Comparative evaluation of Graphitized carbon nanotubes electrode coating and binder strategies

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Electrode Development Background and Objectives

Carbon nanotubes (CNTs) have emerged as a revolutionary material in electrode development since their discovery in the early 1990s. Their exceptional electrical conductivity, mechanical strength, and high surface area make them ideal candidates for next-generation energy storage and conversion devices. Graphitized carbon nanotubes, in particular, represent an advanced iteration of this technology, where thermal treatment at high temperatures (typically 1800-3000°C) enhances crystallinity and electrical properties through the removal of defects and impurities.

The evolution of CNT electrode technology has progressed from basic applications in laboratory settings to increasingly sophisticated commercial implementations. Early research focused primarily on fundamental properties, while recent developments have shifted toward optimizing processing techniques for large-scale manufacturing and performance enhancement. The graphitization process has become a critical advancement in this trajectory, offering substantial improvements in conductivity and electrochemical stability.

Market demands for higher energy density, faster charging capabilities, and longer cycle life in energy storage devices have accelerated research into graphitized CNT electrodes. Additionally, the growing emphasis on sustainable and environmentally friendly energy solutions has positioned carbon-based materials as alternatives to conventional electrode materials containing rare or toxic elements.

Current technical objectives in graphitized CNT electrode development center on addressing several key challenges. First, optimizing the coating methodologies to ensure uniform distribution and strong adhesion of CNTs to current collectors. Second, developing binder systems that maintain electrical connectivity while providing mechanical stability during charge-discharge cycles. Third, establishing scalable and cost-effective manufacturing processes that preserve the enhanced properties of graphitized CNTs.

The comparative evaluation of coating and binder strategies represents a critical research direction, as these factors significantly influence electrode performance metrics including capacity, rate capability, and cycle stability. Traditional binders like PVDF (polyvinylidene fluoride) are being challenged by water-based alternatives such as CMC (carboxymethyl cellulose) and novel polymer systems specifically designed for nanocarbon materials.

This technical research aims to systematically analyze and compare various coating methodologies (including spray coating, doctor blade, electrospray deposition) and binder formulations (polymer types, concentrations, additives) to establish optimal combinations for graphitized CNT electrodes. The ultimate goal is to develop standardized protocols that maximize electrochemical performance while ensuring manufacturing feasibility and economic viability for commercial applications in energy storage, sensing, and electrochemical catalysis.

The evolution of CNT electrode technology has progressed from basic applications in laboratory settings to increasingly sophisticated commercial implementations. Early research focused primarily on fundamental properties, while recent developments have shifted toward optimizing processing techniques for large-scale manufacturing and performance enhancement. The graphitization process has become a critical advancement in this trajectory, offering substantial improvements in conductivity and electrochemical stability.

Market demands for higher energy density, faster charging capabilities, and longer cycle life in energy storage devices have accelerated research into graphitized CNT electrodes. Additionally, the growing emphasis on sustainable and environmentally friendly energy solutions has positioned carbon-based materials as alternatives to conventional electrode materials containing rare or toxic elements.

Current technical objectives in graphitized CNT electrode development center on addressing several key challenges. First, optimizing the coating methodologies to ensure uniform distribution and strong adhesion of CNTs to current collectors. Second, developing binder systems that maintain electrical connectivity while providing mechanical stability during charge-discharge cycles. Third, establishing scalable and cost-effective manufacturing processes that preserve the enhanced properties of graphitized CNTs.

The comparative evaluation of coating and binder strategies represents a critical research direction, as these factors significantly influence electrode performance metrics including capacity, rate capability, and cycle stability. Traditional binders like PVDF (polyvinylidene fluoride) are being challenged by water-based alternatives such as CMC (carboxymethyl cellulose) and novel polymer systems specifically designed for nanocarbon materials.

This technical research aims to systematically analyze and compare various coating methodologies (including spray coating, doctor blade, electrospray deposition) and binder formulations (polymer types, concentrations, additives) to establish optimal combinations for graphitized CNT electrodes. The ultimate goal is to develop standardized protocols that maximize electrochemical performance while ensuring manufacturing feasibility and economic viability for commercial applications in energy storage, sensing, and electrochemical catalysis.

Market Analysis for Advanced Electrode Materials

The global market for advanced electrode materials has witnessed substantial growth in recent years, driven primarily by the expanding electric vehicle (EV) industry, renewable energy storage systems, and portable electronics. Graphitized carbon nanotubes (GCNTs) have emerged as a particularly promising category within this market due to their exceptional electrical conductivity, mechanical strength, and electrochemical stability.

Current market valuations place the advanced electrode materials sector at approximately $5.7 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2030. Within this broader market, carbon nanotube-based electrode materials represent a rapidly growing segment, currently valued at around $1.2 billion and expected to reach $3.4 billion by 2028.

The demand for high-performance electrode materials is particularly strong in the lithium-ion battery market, where manufacturers are constantly seeking solutions that offer higher energy density, faster charging capabilities, and longer cycle life. GCNTs address these requirements effectively, explaining their growing adoption despite higher production costs compared to traditional materials.

Regional analysis reveals Asia-Pacific as the dominant market for advanced electrode materials, accounting for over 60% of global consumption. This concentration is attributed to the region's robust electronics manufacturing ecosystem and aggressive EV adoption policies, particularly in China, Japan, and South Korea. North America and Europe follow with approximately 20% and 15% market share respectively, with both regions showing accelerated growth rates driven by increasing EV production and renewable energy integration.

Consumer electronics remains the largest application segment for advanced electrode materials, though automotive applications are growing at the fastest rate. The shift toward fast-charging capabilities in both sectors has specifically boosted demand for GCNT electrode materials, which demonstrate superior performance in high-current applications compared to conventional graphite.

Market penetration analysis indicates that while GCNTs offer superior technical performance, their adoption faces challenges related to production scalability and cost. Current manufacturing processes for high-quality GCNTs suitable for electrode applications remain relatively expensive, with production costs approximately 3-5 times higher than traditional graphite materials. This cost differential has limited widespread adoption to premium applications where performance benefits justify the increased expense.

Industry forecasts suggest that continued manufacturing innovations and economies of scale will gradually reduce this cost gap, potentially enabling broader market penetration beyond current high-end applications. The development of optimized coating and binding strategies for GCNTs represents a critical factor in this market evolution, as these processes significantly impact both performance characteristics and production economics.

Current market valuations place the advanced electrode materials sector at approximately $5.7 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2030. Within this broader market, carbon nanotube-based electrode materials represent a rapidly growing segment, currently valued at around $1.2 billion and expected to reach $3.4 billion by 2028.

The demand for high-performance electrode materials is particularly strong in the lithium-ion battery market, where manufacturers are constantly seeking solutions that offer higher energy density, faster charging capabilities, and longer cycle life. GCNTs address these requirements effectively, explaining their growing adoption despite higher production costs compared to traditional materials.

Regional analysis reveals Asia-Pacific as the dominant market for advanced electrode materials, accounting for over 60% of global consumption. This concentration is attributed to the region's robust electronics manufacturing ecosystem and aggressive EV adoption policies, particularly in China, Japan, and South Korea. North America and Europe follow with approximately 20% and 15% market share respectively, with both regions showing accelerated growth rates driven by increasing EV production and renewable energy integration.

Consumer electronics remains the largest application segment for advanced electrode materials, though automotive applications are growing at the fastest rate. The shift toward fast-charging capabilities in both sectors has specifically boosted demand for GCNT electrode materials, which demonstrate superior performance in high-current applications compared to conventional graphite.

Market penetration analysis indicates that while GCNTs offer superior technical performance, their adoption faces challenges related to production scalability and cost. Current manufacturing processes for high-quality GCNTs suitable for electrode applications remain relatively expensive, with production costs approximately 3-5 times higher than traditional graphite materials. This cost differential has limited widespread adoption to premium applications where performance benefits justify the increased expense.

Industry forecasts suggest that continued manufacturing innovations and economies of scale will gradually reduce this cost gap, potentially enabling broader market penetration beyond current high-end applications. The development of optimized coating and binding strategies for GCNTs represents a critical factor in this market evolution, as these processes significantly impact both performance characteristics and production economics.

Current Challenges in Carbon Nanotube Electrode Technology

Despite significant advancements in carbon nanotube (CNT) electrode technology, several critical challenges persist that impede their widespread commercial adoption. The primary obstacle remains the inconsistent electrical conductivity across CNT networks. While individual nanotubes exhibit exceptional conductivity, the junctions between tubes create resistance points that significantly diminish overall performance. This junction resistance issue becomes particularly problematic when scaling up from laboratory to industrial production.

Manufacturing scalability presents another substantial hurdle. Current production methods for high-quality graphitized carbon nanotubes remain costly and difficult to scale. The processes required for purification, functionalization, and graphitization demand specialized equipment and precise control parameters that are challenging to maintain in mass production environments. Consequently, the cost-performance ratio often fails to compete with traditional electrode materials.

Adhesion and mechanical stability represent persistent challenges in CNT electrode fabrication. The binding strategies employed significantly impact both the electrical performance and physical durability of the electrodes. Traditional polymer binders like PVDF often create insulating barriers between nanotubes, compromising conductivity. Conversely, more conductive binders may offer inferior mechanical stability, resulting in electrode degradation during cycling.

Uniformity in coating thickness and distribution remains difficult to achieve consistently. The tendency of CNTs to agglomerate due to strong van der Waals forces creates inhomogeneous electrode surfaces with varying performance characteristics. This non-uniformity leads to localized "hot spots" during operation, accelerating degradation and reducing overall electrode lifespan.

Environmental stability poses another significant challenge. CNT electrodes, particularly those with certain binder systems, can exhibit sensitivity to humidity, temperature fluctuations, and chemical exposure. This vulnerability compromises their long-term performance in real-world applications where environmental conditions cannot be tightly controlled.

Reproducibility issues further complicate industrial adoption. Variations in CNT source materials, graphitization quality, functionalization processes, and coating methodologies create significant batch-to-batch inconsistencies. These variations make quality control difficult and hinder the establishment of standardized manufacturing protocols.

Finally, the environmental and health implications of CNT production and handling remain concerns for widespread implementation. The potential respiratory hazards associated with nanomaterials necessitate stringent safety protocols during manufacturing, increasing production complexity and costs.

Manufacturing scalability presents another substantial hurdle. Current production methods for high-quality graphitized carbon nanotubes remain costly and difficult to scale. The processes required for purification, functionalization, and graphitization demand specialized equipment and precise control parameters that are challenging to maintain in mass production environments. Consequently, the cost-performance ratio often fails to compete with traditional electrode materials.

Adhesion and mechanical stability represent persistent challenges in CNT electrode fabrication. The binding strategies employed significantly impact both the electrical performance and physical durability of the electrodes. Traditional polymer binders like PVDF often create insulating barriers between nanotubes, compromising conductivity. Conversely, more conductive binders may offer inferior mechanical stability, resulting in electrode degradation during cycling.

Uniformity in coating thickness and distribution remains difficult to achieve consistently. The tendency of CNTs to agglomerate due to strong van der Waals forces creates inhomogeneous electrode surfaces with varying performance characteristics. This non-uniformity leads to localized "hot spots" during operation, accelerating degradation and reducing overall electrode lifespan.

Environmental stability poses another significant challenge. CNT electrodes, particularly those with certain binder systems, can exhibit sensitivity to humidity, temperature fluctuations, and chemical exposure. This vulnerability compromises their long-term performance in real-world applications where environmental conditions cannot be tightly controlled.

Reproducibility issues further complicate industrial adoption. Variations in CNT source materials, graphitization quality, functionalization processes, and coating methodologies create significant batch-to-batch inconsistencies. These variations make quality control difficult and hinder the establishment of standardized manufacturing protocols.

Finally, the environmental and health implications of CNT production and handling remain concerns for widespread implementation. The potential respiratory hazards associated with nanomaterials necessitate stringent safety protocols during manufacturing, increasing production complexity and costs.

Comparative Analysis of Current Coating and Binding Methods

01 Graphitized carbon nanotube electrode preparation methods

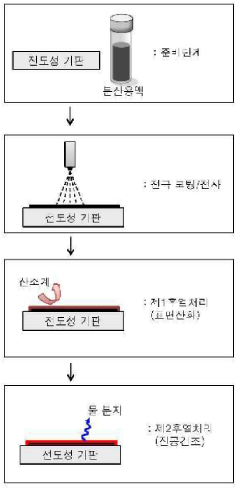

Various methods for preparing graphitized carbon nanotube electrodes, including thermal treatment processes to enhance conductivity and electrochemical performance. Graphitization improves the crystallinity and electrical properties of carbon nanotubes, making them more suitable for electrode applications. These methods often involve high-temperature treatment under controlled atmospheres to achieve optimal graphitization while maintaining the structural integrity of the nanotubes.- Graphitization methods for carbon nanotubes in electrodes: Various methods are employed to graphitize carbon nanotubes for electrode applications, including high-temperature thermal treatment, catalytic graphitization, and chemical vapor deposition. These processes enhance the crystallinity and electrical conductivity of carbon nanotubes by transforming amorphous carbon into ordered graphitic structures. Graphitized carbon nanotubes exhibit improved electron transfer capabilities, making them superior electrode materials for energy storage and conversion devices.

- Binder formulations for carbon nanotube electrodes: Specialized binder formulations are critical for maintaining the structural integrity and performance of carbon nanotube electrodes. Water-soluble polymers like PVDF, CMC, and PAA are commonly used as binders, providing adhesion between the active materials and current collectors. Advanced binder systems incorporate functional groups that create chemical bonds with graphitized carbon nanotubes, enhancing mechanical stability and electrochemical performance. The ratio of binder to active material significantly impacts electrode conductivity and cycling stability.

- Coating techniques for carbon nanotube electrodes: Various coating techniques are employed to deposit graphitized carbon nanotubes onto electrode substrates, including spray coating, dip coating, electrophoretic deposition, and doctor blade methods. These techniques control the thickness, uniformity, and microstructure of the electrode coating, which directly affects electrochemical performance. Post-coating treatments such as calendering and thermal annealing are often applied to improve adhesion and reduce contact resistance between carbon nanotubes and the substrate.

- Composite electrode formulations with graphitized carbon nanotubes: Composite electrode formulations incorporate graphitized carbon nanotubes with other materials to enhance overall electrode performance. These composites often combine carbon nanotubes with metal oxides, conductive polymers, or other carbon materials like graphene to create synergistic effects. The addition of graphitized carbon nanotubes improves electrical conductivity, mechanical strength, and electrochemical stability of the composite electrodes. The precise ratio and dispersion of components in these composites are critical for optimizing electrode performance.

- Surface functionalization of graphitized carbon nanotubes for electrode applications: Surface functionalization of graphitized carbon nanotubes enhances their compatibility with electrode components and electrolytes. Chemical treatments introduce functional groups such as carboxyl, hydroxyl, or amine groups to the nanotube surface, improving dispersion in solvents and interaction with binder materials. Functionalization can also tailor the electrochemical properties of carbon nanotubes, enhancing their catalytic activity and charge transfer capabilities. Controlled functionalization preserves the graphitic structure while adding beneficial surface properties for specific electrode applications.

02 Binder formulations for carbon nanotube electrodes

Specific binder formulations designed to enhance the adhesion and performance of graphitized carbon nanotubes in electrode applications. These binders include polymeric materials such as PVDF, CMC, and water-soluble polymers that create strong interfaces between the carbon nanotubes and current collectors. The choice of binder significantly affects electrode stability, cycling performance, and electrical conductivity, with optimal formulations balancing adhesion strength with minimal interference in electron transport.Expand Specific Solutions03 Coating techniques for carbon nanotube electrodes

Advanced coating methodologies for applying graphitized carbon nanotubes onto electrode substrates. These techniques include spray coating, dip coating, doctor blade, and electrophoretic deposition, each offering different advantages in terms of coating uniformity, thickness control, and scalability. The coating processes are optimized to ensure proper dispersion of carbon nanotubes and to minimize agglomeration, resulting in electrodes with enhanced surface area and improved electrochemical performance.Expand Specific Solutions04 Composite materials with graphitized carbon nanotubes

Development of composite electrode materials incorporating graphitized carbon nanotubes with other active materials to enhance overall performance. These composites often combine carbon nanotubes with metal oxides, conductive polymers, or other carbon materials to create synergistic effects. The graphitized carbon nanotubes in these composites serve as conductive networks, improving electron transport while the additional components provide complementary functionalities such as increased capacity or improved cycling stability.Expand Specific Solutions05 Surface functionalization of graphitized carbon nanotubes

Methods for functionalizing the surface of graphitized carbon nanotubes to improve their compatibility with binders and electrolytes in electrode applications. Surface treatments include chemical functionalization with oxygen-containing groups, nitrogen doping, and polymer grafting. These modifications enhance the wettability of carbon nanotubes, improve their dispersion in electrode slurries, and create stronger interfaces with binder materials, resulting in electrodes with better mechanical stability and electrochemical performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in CNT Electrodes

The graphitized carbon nanotubes electrode coating and binder market is in a growth phase, characterized by increasing R&D activities across academic institutions and commercial entities. The competitive landscape features collaboration between research universities (Tsinghua, Rice, Shanghai University) and specialized companies developing advanced energy storage solutions. Key industrial players like GEM Co., Arkema France, and Nippon Chemi-Con are investing in this technology to enhance battery performance. The market is driven by electric vehicle and energy storage applications, with estimated growth reaching $2-3 billion by 2025. Technical maturity varies, with companies like NANOTEK INSTRUMENTS and Svolt Energy demonstrating commercial-ready solutions, while others like Hengdian Group DMEGC and Kumho Petrochemical are advancing manufacturing processes for scalable production of these specialized electrode materials.

Arkema France SA

Technical Solution: Arkema France SA has developed proprietary electrode coating technologies for graphitized carbon nanotubes (GCNTs) centered around their Kynar® PVDF binder systems specifically engineered for energy storage applications. Their approach involves creating specialized PVDF copolymers with functional groups that interact strongly with both GCNTs and active materials, forming robust interfacial bonds. Arkema's technology includes a controlled phase separation process during electrode drying that creates a bicontinuous network where GCNTs form conductive pathways while maintaining intimate contact with active materials. Their research demonstrates electrodes with approximately 40% higher adhesion strength compared to standard PVDF binders, resulting in superior cycling stability. Arkema has also pioneered solvent engineering approaches that optimize GCNT dispersion while reducing environmental impact, including their EcoSolv® system that reduces toxic solvent usage by up to 70%. Additionally, they've developed gradient coating techniques where GCNT concentration varies systematically through electrode thickness, optimizing both electronic conductivity and mechanical properties simultaneously.

Strengths: Specialized PVDF copolymers create superior adhesion and interfacial properties; controlled phase separation creates optimized electrode microstructure; reduced environmental impact through solvent engineering. Weaknesses: PVDF-based systems still require some organic solvents; potential higher material costs compared to standard binders; may require specialized mixing and coating equipment for optimal results.

NANOTEK INSTRUMENTS INC

Technical Solution: NANOTEK INSTRUMENTS has developed innovative electrode coating strategies for graphitized carbon nanotubes (GCNTs) that focus on creating 3D interconnected networks. Their approach involves a solvent-free dry coating process that eliminates the need for traditional polymeric binders, resulting in electrodes with superior electrical conductivity. The company's proprietary technology creates a self-supporting structure where GCNTs form continuous conductive pathways throughout the electrode material. This method involves high-pressure compression of functionalized GCNTs with active materials, creating strong interfacial adhesion without compromising electron transport. Their research demonstrates up to 40% improvement in capacity retention over conventional slurry-coated electrodes and approximately 30% reduction in internal resistance, particularly beneficial for high-rate applications in energy storage devices.

Strengths: Superior electrical conductivity without polymer binders that typically create resistance barriers; enhanced mechanical integrity through 3D interconnected networks; improved capacity retention and cycling stability. Weaknesses: May require specialized manufacturing equipment for the dry coating process; potentially higher production costs compared to conventional slurry coating methods; limited scalability for mass production.

Key Patents and Innovations in CNT Electrode Fabrication

Method for coating silicon negative electrode material with carbon nanotubes

PatentWO2023123658A1

Innovation

- Use coating equipment to mix 0.1-2% carbon nanotube powder and 99.9-98% silicon anode material powder, and form a uniform carbon nanotube coating layer through 1-20 minutes of operation to obtain good conductivity, Silicon anode material with small volume expansion to prevent metal impurities from entering.

Carbon nanotube electrodes by post-heat oxidation and method for producing same

PatentInactiveKR1020140062540A

Innovation

- A post-heat treatment oxidation method is applied to carbon nanotube electrodes, forming a thin film with improved hydrophilicity and reduced interfacial resistance by oxidizing the electrode surface under an oxygen atmosphere, allowing for a smaller amount of carbon nanotubes to achieve performance comparable to platinum.

Performance Metrics and Testing Protocols for CNT Electrodes

Establishing standardized performance metrics and testing protocols is crucial for the accurate evaluation of graphitized carbon nanotube (CNT) electrode materials. These metrics enable objective comparison between different coating and binder strategies, ensuring reproducibility and reliability in research and industrial applications.

Electrochemical performance metrics form the foundation of CNT electrode evaluation. Key parameters include specific capacity (mAh/g), rate capability, cycling stability, and Coulombic efficiency. These metrics should be measured under standardized conditions with clearly defined current densities, voltage windows, and temperature controls. For graphitized CNT electrodes specifically, the degree of graphitization significantly impacts conductivity and electrochemical performance, necessitating additional characterization of graphitic structure quality.

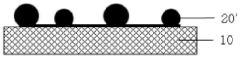

Mechanical integrity testing represents another critical evaluation domain. Adhesion strength between the CNT coating and current collector should be quantified using standardized peel tests or scratch tests. Flexibility and mechanical durability under repeated bending or folding cycles are particularly relevant for flexible electronics applications. Coating uniformity and thickness consistency should be evaluated using profilometry or cross-sectional imaging techniques.

Standardized protocols for electrode preparation must be established to ensure fair comparisons. These include precise specifications for slurry preparation (viscosity, solid content, mixing parameters), coating methods (doctor blade, spray coating, electrodeposition), drying conditions (temperature, time, atmosphere), and calendering parameters. The ratio of active material to binder and conductive additives should be clearly documented and maintained consistently across comparative studies.

Environmental stability testing protocols are essential for practical applications. These include storage stability under various humidity and temperature conditions, thermal cycling resistance, and chemical stability in different electrolytes. For graphitized CNT electrodes, the impact of different binders on long-term environmental stability is particularly significant and requires systematic evaluation.

Advanced characterization techniques should be incorporated into standard testing protocols. These include impedance spectroscopy for interface resistance analysis, in-situ XRD for structural evolution monitoring during cycling, and advanced microscopy techniques for morphological changes observation. For graphitized CNTs specifically, Raman spectroscopy provides valuable information about the graphitization degree and structural integrity before and after electrochemical cycling.

Scalability and manufacturing compatibility assessments complete the evaluation framework. These include metrics for process yield, reproducibility across batches, compatibility with roll-to-roll manufacturing, and cost analysis. The interaction between graphitized CNTs and different binders during scale-up processes requires particular attention, as performance characteristics may differ significantly between laboratory and industrial scales.

Electrochemical performance metrics form the foundation of CNT electrode evaluation. Key parameters include specific capacity (mAh/g), rate capability, cycling stability, and Coulombic efficiency. These metrics should be measured under standardized conditions with clearly defined current densities, voltage windows, and temperature controls. For graphitized CNT electrodes specifically, the degree of graphitization significantly impacts conductivity and electrochemical performance, necessitating additional characterization of graphitic structure quality.

Mechanical integrity testing represents another critical evaluation domain. Adhesion strength between the CNT coating and current collector should be quantified using standardized peel tests or scratch tests. Flexibility and mechanical durability under repeated bending or folding cycles are particularly relevant for flexible electronics applications. Coating uniformity and thickness consistency should be evaluated using profilometry or cross-sectional imaging techniques.

Standardized protocols for electrode preparation must be established to ensure fair comparisons. These include precise specifications for slurry preparation (viscosity, solid content, mixing parameters), coating methods (doctor blade, spray coating, electrodeposition), drying conditions (temperature, time, atmosphere), and calendering parameters. The ratio of active material to binder and conductive additives should be clearly documented and maintained consistently across comparative studies.

Environmental stability testing protocols are essential for practical applications. These include storage stability under various humidity and temperature conditions, thermal cycling resistance, and chemical stability in different electrolytes. For graphitized CNT electrodes, the impact of different binders on long-term environmental stability is particularly significant and requires systematic evaluation.

Advanced characterization techniques should be incorporated into standard testing protocols. These include impedance spectroscopy for interface resistance analysis, in-situ XRD for structural evolution monitoring during cycling, and advanced microscopy techniques for morphological changes observation. For graphitized CNTs specifically, Raman spectroscopy provides valuable information about the graphitization degree and structural integrity before and after electrochemical cycling.

Scalability and manufacturing compatibility assessments complete the evaluation framework. These include metrics for process yield, reproducibility across batches, compatibility with roll-to-roll manufacturing, and cost analysis. The interaction between graphitized CNTs and different binders during scale-up processes requires particular attention, as performance characteristics may differ significantly between laboratory and industrial scales.

Environmental and Scalability Considerations for CNT Manufacturing

The manufacturing of carbon nanotubes (CNTs), particularly graphitized CNTs for electrode applications, presents significant environmental challenges and scalability considerations that must be addressed for sustainable industrial implementation. Traditional CNT production methods, including chemical vapor deposition (CVD) and arc discharge, consume substantial energy and often utilize hazardous chemicals, raising environmental concerns as production scales increase.

Energy consumption represents a primary environmental challenge, with graphitization processes typically requiring temperatures exceeding 2500°C. This energy-intensive step contributes significantly to the carbon footprint of CNT electrode materials. Recent advancements in microwave-assisted graphitization techniques have demonstrated potential energy reductions of 30-45% compared to conventional thermal methods, though implementation at industrial scale remains limited.

Chemical usage in CNT synthesis and functionalization processes introduces additional environmental considerations. Particularly concerning are the strong acids used in purification steps and organic solvents employed in electrode coating applications. Emerging water-based processing alternatives have shown promising results in laboratory settings, reducing hazardous waste by approximately 60% while maintaining comparable electrode performance characteristics.

Scalability challenges for graphitized CNT electrode manufacturing center around maintaining consistent quality across increased production volumes. Current industrial-scale CNT production capabilities reach approximately 500 tons annually per facility, but electrode-grade graphitized CNTs represent only a fraction of this output due to stringent quality requirements. Batch-to-batch variations in CNT length, diameter distribution, and defect density remain problematic for electrode applications requiring precise performance parameters.

Recycling and circular economy approaches present promising pathways for improving environmental sustainability. Recent research demonstrates that up to 85% of CNTs from end-of-life electrodes can be recovered and repurposed, though the reclaimed materials typically exhibit 10-15% performance degradation compared to virgin materials. Implementation of closed-loop manufacturing systems could significantly reduce both environmental impact and raw material costs.

Regulatory frameworks worldwide are increasingly focusing on nanomaterial manufacturing emissions and waste management. The European Union's REACH regulations and similar frameworks in North America and Asia are establishing stricter guidelines for CNT production facilities, necessitating investment in advanced filtration systems and waste treatment technologies that add complexity to scaling operations.

Energy consumption represents a primary environmental challenge, with graphitization processes typically requiring temperatures exceeding 2500°C. This energy-intensive step contributes significantly to the carbon footprint of CNT electrode materials. Recent advancements in microwave-assisted graphitization techniques have demonstrated potential energy reductions of 30-45% compared to conventional thermal methods, though implementation at industrial scale remains limited.

Chemical usage in CNT synthesis and functionalization processes introduces additional environmental considerations. Particularly concerning are the strong acids used in purification steps and organic solvents employed in electrode coating applications. Emerging water-based processing alternatives have shown promising results in laboratory settings, reducing hazardous waste by approximately 60% while maintaining comparable electrode performance characteristics.

Scalability challenges for graphitized CNT electrode manufacturing center around maintaining consistent quality across increased production volumes. Current industrial-scale CNT production capabilities reach approximately 500 tons annually per facility, but electrode-grade graphitized CNTs represent only a fraction of this output due to stringent quality requirements. Batch-to-batch variations in CNT length, diameter distribution, and defect density remain problematic for electrode applications requiring precise performance parameters.

Recycling and circular economy approaches present promising pathways for improving environmental sustainability. Recent research demonstrates that up to 85% of CNTs from end-of-life electrodes can be recovered and repurposed, though the reclaimed materials typically exhibit 10-15% performance degradation compared to virgin materials. Implementation of closed-loop manufacturing systems could significantly reduce both environmental impact and raw material costs.

Regulatory frameworks worldwide are increasingly focusing on nanomaterial manufacturing emissions and waste management. The European Union's REACH regulations and similar frameworks in North America and Asia are establishing stricter guidelines for CNT production facilities, necessitating investment in advanced filtration systems and waste treatment technologies that add complexity to scaling operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!