Research on Graphitized carbon nanotubes for fast charging and high energy density applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Technology Evolution and Objectives

Carbon nanotubes (CNTs) have emerged as revolutionary nanomaterials since their formal identification in 1991, though their conceptual origins trace back to the 1950s. The evolution of graphitized carbon nanotubes represents a significant advancement in nanomaterial science, characterized by enhanced electrical conductivity, thermal stability, and structural integrity compared to conventional CNTs. This graphitization process, involving high-temperature thermal treatment (typically 1800-3000°C), transforms amorphous carbon into highly ordered graphitic structures, substantially improving electron mobility pathways.

The technological trajectory of graphitized CNTs has accelerated dramatically over the past decade, driven primarily by the exponential growth in energy storage demands across multiple sectors. Initial applications focused on basic composite reinforcement, but research quickly pivoted toward exploiting their exceptional electrical properties. By 2015, researchers had established fundamental correlations between graphitization degree and electrochemical performance, setting the foundation for energy storage applications.

Between 2016-2020, significant breakthroughs occurred in manufacturing scalability, with continuous production methods replacing batch processes, dramatically reducing costs while maintaining quality. Concurrently, surface functionalization techniques evolved to enhance CNT integration with various electrolyte systems and electrode materials, addressing previous compatibility challenges.

Recent developments (2020-present) have centered on precise structural control during graphitization, optimizing the balance between crystallinity and defect density—a critical factor for fast-charging capabilities. Advanced characterization techniques, including in-situ TEM and synchrotron-based methods, have enabled unprecedented insights into charge transfer mechanisms at the nanoscale, accelerating application-specific optimization.

The primary technical objectives for graphitized CNT research in energy storage applications include achieving charging rates exceeding 10C while maintaining 80% capacity retention over 1000+ cycles, developing manufacturing processes compatible with existing battery production infrastructure, and reducing production costs below $100/kg for commercial viability. Additionally, researchers aim to enhance energy density by at least 30% compared to current lithium-ion technologies through CNT-enabled electrode architectures.

Future research trajectories focus on hybrid structures combining graphitized CNTs with silicon, sulfur, or solid-state electrolytes to overcome current energy density limitations. Computational modeling approaches are increasingly employed to predict optimal graphitization parameters for specific applications, potentially reducing development cycles from years to months. The ultimate goal remains creating sustainable, high-performance energy storage solutions that enable widespread electrification across transportation, grid storage, and consumer electronics sectors.

The technological trajectory of graphitized CNTs has accelerated dramatically over the past decade, driven primarily by the exponential growth in energy storage demands across multiple sectors. Initial applications focused on basic composite reinforcement, but research quickly pivoted toward exploiting their exceptional electrical properties. By 2015, researchers had established fundamental correlations between graphitization degree and electrochemical performance, setting the foundation for energy storage applications.

Between 2016-2020, significant breakthroughs occurred in manufacturing scalability, with continuous production methods replacing batch processes, dramatically reducing costs while maintaining quality. Concurrently, surface functionalization techniques evolved to enhance CNT integration with various electrolyte systems and electrode materials, addressing previous compatibility challenges.

Recent developments (2020-present) have centered on precise structural control during graphitization, optimizing the balance between crystallinity and defect density—a critical factor for fast-charging capabilities. Advanced characterization techniques, including in-situ TEM and synchrotron-based methods, have enabled unprecedented insights into charge transfer mechanisms at the nanoscale, accelerating application-specific optimization.

The primary technical objectives for graphitized CNT research in energy storage applications include achieving charging rates exceeding 10C while maintaining 80% capacity retention over 1000+ cycles, developing manufacturing processes compatible with existing battery production infrastructure, and reducing production costs below $100/kg for commercial viability. Additionally, researchers aim to enhance energy density by at least 30% compared to current lithium-ion technologies through CNT-enabled electrode architectures.

Future research trajectories focus on hybrid structures combining graphitized CNTs with silicon, sulfur, or solid-state electrolytes to overcome current energy density limitations. Computational modeling approaches are increasingly employed to predict optimal graphitization parameters for specific applications, potentially reducing development cycles from years to months. The ultimate goal remains creating sustainable, high-performance energy storage solutions that enable widespread electrification across transportation, grid storage, and consumer electronics sectors.

Market Analysis for Fast Charging Energy Storage Solutions

The fast charging energy storage market is experiencing unprecedented growth, driven by the increasing adoption of electric vehicles (EVs) and portable electronics. The global market for fast charging solutions was valued at approximately $12.3 billion in 2022 and is projected to reach $49.7 billion by 2030, representing a compound annual growth rate (CAGR) of 19.2%. This remarkable expansion reflects the urgent consumer demand for reduced charging times while maintaining high energy density capabilities.

Consumer behavior studies indicate that charging anxiety remains a significant barrier to EV adoption, with 65% of potential buyers citing charging time as a major concern. This has created a substantial market opportunity for advanced materials like graphitized carbon nanotubes (GCNTs) that can facilitate faster charging without compromising battery life or safety.

The industrial sector represents another significant market segment, with demand for rapid-charging industrial equipment and grid-scale energy storage solutions growing at 22.3% annually. These applications require materials that can withstand thousands of charge-discharge cycles while maintaining structural integrity and performance—specifications that GCNTs are uniquely positioned to address.

Regional market analysis reveals that Asia-Pacific currently dominates the fast charging technology landscape, accounting for 43% of global market share, followed by North America (28%) and Europe (22%). China leads manufacturing capacity for advanced battery materials, while South Korea and Japan excel in high-precision battery technology development. The United States maintains competitive advantages in fundamental research and intellectual property related to nanotube technologies.

Market segmentation by application shows that automotive applications represent the largest share (38%), followed by consumer electronics (27%), industrial equipment (18%), and grid storage solutions (12%). The remaining 5% encompasses emerging applications including medical devices and aerospace technologies.

Demand forecasting models suggest that the market for GCNT-enhanced energy storage will grow at 24.7% CAGR through 2028, outpacing the broader energy storage market. This accelerated growth is attributed to the superior performance characteristics of graphitized carbon nanotubes, particularly their ability to enable ultra-fast charging while maintaining high energy density.

Customer willingness-to-pay analysis indicates that manufacturers are prepared to absorb a 15-20% premium for materials that can demonstrably reduce charging times by 50% or more while maintaining current energy density levels. This price elasticity creates a favorable environment for commercializing advanced GCNT technologies despite their potentially higher production costs.

Consumer behavior studies indicate that charging anxiety remains a significant barrier to EV adoption, with 65% of potential buyers citing charging time as a major concern. This has created a substantial market opportunity for advanced materials like graphitized carbon nanotubes (GCNTs) that can facilitate faster charging without compromising battery life or safety.

The industrial sector represents another significant market segment, with demand for rapid-charging industrial equipment and grid-scale energy storage solutions growing at 22.3% annually. These applications require materials that can withstand thousands of charge-discharge cycles while maintaining structural integrity and performance—specifications that GCNTs are uniquely positioned to address.

Regional market analysis reveals that Asia-Pacific currently dominates the fast charging technology landscape, accounting for 43% of global market share, followed by North America (28%) and Europe (22%). China leads manufacturing capacity for advanced battery materials, while South Korea and Japan excel in high-precision battery technology development. The United States maintains competitive advantages in fundamental research and intellectual property related to nanotube technologies.

Market segmentation by application shows that automotive applications represent the largest share (38%), followed by consumer electronics (27%), industrial equipment (18%), and grid storage solutions (12%). The remaining 5% encompasses emerging applications including medical devices and aerospace technologies.

Demand forecasting models suggest that the market for GCNT-enhanced energy storage will grow at 24.7% CAGR through 2028, outpacing the broader energy storage market. This accelerated growth is attributed to the superior performance characteristics of graphitized carbon nanotubes, particularly their ability to enable ultra-fast charging while maintaining high energy density.

Customer willingness-to-pay analysis indicates that manufacturers are prepared to absorb a 15-20% premium for materials that can demonstrably reduce charging times by 50% or more while maintaining current energy density levels. This price elasticity creates a favorable environment for commercializing advanced GCNT technologies despite their potentially higher production costs.

Current Limitations and Challenges in Graphitized CNT Development

Despite significant advancements in graphitized carbon nanotube (CNT) technology for energy storage applications, several critical limitations and challenges persist that hinder their widespread commercial adoption. The primary challenge remains in achieving consistent, large-scale production of high-quality graphitized CNTs with uniform properties. Current manufacturing processes suffer from batch-to-batch variations, leading to inconsistent performance in fast-charging applications and energy density capabilities.

The graphitization process itself presents significant technical hurdles. Traditional high-temperature thermal treatments (typically 2500-3000°C) required for effective graphitization are energy-intensive and costly, making mass production economically challenging. Additionally, these processes often result in structural defects and non-uniform graphitization across the CNT structure, compromising their electrochemical performance.

Surface functionalization of graphitized CNTs represents another major challenge. While pristine graphitized CNTs offer excellent electrical conductivity, their integration into electrode materials requires appropriate surface chemistry modifications. Current functionalization methods often damage the graphitic structure, creating a trade-off between improved electrolyte interaction and preserved electrical conductivity.

The interface between graphitized CNTs and other battery components remains problematic. Poor adhesion to current collectors and inadequate dispersion in electrode slurries lead to mechanical instability during cycling, particularly under fast-charging conditions. This results in capacity fading and reduced cycle life, undermining the advantages of using graphitized CNTs in the first place.

From a practical application perspective, the high cost of graphitized CNTs compared to conventional carbon materials presents a significant market barrier. The complex purification processes required to remove catalytic impurities and amorphous carbon further increase production costs, making it difficult to compete with established technologies on a cost-performance basis.

Safety concerns also persist, particularly regarding the potential release of nanomaterials during manufacturing, usage, or disposal. The long-term environmental and health impacts of graphitized CNTs remain inadequately understood, creating regulatory uncertainties that slow commercial adoption.

Finally, integration challenges exist when incorporating graphitized CNTs into existing battery manufacturing processes. Current industrial battery production lines are optimized for conventional materials, and significant modifications would be required to accommodate the unique processing requirements of graphitized CNT-based components, representing a substantial barrier to industrial implementation.

The graphitization process itself presents significant technical hurdles. Traditional high-temperature thermal treatments (typically 2500-3000°C) required for effective graphitization are energy-intensive and costly, making mass production economically challenging. Additionally, these processes often result in structural defects and non-uniform graphitization across the CNT structure, compromising their electrochemical performance.

Surface functionalization of graphitized CNTs represents another major challenge. While pristine graphitized CNTs offer excellent electrical conductivity, their integration into electrode materials requires appropriate surface chemistry modifications. Current functionalization methods often damage the graphitic structure, creating a trade-off between improved electrolyte interaction and preserved electrical conductivity.

The interface between graphitized CNTs and other battery components remains problematic. Poor adhesion to current collectors and inadequate dispersion in electrode slurries lead to mechanical instability during cycling, particularly under fast-charging conditions. This results in capacity fading and reduced cycle life, undermining the advantages of using graphitized CNTs in the first place.

From a practical application perspective, the high cost of graphitized CNTs compared to conventional carbon materials presents a significant market barrier. The complex purification processes required to remove catalytic impurities and amorphous carbon further increase production costs, making it difficult to compete with established technologies on a cost-performance basis.

Safety concerns also persist, particularly regarding the potential release of nanomaterials during manufacturing, usage, or disposal. The long-term environmental and health impacts of graphitized CNTs remain inadequately understood, creating regulatory uncertainties that slow commercial adoption.

Finally, integration challenges exist when incorporating graphitized CNTs into existing battery manufacturing processes. Current industrial battery production lines are optimized for conventional materials, and significant modifications would be required to accommodate the unique processing requirements of graphitized CNT-based components, representing a substantial barrier to industrial implementation.

Existing Graphitized CNT Implementation Approaches

01 Graphitized carbon nanotubes for battery electrodes

Graphitized carbon nanotubes can be used as electrode materials in batteries to enhance fast charging capabilities and energy density. The graphitization process improves the electrical conductivity and structural stability of carbon nanotubes, allowing for more efficient electron transfer during charging and discharging cycles. These properties make graphitized carbon nanotubes ideal for high-performance battery applications where rapid charging and high energy storage are required.- Graphitized carbon nanotubes for battery electrodes: Graphitized carbon nanotubes can be incorporated into battery electrodes to enhance fast charging capabilities and increase energy density. The graphitization process improves the electrical conductivity and structural stability of carbon nanotubes, allowing for more efficient electron transport during charging and discharging cycles. These materials can be used in lithium-ion batteries to achieve higher energy densities while maintaining fast charging capabilities.

- Surface modification of graphitized carbon nanotubes: Surface modification techniques can be applied to graphitized carbon nanotubes to further enhance their performance in energy storage applications. These modifications can include functionalization with specific chemical groups, coating with conductive polymers, or creating hybrid structures with other nanomaterials. Such modifications can improve the interface between the nanotubes and the electrolyte, leading to better ion transport, reduced internal resistance, and ultimately faster charging rates while maintaining high energy density.

- Composite materials with graphitized carbon nanotubes: Composite materials incorporating graphitized carbon nanotubes can be developed to achieve superior electrochemical performance. These composites often combine the nanotubes with other materials such as silicon, metal oxides, or graphene to create synergistic effects. The resulting materials can exhibit enhanced electrical conductivity, mechanical stability, and ion storage capacity, making them ideal for fast-charging battery applications with high energy density.

- Manufacturing processes for high-performance graphitized nanotubes: Specialized manufacturing processes can be employed to produce graphitized carbon nanotubes with optimized properties for energy storage applications. These processes may include controlled heat treatment under specific atmospheres, catalyst-assisted growth methods, or post-synthesis treatments. By carefully controlling the manufacturing parameters, it is possible to tailor the structure, purity, and degree of graphitization of the nanotubes to maximize their performance in fast-charging, high-energy-density applications.

- Electrode architecture design with graphitized carbon nanotubes: The architecture and design of electrodes incorporating graphitized carbon nanotubes play a crucial role in achieving fast charging and high energy density. Various approaches include creating three-dimensional networks, aligned nanotube arrays, or hierarchical structures that facilitate both electron and ion transport. Optimized electrode designs can minimize diffusion distances, reduce internal resistance, and provide sufficient space for electrolyte penetration, resulting in batteries that can be charged rapidly while storing large amounts of energy.

02 Synthesis methods for graphitized carbon nanotubes

Various synthesis methods can be employed to produce graphitized carbon nanotubes with optimized properties for energy storage applications. These methods include high-temperature thermal treatment, catalyst-assisted graphitization, and chemical vapor deposition techniques. The synthesis parameters significantly influence the degree of graphitization, tube morphology, and electrochemical performance, which directly impact the fast charging capabilities and energy density of the resulting materials.Expand Specific Solutions03 Composite materials with graphitized carbon nanotubes

Combining graphitized carbon nanotubes with other materials creates composite structures that exhibit enhanced electrochemical properties. These composites often incorporate metal oxides, conductive polymers, or other carbon materials to create synergistic effects. The resulting hybrid materials demonstrate improved ion diffusion pathways, increased active surface area, and better electrical conductivity, leading to superior fast charging performance and higher energy density in energy storage devices.Expand Specific Solutions04 Surface modification of graphitized carbon nanotubes

Surface modification techniques can be applied to graphitized carbon nanotubes to enhance their electrochemical properties. These modifications include functionalization with specific chemical groups, doping with heteroatoms, or creating defect sites on the nanotube surface. Such treatments can improve the wettability, ion adsorption capacity, and charge transfer kinetics of the nanotubes, resulting in better fast charging performance and increased energy density in battery applications.Expand Specific Solutions05 Device integration and performance optimization

Integrating graphitized carbon nanotubes into practical energy storage devices requires optimization of electrode architecture, electrolyte composition, and cell design. Techniques such as controlled nanotube alignment, optimized porosity, and tailored electrolyte formulations can maximize the fast charging capabilities and energy density of the final devices. Advanced manufacturing methods ensure uniform distribution of the nanotubes and proper interfacial contact with other components, leading to enhanced overall performance in real-world applications.Expand Specific Solutions

Key Patents and Scientific Breakthroughs in Graphitized CNT Technology

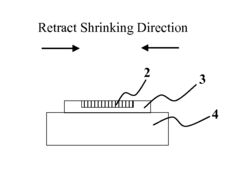

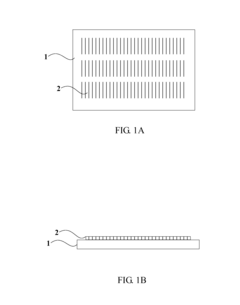

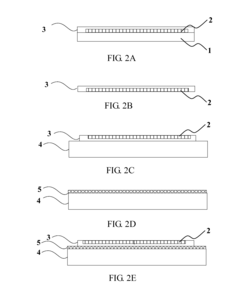

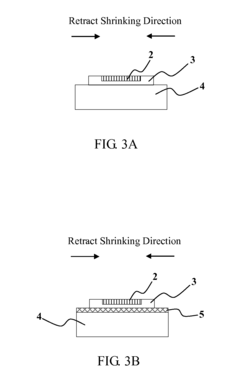

Method for increasing density of aligned carbon nanotubes

PatentActiveUS9340428B2

Innovation

- A method involving the transfer of aligned carbon nanotubes onto a uni-directionally stretched retractable film, which is then shrunk to increase density, and finally transferred to a target substrate using a chemical or mechanical method, utilizing materials like polymeric rubber or shape memory alloys to maintain alignment and prevent intertwining.

Safety and Performance Testing Standards for Fast-Charging Technologies

The development of fast-charging technologies utilizing graphitized carbon nanotubes necessitates comprehensive safety and performance testing standards to ensure reliability, consistency, and consumer safety. Current international standards for fast-charging batteries include IEC 61851 for electric vehicle charging systems and IEC 62196 for plugs and socket-outlets, which provide baseline requirements but require adaptation for nanotube-enhanced technologies.

Safety testing protocols for graphitized carbon nanotube applications must address thermal stability concerns through accelerated aging tests at elevated temperatures (45-60°C) and thermal runaway assessments. These tests evaluate the structural integrity of nanotube networks under extreme conditions and their resistance to degradation during rapid charging cycles.

Electrical safety standards focus on measuring leakage currents, insulation resistance, and dielectric strength of nanotube-enhanced components. The unique conductivity properties of graphitized carbon nanotubes require specialized testing methodologies beyond conventional battery standards, particularly for high-voltage fast-charging scenarios exceeding 100kW.

Performance testing frameworks must evaluate charging efficiency metrics, including coulombic efficiency (target >99%), energy efficiency (target >95%), and capacity retention after multiple fast-charging cycles. The ISO/IEC 17025 accreditation serves as the foundation for laboratory competence in conducting these specialized tests.

Cycle life assessment protocols typically require 1,000+ fast-charging cycles while maintaining at least 80% of initial capacity. For graphitized carbon nanotube applications, this standard should be elevated to 1,500+ cycles to account for the enhanced durability claims of these materials.

Environmental testing standards address the potential release of nanomaterials during use, recycling, or disposal. The OECD Guidelines for Testing of Chemicals provide methodologies for assessing environmental impacts, while UN Transportation of Dangerous Goods regulations govern shipping requirements for nanotube-enhanced batteries.

Emerging standards development is being led by organizations including IEEE, UL, and ASTM International, which are creating nanotechnology-specific testing protocols. The IEC Technical Committee 113 is specifically developing standards for nanotechnology in electrical and electronic products and systems that will impact graphitized carbon nanotube applications.

Harmonization of these standards across global markets remains a significant challenge, with regulatory bodies in North America, Europe, and Asia developing region-specific requirements that manufacturers must navigate to achieve global market access for fast-charging technologies incorporating graphitized carbon nanotubes.

Safety testing protocols for graphitized carbon nanotube applications must address thermal stability concerns through accelerated aging tests at elevated temperatures (45-60°C) and thermal runaway assessments. These tests evaluate the structural integrity of nanotube networks under extreme conditions and their resistance to degradation during rapid charging cycles.

Electrical safety standards focus on measuring leakage currents, insulation resistance, and dielectric strength of nanotube-enhanced components. The unique conductivity properties of graphitized carbon nanotubes require specialized testing methodologies beyond conventional battery standards, particularly for high-voltage fast-charging scenarios exceeding 100kW.

Performance testing frameworks must evaluate charging efficiency metrics, including coulombic efficiency (target >99%), energy efficiency (target >95%), and capacity retention after multiple fast-charging cycles. The ISO/IEC 17025 accreditation serves as the foundation for laboratory competence in conducting these specialized tests.

Cycle life assessment protocols typically require 1,000+ fast-charging cycles while maintaining at least 80% of initial capacity. For graphitized carbon nanotube applications, this standard should be elevated to 1,500+ cycles to account for the enhanced durability claims of these materials.

Environmental testing standards address the potential release of nanomaterials during use, recycling, or disposal. The OECD Guidelines for Testing of Chemicals provide methodologies for assessing environmental impacts, while UN Transportation of Dangerous Goods regulations govern shipping requirements for nanotube-enhanced batteries.

Emerging standards development is being led by organizations including IEEE, UL, and ASTM International, which are creating nanotechnology-specific testing protocols. The IEC Technical Committee 113 is specifically developing standards for nanotechnology in electrical and electronic products and systems that will impact graphitized carbon nanotube applications.

Harmonization of these standards across global markets remains a significant challenge, with regulatory bodies in North America, Europe, and Asia developing region-specific requirements that manufacturers must navigate to achieve global market access for fast-charging technologies incorporating graphitized carbon nanotubes.

Environmental Impact and Sustainability of Graphitized CNT Production

The production of graphitized carbon nanotubes (CNTs) presents significant environmental considerations that must be addressed as this technology scales for fast charging and high energy density applications. Traditional CNT manufacturing processes, particularly chemical vapor deposition (CVD), consume substantial energy and often utilize environmentally harmful catalysts and carbon feedstocks. The graphitization process itself, requiring temperatures exceeding 2500°C, further intensifies the carbon footprint of production.

Water usage represents another critical environmental concern, as purification and functionalization steps typically demand large volumes of water and potentially hazardous solvents. These processes generate contaminated wastewater containing metal catalysts and carbonaceous impurities that require specialized treatment before discharge to prevent ecosystem damage.

Airborne emissions during CNT production include volatile organic compounds, carbon monoxide, and ultrafine particulate matter. The potential release of CNT particulates themselves poses additional environmental and health risks that necessitate robust containment systems and workplace safety protocols.

From a sustainability perspective, the raw material sourcing for CNT production warrants careful consideration. Current methods rely heavily on fossil fuel-derived precursors, though research into bio-based carbon sources shows promise for reducing the overall environmental impact. The energy-intensive nature of graphitization has prompted investigations into renewable energy integration and process optimization to improve efficiency.

Life cycle assessment (LCA) studies indicate that the environmental benefits of graphitized CNTs in battery applications—including extended device lifespans and improved energy efficiency—may ultimately offset production impacts. However, these benefits depend on developing closed-loop recycling systems for CNT-containing devices, an area still in its infancy.

Recent innovations in green synthesis approaches demonstrate potential pathways toward more sustainable production. These include microwave-assisted synthesis, continuous-flow reactors that reduce energy consumption, and catalyst recovery systems that minimize waste. Several research groups have reported success with lower-temperature graphitization techniques that could substantially reduce energy requirements while maintaining performance characteristics.

Regulatory frameworks governing CNT production vary globally, with increasing emphasis on environmental compliance and sustainable manufacturing practices. Companies pioneering commercial-scale graphitized CNT production are increasingly adopting circular economy principles, implementing waste heat recovery systems, and exploring carbon capture technologies to mitigate environmental impacts.

Water usage represents another critical environmental concern, as purification and functionalization steps typically demand large volumes of water and potentially hazardous solvents. These processes generate contaminated wastewater containing metal catalysts and carbonaceous impurities that require specialized treatment before discharge to prevent ecosystem damage.

Airborne emissions during CNT production include volatile organic compounds, carbon monoxide, and ultrafine particulate matter. The potential release of CNT particulates themselves poses additional environmental and health risks that necessitate robust containment systems and workplace safety protocols.

From a sustainability perspective, the raw material sourcing for CNT production warrants careful consideration. Current methods rely heavily on fossil fuel-derived precursors, though research into bio-based carbon sources shows promise for reducing the overall environmental impact. The energy-intensive nature of graphitization has prompted investigations into renewable energy integration and process optimization to improve efficiency.

Life cycle assessment (LCA) studies indicate that the environmental benefits of graphitized CNTs in battery applications—including extended device lifespans and improved energy efficiency—may ultimately offset production impacts. However, these benefits depend on developing closed-loop recycling systems for CNT-containing devices, an area still in its infancy.

Recent innovations in green synthesis approaches demonstrate potential pathways toward more sustainable production. These include microwave-assisted synthesis, continuous-flow reactors that reduce energy consumption, and catalyst recovery systems that minimize waste. Several research groups have reported success with lower-temperature graphitization techniques that could substantially reduce energy requirements while maintaining performance characteristics.

Regulatory frameworks governing CNT production vary globally, with increasing emphasis on environmental compliance and sustainable manufacturing practices. Companies pioneering commercial-scale graphitized CNT production are increasingly adopting circular economy principles, implementing waste heat recovery systems, and exploring carbon capture technologies to mitigate environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!