Research on Graphitized carbon nanotubes for advanced electrodes and energy devices

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Technology Evolution and Objectives

Carbon nanotubes (CNTs) have evolved significantly since their discovery in 1991 by Sumio Iijima. The journey of graphitized CNTs represents a fascinating progression from fundamental carbon science to advanced energy applications. Initially, CNTs were primarily studied as novel carbon allotropes with unique structural properties. By the late 1990s, researchers began exploring thermal treatment processes to enhance CNT crystallinity, marking the early stages of graphitization techniques.

The graphitization process fundamentally transforms standard CNTs by increasing their sp2 carbon content, reducing defects, and enhancing their electrical conductivity. This evolution accelerated in the early 2000s when researchers established correlations between graphitization temperature and resulting electronic properties. The field gained significant momentum around 2005-2010 when energy storage applications began demanding electrode materials with superior conductivity and stability.

A critical milestone occurred when researchers demonstrated that graphitized CNTs could achieve conductivity values approaching those of theoretical limits for carbon structures. This breakthrough expanded their potential applications beyond basic electronics into advanced energy systems including supercapacitors, lithium-ion batteries, and fuel cells. The period between 2010-2015 saw substantial refinement of graphitization techniques, including catalyst-assisted methods and hybrid thermal-chemical approaches.

Recent technological evolution has focused on scalable production methods and precise control over the degree of graphitization. Current objectives center on optimizing graphitized CNTs for specific energy applications by tailoring their surface chemistry, porosity, and interfacial properties. Researchers aim to achieve graphitized CNTs with conductivity exceeding 10^6 S/m while maintaining mechanical integrity and processability for industrial applications.

The primary technological goal is developing graphitized CNTs that can enable next-generation energy storage devices with energy densities surpassing 500 Wh/kg while maintaining high power capabilities. Secondary objectives include enhancing cycle stability beyond 10,000 cycles and reducing production costs to below $100/kg to enable commercial viability. Researchers are also pursuing graphitized CNT composites that can function effectively in extreme conditions, including high temperatures (>200°C) and corrosive environments.

Looking forward, the field is moving toward precision-engineered graphitized CNTs with tailored properties for specific applications, moving beyond generic high-conductivity materials toward application-optimized variants. The integration of computational modeling with experimental approaches is accelerating this evolution, enabling rational design of graphitized CNT structures for targeted performance metrics in energy devices.

The graphitization process fundamentally transforms standard CNTs by increasing their sp2 carbon content, reducing defects, and enhancing their electrical conductivity. This evolution accelerated in the early 2000s when researchers established correlations between graphitization temperature and resulting electronic properties. The field gained significant momentum around 2005-2010 when energy storage applications began demanding electrode materials with superior conductivity and stability.

A critical milestone occurred when researchers demonstrated that graphitized CNTs could achieve conductivity values approaching those of theoretical limits for carbon structures. This breakthrough expanded their potential applications beyond basic electronics into advanced energy systems including supercapacitors, lithium-ion batteries, and fuel cells. The period between 2010-2015 saw substantial refinement of graphitization techniques, including catalyst-assisted methods and hybrid thermal-chemical approaches.

Recent technological evolution has focused on scalable production methods and precise control over the degree of graphitization. Current objectives center on optimizing graphitized CNTs for specific energy applications by tailoring their surface chemistry, porosity, and interfacial properties. Researchers aim to achieve graphitized CNTs with conductivity exceeding 10^6 S/m while maintaining mechanical integrity and processability for industrial applications.

The primary technological goal is developing graphitized CNTs that can enable next-generation energy storage devices with energy densities surpassing 500 Wh/kg while maintaining high power capabilities. Secondary objectives include enhancing cycle stability beyond 10,000 cycles and reducing production costs to below $100/kg to enable commercial viability. Researchers are also pursuing graphitized CNT composites that can function effectively in extreme conditions, including high temperatures (>200°C) and corrosive environments.

Looking forward, the field is moving toward precision-engineered graphitized CNTs with tailored properties for specific applications, moving beyond generic high-conductivity materials toward application-optimized variants. The integration of computational modeling with experimental approaches is accelerating this evolution, enabling rational design of graphitized CNT structures for targeted performance metrics in energy devices.

Market Analysis for Advanced Electrode Materials

The global market for advanced electrode materials has witnessed substantial growth in recent years, primarily driven by the increasing demand for high-performance energy storage and conversion devices. The market value for advanced electrode materials reached approximately $15 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.7% through 2030, potentially reaching $30 billion by the end of the decade.

Graphitized carbon nanotubes (GCNTs) represent a rapidly expanding segment within this market, with their unique combination of electrical conductivity, mechanical strength, and surface area properties positioning them as premium materials for next-generation electrodes. The GCNT market segment was valued at $1.2 billion in 2022 and is expected to grow at a CAGR of 12.3% through 2028.

The electric vehicle (EV) sector constitutes the largest application area for advanced electrode materials, accounting for approximately 45% of the total market share. The push for higher energy density batteries with faster charging capabilities has intensified demand for GCNT-enhanced electrodes, which can significantly improve battery performance metrics. Major automotive manufacturers have increased their R&D investments in GCNT technology by an average of 18% annually since 2020.

Consumer electronics represents the second-largest market segment (27%), where the demand for smaller yet more powerful devices continues to drive innovation in electrode materials. GCNTs enable thinner, more flexible battery designs while maintaining or improving energy capacity, making them particularly valuable for wearable technology and foldable devices.

Renewable energy storage systems comprise a rapidly growing market segment (15%), with grid-scale storage solutions increasingly incorporating advanced electrode materials to improve efficiency and longevity. The remaining market share is distributed across medical devices, aerospace applications, and industrial equipment.

Regionally, Asia-Pacific dominates the market with 52% share, led by China, Japan, and South Korea, where major battery manufacturers have established production facilities. North America follows with 24% market share, while Europe accounts for 19%. Both regions are experiencing accelerated growth due to governmental policies supporting clean energy technologies and electric mobility.

The competitive landscape features both established materials companies and specialized startups. Key market challenges include scaling production while maintaining quality, reducing manufacturing costs, and addressing environmental concerns related to nanomaterial production. Despite these challenges, investor confidence remains strong, with venture capital funding for GCNT electrode technology startups exceeding $800 million in 2022 alone.

Graphitized carbon nanotubes (GCNTs) represent a rapidly expanding segment within this market, with their unique combination of electrical conductivity, mechanical strength, and surface area properties positioning them as premium materials for next-generation electrodes. The GCNT market segment was valued at $1.2 billion in 2022 and is expected to grow at a CAGR of 12.3% through 2028.

The electric vehicle (EV) sector constitutes the largest application area for advanced electrode materials, accounting for approximately 45% of the total market share. The push for higher energy density batteries with faster charging capabilities has intensified demand for GCNT-enhanced electrodes, which can significantly improve battery performance metrics. Major automotive manufacturers have increased their R&D investments in GCNT technology by an average of 18% annually since 2020.

Consumer electronics represents the second-largest market segment (27%), where the demand for smaller yet more powerful devices continues to drive innovation in electrode materials. GCNTs enable thinner, more flexible battery designs while maintaining or improving energy capacity, making them particularly valuable for wearable technology and foldable devices.

Renewable energy storage systems comprise a rapidly growing market segment (15%), with grid-scale storage solutions increasingly incorporating advanced electrode materials to improve efficiency and longevity. The remaining market share is distributed across medical devices, aerospace applications, and industrial equipment.

Regionally, Asia-Pacific dominates the market with 52% share, led by China, Japan, and South Korea, where major battery manufacturers have established production facilities. North America follows with 24% market share, while Europe accounts for 19%. Both regions are experiencing accelerated growth due to governmental policies supporting clean energy technologies and electric mobility.

The competitive landscape features both established materials companies and specialized startups. Key market challenges include scaling production while maintaining quality, reducing manufacturing costs, and addressing environmental concerns related to nanomaterial production. Despite these challenges, investor confidence remains strong, with venture capital funding for GCNT electrode technology startups exceeding $800 million in 2022 alone.

Current Status and Technical Barriers in Graphitized CNTs

Graphitized carbon nanotubes (g-CNTs) have emerged as promising materials for advanced electrode applications and energy storage devices. Currently, the global research landscape shows significant advancements in synthesis methods, with controlled thermal treatment at temperatures between 1800-3000°C being the predominant approach for transforming amorphous carbon into highly ordered graphitic structures. This process substantially enhances electrical conductivity, thermal stability, and mechanical strength of CNTs, making them superior to conventional carbon materials.

The commercial production of high-quality g-CNTs remains limited, with annual global production capacity estimated at approximately 5,000-7,000 tons. Major production centers are concentrated in Asia (particularly Japan, South Korea, and China), North America, and Western Europe, with emerging capabilities in countries like India and Brazil. This geographical distribution creates supply chain vulnerabilities for regions without domestic production capabilities.

Despite progress, several critical technical barriers impede widespread adoption of g-CNTs in energy applications. The foremost challenge is scalability of production processes that maintain structural integrity and performance characteristics. Current graphitization methods are energy-intensive and expensive, with estimated production costs ranging from $500-2,000 per kilogram for high-quality g-CNTs, significantly higher than conventional electrode materials.

Quality consistency presents another major obstacle. Batch-to-batch variations in graphitization degree, defect density, and impurity levels compromise performance reproducibility in energy devices. The industry lacks standardized characterization protocols and quality metrics, further complicating quality control efforts.

Integration challenges also persist at the device level. The incorporation of g-CNTs into existing manufacturing processes for batteries, supercapacitors, and fuel cells requires significant process modifications. Interface engineering between g-CNTs and other device components (electrolytes, current collectors, binders) remains suboptimal, limiting full performance potential.

Environmental considerations constitute another barrier, as graphitization processes generate significant carbon emissions (estimated 20-30 kg CO2 per kg of g-CNTs produced). Recycling and end-of-life management strategies for g-CNT-containing devices are underdeveloped, raising sustainability concerns.

Regulatory uncertainties further complicate commercialization. The unique physicochemical properties of g-CNTs raise questions about potential environmental and health impacts, with regulatory frameworks still evolving in most jurisdictions. This regulatory ambiguity creates market entry barriers and investment hesitation.

Addressing these technical and non-technical barriers requires coordinated efforts across the value chain, from materials scientists developing more efficient graphitization processes to device engineers optimizing integration strategies and regulatory bodies establishing clear guidelines for safe implementation.

The commercial production of high-quality g-CNTs remains limited, with annual global production capacity estimated at approximately 5,000-7,000 tons. Major production centers are concentrated in Asia (particularly Japan, South Korea, and China), North America, and Western Europe, with emerging capabilities in countries like India and Brazil. This geographical distribution creates supply chain vulnerabilities for regions without domestic production capabilities.

Despite progress, several critical technical barriers impede widespread adoption of g-CNTs in energy applications. The foremost challenge is scalability of production processes that maintain structural integrity and performance characteristics. Current graphitization methods are energy-intensive and expensive, with estimated production costs ranging from $500-2,000 per kilogram for high-quality g-CNTs, significantly higher than conventional electrode materials.

Quality consistency presents another major obstacle. Batch-to-batch variations in graphitization degree, defect density, and impurity levels compromise performance reproducibility in energy devices. The industry lacks standardized characterization protocols and quality metrics, further complicating quality control efforts.

Integration challenges also persist at the device level. The incorporation of g-CNTs into existing manufacturing processes for batteries, supercapacitors, and fuel cells requires significant process modifications. Interface engineering between g-CNTs and other device components (electrolytes, current collectors, binders) remains suboptimal, limiting full performance potential.

Environmental considerations constitute another barrier, as graphitization processes generate significant carbon emissions (estimated 20-30 kg CO2 per kg of g-CNTs produced). Recycling and end-of-life management strategies for g-CNT-containing devices are underdeveloped, raising sustainability concerns.

Regulatory uncertainties further complicate commercialization. The unique physicochemical properties of g-CNTs raise questions about potential environmental and health impacts, with regulatory frameworks still evolving in most jurisdictions. This regulatory ambiguity creates market entry barriers and investment hesitation.

Addressing these technical and non-technical barriers requires coordinated efforts across the value chain, from materials scientists developing more efficient graphitization processes to device engineers optimizing integration strategies and regulatory bodies establishing clear guidelines for safe implementation.

Current Graphitization Methods and Electrode Applications

01 Graphitization methods for carbon nanotube electrodes

Various methods are employed to graphitize carbon nanotubes for electrode applications, including high-temperature thermal treatment, laser irradiation, and chemical vapor deposition. These processes enhance the crystallinity and electrical conductivity of carbon nanotubes by transforming amorphous carbon into ordered graphitic structures. Graphitization typically occurs at temperatures above 2000°C, resulting in improved electron transfer properties and electrochemical performance when used as electrode materials.- Graphitization methods for carbon nanotube electrodes: Various methods are employed to graphitize carbon nanotubes for electrode applications, including high-temperature thermal treatment, laser irradiation, and chemical vapor deposition. These processes enhance the crystallinity and electrical conductivity of carbon nanotubes by converting amorphous carbon to graphitic structures. Graphitization typically occurs at temperatures above 2000°C, resulting in improved electron transfer properties and structural stability, which are crucial for high-performance electrodes in energy storage and conversion devices.

- Electrode composition and structure optimization: The performance of graphitized carbon nanotube electrodes can be significantly enhanced through composition and structural optimization. This includes controlling the nanotube alignment, density, length, and diameter, as well as incorporating additional components such as conductive polymers or metal nanoparticles. Multi-walled carbon nanotubes with specific graphitization degrees offer different performance characteristics compared to single-walled variants. Hierarchical structures combining graphitized nanotubes with other carbon materials can create synergistic effects that improve electrode performance in terms of conductivity, stability, and electrochemical activity.

- Applications in energy storage devices: Graphitized carbon nanotube electrodes are extensively used in various energy storage applications, including lithium-ion batteries, supercapacitors, and fuel cells. The high electrical conductivity, large surface area, and excellent mechanical properties of graphitized nanotubes contribute to improved energy density, power density, and cycling stability. In lithium-ion batteries, these electrodes facilitate faster lithium-ion diffusion and electron transport. For supercapacitors, they provide enhanced charge storage capacity and rate capability. The controlled graphitization degree can be tailored to specific energy storage requirements, optimizing performance for different applications.

- Surface functionalization and modification techniques: Surface functionalization of graphitized carbon nanotubes is employed to enhance their electrochemical properties and compatibility with electrolytes. Various techniques include chemical doping with nitrogen, boron, or other heteroatoms, acid treatment to introduce oxygen-containing functional groups, and coating with metal oxides or conductive polymers. These modifications can improve wettability, increase active sites for electrochemical reactions, and enhance the interface between the electrode and electrolyte. Controlled functionalization preserves the graphitic structure while introducing beneficial surface properties, resulting in electrodes with improved performance characteristics.

- Manufacturing processes for scalable production: Scalable manufacturing processes for graphitized carbon nanotube electrodes include continuous CVD methods, roll-to-roll processing, and spray deposition techniques. These approaches address challenges in mass production while maintaining quality and performance. Innovations in electrode fabrication involve controlling the graphitization process parameters, developing binder systems compatible with graphitized nanotubes, and optimizing electrode thickness and porosity. Advanced manufacturing techniques enable the production of flexible, transparent, or 3D-structured electrodes for specialized applications. Cost-effective methods for large-scale production focus on reducing energy consumption during graphitization while maintaining the desired electrochemical properties.

02 Composite electrodes with graphitized carbon nanotubes

Graphitized carbon nanotubes can be combined with other materials to create composite electrodes with enhanced properties. These composites often incorporate metal nanoparticles, conductive polymers, or other carbon materials like graphene. The synergistic effects between graphitized carbon nanotubes and these additional components result in electrodes with improved conductivity, mechanical strength, and electrochemical performance. Such composite electrodes find applications in energy storage devices, sensors, and electrocatalysis.Expand Specific Solutions03 Graphitized carbon nanotube electrodes for energy storage

Graphitized carbon nanotubes are particularly valuable as electrode materials in energy storage applications such as lithium-ion batteries, supercapacitors, and fuel cells. The graphitization process creates a more ordered carbon structure with improved electrical conductivity and electrochemical stability. These properties enable faster charge transfer, higher energy density, and longer cycle life in energy storage devices. The high surface area and porous structure of graphitized carbon nanotube electrodes also facilitate ion transport and electrolyte accessibility.Expand Specific Solutions04 Surface functionalization of graphitized carbon nanotube electrodes

Surface functionalization techniques can be applied to graphitized carbon nanotube electrodes to introduce specific chemical groups or modify their surface properties. These modifications can enhance electrode performance by improving wettability, increasing active sites for reactions, or enabling selective interactions with target molecules. Common functionalization methods include acid treatment, plasma processing, and chemical grafting. Functionalized graphitized carbon nanotube electrodes show improved performance in applications such as biosensing, electrochemical detection, and catalysis.Expand Specific Solutions05 Manufacturing processes for graphitized carbon nanotube electrodes

Various manufacturing techniques are employed to produce graphitized carbon nanotube electrodes with controlled structure and properties. These include solution-based methods like filtration, spray coating, and electrophoretic deposition, as well as direct growth approaches such as chemical vapor deposition on electrode substrates. Post-processing steps like compression, annealing, and patterning can further optimize electrode performance. Advanced manufacturing methods focus on achieving uniform dispersion of carbon nanotubes, good adhesion to substrates, and scalable production for commercial applications.Expand Specific Solutions

Leading Companies and Research Institutions in CNT Field

The graphitized carbon nanotube market for advanced electrodes and energy devices is in a growth phase, with increasing demand driven by the clean energy transition. The market is expanding rapidly as research demonstrates superior performance in energy storage applications. Technologically, the field is maturing with key players at different development stages. Tsinghua University and Nankai University lead academic research, while industrial players like Hon Hai Precision Industry and Panasonic Holdings are commercializing applications. The National Center for Nanoscience & Technology provides crucial infrastructure support. Companies like Hangzhou Highene Technology are developing specialized manufacturing processes, while established electronics manufacturers such as Honda Motor and FUJIFILM are integrating these materials into next-generation products, creating a competitive landscape spanning research institutions and commercial enterprises.

Tsinghua University

Technical Solution: Tsinghua University has developed innovative approaches to graphitized carbon nanotube electrodes focusing on scalable synthesis and performance optimization. Their research employs a two-stage catalytic CVD process followed by controlled high-temperature treatment (2200-2800°C) to achieve precise graphitization levels. Tsinghua's technology features nitrogen-doped graphitized CNTs with optimized pore structures that facilitate rapid ion diffusion while maintaining structural integrity. Their electrodes exhibit exceptional specific capacitance (>180 F/g) and rate capability (>85% capacity retention at 50A/g). A key innovation is their in-situ graphitization technique that allows simultaneous CNT growth and partial graphitization, reducing processing steps and energy consumption. Tsinghua researchers have also pioneered graphitized CNT-silicon composite anodes that effectively address silicon's volume expansion issues in lithium-ion batteries, achieving >1000 mAh/g capacity with 80% retention after 500 cycles. Their recent work includes graphitized CNT aerogels with ultra-low density (<10 mg/cm³) yet high mechanical strength for flexible energy storage devices.

Strengths: Excellent balance between graphitization degree and electrochemical active sites through controlled processing. The in-situ graphitization technique offers significant cost and energy savings in manufacturing. Weaknesses: Catalyst residues from the CVD process may affect electrochemical performance and require additional purification steps. Achieving uniform graphitization throughout large-scale CNT networks remains challenging.

Korea Advanced Institute of Science & Technology

Technical Solution: KAIST has developed sophisticated approaches to graphitized carbon nanotube electrodes focusing on structural engineering and interface optimization. Their research employs plasma-enhanced chemical vapor deposition (PECVD) followed by controlled thermal annealing at 2500-3000°C in inert atmospheres to achieve highly graphitized CNT structures. KAIST's technology features vertically aligned graphitized CNT arrays with precisely engineered interspacing (50-200 nm) that maximizes electrolyte accessibility while maintaining excellent electrical conductivity (>10⁴ S/cm). Their electrodes demonstrate exceptional power density (>10 kW/kg) and cycling stability (>95% capacity retention after 5000 cycles). A key innovation is their gradient graphitization technique that creates CNTs with varying degrees of graphitization from core to surface, optimizing both conductivity and electrochemical activity. KAIST researchers have also developed graphitized CNT-transition metal oxide hybrids where ultrathin metal oxide layers (3-5 nm) are uniformly deposited on graphitized CNTs, creating synergistic effects that enhance both capacity and rate capability for supercapacitors and lithium-ion batteries.

Strengths: Exceptional electrical conductivity and structural stability through controlled high-temperature graphitization. The vertically aligned architecture maximizes electrolyte accessibility and ion transport efficiency. Weaknesses: The high-temperature processing (2500-3000°C) increases production costs and energy consumption. Achieving uniform vertical alignment over large areas presents scaling challenges for industrial applications.

Key Patents and Breakthroughs in CNT Graphitization

NANO composite consisting of carbon nanotubes and metal oxide and method for manufacturing the same

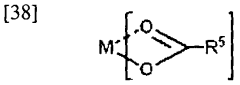

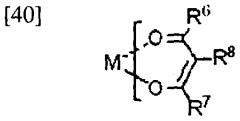

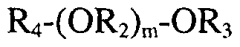

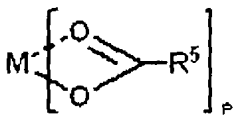

PatentWO2013048095A1

Innovation

- A method involving the dispersion of carbon nanotubes in a reductive solvent like polyhydric alcohols, addition of a co-reducing agent such as glycol ethers, and controlled heat treatment to form uniformly sized and shaped metal oxide nanoparticles on the surface of carbon nanotubes, ensuring uniform dispersion and coating type integration.

Graphenated carbon nanotubes, a method for preparing same and the use thereof as an electrode

PatentWO2018055226A2

Innovation

- A graphene-doped nanoporous carbon material is developed through a process involving resorcinol, formaldehyde, methanol, and graphene oxide, subjected to microwave heating and carbonization, resulting in a material with high specific surface area, electrical conductivity, and appropriate porosity for supercapacitor applications.

Sustainability and Scalability Considerations

The sustainability and scalability of graphitized carbon nanotube (GCNT) technologies represent critical factors in their successful transition from laboratory research to commercial applications in advanced electrodes and energy devices. Current production methods for GCNTs face significant environmental challenges, particularly regarding energy consumption during the graphitization process, which typically requires temperatures exceeding 2500°C. This intensive energy requirement contributes substantially to the carbon footprint of GCNT manufacturing, raising concerns about the environmental sustainability of these materials despite their potential benefits in clean energy applications.

Water usage and chemical waste management present additional sustainability concerns. Purification processes often involve strong acids and organic solvents that require careful handling and disposal to prevent environmental contamination. Recent research has focused on developing greener synthesis routes, including hydrothermal methods and microwave-assisted processes that can reduce energy consumption by up to 40% compared to conventional techniques.

From a scalability perspective, current GCNT production remains predominantly laboratory-scale, with global production capacity estimated at less than 500 tons annually. The transition to industrial-scale manufacturing faces several bottlenecks, including reactor design limitations, quality control challenges, and high capital investment requirements. Continuous flow reactors show promise for addressing these scalability issues, potentially increasing throughput by orders of magnitude while maintaining consistent product quality.

Raw material availability presents another critical consideration for long-term scalability. Carbon precursors and catalyst materials must be abundant and economically viable for large-scale production. Recent innovations in catalyst recovery and recycling have demonstrated recovery rates exceeding 85%, significantly improving the economic feasibility of scaled production.

Life cycle assessment (LCA) studies indicate that the environmental benefits of GCNT-enhanced energy devices may outweigh the production impacts if manufacturing processes can be optimized. For example, GCNT-based lithium-ion batteries potentially extend cycle life by 30-40%, reducing the overall environmental impact through longer product lifespans and decreased material consumption.

Economic viability remains closely tied to production scale. Current GCNT production costs range from $200-500 per kilogram, significantly higher than conventional electrode materials. Achieving price points below $100 per kilogram is widely considered the threshold for widespread commercial adoption in energy storage applications. Industry projections suggest this threshold could be reached within 5-7 years through continued process optimization and economies of scale.

Regulatory frameworks and standardization efforts will play crucial roles in facilitating sustainable scaling of GCNT technologies. The development of international standards for quality assessment, safety protocols, and environmental impact measurement will be essential for building market confidence and ensuring responsible industry growth.

Water usage and chemical waste management present additional sustainability concerns. Purification processes often involve strong acids and organic solvents that require careful handling and disposal to prevent environmental contamination. Recent research has focused on developing greener synthesis routes, including hydrothermal methods and microwave-assisted processes that can reduce energy consumption by up to 40% compared to conventional techniques.

From a scalability perspective, current GCNT production remains predominantly laboratory-scale, with global production capacity estimated at less than 500 tons annually. The transition to industrial-scale manufacturing faces several bottlenecks, including reactor design limitations, quality control challenges, and high capital investment requirements. Continuous flow reactors show promise for addressing these scalability issues, potentially increasing throughput by orders of magnitude while maintaining consistent product quality.

Raw material availability presents another critical consideration for long-term scalability. Carbon precursors and catalyst materials must be abundant and economically viable for large-scale production. Recent innovations in catalyst recovery and recycling have demonstrated recovery rates exceeding 85%, significantly improving the economic feasibility of scaled production.

Life cycle assessment (LCA) studies indicate that the environmental benefits of GCNT-enhanced energy devices may outweigh the production impacts if manufacturing processes can be optimized. For example, GCNT-based lithium-ion batteries potentially extend cycle life by 30-40%, reducing the overall environmental impact through longer product lifespans and decreased material consumption.

Economic viability remains closely tied to production scale. Current GCNT production costs range from $200-500 per kilogram, significantly higher than conventional electrode materials. Achieving price points below $100 per kilogram is widely considered the threshold for widespread commercial adoption in energy storage applications. Industry projections suggest this threshold could be reached within 5-7 years through continued process optimization and economies of scale.

Regulatory frameworks and standardization efforts will play crucial roles in facilitating sustainable scaling of GCNT technologies. The development of international standards for quality assessment, safety protocols, and environmental impact measurement will be essential for building market confidence and ensuring responsible industry growth.

Comparative Analysis with Alternative Electrode Materials

Graphitized carbon nanotubes (GCNTs) represent a significant advancement in electrode materials, yet their performance must be evaluated against established alternatives to fully understand their competitive advantages and limitations. Traditional carbon-based electrodes, including activated carbon, carbon black, and graphene, have dominated the market due to their cost-effectiveness and established manufacturing processes.

When comparing GCNTs with activated carbon, the former demonstrates superior electrical conductivity—typically 10-100 times higher—and significantly enhanced surface area utilization efficiency. However, activated carbon maintains advantages in raw material cost and established large-scale production infrastructure, making it still preferable for applications where cost sensitivity outweighs performance requirements.

Graphene-based electrodes offer comparable or sometimes superior electrical conductivity to GCNTs, with theoretical values approaching 6000 S/cm. Nevertheless, GCNTs demonstrate better mechanical stability in composite structures and superior performance in high-rate applications due to their unique tubular structure facilitating faster ion transport kinetics. Recent studies indicate that GCNT electrodes maintain up to 85% capacity at 10C discharge rates, compared to approximately 60% for graphene-based alternatives.

Metal oxide electrodes, particularly those based on ruthenium oxide and manganese oxide, provide higher theoretical capacitance than carbon-based materials. However, GCNTs offer substantially better cycling stability, with some formulations maintaining over 95% capacity after 10,000 cycles compared to 70-80% for metal oxide electrodes. The hybridization of GCNTs with metal oxides has emerged as a promising approach to leverage the advantages of both material classes.

Silicon and lithium-based electrode materials deliver higher energy density in battery applications but suffer from significant volume changes during cycling. GCNTs demonstrate remarkable structural stability, making them excellent scaffolds for these high-capacity materials. Recent research shows that GCNT-silicon composite electrodes can accommodate silicon's volumetric expansion while maintaining electrical connectivity throughout the electrode structure.

From a manufacturing perspective, GCNTs currently present higher production costs than traditional carbon materials, averaging $100-500/kg compared to $10-50/kg for activated carbon. However, ongoing advancements in synthesis methods, particularly continuous CVD processes, are progressively reducing this cost gap, with projections suggesting potential price parity within the next decade for certain applications.

Environmental considerations also favor GCNTs over several alternatives, particularly metal-based electrodes containing cobalt or nickel, as carbon nanotubes demonstrate lower toxicity profiles and better recyclability potential when properly processed.

When comparing GCNTs with activated carbon, the former demonstrates superior electrical conductivity—typically 10-100 times higher—and significantly enhanced surface area utilization efficiency. However, activated carbon maintains advantages in raw material cost and established large-scale production infrastructure, making it still preferable for applications where cost sensitivity outweighs performance requirements.

Graphene-based electrodes offer comparable or sometimes superior electrical conductivity to GCNTs, with theoretical values approaching 6000 S/cm. Nevertheless, GCNTs demonstrate better mechanical stability in composite structures and superior performance in high-rate applications due to their unique tubular structure facilitating faster ion transport kinetics. Recent studies indicate that GCNT electrodes maintain up to 85% capacity at 10C discharge rates, compared to approximately 60% for graphene-based alternatives.

Metal oxide electrodes, particularly those based on ruthenium oxide and manganese oxide, provide higher theoretical capacitance than carbon-based materials. However, GCNTs offer substantially better cycling stability, with some formulations maintaining over 95% capacity after 10,000 cycles compared to 70-80% for metal oxide electrodes. The hybridization of GCNTs with metal oxides has emerged as a promising approach to leverage the advantages of both material classes.

Silicon and lithium-based electrode materials deliver higher energy density in battery applications but suffer from significant volume changes during cycling. GCNTs demonstrate remarkable structural stability, making them excellent scaffolds for these high-capacity materials. Recent research shows that GCNT-silicon composite electrodes can accommodate silicon's volumetric expansion while maintaining electrical connectivity throughout the electrode structure.

From a manufacturing perspective, GCNTs currently present higher production costs than traditional carbon materials, averaging $100-500/kg compared to $10-50/kg for activated carbon. However, ongoing advancements in synthesis methods, particularly continuous CVD processes, are progressively reducing this cost gap, with projections suggesting potential price parity within the next decade for certain applications.

Environmental considerations also favor GCNTs over several alternatives, particularly metal-based electrodes containing cobalt or nickel, as carbon nanotubes demonstrate lower toxicity profiles and better recyclability potential when properly processed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!