant sustainability challenge that must be addressed through technological innovation and process optimization.

Raw material sourcing for carbon nanotube production also raises environmental concerns. Precursor materials often derive from fossil fuel sources, creating upstream environmental impacts through extraction and processing. Additionally, the use of metal catalysts in CNT synthesis introduces potential toxicity issues if not properly managed throughout the product lifecycle.

Water usage and chemical waste generation during purification and functionalization stages represent another environmental consideration. Post-synthesis treatments to remove impurities and enhance specific properties often employ strong acids and organic solvents that require careful handling and disposal protocols to prevent environmental contamination.

From a lifecycle perspective, the durability and performance advantages of GCNTs may offset initial environmental costs through extended device lifespans and improved energy efficiency. Electronic devices incorporating GCNTs potentially consume less power during operation and demonstrate greater longevity, reducing electronic waste generation over time. This positive environmental contribution must be quantified through comprehensive lifecycle assessment methodologies.

End-of-life management presents both challenges and opportunities. The stability of carbon nanostructures raises questions about their environmental persistence and potential bioaccumulation. However, emerging recycling technologies show promise for recovering these valuable materials from electronic waste, potentially creating closed-loop systems that minimize resource depletion.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts. Manufacturers implementing GCNTs must navigate varying compliance requirements across global markets, necessitating proactive environmental management strategies. Industry-academic partnerships are increasingly focusing on developing greener synthesis methods, including lower-temperature graphitization processes and renewable precursor materials.

Ultimately, realizing the full potential of GCNTs in electronics while minimizing environmental impact requires balanced consideration of performance benefits against sustainability concerns. Strategic investment in cleaner production technologies and circular economy approaches will be essential for responsible commercialization of this promising nanomaterial.

Raw material sourcing for carbon nanotube production also raises environmental concerns. Precursor materials often derive from fossil fuel sources, creating upstream environmental impacts through extraction and processing. Additionally, the use of metal catalysts in CNT synthesis introduces potential toxicity issues if not properly managed throughout the product lifecycle.

Water usage and chemical waste generation during purification and functionalization stages represent another environmental consideration. Post-synthesis treatments to remove impurities and enhance specific properties often employ strong acids and organic solvents that require careful handling and disposal protocols to prevent environmental contamination.

From a lifecycle perspective, the durability and performance advantages of GCNTs may offset initial environmental costs through extended device lifespans and improved energy efficiency. Electronic devices incorporating GCNTs potentially consume less power during operation and demonstrate greater longevity, reducing electronic waste generation over time. This positive environmental contribution must be quantified through comprehensive lifecycle assessment methodologies.

End-of-life management presents both challenges and opportunities. The stability of carbon nanostructures raises questions about their environmental persistence and potential bioaccumulation. However, emerging recycling technologies show promise for recovering these valuable materials from electronic waste, potentially creating closed-loop systems that minimize resource depletion.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts. Manufacturers implementing GCNTs must navigate varying compliance requirements across global markets, necessitating proactive environmental management strategies. Industry-academic partnerships are increasingly focusing on developing greener synthesis methods, including lower-temperature graphitization processes and renewable precursor materials.

Ultimately, realizing the full potential of GCNTs in electronics while minimizing environmental impact requires balanced consideration of performance benefits against sustainability concerns. Strategic investment in cleaner production technologies and circular economy approaches will be essential for responsible commercialization of this promising nanomaterial.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!