How nanotube structure and material composition influence Graphitized carbon nanotubes efficiency

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotube Structure and Efficiency Goals

Graphitized carbon nanotubes (GCNTs) represent a significant advancement in nanomaterial science, evolving from conventional carbon nanotubes through specialized thermal treatment processes. The graphitization process transforms the carbon structure into a more ordered, crystalline arrangement, substantially enhancing electrical conductivity, thermal stability, and mechanical strength. Understanding how nanotube structure and material composition influence GCNT efficiency is crucial for optimizing their performance across various applications.

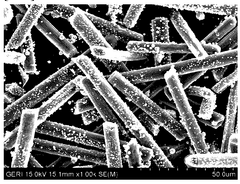

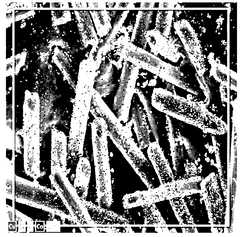

The structural characteristics of GCNTs, including diameter, length, wall thickness, and chirality, directly impact their functional properties. Single-walled nanotubes (SWNTs) typically exhibit superior electrical conductivity compared to multi-walled variants (MWNTs), while the latter often demonstrate enhanced mechanical robustness. The diameter of nanotubes significantly affects their surface area-to-volume ratio, with smaller diameters generally yielding higher surface areas beneficial for applications requiring extensive interaction sites.

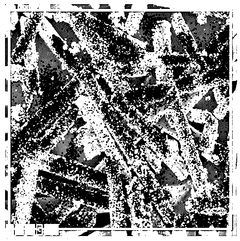

Chirality—the specific arrangement of carbon atoms along the nanotube axis—determines whether GCNTs exhibit metallic or semiconducting behavior. This property is particularly critical for electronic applications where precise conductivity characteristics are required. The graphitization degree, measured by the crystallinity and alignment of graphene layers, directly correlates with electrical conductivity and thermal stability improvements.

Material composition plays an equally vital role in GCNT efficiency. The carbon source material used during synthesis influences the resulting nanotube purity and defect concentration. High-purity carbon sources typically yield GCNTs with fewer structural defects, enhancing overall performance. Additionally, the incorporation of dopants or functional groups can strategically modify GCNT properties, enabling tailored characteristics for specific applications.

The graphitization temperature represents a critical parameter affecting GCNT quality. Higher temperatures (typically 2000-3000°C) promote more complete graphitization, resulting in superior crystallinity and reduced defect density. However, excessive temperatures may induce structural damage or unwanted phase transformations, highlighting the importance of precise temperature control during processing.

Our technical research aims to establish quantitative relationships between structural parameters, material composition, and resulting GCNT efficiency metrics. Key objectives include developing predictive models correlating nanotube diameter and wall configuration with electrical conductivity, establishing optimal graphitization protocols for various carbon precursors, and identifying synergistic dopant combinations that enhance specific performance attributes.

By systematically investigating these structure-property relationships, we aim to enable precise engineering of GCNTs with tailored characteristics for applications ranging from high-performance electronics to energy storage systems and advanced composite materials. This research will provide fundamental insights necessary for transitioning GCNTs from laboratory curiosities to commercially viable technological solutions.

The structural characteristics of GCNTs, including diameter, length, wall thickness, and chirality, directly impact their functional properties. Single-walled nanotubes (SWNTs) typically exhibit superior electrical conductivity compared to multi-walled variants (MWNTs), while the latter often demonstrate enhanced mechanical robustness. The diameter of nanotubes significantly affects their surface area-to-volume ratio, with smaller diameters generally yielding higher surface areas beneficial for applications requiring extensive interaction sites.

Chirality—the specific arrangement of carbon atoms along the nanotube axis—determines whether GCNTs exhibit metallic or semiconducting behavior. This property is particularly critical for electronic applications where precise conductivity characteristics are required. The graphitization degree, measured by the crystallinity and alignment of graphene layers, directly correlates with electrical conductivity and thermal stability improvements.

Material composition plays an equally vital role in GCNT efficiency. The carbon source material used during synthesis influences the resulting nanotube purity and defect concentration. High-purity carbon sources typically yield GCNTs with fewer structural defects, enhancing overall performance. Additionally, the incorporation of dopants or functional groups can strategically modify GCNT properties, enabling tailored characteristics for specific applications.

The graphitization temperature represents a critical parameter affecting GCNT quality. Higher temperatures (typically 2000-3000°C) promote more complete graphitization, resulting in superior crystallinity and reduced defect density. However, excessive temperatures may induce structural damage or unwanted phase transformations, highlighting the importance of precise temperature control during processing.

Our technical research aims to establish quantitative relationships between structural parameters, material composition, and resulting GCNT efficiency metrics. Key objectives include developing predictive models correlating nanotube diameter and wall configuration with electrical conductivity, establishing optimal graphitization protocols for various carbon precursors, and identifying synergistic dopant combinations that enhance specific performance attributes.

By systematically investigating these structure-property relationships, we aim to enable precise engineering of GCNTs with tailored characteristics for applications ranging from high-performance electronics to energy storage systems and advanced composite materials. This research will provide fundamental insights necessary for transitioning GCNTs from laboratory curiosities to commercially viable technological solutions.

Market Applications for Graphitized Carbon Nanotubes

Graphitized carbon nanotubes (GCNTs) have emerged as revolutionary materials with diverse market applications across multiple industries. Their exceptional properties, including high thermal conductivity, electrical conductivity, and mechanical strength, make them valuable components in numerous high-performance applications.

In the electronics industry, GCNTs are increasingly utilized in semiconductor manufacturing, where their structure-dependent electrical properties enable the development of more efficient transistors and integrated circuits. The degree of graphitization directly influences conductivity, with highly graphitized nanotubes showing superior performance in electronic applications. Companies are incorporating these materials into conductive films, transparent electrodes, and next-generation flexible electronics.

Energy storage represents another significant market, with GCNTs finding applications in lithium-ion batteries, supercapacitors, and fuel cells. The nanotube structure and composition critically affect energy density and charge-discharge cycles. Specifically, nitrogen-doped graphitized carbon nanotubes have demonstrated enhanced electrochemical properties for energy storage applications, while boron-doped variants show promise for hydrogen storage systems.

The aerospace and automotive sectors leverage GCNTs for lightweight composite materials that maintain exceptional strength. The aspect ratio and alignment of nanotubes within composite matrices determine the mechanical reinforcement efficiency. These composites are increasingly used in structural components where weight reduction without compromising strength is essential, leading to improved fuel efficiency and performance.

In environmental applications, GCNTs serve as advanced filtration materials and adsorbents. Their surface area and pore structure, which vary based on graphitization conditions, directly impact adsorption capacity for contaminants. Modified GCNTs with specific functional groups are being deployed in water purification systems and air filtration technologies.

The biomedical field represents an emerging market for GCNTs, particularly in drug delivery systems, biosensors, and tissue engineering. Surface functionalization of graphitized nanotubes influences their biocompatibility and interaction with biological systems. Researchers are developing cancer therapies utilizing GCNTs as carriers for targeted drug delivery, where the nanotube dimensions and surface chemistry determine cellular uptake efficiency.

Thermal management applications benefit from the exceptional thermal conductivity of GCNTs, which is directly related to their graphitization degree and structural perfection. These materials are incorporated into thermal interface materials for electronics cooling and heat spreaders in high-power devices, addressing critical thermal management challenges in miniaturized electronic systems.

In the electronics industry, GCNTs are increasingly utilized in semiconductor manufacturing, where their structure-dependent electrical properties enable the development of more efficient transistors and integrated circuits. The degree of graphitization directly influences conductivity, with highly graphitized nanotubes showing superior performance in electronic applications. Companies are incorporating these materials into conductive films, transparent electrodes, and next-generation flexible electronics.

Energy storage represents another significant market, with GCNTs finding applications in lithium-ion batteries, supercapacitors, and fuel cells. The nanotube structure and composition critically affect energy density and charge-discharge cycles. Specifically, nitrogen-doped graphitized carbon nanotubes have demonstrated enhanced electrochemical properties for energy storage applications, while boron-doped variants show promise for hydrogen storage systems.

The aerospace and automotive sectors leverage GCNTs for lightweight composite materials that maintain exceptional strength. The aspect ratio and alignment of nanotubes within composite matrices determine the mechanical reinforcement efficiency. These composites are increasingly used in structural components where weight reduction without compromising strength is essential, leading to improved fuel efficiency and performance.

In environmental applications, GCNTs serve as advanced filtration materials and adsorbents. Their surface area and pore structure, which vary based on graphitization conditions, directly impact adsorption capacity for contaminants. Modified GCNTs with specific functional groups are being deployed in water purification systems and air filtration technologies.

The biomedical field represents an emerging market for GCNTs, particularly in drug delivery systems, biosensors, and tissue engineering. Surface functionalization of graphitized nanotubes influences their biocompatibility and interaction with biological systems. Researchers are developing cancer therapies utilizing GCNTs as carriers for targeted drug delivery, where the nanotube dimensions and surface chemistry determine cellular uptake efficiency.

Thermal management applications benefit from the exceptional thermal conductivity of GCNTs, which is directly related to their graphitization degree and structural perfection. These materials are incorporated into thermal interface materials for electronics cooling and heat spreaders in high-power devices, addressing critical thermal management challenges in miniaturized electronic systems.

Current Challenges in Nanotube Material Composition

Despite significant advancements in graphitized carbon nanotube (GCNT) technology, several critical challenges persist regarding material composition that limit their efficiency and widespread application. One fundamental challenge involves achieving consistent carbon purity during the graphitization process. Current manufacturing methods struggle to eliminate catalyst residues and amorphous carbon impurities, which significantly impact electrical conductivity and thermal properties. These impurities create defect sites that interrupt the sp² hybridized carbon network, reducing overall performance.

The controlled incorporation of heteroatoms (nitrogen, boron, phosphorus) presents another significant hurdle. While heteroatom doping can enhance specific properties, precise control over doping concentration, distribution patterns, and bonding configurations remains difficult to achieve at industrial scales. This inconsistency leads to batch-to-batch variations that complicate quality control and performance predictability.

Surface functionalization of graphitized nanotubes introduces additional complexity. The trade-off between enhanced solubility/dispersibility and preservation of intrinsic electronic properties creates a delicate balance that researchers continue to struggle with. Aggressive functionalization methods often damage the graphitic structure, while milder approaches may not provide sufficient functional group density for specific applications.

The scalable production of composition-controlled GCNTs represents perhaps the most pressing challenge. Laboratory-scale synthesis methods that produce high-quality, composition-controlled nanotubes often fail to translate to industrial production environments. The gap between small-batch excellence and mass production consistency remains substantial, limiting commercial viability.

Material characterization techniques also present limitations. Current analytical methods struggle to provide comprehensive, high-resolution data on the three-dimensional distribution of elements and defects within graphitized nanotubes. This analytical gap hinders the development of structure-property relationships necessary for rational material design.

Stability issues under operating conditions further complicate material composition optimization. Many promising compositional modifications show excellent initial performance but degrade under realistic operating environments involving temperature fluctuations, mechanical stress, or chemical exposure. This degradation often manifests as compositional changes that alter the material's fundamental properties.

Computational modeling capabilities, while advancing rapidly, still cannot accurately predict how specific compositional changes will affect macroscale properties. This limitation forces researchers to rely heavily on empirical approaches, slowing innovation and increasing development costs for new GCNT compositions tailored to specific applications.

The controlled incorporation of heteroatoms (nitrogen, boron, phosphorus) presents another significant hurdle. While heteroatom doping can enhance specific properties, precise control over doping concentration, distribution patterns, and bonding configurations remains difficult to achieve at industrial scales. This inconsistency leads to batch-to-batch variations that complicate quality control and performance predictability.

Surface functionalization of graphitized nanotubes introduces additional complexity. The trade-off between enhanced solubility/dispersibility and preservation of intrinsic electronic properties creates a delicate balance that researchers continue to struggle with. Aggressive functionalization methods often damage the graphitic structure, while milder approaches may not provide sufficient functional group density for specific applications.

The scalable production of composition-controlled GCNTs represents perhaps the most pressing challenge. Laboratory-scale synthesis methods that produce high-quality, composition-controlled nanotubes often fail to translate to industrial production environments. The gap between small-batch excellence and mass production consistency remains substantial, limiting commercial viability.

Material characterization techniques also present limitations. Current analytical methods struggle to provide comprehensive, high-resolution data on the three-dimensional distribution of elements and defects within graphitized nanotubes. This analytical gap hinders the development of structure-property relationships necessary for rational material design.

Stability issues under operating conditions further complicate material composition optimization. Many promising compositional modifications show excellent initial performance but degrade under realistic operating environments involving temperature fluctuations, mechanical stress, or chemical exposure. This degradation often manifests as compositional changes that alter the material's fundamental properties.

Computational modeling capabilities, while advancing rapidly, still cannot accurately predict how specific compositional changes will affect macroscale properties. This limitation forces researchers to rely heavily on empirical approaches, slowing innovation and increasing development costs for new GCNT compositions tailored to specific applications.

Current Synthesis and Modification Techniques

01 Enhanced electrical conductivity through graphitization

Graphitization of carbon nanotubes significantly improves their electrical conductivity properties. The process involves high-temperature treatment that transforms amorphous carbon into a more ordered graphitic structure, reducing defects and increasing electron mobility. This enhanced conductivity makes graphitized carbon nanotubes particularly valuable for applications in electronics, energy storage, and conductive composites where efficient electron transfer is critical.- Enhanced electrical conductivity through graphitization: Graphitization of carbon nanotubes significantly improves their electrical conductivity properties. The process involves high-temperature treatment that transforms amorphous carbon into a more ordered graphitic structure, reducing defects and increasing electron mobility. This enhancement makes graphitized carbon nanotubes particularly valuable for applications requiring efficient electrical transmission, such as electrodes, conductive films, and electronic components.

- Thermal efficiency improvements in graphitized CNTs: Graphitized carbon nanotubes demonstrate superior thermal conductivity compared to their non-graphitized counterparts. The graphitization process aligns the carbon structure, creating more efficient pathways for heat transfer. This property makes them excellent candidates for thermal management applications in electronics, heat exchangers, and composite materials where efficient heat dissipation is critical for performance and longevity.

- Manufacturing processes for high-efficiency graphitized nanotubes: Various manufacturing techniques have been developed to optimize the graphitization efficiency of carbon nanotubes. These include catalytic graphitization, high-temperature thermal treatment in controlled atmospheres, laser-assisted processes, and chemical vapor deposition methods. Each approach offers different advantages in terms of graphitization degree, structural integrity, scalability, and energy consumption, allowing for tailored production based on specific application requirements.

- Energy storage applications of graphitized CNTs: Graphitized carbon nanotubes show enhanced performance in energy storage applications due to their improved electrical conductivity and structural stability. When used in batteries, supercapacitors, and hydrogen storage systems, they provide higher energy density, faster charge/discharge rates, and longer cycle life. The graphitization process creates a more ordered structure with increased surface area and improved ion intercalation properties, making them particularly effective for next-generation energy storage solutions.

- Composite materials with graphitized CNTs for enhanced efficiency: Incorporating graphitized carbon nanotubes into composite materials creates synergistic effects that enhance mechanical, electrical, and thermal properties. These composites demonstrate improved strength-to-weight ratios, better load distribution, enhanced conductivity, and superior thermal management. Applications range from aerospace components and automotive parts to sporting goods and electronic packaging, where the unique properties of graphitized CNTs contribute to overall system efficiency and performance.

02 Thermal efficiency and heat transfer applications

Graphitized carbon nanotubes demonstrate superior thermal conductivity compared to their non-graphitized counterparts. The ordered graphitic structure facilitates efficient phonon transport, enabling rapid heat dissipation. These properties make them excellent additives for thermal interface materials, heat sinks, and thermal management systems in electronics. The improved thermal efficiency also contributes to better performance in high-temperature applications where heat transfer is critical.Expand Specific Solutions03 Production methods for efficiency optimization

Various production techniques have been developed to optimize the efficiency of graphitized carbon nanotubes. These include catalytic chemical vapor deposition, high-temperature annealing processes, and specialized treatment methods that control the degree of graphitization. The production parameters significantly influence the final properties, with factors such as temperature, duration, catalyst type, and atmosphere playing crucial roles in determining the efficiency of the resulting graphitized nanotubes.Expand Specific Solutions04 Energy storage and electrode applications

Graphitized carbon nanotubes show enhanced performance in energy storage applications, particularly as electrode materials in batteries and supercapacitors. The graphitization process increases surface area and improves charge transfer capabilities, resulting in higher energy and power densities. These materials enable faster charging rates, improved cycling stability, and greater overall efficiency in energy storage devices, making them valuable components for next-generation energy technologies.Expand Specific Solutions05 Composite reinforcement and mechanical properties

Graphitized carbon nanotubes serve as excellent reinforcement agents in composite materials, enhancing mechanical strength, stiffness, and durability. The graphitization process improves the interfacial bonding between nanotubes and matrix materials, leading to more efficient load transfer. These reinforced composites demonstrate superior mechanical properties including tensile strength, modulus, and fatigue resistance, making them suitable for high-performance structural applications in aerospace, automotive, and construction industries.Expand Specific Solutions

Leading Research Institutions and Manufacturers

The graphitized carbon nanotubes (GCNTs) market is currently in a growth phase, with increasing applications across electronics, energy storage, and advanced materials sectors. The global market size for carbon nanotubes is projected to reach approximately $15 billion by 2027, with GCNTs representing a significant segment. Technologically, this field is advancing from early commercial adoption toward maturity, with research institutions like Tsinghua University and Clemson University driving fundamental understanding of nanotube structure-property relationships. Leading companies including Samsung Electronics, Intel, and Dow Global Technologies are developing commercial applications, while specialized firms such as Molecular Rebar Design and Xiamen Knano Graphene Technology focus on optimizing nanotube composition and structure for enhanced efficiency. The competitive landscape features both established technology corporations and emerging materials science companies collaborating with research institutions to overcome remaining technical challenges in scalable production and performance consistency.

Tsinghua University

Technical Solution: Tsinghua University has pioneered research on the relationship between nanotube structure and graphitized carbon nanotube efficiency. Their approach focuses on controlling the diameter, length, and wall thickness of carbon nanotubes during synthesis to optimize electrical conductivity and thermal properties. They've developed a precise chemical vapor deposition (CVD) method that allows for atomic-level control of nanotube morphology, achieving graphitization degrees above 95% through controlled high-temperature treatment (2800-3000°C). Their research demonstrates that smaller diameter nanotubes (1-2 nm) with fewer walls exhibit superior electrical properties after graphitization, while multi-walled variants show enhanced mechanical strength. Tsinghua's work has established clear correlations between nitrogen/boron doping concentrations and resulting conductivity improvements, showing up to 40% enhancement in electron mobility with optimized doping profiles.

Strengths: Exceptional control over nanotube morphology and graphitization parameters, allowing for tailored electrical and thermal properties. Their advanced characterization techniques provide unprecedented insights into structure-property relationships. Weaknesses: Their high-temperature graphitization processes are energy-intensive and challenging to scale commercially, potentially limiting industrial applications.

Arkema France SA

Technical Solution: Arkema France has developed a proprietary technology called "Graphistrength" that focuses on optimizing the graphitization process of carbon nanotubes through controlled material composition. Their approach involves precise catalyst formulation using transition metals (Fe, Co, Ni) in specific ratios to control nanotube chirality and diameter distribution. Arkema's process incorporates a two-stage graphitization technique where nanotubes undergo initial low-temperature (1200-1500°C) structural reorganization followed by high-temperature (2500-2800°C) treatment in an inert atmosphere with controlled tension. This method results in highly crystalline graphitic structures with minimized defects. Their research demonstrates that incorporating small amounts (0.5-2%) of boron during synthesis significantly enhances the graphitization efficiency by lowering the required temperature by approximately 200°C while maintaining structural integrity. Arkema has also pioneered surface functionalization techniques that preserve the graphitic structure while enabling better dispersion in various matrices.

Strengths: Industry-leading expertise in scalable production of graphitized carbon nanotubes with consistent quality and tailored properties. Their two-stage process offers excellent control over defect density and graphitization degree. Weaknesses: Their technology requires specialized equipment and precise process control, making it relatively expensive compared to conventional carbon materials. Some functionalization methods may introduce structural defects that partially compromise electrical conductivity.

Key Patents in Nanotube Structure-Property Relationships

Carbon nanotube preparation method and carbon nanotube prepared using same

PatentWO2025110320A1

Innovation

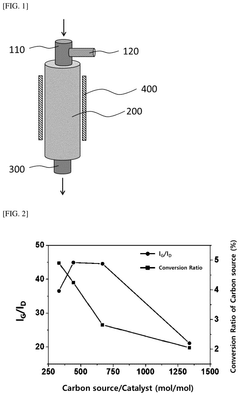

- A method using graphitized carbon nitride to produce carbon nanotubes with controlled diameter and length, involving a composition of carbon nitride precursor, metal salt, and denitrifying agent, followed by calcination steps to form carbon tubes with metal nanoparticles on the surface, which are then used to grow carbon nanotubes in a reactor.

Carbon Nanotube and Manufacturing Method Thereof

PatentPendingUS20250214842A1

Innovation

- A method involving floating catalyst chemical vapor deposition (FC-CVD) with specific molar flow rate ratios of carbon source, metal catalyst, cocatalyst, and transport gas is employed to manufacture carbon nanotubes, optimizing the reaction conditions to enhance graphite crystallinity and conversion efficiency.

Environmental Impact and Sustainability Considerations

The environmental impact of graphitized carbon nanotubes (GCNTs) is intrinsically linked to their structure and material composition. Different nanotube architectures and compositional variations significantly influence their ecological footprint throughout their lifecycle. Single-walled carbon nanotubes typically require more energy-intensive production methods compared to multi-walled variants, resulting in higher carbon emissions during manufacturing. However, their enhanced efficiency in applications often translates to reduced environmental impact during operational phases.

Material composition plays a crucial role in determining the environmental sustainability of GCNTs. Pure carbon nanotubes generally present fewer toxicity concerns than those incorporating metallic catalysts or functional groups. Research indicates that residual metal catalysts in nanotube structures can leach into ecosystems, potentially disrupting aquatic and soil environments. The degree of graphitization also affects environmental persistence, with highly graphitized nanotubes demonstrating greater resistance to degradation, raising concerns about long-term accumulation in natural systems.

Production methods significantly influence the sustainability profile of GCNTs. Chemical vapor deposition techniques, while efficient for controlling nanotube structure, often utilize hazardous precursors and generate substantial waste. Alternative synthesis approaches such as laser ablation may reduce certain environmental impacts but typically consume more energy. Recent advances in green synthesis methods utilizing biological templates or environmentally benign catalysts show promise for reducing the ecological footprint of GCNT production.

The end-of-life considerations for GCNT-containing products remain a significant challenge. The exceptional durability that makes these materials valuable in applications also complicates their biodegradation and recycling. Nanotube structure influences recyclability, with certain architectures more amenable to recovery processes than others. Material composition affects potential toxicity during disposal, with functionalized nanotubes potentially releasing harmful compounds during degradation.

Life cycle assessment studies reveal that the environmental benefits of GCNTs often depend on application efficiency gains offsetting production impacts. For instance, GCNTs in energy storage applications can enable renewable energy technologies that reduce overall carbon emissions. Similarly, their use in lightweight composites for transportation can decrease fuel consumption and associated emissions. The sustainability equation must therefore consider both the immediate environmental costs of production and the long-term benefits derived from enhanced efficiency and performance.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with structure and composition becoming key factors in risk assessment protocols. Future sustainable development of GCNT technologies will require deliberate engineering of nanotube structures and compositions that minimize environmental hazards while maintaining or enhancing functional efficiency.

Material composition plays a crucial role in determining the environmental sustainability of GCNTs. Pure carbon nanotubes generally present fewer toxicity concerns than those incorporating metallic catalysts or functional groups. Research indicates that residual metal catalysts in nanotube structures can leach into ecosystems, potentially disrupting aquatic and soil environments. The degree of graphitization also affects environmental persistence, with highly graphitized nanotubes demonstrating greater resistance to degradation, raising concerns about long-term accumulation in natural systems.

Production methods significantly influence the sustainability profile of GCNTs. Chemical vapor deposition techniques, while efficient for controlling nanotube structure, often utilize hazardous precursors and generate substantial waste. Alternative synthesis approaches such as laser ablation may reduce certain environmental impacts but typically consume more energy. Recent advances in green synthesis methods utilizing biological templates or environmentally benign catalysts show promise for reducing the ecological footprint of GCNT production.

The end-of-life considerations for GCNT-containing products remain a significant challenge. The exceptional durability that makes these materials valuable in applications also complicates their biodegradation and recycling. Nanotube structure influences recyclability, with certain architectures more amenable to recovery processes than others. Material composition affects potential toxicity during disposal, with functionalized nanotubes potentially releasing harmful compounds during degradation.

Life cycle assessment studies reveal that the environmental benefits of GCNTs often depend on application efficiency gains offsetting production impacts. For instance, GCNTs in energy storage applications can enable renewable energy technologies that reduce overall carbon emissions. Similarly, their use in lightweight composites for transportation can decrease fuel consumption and associated emissions. The sustainability equation must therefore consider both the immediate environmental costs of production and the long-term benefits derived from enhanced efficiency and performance.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with structure and composition becoming key factors in risk assessment protocols. Future sustainable development of GCNT technologies will require deliberate engineering of nanotube structures and compositions that minimize environmental hazards while maintaining or enhancing functional efficiency.

Scalability and Industrial Production Challenges

The scaling of graphitized carbon nanotube (GCNT) production from laboratory to industrial scale presents significant challenges that directly relate to how nanotube structure and material composition influence efficiency. Current industrial production methods struggle with maintaining consistent nanotube diameter, length, and wall thickness during large-scale synthesis, which critically affects the final performance characteristics of GCNTs.

Mass production of high-quality GCNTs faces several technical barriers. The graphitization process, which transforms amorphous carbon into crystalline graphitic structures, requires precise temperature control (typically 1800-3000°C) across large production volumes. Even minor temperature variations can lead to inconsistent graphitization levels, directly impacting electrical conductivity and mechanical strength. This challenge is magnified when scaling up, as maintaining uniform heat distribution becomes exponentially more difficult in larger reactors.

Material composition plays a crucial role in scalability challenges. Catalyst impurities introduced during bulk production can significantly alter the graphitization process, creating defects in the nanotube structure. These defects not only reduce efficiency but also create inconsistencies across production batches. The purification processes required to remove these impurities add substantial cost and complexity to industrial production.

Energy consumption represents another major hurdle in GCNT manufacturing. The high-temperature graphitization process is extremely energy-intensive, with costs scaling non-linearly with production volume. The energy requirements are directly influenced by the starting material composition and desired nanotube structure, creating a complex optimization problem for industrial producers seeking cost-effective manufacturing routes.

Environmental considerations also impact scalability. Traditional production methods generate significant waste and potentially harmful byproducts. The precursor materials and catalysts used can contain toxic elements that require special handling and disposal procedures, adding regulatory complexity to large-scale operations.

Recent innovations have focused on continuous flow production methods rather than batch processing to address some scalability issues. These approaches show promise for maintaining more consistent nanotube structures during large-scale production but require significant capital investment and process redesign. The relationship between production method, nanotube structure, and material composition becomes even more critical in these continuous systems, where process parameters must be precisely controlled throughout the production line.

Ultimately, the industrial viability of GCNT technology depends on resolving these scalability challenges through innovations that better control how nanotube structure and material composition influence efficiency during mass production.

Mass production of high-quality GCNTs faces several technical barriers. The graphitization process, which transforms amorphous carbon into crystalline graphitic structures, requires precise temperature control (typically 1800-3000°C) across large production volumes. Even minor temperature variations can lead to inconsistent graphitization levels, directly impacting electrical conductivity and mechanical strength. This challenge is magnified when scaling up, as maintaining uniform heat distribution becomes exponentially more difficult in larger reactors.

Material composition plays a crucial role in scalability challenges. Catalyst impurities introduced during bulk production can significantly alter the graphitization process, creating defects in the nanotube structure. These defects not only reduce efficiency but also create inconsistencies across production batches. The purification processes required to remove these impurities add substantial cost and complexity to industrial production.

Energy consumption represents another major hurdle in GCNT manufacturing. The high-temperature graphitization process is extremely energy-intensive, with costs scaling non-linearly with production volume. The energy requirements are directly influenced by the starting material composition and desired nanotube structure, creating a complex optimization problem for industrial producers seeking cost-effective manufacturing routes.

Environmental considerations also impact scalability. Traditional production methods generate significant waste and potentially harmful byproducts. The precursor materials and catalysts used can contain toxic elements that require special handling and disposal procedures, adding regulatory complexity to large-scale operations.

Recent innovations have focused on continuous flow production methods rather than batch processing to address some scalability issues. These approaches show promise for maintaining more consistent nanotube structures during large-scale production but require significant capital investment and process redesign. The relationship between production method, nanotube structure, and material composition becomes even more critical in these continuous systems, where process parameters must be precisely controlled throughout the production line.

Ultimately, the industrial viability of GCNT technology depends on resolving these scalability challenges through innovations that better control how nanotube structure and material composition influence efficiency during mass production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!