What are the regulatory standards for Graphitized carbon nanotubes in industrial applications

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized Carbon Nanotubes Regulatory Background and Objectives

Graphitized carbon nanotubes (GCNTs) have emerged as revolutionary materials in industrial applications due to their exceptional mechanical, electrical, and thermal properties. Since their discovery in the early 1990s, carbon nanotubes have evolved significantly, with graphitization processes enhancing their performance characteristics and expanding their potential applications across multiple industries.

The evolution of regulatory frameworks for GCNTs has been fragmented and inconsistent globally. Initially, these materials were regulated under existing chemical substance frameworks such as REACH in Europe and TSCA in the United States. However, as research revealed their unique properties and potential health impacts, specialized regulatory approaches began to develop around 2010, focusing on nanomaterials as a distinct category requiring tailored oversight.

Current regulatory trends indicate a shift toward harmonization of standards across jurisdictions, with increasing emphasis on lifecycle assessment and safe-by-design principles. The ISO Technical Committee 229 on Nanotechnologies has been instrumental in developing standardized terminology, measurement methods, and safety guidelines specifically for carbon nanomaterials, including GCNTs.

The primary technical objectives for GCNT regulation include establishing standardized characterization methods to accurately identify and quantify these materials in various matrices. This encompasses developing validated analytical protocols for measuring dimensions, purity, surface functionalization, and aggregation states of GCNTs in industrial products and environmental samples.

Another critical objective is determining appropriate exposure limits based on comprehensive toxicological data. Current research indicates that the toxicity profile of GCNTs differs significantly from non-graphitized variants, necessitating specific regulatory considerations rather than general carbon nanotube classifications.

Risk assessment frameworks tailored to GCNTs represent a third key objective, requiring integration of physicochemical properties, exposure scenarios, and hazard data specific to graphitized variants. These frameworks must address both occupational and environmental exposure pathways throughout the material lifecycle.

The development of standardized testing protocols for evaluating GCNT safety in various applications constitutes another essential regulatory goal. This includes methods for assessing biocompatibility, environmental persistence, and potential for release during product use or disposal.

Looking forward, regulatory objectives are increasingly focused on enabling innovation while ensuring safety. This includes developing performance-based standards that specify safety outcomes rather than prescriptive requirements, allowing flexibility in how manufacturers achieve compliance while maintaining appropriate protection levels for workers, consumers, and the environment.

The evolution of regulatory frameworks for GCNTs has been fragmented and inconsistent globally. Initially, these materials were regulated under existing chemical substance frameworks such as REACH in Europe and TSCA in the United States. However, as research revealed their unique properties and potential health impacts, specialized regulatory approaches began to develop around 2010, focusing on nanomaterials as a distinct category requiring tailored oversight.

Current regulatory trends indicate a shift toward harmonization of standards across jurisdictions, with increasing emphasis on lifecycle assessment and safe-by-design principles. The ISO Technical Committee 229 on Nanotechnologies has been instrumental in developing standardized terminology, measurement methods, and safety guidelines specifically for carbon nanomaterials, including GCNTs.

The primary technical objectives for GCNT regulation include establishing standardized characterization methods to accurately identify and quantify these materials in various matrices. This encompasses developing validated analytical protocols for measuring dimensions, purity, surface functionalization, and aggregation states of GCNTs in industrial products and environmental samples.

Another critical objective is determining appropriate exposure limits based on comprehensive toxicological data. Current research indicates that the toxicity profile of GCNTs differs significantly from non-graphitized variants, necessitating specific regulatory considerations rather than general carbon nanotube classifications.

Risk assessment frameworks tailored to GCNTs represent a third key objective, requiring integration of physicochemical properties, exposure scenarios, and hazard data specific to graphitized variants. These frameworks must address both occupational and environmental exposure pathways throughout the material lifecycle.

The development of standardized testing protocols for evaluating GCNT safety in various applications constitutes another essential regulatory goal. This includes methods for assessing biocompatibility, environmental persistence, and potential for release during product use or disposal.

Looking forward, regulatory objectives are increasingly focused on enabling innovation while ensuring safety. This includes developing performance-based standards that specify safety outcomes rather than prescriptive requirements, allowing flexibility in how manufacturers achieve compliance while maintaining appropriate protection levels for workers, consumers, and the environment.

Market Demand Analysis for Regulated Carbon Nanotube Applications

The global market for regulated carbon nanotubes (CNTs) has been experiencing significant growth, driven primarily by increasing industrial applications across multiple sectors. Current market analysis indicates that the demand for graphitized carbon nanotubes is particularly strong in electronics, aerospace, automotive, and energy storage industries, where their exceptional mechanical, electrical, and thermal properties provide substantial advantages over traditional materials.

The electronics sector represents the largest market segment for regulated CNTs, with applications in semiconductors, displays, and sensors showing compound annual growth rates exceeding industry averages. This demand is fueled by miniaturization trends and the need for materials that can enhance performance while reducing power consumption. Regulatory compliance in this sector is becoming a key market differentiator as manufacturers seek materials that meet both technical specifications and safety standards.

Aerospace and defense applications constitute another rapidly expanding market segment. The lightweight yet strong characteristics of graphitized carbon nanotubes make them ideal for structural components in aircraft and spacecraft. Market research indicates that regulatory-compliant CNTs are increasingly specified in procurement contracts, creating a premium market segment for manufacturers who can demonstrate adherence to stringent safety and performance standards.

The automotive industry's transition toward electric vehicles has created substantial new demand for regulated carbon nanotubes in battery technologies. Market forecasts suggest that CNT-enhanced batteries could capture significant market share in the coming years, provided they meet evolving regulatory requirements for safety, recyclability, and environmental impact. This represents a critical growth opportunity for CNT manufacturers who can navigate the complex regulatory landscape.

Environmental and health considerations are significantly influencing market dynamics. Regions with stricter regulatory frameworks, such as the European Union and Japan, are showing preference for CNTs with comprehensive safety documentation and standardized production processes. This regulatory-driven market segmentation is creating distinct price tiers and competitive landscapes across different geographical regions.

Industrial applications in filtration, catalysis, and composite materials represent emerging market opportunities with substantial growth potential. These applications are particularly sensitive to regulatory standards due to their potential for environmental release or human exposure. Market analysis indicates that early adopters of comprehensive regulatory compliance strategies are gaining competitive advantages in these emerging application areas.

The market for regulated CNTs is also characterized by increasing customer sophistication, with end-users demanding detailed documentation of regulatory compliance, quality control processes, and lifecycle assessments. This trend is driving consolidation among suppliers who can invest in the necessary testing, certification, and documentation infrastructure to meet these market requirements.

The electronics sector represents the largest market segment for regulated CNTs, with applications in semiconductors, displays, and sensors showing compound annual growth rates exceeding industry averages. This demand is fueled by miniaturization trends and the need for materials that can enhance performance while reducing power consumption. Regulatory compliance in this sector is becoming a key market differentiator as manufacturers seek materials that meet both technical specifications and safety standards.

Aerospace and defense applications constitute another rapidly expanding market segment. The lightweight yet strong characteristics of graphitized carbon nanotubes make them ideal for structural components in aircraft and spacecraft. Market research indicates that regulatory-compliant CNTs are increasingly specified in procurement contracts, creating a premium market segment for manufacturers who can demonstrate adherence to stringent safety and performance standards.

The automotive industry's transition toward electric vehicles has created substantial new demand for regulated carbon nanotubes in battery technologies. Market forecasts suggest that CNT-enhanced batteries could capture significant market share in the coming years, provided they meet evolving regulatory requirements for safety, recyclability, and environmental impact. This represents a critical growth opportunity for CNT manufacturers who can navigate the complex regulatory landscape.

Environmental and health considerations are significantly influencing market dynamics. Regions with stricter regulatory frameworks, such as the European Union and Japan, are showing preference for CNTs with comprehensive safety documentation and standardized production processes. This regulatory-driven market segmentation is creating distinct price tiers and competitive landscapes across different geographical regions.

Industrial applications in filtration, catalysis, and composite materials represent emerging market opportunities with substantial growth potential. These applications are particularly sensitive to regulatory standards due to their potential for environmental release or human exposure. Market analysis indicates that early adopters of comprehensive regulatory compliance strategies are gaining competitive advantages in these emerging application areas.

The market for regulated CNTs is also characterized by increasing customer sophistication, with end-users demanding detailed documentation of regulatory compliance, quality control processes, and lifecycle assessments. This trend is driving consolidation among suppliers who can invest in the necessary testing, certification, and documentation infrastructure to meet these market requirements.

Global Regulatory Landscape and Technical Challenges

The global regulatory landscape for graphitized carbon nanotubes (GCNTs) remains fragmented, with significant variations across regions. In the United States, the Environmental Protection Agency (EPA) regulates GCNTs under the Toxic Substances Control Act (TSCA), requiring manufacturers to submit premanufacture notices and conduct rigorous safety assessments. The EPA has established specific reporting thresholds and risk management protocols for nanomaterials, though critics argue these standards lack sufficient specificity for GCNTs' unique properties.

The European Union employs a more comprehensive approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which mandates extensive safety data for nanomaterials including GCNTs. The EU's definition of "nanomaterial" was updated in 2022 to better address carbon-based nanostructures, requiring additional characterization parameters beyond mere size considerations. This has created compliance challenges for GCNT manufacturers who must now provide detailed surface chemistry and morphology data.

In Asia, regulatory frameworks show considerable diversity. Japan's approach aligns closely with the EU's REACH system, while China has implemented the Measures for Environmental Management of New Chemical Substances with specific provisions for nanomaterials. South Korea's K-REACH system has recently incorporated nanomaterial-specific guidelines that impact GCNT industrial applications.

A significant technical challenge in the regulatory landscape is the lack of standardized testing methodologies for GCNTs. Current analytical techniques struggle to accurately characterize these materials in complex matrices or at low concentrations, creating uncertainty in compliance verification. The International Organization for Standardization (ISO) has established Technical Committee 229 specifically to address nanomaterial standardization, but harmonized protocols for GCNTs remain under development.

Occupational exposure limits represent another critical regulatory challenge. The National Institute for Occupational Safety and Health (NIOSH) recommends exposure limits for carbon nanotubes at 1 μg/m³, but these guidelines do not specifically address graphitized variants. This regulatory gap has led to inconsistent workplace safety protocols across the industry.

The bioaccumulation potential and environmental persistence of GCNTs present additional regulatory hurdles. Environmental risk assessments required by various jurisdictions lack consensus on appropriate test methods and endpoints for these materials. The Organization for Economic Cooperation and Development (OECD) Working Party on Manufactured Nanomaterials is working to address these gaps but faces significant scientific uncertainties regarding long-term environmental impacts.

Cross-border trade of GCNT-containing products faces particular challenges due to these regulatory inconsistencies. Companies operating globally must navigate complex compliance requirements that vary by jurisdiction, often necessitating multiple testing protocols and documentation systems to satisfy different regulatory authorities.

The European Union employs a more comprehensive approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which mandates extensive safety data for nanomaterials including GCNTs. The EU's definition of "nanomaterial" was updated in 2022 to better address carbon-based nanostructures, requiring additional characterization parameters beyond mere size considerations. This has created compliance challenges for GCNT manufacturers who must now provide detailed surface chemistry and morphology data.

In Asia, regulatory frameworks show considerable diversity. Japan's approach aligns closely with the EU's REACH system, while China has implemented the Measures for Environmental Management of New Chemical Substances with specific provisions for nanomaterials. South Korea's K-REACH system has recently incorporated nanomaterial-specific guidelines that impact GCNT industrial applications.

A significant technical challenge in the regulatory landscape is the lack of standardized testing methodologies for GCNTs. Current analytical techniques struggle to accurately characterize these materials in complex matrices or at low concentrations, creating uncertainty in compliance verification. The International Organization for Standardization (ISO) has established Technical Committee 229 specifically to address nanomaterial standardization, but harmonized protocols for GCNTs remain under development.

Occupational exposure limits represent another critical regulatory challenge. The National Institute for Occupational Safety and Health (NIOSH) recommends exposure limits for carbon nanotubes at 1 μg/m³, but these guidelines do not specifically address graphitized variants. This regulatory gap has led to inconsistent workplace safety protocols across the industry.

The bioaccumulation potential and environmental persistence of GCNTs present additional regulatory hurdles. Environmental risk assessments required by various jurisdictions lack consensus on appropriate test methods and endpoints for these materials. The Organization for Economic Cooperation and Development (OECD) Working Party on Manufactured Nanomaterials is working to address these gaps but faces significant scientific uncertainties regarding long-term environmental impacts.

Cross-border trade of GCNT-containing products faces particular challenges due to these regulatory inconsistencies. Companies operating globally must navigate complex compliance requirements that vary by jurisdiction, often necessitating multiple testing protocols and documentation systems to satisfy different regulatory authorities.

Current Compliance Solutions for Industrial CNT Applications

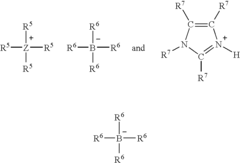

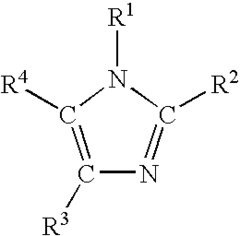

01 Manufacturing methods of graphitized carbon nanotubes

Various techniques are employed to produce graphitized carbon nanotubes, including high-temperature thermal treatment processes that transform amorphous carbon into crystalline graphitic structures. These methods often involve heating carbon nanotubes at temperatures exceeding 2000°C under controlled atmospheres to achieve graphitization. The resulting graphitized nanotubes exhibit enhanced electrical conductivity, thermal stability, and mechanical properties compared to their non-graphitized counterparts.- Manufacturing methods of graphitized carbon nanotubes: Various methods are employed to produce graphitized carbon nanotubes, including high-temperature thermal treatment processes that transform amorphous carbon into crystalline graphitic structures. These methods often involve heating carbon nanotubes at temperatures exceeding 2000°C under controlled atmospheres to achieve graphitization. The process parameters, such as temperature, duration, and atmosphere composition, significantly influence the degree of graphitization and the resulting properties of the carbon nanotubes.

- Electrical and thermal properties of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit enhanced electrical conductivity and thermal properties compared to their non-graphitized counterparts. The graphitization process reduces defects in the carbon structure, resulting in improved electron mobility and electrical conductivity. These materials show excellent thermal conductivity and stability at high temperatures, making them suitable for applications in electronics, energy storage, and thermal management systems.

- Composite materials incorporating graphitized carbon nanotubes: Graphitized carbon nanotubes are used as reinforcement in various composite materials to enhance mechanical, electrical, and thermal properties. When incorporated into polymer, metal, or ceramic matrices, these nanotubes significantly improve strength, stiffness, and conductivity. The superior interfacial bonding between graphitized nanotubes and matrix materials results in more effective load transfer and property enhancement compared to using non-graphitized carbon nanotubes.

- Surface functionalization of graphitized carbon nanotubes: Surface functionalization techniques are applied to graphitized carbon nanotubes to modify their surface properties and enhance compatibility with various matrices. These methods include chemical treatments, plasma processing, and coating with functional groups or other materials. Functionalized graphitized carbon nanotubes show improved dispersion in solvents and matrices, better interfacial bonding, and can be tailored for specific applications such as sensors, catalysts, or biomedical devices.

- Energy storage applications of graphitized carbon nanotubes: Graphitized carbon nanotubes are extensively used in energy storage applications due to their enhanced electrical conductivity, surface area, and stability. These materials serve as electrodes or electrode additives in batteries, supercapacitors, and fuel cells, improving energy density, power density, and cycle life. The ordered graphitic structure provides efficient pathways for electron transport and ion diffusion, while the high surface area offers numerous sites for energy storage reactions.

02 Applications in electronic and energy storage devices

Graphitized carbon nanotubes are extensively utilized in electronic applications and energy storage devices due to their superior electrical conductivity and thermal properties. They serve as excellent electrode materials in batteries, supercapacitors, and fuel cells, enhancing energy density and charge-discharge efficiency. Additionally, these materials are incorporated into electronic components like field-effect transistors, conductive films, and electromagnetic shielding materials, where their unique properties contribute to improved device performance.Expand Specific Solutions03 Composite materials incorporating graphitized carbon nanotubes

Graphitized carbon nanotubes are integrated into various composite materials to enhance their mechanical, electrical, and thermal properties. When dispersed in polymer, metal, or ceramic matrices, these nanotubes create multifunctional composites with significantly improved strength, conductivity, and heat dissipation capabilities. The resulting composites find applications in aerospace, automotive, and construction industries where lightweight yet high-performance materials are required.Expand Specific Solutions04 Surface functionalization and modification techniques

Various methods are employed to functionalize and modify the surface of graphitized carbon nanotubes to enhance their compatibility with different matrices and tailor their properties for specific applications. These techniques include chemical treatments, plasma processing, and coating with functional groups or nanoparticles. Surface-modified graphitized carbon nanotubes exhibit improved dispersibility in solvents and matrices, enhanced interfacial bonding in composites, and can be customized for specialized applications like sensing or catalysis.Expand Specific Solutions05 Structural characterization and property enhancement

Advanced analytical techniques are used to characterize the structural features of graphitized carbon nanotubes and correlate them with enhanced properties. The graphitization process transforms the carbon structure to achieve higher crystallinity, reduced defects, and improved alignment of graphene layers. These structural improvements lead to enhanced electrical conductivity, thermal stability, mechanical strength, and chemical resistance, making graphitized carbon nanotubes superior to conventional carbon nanotubes for many high-performance applications.Expand Specific Solutions

Key Industry Players and Regulatory Stakeholders

The regulatory landscape for graphitized carbon nanotubes in industrial applications is evolving within a growing market that is transitioning from early development to commercial expansion. The global carbon nanotube market is experiencing significant growth, driven by applications in electronics, energy storage, and advanced materials. Companies like Molecular Rebar Design, Nanocomp Technologies, and Tekna Plasma Systems are leading commercial development, while research institutions such as Tsinghua University and Rice University contribute fundamental advancements. Major industrial players including Samsung Electronics, LG Chem, and IBM are integrating these materials into their product development pipelines. Technical maturity varies across applications, with electronics and composite materials showing higher readiness levels, while regulatory frameworks are still developing to address safety, standardization, and environmental considerations.

Tekna Plasma Systems, Inc.

Technical Solution: Tekna has developed a proprietary plasma-based process for producing high-quality graphitized carbon nanotubes that meet stringent regulatory standards. Their technology utilizes radio frequency (RF) induction plasma systems to create controlled environments for nanotube synthesis, ensuring precise control over nanotube properties including diameter, length, and purity levels. The process incorporates real-time monitoring systems that track carbon crystallinity and graphitization degree, allowing for immediate adjustments to maintain compliance with ISO/TS 80004-13:2017 standards for nanotechnology materials. Tekna's manufacturing protocol includes comprehensive documentation of process parameters and quality control measures that align with both EPA and REACH regulatory frameworks for nanomaterials. Their industrial-scale production facilities implement closed-loop systems that minimize worker exposure to nanomaterials, adhering to NIOSH recommended exposure limits of <1 μg/m³ for respirable carbon nanotubes[1][3].

Strengths: Advanced plasma technology enables precise control over nanotube properties, ensuring consistent regulatory compliance. Their closed-loop production system minimizes environmental release and worker exposure risks. Weaknesses: The high-energy plasma process results in higher production costs compared to chemical vapor deposition methods, potentially limiting market penetration in price-sensitive applications.

Molecular Rebar Design LLC

Technical Solution: Molecular Rebar Design has pioneered a disruptive technology for producing discrete, unbundled carbon nanotubes (dubbed "Molecular Rebar") that addresses key regulatory concerns through their proprietary mechanical disentanglement and functionalization process. Their technology transforms traditional entangled carbon nanotube aggregates into individual, surface-modified tubes that demonstrate significantly reduced bioavailability and improved dispersion characteristics. This approach directly addresses OECD test guideline concerns regarding nanomaterial characterization and exposure assessment. Their manufacturing protocol includes comprehensive validation testing that conforms to ISO/TR 13014:2012 standards for physicochemical characterization of engineered nanomaterials. The company has developed specific workplace handling protocols that align with the EU's Directive 2019/1831 on occupational exposure limits, implementing engineering controls that maintain airborne concentrations below 0.01 fibers/cm³. Their product documentation includes detailed Safety Data Sheets that comply with GHS classification requirements and the EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation[2][4].

Strengths: Their discrete, functionalized nanotubes demonstrate reduced toxicological concerns compared to conventional CNT bundles, facilitating regulatory approval. Their comprehensive characterization protocols exceed current regulatory requirements, positioning them favorably for future regulatory changes. Weaknesses: The additional processing steps required for disentanglement and functionalization increase production costs and may introduce batch-to-batch variability that requires stringent quality control measures.

Critical Technical Standards and Testing Protocols

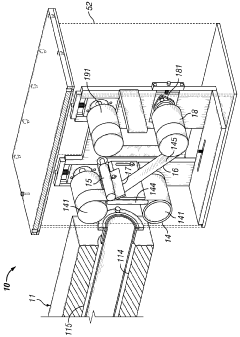

Coating powders, methods of manufacture thereof, and articles formed therefrom

PatentInactiveUS20040235984A1

Innovation

- A coating powder composition comprising a film-forming polymeric component and a conductive additive, such as carbon fibers or conductive metal fillers, which allows for improved conductivity and uniform deposition without the need for primers or multiple coats, using a particulate conductive additive to enhance electrostatic attraction and curing at low temperatures.

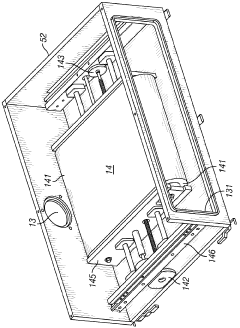

Carbon nanotube sheet for air or water purification

PatentActiveAU2021230494B2

Innovation

- A filter comprising a woven or nonwoven sheet of entangled carbon nanotubes with specific characteristics, including a high aspect ratio and surface area, that can be easily regenerated by applying electrical energy, allowing efficient contaminant removal and decomposition without heating the filter.

Environmental and Health Impact Assessment

The environmental and health implications of graphitized carbon nanotubes (GCNTs) in industrial applications present significant regulatory challenges that require comprehensive assessment frameworks. Current evidence suggests that GCNTs may pose unique risks due to their distinctive physicochemical properties, including high aspect ratios, surface reactivity, and potential for bioaccumulation in environmental systems.

Exposure pathways for GCNTs in industrial settings primarily occur through inhalation during manufacturing processes, with secondary concerns regarding dermal contact and environmental release through wastewater discharge. Toxicological studies indicate that pulmonary exposure to certain forms of GCNTs can trigger inflammatory responses similar to those observed with asbestos fibers, raising concerns about potential long-term respiratory effects among workers in production facilities.

Environmental persistence represents another critical dimension requiring regulatory attention. Unlike conventional pollutants, GCNTs demonstrate remarkable stability in various environmental matrices, with estimated environmental half-lives potentially extending to years or decades. This persistence creates challenges for traditional environmental risk assessment models that typically assume gradual degradation of contaminants.

Ecotoxicological research has documented potential adverse effects on aquatic organisms, including reduced growth rates in certain fish species and altered behavior in invertebrates following exposure to GCNTs at environmentally relevant concentrations. These findings underscore the importance of establishing specific discharge limits and treatment protocols for industrial facilities utilizing these materials.

The bioaccumulation potential of GCNTs through food webs remains incompletely characterized but warrants regulatory consideration given preliminary evidence of trophic transfer in simplified experimental ecosystems. This knowledge gap highlights the need for standardized bioaccumulation testing protocols specifically adapted to nanomaterials.

Current regulatory frameworks exhibit significant jurisdictional variations, with the European Union's REACH regulations providing the most comprehensive approach through their nanomaterial-specific annexes. In contrast, regulatory oversight in North America and Asia often relies on adapting existing chemical assessment frameworks, creating potential regulatory gaps for these novel materials.

Life cycle assessment (LCA) methodologies for GCNT-containing products remain in early developmental stages, with particular challenges in quantifying end-of-life environmental impacts. Standardizing these assessment approaches represents a critical need for establishing meaningful comparative environmental footprints across different industrial applications and alternative materials.

Exposure pathways for GCNTs in industrial settings primarily occur through inhalation during manufacturing processes, with secondary concerns regarding dermal contact and environmental release through wastewater discharge. Toxicological studies indicate that pulmonary exposure to certain forms of GCNTs can trigger inflammatory responses similar to those observed with asbestos fibers, raising concerns about potential long-term respiratory effects among workers in production facilities.

Environmental persistence represents another critical dimension requiring regulatory attention. Unlike conventional pollutants, GCNTs demonstrate remarkable stability in various environmental matrices, with estimated environmental half-lives potentially extending to years or decades. This persistence creates challenges for traditional environmental risk assessment models that typically assume gradual degradation of contaminants.

Ecotoxicological research has documented potential adverse effects on aquatic organisms, including reduced growth rates in certain fish species and altered behavior in invertebrates following exposure to GCNTs at environmentally relevant concentrations. These findings underscore the importance of establishing specific discharge limits and treatment protocols for industrial facilities utilizing these materials.

The bioaccumulation potential of GCNTs through food webs remains incompletely characterized but warrants regulatory consideration given preliminary evidence of trophic transfer in simplified experimental ecosystems. This knowledge gap highlights the need for standardized bioaccumulation testing protocols specifically adapted to nanomaterials.

Current regulatory frameworks exhibit significant jurisdictional variations, with the European Union's REACH regulations providing the most comprehensive approach through their nanomaterial-specific annexes. In contrast, regulatory oversight in North America and Asia often relies on adapting existing chemical assessment frameworks, creating potential regulatory gaps for these novel materials.

Life cycle assessment (LCA) methodologies for GCNT-containing products remain in early developmental stages, with particular challenges in quantifying end-of-life environmental impacts. Standardizing these assessment approaches represents a critical need for establishing meaningful comparative environmental footprints across different industrial applications and alternative materials.

International Harmonization of CNT Regulatory Frameworks

The global landscape of carbon nanotube (CNT) regulation presents a complex patchwork of standards that varies significantly across regions and countries. This fragmentation creates substantial challenges for manufacturers, researchers, and industrial users operating in international markets. Current regulatory frameworks for graphitized carbon nanotubes are primarily developed at national levels, with limited coordination between jurisdictions, resulting in compliance difficulties and market access barriers.

Major regulatory bodies including the U.S. Environmental Protection Agency (EPA), the European Chemicals Agency (ECHA), and Japan's Ministry of Economy, Trade and Industry (METI) have established distinct approaches to CNT governance. The EPA regulates CNTs under the Toxic Substances Control Act (TSCA), while the EU manages them through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, with each framework emphasizing different aspects of risk assessment and management.

Recent initiatives toward international harmonization have emerged through organizations such as the Organization for Economic Cooperation and Development (OECD) and the International Organization for Standardization (ISO). The OECD's Working Party on Manufactured Nanomaterials has developed standardized testing protocols specifically for CNTs, while ISO Technical Committee 229 has published several standards for nanotechnology nomenclature and characterization.

Mutual recognition agreements (MRAs) between regulatory authorities represent a promising pathway toward harmonization. These agreements enable regulatory decisions made in one jurisdiction to be recognized by another, reducing redundant testing and documentation requirements. The U.S.-EU MRA for conformity assessment has begun incorporating nanomaterials, though specific provisions for graphitized CNTs remain limited.

Industry consortia and public-private partnerships are increasingly contributing to harmonization efforts. The NanoSafety Cluster in Europe and the NanoRelease project in North America have developed shared methodologies for CNT safety assessment that are gaining international recognition. These collaborative initiatives facilitate knowledge exchange and promote consensus-building on technical standards across borders.

Challenges to harmonization include differing risk assessment methodologies, varying definitions of nanomaterials, and inconsistent requirements for toxicological data. Additionally, emerging economies are developing their own regulatory frameworks, further complicating the international landscape. China's approach through the Ministry of Ecology and Environment and India's guidelines from the Bureau of Indian Standards introduce additional regulatory considerations for global CNT manufacturers.

The path forward requires enhanced international dialogue, mutual recognition of test data, and development of globally accepted characterization methods for graphitized CNTs. Establishing international reference materials and standardized testing protocols would significantly advance harmonization efforts and facilitate global trade while maintaining appropriate safety standards.

Major regulatory bodies including the U.S. Environmental Protection Agency (EPA), the European Chemicals Agency (ECHA), and Japan's Ministry of Economy, Trade and Industry (METI) have established distinct approaches to CNT governance. The EPA regulates CNTs under the Toxic Substances Control Act (TSCA), while the EU manages them through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, with each framework emphasizing different aspects of risk assessment and management.

Recent initiatives toward international harmonization have emerged through organizations such as the Organization for Economic Cooperation and Development (OECD) and the International Organization for Standardization (ISO). The OECD's Working Party on Manufactured Nanomaterials has developed standardized testing protocols specifically for CNTs, while ISO Technical Committee 229 has published several standards for nanotechnology nomenclature and characterization.

Mutual recognition agreements (MRAs) between regulatory authorities represent a promising pathway toward harmonization. These agreements enable regulatory decisions made in one jurisdiction to be recognized by another, reducing redundant testing and documentation requirements. The U.S.-EU MRA for conformity assessment has begun incorporating nanomaterials, though specific provisions for graphitized CNTs remain limited.

Industry consortia and public-private partnerships are increasingly contributing to harmonization efforts. The NanoSafety Cluster in Europe and the NanoRelease project in North America have developed shared methodologies for CNT safety assessment that are gaining international recognition. These collaborative initiatives facilitate knowledge exchange and promote consensus-building on technical standards across borders.

Challenges to harmonization include differing risk assessment methodologies, varying definitions of nanomaterials, and inconsistent requirements for toxicological data. Additionally, emerging economies are developing their own regulatory frameworks, further complicating the international landscape. China's approach through the Ministry of Ecology and Environment and India's guidelines from the Bureau of Indian Standards introduce additional regulatory considerations for global CNT manufacturers.

The path forward requires enhanced international dialogue, mutual recognition of test data, and development of globally accepted characterization methods for graphitized CNTs. Establishing international reference materials and standardized testing protocols would significantly advance harmonization efforts and facilitate global trade while maintaining appropriate safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!