Comparative analysis of Graphitized carbon nanotubes layered versus rolled structures

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Nanotube Structures Background and Objectives

Carbon nanotubes (CNTs) have emerged as one of the most promising nanomaterials since their formal identification in 1991 by Sumio Iijima. These cylindrical structures composed of carbon atoms arranged in a hexagonal lattice have revolutionized materials science due to their exceptional mechanical, electrical, and thermal properties. The evolution of CNT research has progressed from single-walled carbon nanotubes (SWCNTs) to multi-walled carbon nanotubes (MWCNTs), and more recently to graphitized carbon nanotubes with various structural configurations.

The structural arrangement of carbon atoms in CNTs significantly influences their properties and potential applications. Particularly, the comparison between layered and rolled structures of graphitized carbon nanotubes represents a critical area of investigation that could unlock new technological capabilities. Layered structures typically consist of stacked graphene sheets with specific interlayer spacing, while rolled structures form concentric cylinders with unique radial properties.

The technological evolution in this field has been driven by advancements in synthesis methods, including arc discharge, laser ablation, chemical vapor deposition (CVD), and more recently, controlled graphitization processes. These developments have enabled greater control over CNT morphology, purity, and structural characteristics, facilitating the exploration of both layered and rolled configurations.

Current research trends indicate growing interest in understanding the fundamental differences between these structural arrangements and their implications for material performance. The graphitization process, which involves high-temperature treatment to improve crystallinity and reduce defects, affects layered and rolled structures differently, resulting in distinct property profiles that merit systematic comparison.

The primary objectives of this technical investigation are threefold: first, to comprehensively analyze the structural differences between layered and rolled graphitized carbon nanotubes at the molecular and macroscopic levels; second, to evaluate comparative performance metrics including mechanical strength, electrical conductivity, thermal stability, and surface characteristics; and third, to identify optimal structural configurations for specific application domains.

This analysis aims to establish a foundation for strategic decision-making regarding which structural configuration offers superior performance for targeted applications such as energy storage, composite reinforcement, electronic devices, and thermal management systems. By understanding the fundamental structure-property relationships in these different CNT arrangements, we can better predict performance outcomes and guide future development efforts.

The technological trajectory suggests that hybrid structures combining elements of both layered and rolled configurations may represent the next frontier in CNT research, potentially offering synergistic benefits that exceed the capabilities of either structure independently. This comparative analysis will therefore also explore emerging hybrid approaches and their potential to address current technological limitations.

The structural arrangement of carbon atoms in CNTs significantly influences their properties and potential applications. Particularly, the comparison between layered and rolled structures of graphitized carbon nanotubes represents a critical area of investigation that could unlock new technological capabilities. Layered structures typically consist of stacked graphene sheets with specific interlayer spacing, while rolled structures form concentric cylinders with unique radial properties.

The technological evolution in this field has been driven by advancements in synthesis methods, including arc discharge, laser ablation, chemical vapor deposition (CVD), and more recently, controlled graphitization processes. These developments have enabled greater control over CNT morphology, purity, and structural characteristics, facilitating the exploration of both layered and rolled configurations.

Current research trends indicate growing interest in understanding the fundamental differences between these structural arrangements and their implications for material performance. The graphitization process, which involves high-temperature treatment to improve crystallinity and reduce defects, affects layered and rolled structures differently, resulting in distinct property profiles that merit systematic comparison.

The primary objectives of this technical investigation are threefold: first, to comprehensively analyze the structural differences between layered and rolled graphitized carbon nanotubes at the molecular and macroscopic levels; second, to evaluate comparative performance metrics including mechanical strength, electrical conductivity, thermal stability, and surface characteristics; and third, to identify optimal structural configurations for specific application domains.

This analysis aims to establish a foundation for strategic decision-making regarding which structural configuration offers superior performance for targeted applications such as energy storage, composite reinforcement, electronic devices, and thermal management systems. By understanding the fundamental structure-property relationships in these different CNT arrangements, we can better predict performance outcomes and guide future development efforts.

The technological trajectory suggests that hybrid structures combining elements of both layered and rolled configurations may represent the next frontier in CNT research, potentially offering synergistic benefits that exceed the capabilities of either structure independently. This comparative analysis will therefore also explore emerging hybrid approaches and their potential to address current technological limitations.

Market Applications Analysis for CNT Architectures

Carbon nanotube (CNT) architectures have emerged as transformative materials across multiple industries due to their exceptional mechanical, electrical, and thermal properties. The market applications for CNT architectures, particularly comparing layered versus rolled structures, demonstrate significant diversity and growth potential across several key sectors.

The electronics industry represents one of the most promising markets for CNT architectures. Layered graphitized CNT structures are increasingly utilized in transparent conductive films for touchscreens and displays, offering superior flexibility and durability compared to traditional indium tin oxide. Meanwhile, rolled CNT structures have found applications in high-performance transistors and integrated circuits, where their tubular geometry provides enhanced electron mobility and heat dissipation characteristics.

Energy storage represents another substantial market opportunity. Layered CNT architectures are being incorporated into next-generation lithium-ion battery electrodes, where their sheet-like structure facilitates ion transport and increases energy density. Rolled CNT structures, conversely, are showing promise in supercapacitor applications, where their cylindrical configuration creates optimal pore structures for electrolyte access and rapid charge/discharge cycles.

The aerospace and automotive sectors are adopting CNT architectures for lightweight structural composites. Layered CNT structures provide exceptional in-plane strength and are being integrated into carbon fiber reinforced polymers to enhance mechanical properties while reducing weight. Rolled CNT structures offer multidirectional reinforcement capabilities, making them suitable for components requiring isotropic mechanical properties under complex stress conditions.

In healthcare and biomedical applications, the distinct architectures serve different purposes. Layered CNT structures are being developed for biosensors and diagnostic platforms, where their high surface area enables efficient biomolecule immobilization. Rolled CNT structures show promise in drug delivery systems and tissue engineering scaffolds, where their tubular geometry can encapsulate therapeutic agents or guide cellular growth.

Environmental technologies represent an emerging application area. Layered CNT architectures are being developed for advanced filtration membranes and water purification systems, leveraging their nanoporous structure. Rolled CNT configurations are being explored for gas separation and carbon capture technologies, where their hollow cores can facilitate selective molecular transport.

The thermal management market is increasingly adopting CNT architectures for next-generation cooling solutions. Layered structures excel in planar heat spreading applications for electronics, while rolled structures are being developed for thermal interface materials where through-plane heat conduction is critical.

The electronics industry represents one of the most promising markets for CNT architectures. Layered graphitized CNT structures are increasingly utilized in transparent conductive films for touchscreens and displays, offering superior flexibility and durability compared to traditional indium tin oxide. Meanwhile, rolled CNT structures have found applications in high-performance transistors and integrated circuits, where their tubular geometry provides enhanced electron mobility and heat dissipation characteristics.

Energy storage represents another substantial market opportunity. Layered CNT architectures are being incorporated into next-generation lithium-ion battery electrodes, where their sheet-like structure facilitates ion transport and increases energy density. Rolled CNT structures, conversely, are showing promise in supercapacitor applications, where their cylindrical configuration creates optimal pore structures for electrolyte access and rapid charge/discharge cycles.

The aerospace and automotive sectors are adopting CNT architectures for lightweight structural composites. Layered CNT structures provide exceptional in-plane strength and are being integrated into carbon fiber reinforced polymers to enhance mechanical properties while reducing weight. Rolled CNT structures offer multidirectional reinforcement capabilities, making them suitable for components requiring isotropic mechanical properties under complex stress conditions.

In healthcare and biomedical applications, the distinct architectures serve different purposes. Layered CNT structures are being developed for biosensors and diagnostic platforms, where their high surface area enables efficient biomolecule immobilization. Rolled CNT structures show promise in drug delivery systems and tissue engineering scaffolds, where their tubular geometry can encapsulate therapeutic agents or guide cellular growth.

Environmental technologies represent an emerging application area. Layered CNT architectures are being developed for advanced filtration membranes and water purification systems, leveraging their nanoporous structure. Rolled CNT configurations are being explored for gas separation and carbon capture technologies, where their hollow cores can facilitate selective molecular transport.

The thermal management market is increasingly adopting CNT architectures for next-generation cooling solutions. Layered structures excel in planar heat spreading applications for electronics, while rolled structures are being developed for thermal interface materials where through-plane heat conduction is critical.

Current Technical Challenges in Graphitized CNT Structures

Despite significant advancements in graphitized carbon nanotube (CNT) structures, several technical challenges persist in both layered and rolled configurations. The primary challenge involves achieving uniform graphitization across the entire structure. Current manufacturing processes often result in inconsistent graphitization levels, with some regions exhibiting higher crystallinity than others. This heterogeneity significantly impacts the mechanical, electrical, and thermal properties of the final product, creating reliability issues in applications requiring consistent performance parameters.

Material integrity during the high-temperature graphitization process (typically 2500-3000°C) represents another substantial challenge. Layered structures frequently experience delamination due to thermal expansion differences between layers, while rolled structures may develop structural defects from internal stresses during thermal processing. These integrity issues compromise the mechanical stability and functional properties of the structures, limiting their practical applications in demanding environments.

Interface engineering between individual CNTs remains problematic in both configurations. In layered structures, achieving optimal interlayer bonding without compromising the unique properties of each layer presents significant difficulties. Similarly, in rolled structures, maintaining consistent contact points between adjacent tube walls during the rolling process affects overall performance characteristics. These interface challenges directly influence charge transfer efficiency and mechanical load distribution throughout the structure.

Scalable manufacturing represents perhaps the most significant barrier to widespread adoption. Current production methods for precisely controlled layered or rolled graphitized CNT structures remain largely laboratory-based, with limited throughput and high production costs. The transition from laboratory demonstrations to industrial-scale manufacturing while maintaining structural precision and performance characteristics has proven exceptionally difficult.

Characterization and quality control methodologies present additional challenges. Existing analytical techniques struggle to provide comprehensive, non-destructive assessment of internal structural features, particularly in rolled configurations where internal layers are not readily accessible. This limitation hampers both research advancement and quality assurance in production environments.

Lastly, environmental stability poses ongoing concerns. Both layered and rolled graphitized CNT structures can experience performance degradation when exposed to oxygen, humidity, or certain chemical environments. Developing effective protection strategies without compromising the inherent properties of these structures remains an active research area with significant technical hurdles.

Material integrity during the high-temperature graphitization process (typically 2500-3000°C) represents another substantial challenge. Layered structures frequently experience delamination due to thermal expansion differences between layers, while rolled structures may develop structural defects from internal stresses during thermal processing. These integrity issues compromise the mechanical stability and functional properties of the structures, limiting their practical applications in demanding environments.

Interface engineering between individual CNTs remains problematic in both configurations. In layered structures, achieving optimal interlayer bonding without compromising the unique properties of each layer presents significant difficulties. Similarly, in rolled structures, maintaining consistent contact points between adjacent tube walls during the rolling process affects overall performance characteristics. These interface challenges directly influence charge transfer efficiency and mechanical load distribution throughout the structure.

Scalable manufacturing represents perhaps the most significant barrier to widespread adoption. Current production methods for precisely controlled layered or rolled graphitized CNT structures remain largely laboratory-based, with limited throughput and high production costs. The transition from laboratory demonstrations to industrial-scale manufacturing while maintaining structural precision and performance characteristics has proven exceptionally difficult.

Characterization and quality control methodologies present additional challenges. Existing analytical techniques struggle to provide comprehensive, non-destructive assessment of internal structural features, particularly in rolled configurations where internal layers are not readily accessible. This limitation hampers both research advancement and quality assurance in production environments.

Lastly, environmental stability poses ongoing concerns. Both layered and rolled graphitized CNT structures can experience performance degradation when exposed to oxygen, humidity, or certain chemical environments. Developing effective protection strategies without compromising the inherent properties of these structures remains an active research area with significant technical hurdles.

Comparative Analysis of Layered vs Rolled CNT Architectures

01 Structural differences between layered and rolled carbon nanotubes

Carbon nanotubes can exist in different structural forms, primarily as rolled cylindrical structures or as layered graphitic structures. The rolled structure consists of graphene sheets wrapped into cylindrical tubes, while the layered structure involves stacked graphene layers. These structural differences significantly affect the physical and chemical properties of the nanotubes, including electrical conductivity, mechanical strength, and thermal stability. The graphitization process can transform amorphous carbon into more ordered structures, affecting whether the final form is layered or rolled.- Structural characteristics of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit distinct structural characteristics where carbon atoms are arranged in hexagonal lattices. The graphitization process transforms amorphous carbon into crystalline graphitic structures, resulting in improved electrical conductivity and mechanical properties. These nanotubes can exist in both layered (multi-walled) configurations where graphene sheets are concentrically arranged, and rolled (single-walled) structures where a single graphene sheet is rolled into a cylinder.

- Layered structure of multi-walled carbon nanotubes: Multi-walled carbon nanotubes (MWCNTs) feature a layered structure consisting of multiple concentric graphene cylinders with interlayer spacing similar to graphite. The graphitization process enhances the crystallinity of these layers, reducing defects and improving alignment between the graphitic planes. This layered architecture provides superior mechanical strength and thermal stability compared to single-walled variants, making them suitable for applications requiring robust structural properties.

- Rolled structure of single-walled carbon nanotubes: Single-walled carbon nanotubes (SWCNTs) possess a rolled structure where a single graphene sheet is seamlessly wrapped into a cylindrical form. The graphitization of these rolled structures enhances their crystallinity and reduces structural defects. The rolling direction (chirality) significantly influences the electronic properties, determining whether the nanotube exhibits metallic or semiconducting behavior. This rolled configuration provides unique quantum confinement effects not present in layered structures.

- Transformation between layered and rolled structures during graphitization: During the graphitization process, carbon nanotubes can undergo structural transformations between layered and rolled configurations. High-temperature treatment can cause the walls of multi-walled nanotubes to partially exfoliate or reorient, while single-walled tubes may coalesce into multi-walled structures. These transformations are influenced by factors such as temperature, pressure, and catalyst presence, allowing for controlled modification of nanotube structures for specific applications.

- Applications leveraging structural differences between layered and rolled graphitized nanotubes: The structural differences between layered and rolled graphitized carbon nanotubes enable diverse applications across multiple fields. Layered multi-walled structures are preferred for applications requiring mechanical reinforcement, thermal management, and electrical conductivity in composite materials. In contrast, rolled single-walled structures are advantageous for electronic devices, sensors, and biomedical applications due to their unique electronic properties and higher surface-to-volume ratio. The choice between these structures depends on the specific performance requirements of the intended application.

02 Graphitization process effects on nanotube structure

The graphitization process significantly influences whether carbon nanotubes adopt a layered or rolled configuration. High-temperature thermal treatments (typically above 2000°C) promote the formation of more ordered graphitic structures by rearranging carbon atoms. The degree of graphitization affects the crystallinity, interlayer spacing, and structural integrity of the nanotubes. Controlled graphitization can be used to deliberately convert between structural forms or to enhance specific properties while maintaining the desired morphology. Various catalysts and processing conditions can be employed to direct the graphitization pathway toward either layered or rolled structures.Expand Specific Solutions03 Property differences between layered and rolled graphitized carbon nanotubes

Layered and rolled graphitized carbon nanotubes exhibit distinct property profiles that make them suitable for different applications. Rolled structures typically offer superior mechanical strength, flexibility, and higher aspect ratios, making them ideal for reinforcement in composites. Layered structures generally provide better electrical conductivity along the plane of the layers and enhanced thermal stability. The electron transport mechanisms differ significantly between the two structures, with rolled nanotubes showing more quantum confinement effects. Surface area characteristics also vary, with rolled structures typically offering higher accessible surface area compared to layered structures.Expand Specific Solutions04 Fabrication methods for controlling layered versus rolled structures

Various fabrication techniques can be employed to selectively produce either layered or rolled graphitized carbon nanotube structures. Chemical vapor deposition (CVD) methods with specific catalysts and process parameters can direct the growth toward cylindrical rolled structures. Arc discharge and laser ablation techniques can be modified to favor either structure type. Post-synthesis treatments, including specific thermal annealing protocols, chemical treatments, and mechanical processing, can transform or enhance structural characteristics. The choice of carbon precursors and catalyst materials significantly influences the resulting nanotube morphology. Hybrid structures combining both layered and rolled elements can be created through specialized multi-step fabrication processes.Expand Specific Solutions05 Applications leveraging specific structural forms of graphitized carbon nanotubes

The distinct structural characteristics of layered versus rolled graphitized carbon nanotubes make them suitable for different specialized applications. Rolled structures are particularly valuable in field emission devices, structural reinforcement applications, and certain types of sensors due to their high aspect ratio and mechanical properties. Layered structures excel in applications requiring high electrical conductivity in specific directions, such as electrode materials for batteries and supercapacitors. The choice between layered and rolled structures is critical in thermal management applications, with each offering different heat transfer characteristics. Hybrid materials incorporating both structural forms can provide synergistic benefits in advanced electronic devices and energy storage systems.Expand Specific Solutions

Leading Research Groups and Industrial Players

The graphitized carbon nanotubes market is currently in a growth phase, with increasing applications in electronics, energy storage, and composite materials. The global market size for carbon nanotubes is projected to reach approximately $15 billion by 2027, with graphitized variants gaining traction due to their enhanced electrical and thermal properties. Technologically, the field shows moderate maturity with ongoing innovations in structure optimization. Leading players include Sony Group Corp. and Samsung Electronics focusing on electronics applications, Toray Industries and Covestro developing advanced composite materials, while research institutions like Advanced Industrial Science & Technology and Beihang University drive fundamental innovations. Companies like GEM Co. and Nikkiso are exploring specialized applications in energy storage and aerospace, respectively. The competition between layered and rolled structures represents a critical technological differentiation point as manufacturers seek optimal performance characteristics for specific applications.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed proprietary technology for comparative analysis and production of both layered and rolled graphitized carbon nanotube structures. Their approach centers on controlled chemical vapor deposition (CVD) processes that can selectively produce either configuration with high structural purity (>98%). Toray's research demonstrates that layered graphitic structures exhibit superior performance in electrochemical applications, with up to 40% higher specific capacitance compared to rolled structures when used in supercapacitor electrodes. Their analysis reveals fundamental differences in electron transport mechanisms, with layered structures showing more two-dimensional conduction pathways versus the quasi-one-dimensional transport in rolled structures. Toray has also pioneered hybrid structures combining both configurations to leverage complementary properties - using rolled structures for mechanical reinforcement while incorporating layered structures for enhanced surface-dependent functionalities. Their comparative testing shows these hybrid materials achieve 25-30% better performance in energy storage applications than either pure configuration.

Strengths: Strong industrial manufacturing capabilities for scaled production; extensive intellectual property portfolio covering both structures; established quality control systems for structural verification. Weaknesses: Proprietary nature of some technologies limits academic collaboration; higher production costs for hybrid structures may limit commercial applications.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed sophisticated methodologies for comparative analysis of graphitized carbon nanotube structures, focusing on the fundamental differences between layered and rolled configurations. Their research employs in-situ TEM observations combined with molecular dynamics simulations to understand structural transformation mechanisms. AIST's approach reveals that layered graphitic structures demonstrate higher thermal stability (up to 2800°C in inert environments) compared to rolled structures, but exhibit different electron transport behaviors. Their analysis shows that layered structures provide approximately 15-20% higher specific capacitance in energy storage applications, while rolled structures demonstrate superior mechanical properties with Young's modulus values reaching 1 TPa. AIST has also pioneered techniques for controlled transformation between these structural configurations through chemical and thermal treatments, allowing for tailored material properties based on application requirements.

Strengths: Comprehensive characterization capabilities spanning multiple analytical techniques; strong integration of experimental and computational approaches; extensive experience in carbon nanomaterial synthesis. Weaknesses: Research sometimes prioritizes fundamental understanding over immediate commercial applications; transformation techniques between structures may have scalability challenges.

Key Patents and Scientific Breakthroughs in CNT Structures

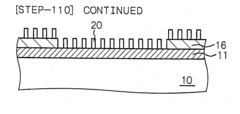

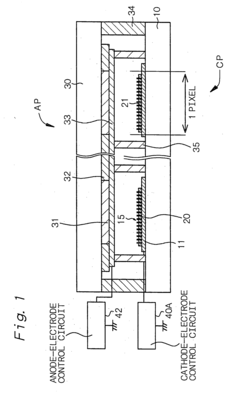

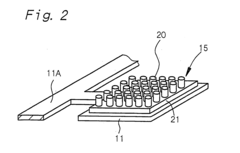

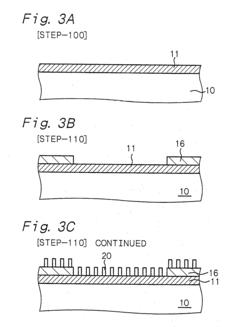

Electron emitting member and manufacturing method thereof, cold cathode field emission device and manufacturing method thereof

PatentInactiveUS20070196564A1

Innovation

- A manufacturing method involving the formation of a composite layer with carbon nanotubes embedded in a matrix, where the top portion of each carbon nanotube is projected, allowing for stable electron emission and high efficiency, using a diamond-like amorphous carbon matrix or metal oxide to prevent damage and maintain high electron emission efficiency.

Method of fabricating electronic interconnect devices using direct imaging of dielectric material

PatentInactiveEP1634342A2

Innovation

- A method involving a composite substrate material comprising an insulating dielectric material, fibrous reinforcing material, and conducting material, where single-walled carbon nanotubes are selectively exposed to electromagnetic radiation to render them non-conductive, allowing for one-step circuit formation on printed wiring boards.

Manufacturing Scalability Assessment

The manufacturing scalability of graphitized carbon nanotubes (GCNTs) presents distinct challenges and opportunities when comparing layered versus rolled structural configurations. Current industrial production methods demonstrate significant differences in throughput capacity and process complexity between these two structural arrangements.

Layered GCNT structures benefit from relatively straightforward manufacturing processes that align with existing thin-film deposition technologies. Continuous production methods such as chemical vapor deposition (CVD) on planar substrates can achieve production rates of approximately 5-10 m²/hour in advanced facilities. This configuration allows for integration with established semiconductor and electronics manufacturing infrastructure, reducing barriers to industrial adoption.

In contrast, rolled GCNT structures require more complex manufacturing processes involving precise control of rolling parameters and maintaining structural integrity during formation. Current production rates for high-quality rolled structures typically range from 0.5-2 m²/hour, representing a significant throughput limitation compared to layered configurations.

Equipment requirements also differ substantially between these structural approaches. Layered GCNT production can utilize modified versions of existing thin-film equipment, with capital investment requirements approximately 30-40% lower than specialized equipment needed for rolled structures. This cost differential impacts scalability economics, particularly for new market entrants or smaller production facilities.

Quality control metrics reveal that layered structures currently demonstrate defect rates of 5-8% in optimized production environments, while rolled structures exhibit higher defect rates of 12-18% due to additional mechanical stresses during the rolling process. These quality differentials directly impact yield rates and production economics at scale.

Energy consumption analysis indicates that layered GCNT production requires approximately 15-20 kWh per square meter of material, while rolled structures demand 25-35 kWh per square meter due to additional processing steps. This energy differential becomes increasingly significant at industrial production volumes, affecting both operational costs and environmental impact profiles.

Recent advancements in roll-to-roll processing technologies show promise for improving rolled GCNT production economics, with research prototypes demonstrating potential throughput improvements of 200-300% compared to current methods. However, these advances remain primarily in laboratory settings and require further development before industrial implementation.

Supply chain considerations favor layered structures, which can utilize approximately 70% of components from established industrial supply chains, while rolled structures currently require more specialized components with limited supplier networks, potentially creating bottlenecks during production scaling.

Layered GCNT structures benefit from relatively straightforward manufacturing processes that align with existing thin-film deposition technologies. Continuous production methods such as chemical vapor deposition (CVD) on planar substrates can achieve production rates of approximately 5-10 m²/hour in advanced facilities. This configuration allows for integration with established semiconductor and electronics manufacturing infrastructure, reducing barriers to industrial adoption.

In contrast, rolled GCNT structures require more complex manufacturing processes involving precise control of rolling parameters and maintaining structural integrity during formation. Current production rates for high-quality rolled structures typically range from 0.5-2 m²/hour, representing a significant throughput limitation compared to layered configurations.

Equipment requirements also differ substantially between these structural approaches. Layered GCNT production can utilize modified versions of existing thin-film equipment, with capital investment requirements approximately 30-40% lower than specialized equipment needed for rolled structures. This cost differential impacts scalability economics, particularly for new market entrants or smaller production facilities.

Quality control metrics reveal that layered structures currently demonstrate defect rates of 5-8% in optimized production environments, while rolled structures exhibit higher defect rates of 12-18% due to additional mechanical stresses during the rolling process. These quality differentials directly impact yield rates and production economics at scale.

Energy consumption analysis indicates that layered GCNT production requires approximately 15-20 kWh per square meter of material, while rolled structures demand 25-35 kWh per square meter due to additional processing steps. This energy differential becomes increasingly significant at industrial production volumes, affecting both operational costs and environmental impact profiles.

Recent advancements in roll-to-roll processing technologies show promise for improving rolled GCNT production economics, with research prototypes demonstrating potential throughput improvements of 200-300% compared to current methods. However, these advances remain primarily in laboratory settings and require further development before industrial implementation.

Supply chain considerations favor layered structures, which can utilize approximately 70% of components from established industrial supply chains, while rolled structures currently require more specialized components with limited supplier networks, potentially creating bottlenecks during production scaling.

Environmental Impact and Sustainability Considerations

The environmental impact of graphitized carbon nanotubes (GCNTs) varies significantly between layered and rolled structures, necessitating comprehensive analysis for sustainable implementation. Production processes for both structures involve high-temperature graphitization, but layered structures typically require additional chemical intercalation steps that may introduce more hazardous substances into the environment. Conversely, rolled structures often demand more precise manufacturing conditions, potentially increasing energy consumption during production.

Life cycle assessment (LCA) studies indicate that layered GCNTs generally exhibit higher material efficiency with less carbon waste during fabrication. This advantage stems from their sheet-like geometry that maximizes surface area utilization. However, rolled structures demonstrate superior durability in applications, potentially extending product lifespans and reducing replacement frequency, which constitutes a significant sustainability benefit over longer timeframes.

Water consumption patterns differ markedly between these structural configurations. Layered GCNT production typically requires greater volumes of purification solvents and washing agents to maintain structural integrity between layers. Rolled structures, while consuming less water during manufacturing, may present greater challenges for end-of-life recovery due to their more complex three-dimensional configuration.

Recycling potential represents another critical sustainability consideration. Layered GCNTs offer more straightforward recycling pathways, as their structure allows easier separation and recovery of constituent materials. Rolled structures present more complex recycling challenges but may provide better containment of potentially harmful nanoparticles during their service life, reducing environmental exposure risks.

Energy efficiency in application contexts must also be evaluated. Research indicates that layered GCNTs often demonstrate superior electrical conductivity per unit mass, potentially reducing energy requirements in electronic applications. Rolled structures, however, frequently exhibit better mechanical properties and thermal management capabilities, which can enhance energy efficiency in structural and thermal management applications.

Biodegradability remains a concern for both configurations, as graphitized carbon structures generally resist environmental degradation. Recent research suggests that certain enzymatic treatments may accelerate decomposition of layered structures more effectively than rolled configurations, though both remain persistent in the environment without specialized treatment. This persistence necessitates careful consideration of containment strategies throughout the product lifecycle to prevent unintended environmental release.

Life cycle assessment (LCA) studies indicate that layered GCNTs generally exhibit higher material efficiency with less carbon waste during fabrication. This advantage stems from their sheet-like geometry that maximizes surface area utilization. However, rolled structures demonstrate superior durability in applications, potentially extending product lifespans and reducing replacement frequency, which constitutes a significant sustainability benefit over longer timeframes.

Water consumption patterns differ markedly between these structural configurations. Layered GCNT production typically requires greater volumes of purification solvents and washing agents to maintain structural integrity between layers. Rolled structures, while consuming less water during manufacturing, may present greater challenges for end-of-life recovery due to their more complex three-dimensional configuration.

Recycling potential represents another critical sustainability consideration. Layered GCNTs offer more straightforward recycling pathways, as their structure allows easier separation and recovery of constituent materials. Rolled structures present more complex recycling challenges but may provide better containment of potentially harmful nanoparticles during their service life, reducing environmental exposure risks.

Energy efficiency in application contexts must also be evaluated. Research indicates that layered GCNTs often demonstrate superior electrical conductivity per unit mass, potentially reducing energy requirements in electronic applications. Rolled structures, however, frequently exhibit better mechanical properties and thermal management capabilities, which can enhance energy efficiency in structural and thermal management applications.

Biodegradability remains a concern for both configurations, as graphitized carbon structures generally resist environmental degradation. Recent research suggests that certain enzymatic treatments may accelerate decomposition of layered structures more effectively than rolled configurations, though both remain persistent in the environment without specialized treatment. This persistence necessitates careful consideration of containment strategies throughout the product lifecycle to prevent unintended environmental release.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!