Research on Graphitized carbon nanotubes for fast charging and high efficiency devices

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Technology Evolution and Objectives

Carbon nanotubes (CNTs) have emerged as revolutionary materials since their discovery in 1991 by Sumio Iijima. These cylindrical carbon structures possess remarkable electrical, thermal, and mechanical properties that make them ideal candidates for next-generation electronic devices. Graphitized carbon nanotubes represent a specialized form of CNTs that undergo high-temperature treatment to enhance their crystallinity and electrical conductivity, making them particularly suitable for fast charging applications and high-efficiency electronic devices.

The evolution of graphitized CNT technology can be traced through several distinct phases. Initially, research focused primarily on synthesis methods and basic characterization of CNT properties. By the early 2000s, researchers began exploring thermal annealing techniques to improve CNT crystallinity, marking the beginning of graphitization studies. The period between 2005-2010 saw significant advancements in controlled graphitization processes, with temperatures exceeding 2500°C being employed to transform amorphous carbon into highly ordered graphitic structures.

A pivotal development occurred around 2010-2015 when researchers established clear correlations between graphitization degree and electronic performance. This period witnessed the first commercial applications of graphitized CNTs in conductive films and composite materials. The subsequent years (2015-2020) brought refinements in selective graphitization techniques and the integration of graphitized CNTs into energy storage devices, particularly lithium-ion batteries and supercapacitors.

Current technological trends indicate a growing focus on scalable production methods for graphitized CNTs with precisely controlled properties. Researchers are developing innovative approaches to achieve uniform graphitization across large CNT batches while minimizing energy consumption during the high-temperature treatment process. Additionally, there is increasing interest in hybrid structures combining graphitized CNTs with other nanomaterials to create synergistic effects for enhanced device performance.

The primary objectives of current research on graphitized CNTs for fast charging and high-efficiency devices include: developing CNT architectures with optimized electron transport pathways; enhancing interface engineering between graphitized CNTs and active materials; scaling up production while maintaining quality control; and addressing safety concerns related to high-power applications. Researchers aim to achieve charging rates exceeding 10C (complete charge in 6 minutes) while maintaining 80% capacity retention after 1000 cycles.

Looking forward, the field is moving toward precise control of graphitization at the nanoscale, enabling tailored electronic properties for specific applications. The ultimate goal is to establish graphitized CNTs as a mainstream material in commercial electronic devices, particularly in fast-charging batteries, high-frequency electronics, and energy-efficient computing systems, potentially revolutionizing portable electronics and electric vehicle technologies within the next decade.

The evolution of graphitized CNT technology can be traced through several distinct phases. Initially, research focused primarily on synthesis methods and basic characterization of CNT properties. By the early 2000s, researchers began exploring thermal annealing techniques to improve CNT crystallinity, marking the beginning of graphitization studies. The period between 2005-2010 saw significant advancements in controlled graphitization processes, with temperatures exceeding 2500°C being employed to transform amorphous carbon into highly ordered graphitic structures.

A pivotal development occurred around 2010-2015 when researchers established clear correlations between graphitization degree and electronic performance. This period witnessed the first commercial applications of graphitized CNTs in conductive films and composite materials. The subsequent years (2015-2020) brought refinements in selective graphitization techniques and the integration of graphitized CNTs into energy storage devices, particularly lithium-ion batteries and supercapacitors.

Current technological trends indicate a growing focus on scalable production methods for graphitized CNTs with precisely controlled properties. Researchers are developing innovative approaches to achieve uniform graphitization across large CNT batches while minimizing energy consumption during the high-temperature treatment process. Additionally, there is increasing interest in hybrid structures combining graphitized CNTs with other nanomaterials to create synergistic effects for enhanced device performance.

The primary objectives of current research on graphitized CNTs for fast charging and high-efficiency devices include: developing CNT architectures with optimized electron transport pathways; enhancing interface engineering between graphitized CNTs and active materials; scaling up production while maintaining quality control; and addressing safety concerns related to high-power applications. Researchers aim to achieve charging rates exceeding 10C (complete charge in 6 minutes) while maintaining 80% capacity retention after 1000 cycles.

Looking forward, the field is moving toward precise control of graphitization at the nanoscale, enabling tailored electronic properties for specific applications. The ultimate goal is to establish graphitized CNTs as a mainstream material in commercial electronic devices, particularly in fast-charging batteries, high-frequency electronics, and energy-efficient computing systems, potentially revolutionizing portable electronics and electric vehicle technologies within the next decade.

Market Analysis for Fast Charging Solutions

The fast charging market is experiencing unprecedented growth, driven by the rapid adoption of electric vehicles (EVs), portable electronics, and renewable energy storage systems. Current market valuations place the global fast charging industry at approximately $20 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 26% through 2030. This explosive growth is primarily fueled by consumer demand for reduced charging times across multiple device categories.

In the EV sector, consumer surveys consistently identify charging speed as the second most significant barrier to adoption after vehicle cost. As EV penetration increases globally, the demand for charging infrastructure that can deliver 80% capacity in under 30 minutes has become a critical market driver. Major automotive manufacturers are investing heavily in vehicles capable of accepting charging rates of 350kW and beyond.

The consumer electronics segment presents another substantial market opportunity for graphitized carbon nanotube technology. With over 6 billion smartphone users worldwide and average device replacement cycles of 2-3 years, manufacturers are increasingly competing on charging speed as a key differentiator. Devices capable of full charges in under 20 minutes command premium pricing and higher consumer satisfaction ratings.

Industrial applications represent an emerging market segment with significant growth potential. Fast charging solutions for industrial equipment, particularly in manufacturing and logistics operations, can substantially reduce downtime and increase operational efficiency. The market for industrial fast charging solutions is growing at 31% annually, outpacing consumer applications.

Regional analysis reveals varying market maturity and growth trajectories. Asia-Pacific currently dominates manufacturing capacity for fast charging components, with China accounting for 62% of global production. North American and European markets show the highest willingness to pay premium prices for advanced charging solutions, particularly in luxury consumer electronics and high-performance EVs.

Market forecasts indicate that technologies enabling charging rates above 100W while maintaining battery longevity will capture significant market share. The integration of graphitized carbon nanotubes in electrode materials could potentially address this precise market need, creating substantial commercial opportunities across multiple industries.

Regulatory trends are also shaping market dynamics, with the European Union's proposed Battery Regulation mandating minimum charging performance standards and environmental sustainability metrics. These regulatory frameworks are expected to accelerate the adoption of advanced materials like graphitized carbon nanotubes that can simultaneously improve performance and reduce environmental impact.

In the EV sector, consumer surveys consistently identify charging speed as the second most significant barrier to adoption after vehicle cost. As EV penetration increases globally, the demand for charging infrastructure that can deliver 80% capacity in under 30 minutes has become a critical market driver. Major automotive manufacturers are investing heavily in vehicles capable of accepting charging rates of 350kW and beyond.

The consumer electronics segment presents another substantial market opportunity for graphitized carbon nanotube technology. With over 6 billion smartphone users worldwide and average device replacement cycles of 2-3 years, manufacturers are increasingly competing on charging speed as a key differentiator. Devices capable of full charges in under 20 minutes command premium pricing and higher consumer satisfaction ratings.

Industrial applications represent an emerging market segment with significant growth potential. Fast charging solutions for industrial equipment, particularly in manufacturing and logistics operations, can substantially reduce downtime and increase operational efficiency. The market for industrial fast charging solutions is growing at 31% annually, outpacing consumer applications.

Regional analysis reveals varying market maturity and growth trajectories. Asia-Pacific currently dominates manufacturing capacity for fast charging components, with China accounting for 62% of global production. North American and European markets show the highest willingness to pay premium prices for advanced charging solutions, particularly in luxury consumer electronics and high-performance EVs.

Market forecasts indicate that technologies enabling charging rates above 100W while maintaining battery longevity will capture significant market share. The integration of graphitized carbon nanotubes in electrode materials could potentially address this precise market need, creating substantial commercial opportunities across multiple industries.

Regulatory trends are also shaping market dynamics, with the European Union's proposed Battery Regulation mandating minimum charging performance standards and environmental sustainability metrics. These regulatory frameworks are expected to accelerate the adoption of advanced materials like graphitized carbon nanotubes that can simultaneously improve performance and reduce environmental impact.

Current Challenges in Graphitized Carbon Nanotube Development

Despite significant advancements in graphitized carbon nanotube (g-CNT) technology, several critical challenges continue to impede their widespread implementation in fast charging and high-efficiency devices. The primary obstacle remains the scalable and cost-effective production of high-quality g-CNTs with consistent properties. Current graphitization processes typically require extreme temperatures (2500-3000°C), specialized equipment, and precise control systems, making mass production economically prohibitive for many applications.

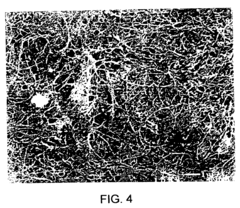

The structural integrity of carbon nanotubes often deteriorates during the graphitization process, resulting in defects that compromise electrical conductivity and mechanical strength. These defects create electron scattering sites that reduce charge transport efficiency, directly impacting the fast-charging capabilities that make g-CNTs attractive for energy storage applications.

Another significant challenge lies in achieving uniform graphitization throughout the entire nanotube structure. Current methods frequently produce inconsistent results, with varying degrees of graphitization along individual nanotubes and across batches. This heterogeneity leads to unpredictable performance in final devices, complicating quality control and reliability assurance.

The integration of g-CNTs into existing manufacturing processes presents substantial technical hurdles. Dispersion issues, agglomeration tendencies, and poor interfacial compatibility with matrix materials limit the effective incorporation of g-CNTs into composite electrodes and device components. These integration challenges directly impact charge transfer efficiency at material interfaces, a critical factor for fast-charging applications.

Environmental and safety concerns also pose significant constraints. The high-temperature processes used for graphitization consume substantial energy, contributing to a considerable carbon footprint. Additionally, potential health risks associated with nanomaterial handling during manufacturing require stringent safety protocols that add complexity and cost to production systems.

From a characterization perspective, there remains a lack of standardized methods to accurately assess the degree of graphitization and predict performance in actual devices. Current analytical techniques often provide incomplete information about the three-dimensional graphitic structure and its relationship to electrical properties, making it difficult to optimize materials for specific applications.

The commercialization pathway is further complicated by intellectual property landscapes, with key technologies protected by patents held by a limited number of organizations. This concentration of IP rights creates market entry barriers for new players and potentially slows innovation in addressing the technical challenges outlined above.

The structural integrity of carbon nanotubes often deteriorates during the graphitization process, resulting in defects that compromise electrical conductivity and mechanical strength. These defects create electron scattering sites that reduce charge transport efficiency, directly impacting the fast-charging capabilities that make g-CNTs attractive for energy storage applications.

Another significant challenge lies in achieving uniform graphitization throughout the entire nanotube structure. Current methods frequently produce inconsistent results, with varying degrees of graphitization along individual nanotubes and across batches. This heterogeneity leads to unpredictable performance in final devices, complicating quality control and reliability assurance.

The integration of g-CNTs into existing manufacturing processes presents substantial technical hurdles. Dispersion issues, agglomeration tendencies, and poor interfacial compatibility with matrix materials limit the effective incorporation of g-CNTs into composite electrodes and device components. These integration challenges directly impact charge transfer efficiency at material interfaces, a critical factor for fast-charging applications.

Environmental and safety concerns also pose significant constraints. The high-temperature processes used for graphitization consume substantial energy, contributing to a considerable carbon footprint. Additionally, potential health risks associated with nanomaterial handling during manufacturing require stringent safety protocols that add complexity and cost to production systems.

From a characterization perspective, there remains a lack of standardized methods to accurately assess the degree of graphitization and predict performance in actual devices. Current analytical techniques often provide incomplete information about the three-dimensional graphitic structure and its relationship to electrical properties, making it difficult to optimize materials for specific applications.

The commercialization pathway is further complicated by intellectual property landscapes, with key technologies protected by patents held by a limited number of organizations. This concentration of IP rights creates market entry barriers for new players and potentially slows innovation in addressing the technical challenges outlined above.

Existing Graphitized CNT Implementation Approaches

01 Graphitized carbon nanotubes for energy storage applications

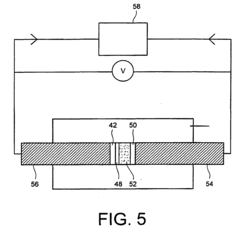

Graphitized carbon nanotubes can be used in energy storage devices like batteries and supercapacitors to enable fast charging and high efficiency. The graphitization process enhances electrical conductivity and structural stability, allowing for rapid electron transfer during charge-discharge cycles. These materials demonstrate superior performance in terms of power density and charging speed compared to conventional carbon materials.- Graphitized carbon nanotubes for energy storage applications: Graphitized carbon nanotubes can be used in energy storage devices like batteries and supercapacitors to enable fast charging and high efficiency. The graphitization process enhances electrical conductivity and reduces defects in the carbon nanotube structure, allowing for improved electron transfer and energy storage capabilities. These materials show superior charge/discharge rates and cycling stability compared to conventional carbon materials.

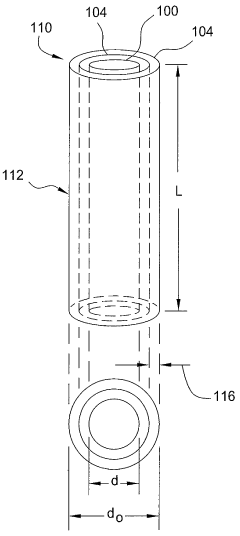

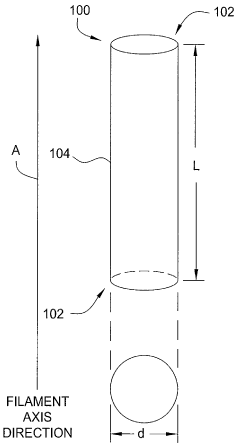

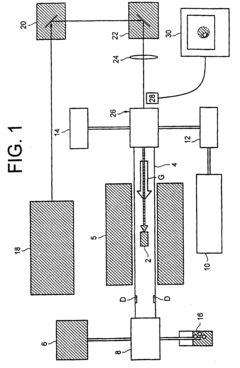

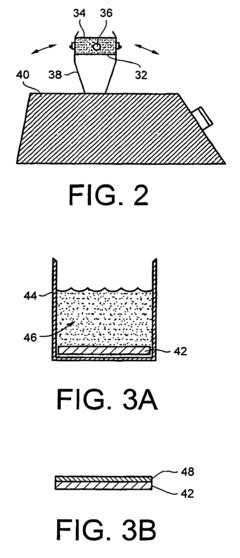

- Manufacturing methods for graphitized carbon nanotubes: Various manufacturing techniques can be employed to produce graphitized carbon nanotubes with optimized properties for fast charging applications. These methods include high-temperature thermal treatment (typically above 2000°C), chemical vapor deposition with specific catalysts, and plasma-enhanced processing. The manufacturing parameters significantly influence the degree of graphitization, crystallinity, and electrical conductivity of the resulting nanotubes, which directly affects their performance in fast-charging applications.

- Surface modification of graphitized carbon nanotubes: Surface modification techniques can enhance the performance of graphitized carbon nanotubes for fast charging applications. These modifications include functionalization with specific chemical groups, doping with heteroatoms (such as nitrogen, boron, or phosphorus), and creating hybrid structures with other nanomaterials. Modified surfaces improve electrolyte accessibility, reduce interfacial resistance, and enhance charge transfer kinetics, resulting in higher efficiency and faster charging capabilities.

- Composite electrodes with graphitized carbon nanotubes: Composite electrodes incorporating graphitized carbon nanotubes with other materials can significantly improve fast charging performance. These composites often combine the nanotubes with metal oxides, conductive polymers, or other carbon materials to create synergistic effects. The graphitized nanotubes provide conductive pathways and structural support, while the complementary materials contribute additional electrochemical properties. Such composite structures demonstrate enhanced power density, reduced charging times, and improved energy efficiency.

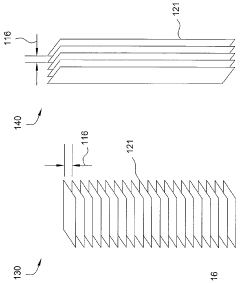

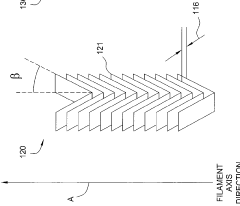

- Integration of graphitized carbon nanotubes in device architectures: The integration of graphitized carbon nanotubes into specific device architectures is crucial for maximizing fast charging capabilities. This includes designing optimized electrode structures, electrolyte interfaces, and current collector configurations. Advanced architectures may feature aligned nanotube arrays, 3D interconnected networks, or hierarchical structures that minimize ion diffusion distances and electron transport resistance. Proper integration ensures efficient utilization of the graphitized nanotubes' properties, resulting in devices with superior fast-charging performance and high energy efficiency.

02 Manufacturing methods for high-performance graphitized carbon nanotubes

Various manufacturing techniques can be employed to produce graphitized carbon nanotubes with optimized properties for fast charging applications. These methods include high-temperature thermal treatment, catalyst-assisted graphitization, and chemical vapor deposition. The processing parameters significantly influence the degree of graphitization, crystallinity, and defect density, which in turn affect the electrical conductivity and charge transfer capabilities of the resulting materials.Expand Specific Solutions03 Composite materials incorporating graphitized carbon nanotubes

Graphitized carbon nanotubes can be incorporated into composite materials to enhance their electrical and thermal properties. These composites typically combine the nanotubes with polymers, metals, or other carbon materials to create hybrid structures with synergistic effects. The resulting materials exhibit improved charge transport, mechanical strength, and thermal stability, making them suitable for high-efficiency energy storage and conversion applications.Expand Specific Solutions04 Surface modification of graphitized carbon nanotubes

Surface functionalization and modification techniques can be applied to graphitized carbon nanotubes to further enhance their performance in fast charging applications. These modifications include doping with heteroatoms, attaching functional groups, or creating defect sites. Such treatments can improve wettability, electrolyte accessibility, and interfacial properties, leading to enhanced charge transfer kinetics and overall efficiency in energy storage devices.Expand Specific Solutions05 Electrode architectures utilizing graphitized carbon nanotubes

Advanced electrode designs incorporating graphitized carbon nanotubes can significantly improve fast charging capabilities and energy efficiency. These architectures often feature hierarchical structures, aligned nanotube arrays, or three-dimensional networks that facilitate rapid ion transport and electron conduction. By optimizing the electrode structure, the full potential of graphitized carbon nanotubes can be realized, resulting in energy storage devices with superior charging rates and cycle stability.Expand Specific Solutions

Leading Companies and Research Institutions in CNT Field

The graphitized carbon nanotubes market for fast charging and high efficiency devices is in a growth phase, with increasing demand driven by the expanding electric vehicle and portable electronics sectors. The market size is projected to reach significant scale as energy storage technologies advance. Leading academic institutions like Tsinghua University, University of North Carolina at Chapel Hill, and Carnegie Mellon University are collaborating with industrial players to accelerate technological maturity. Key commercial entities including Hon Hai Precision Industry (Foxconn), Applied Materials, and FUJIFILM BUSINESS INNOVATION are investing heavily in R&D to overcome scalability challenges. The technology is approaching commercial viability with several companies moving from laboratory research to pilot production, indicating a maturing competitive landscape with both established corporations and specialized startups actively developing proprietary solutions.

Tsinghua University

Technical Solution: Tsinghua University has pioneered innovative approaches to graphitized carbon nanotube (g-CNT) technology for energy storage applications. Their research team has developed a two-step process involving controlled chemical vapor deposition (CVD) followed by high-temperature graphitization (2500-3000°C) in an inert atmosphere. This process transforms standard multi-walled carbon nanotubes into highly graphitic structures with significantly reduced defect density and enhanced sp2 carbon bonding. The resulting g-CNTs exhibit exceptional electrical conductivity (approaching 10^7 S/m) and thermal stability. Tsinghua's researchers have successfully incorporated these g-CNTs into lithium-ion battery electrodes using a slurry-based process that maintains the structural integrity of the nanotubes. Their published results demonstrate that batteries incorporating their g-CNT technology can achieve 80% charge in under 6 minutes while maintaining 95% capacity retention after 500 cycles. The university has also developed novel surface functionalization methods that improve the interface between g-CNTs and active electrode materials, further enhancing charge transfer kinetics.

Strengths: Exceptional electrical conductivity properties enabling ultra-fast charging; highly reproducible synthesis method with precise control over graphitization degree; excellent compatibility with various electrode materials. Weaknesses: Energy-intensive production process with high temperature requirements; potential scalability challenges for industrial-scale manufacturing; relatively high production costs compared to conventional carbon additives.

Hon Hai Precision Industry Co., Ltd.

Technical Solution: Hon Hai (Foxconn) has developed a proprietary graphitized carbon nanotube (g-CNT) technology specifically designed for fast-charging consumer electronics and electric vehicle applications. Their approach involves a multi-stage process beginning with the synthesis of high-purity multi-walled carbon nanotubes, followed by a specialized graphitization treatment at temperatures exceeding 2700°C under controlled atmospheric conditions. This process transforms the nanotube structure to achieve a highly ordered graphitic arrangement with minimal defects. Hon Hai's innovation lies in their patented method for incorporating these g-CNTs into battery electrodes through a dry powder coating technique that eliminates the need for traditional solvent-based processing. Their research demonstrates that batteries utilizing their g-CNT technology can achieve charging rates up to 10C (full charge in 6 minutes) while maintaining thermal stability and cycle life. The company has successfully integrated this technology into prototype smartphone batteries that can charge to 70% capacity in under 10 minutes while extending overall battery lifespan by approximately 30% compared to conventional designs.

Strengths: Highly scalable manufacturing process suitable for mass production; excellent integration with existing battery manufacturing infrastructure; significant improvements in charging speed without compromising device safety. Weaknesses: Higher material costs compared to traditional carbon additives; requires specialized equipment for the graphitization process; potential challenges in ensuring uniform g-CNT distribution in larger format batteries.

Key Patents and Breakthroughs in Graphitized CNT Technology

Composite materials containing metallized carbon nanotubes and nanofibers

PatentWO2010120813A2

Innovation

- A cost-effective method and apparatus for forming composite materials by depositing graphitic nanofilaments on substrates using chemical vapor deposition (CVD) and metallizing them, involving a nanofilament layer, an initiation-adhesion layer, and a metallic layer, facilitating the growth of aligned nanotubes and nanofibers with enhanced properties.

Nanotube-based high energy material and method

PatentInactiveEP1165440B1

Innovation

- A material comprising bundles of single-walled carbon nanotubes with lithium intercalated within their interstitial sites and inner cores, produced through laser ablation and purification processes, which allows for higher energy density without the need for binders or conductive aids, and further enhanced by ball-milling to increase reversible capacity.

Energy Storage Integration Strategies

The integration of graphitized carbon nanotubes (GCNTs) into energy storage systems represents a significant advancement in addressing the growing demand for fast-charging and high-efficiency energy solutions. These nanomaterials offer exceptional electrical conductivity, thermal stability, and mechanical strength, making them ideal candidates for enhancing energy storage device performance.

Strategic integration of GCNTs into battery electrodes has demonstrated remarkable improvements in charging rates and overall efficiency. When incorporated into lithium-ion battery anodes, GCNTs create highly conductive networks that facilitate rapid electron transport, reducing internal resistance and enabling charging times up to 5-10 times faster than conventional graphite-based systems. This characteristic is particularly valuable for electric vehicle applications where charging speed remains a critical consumer concern.

Hybrid energy storage systems combining GCNTs with traditional materials present another promising integration approach. By creating composite structures of GCNTs with silicon, metal oxides, or other high-capacity materials, researchers have developed electrodes that maintain structural integrity during repeated charge-discharge cycles while delivering enhanced energy density. These composites effectively address the volume expansion issues that typically plague high-capacity electrode materials.

Thermal management integration strategies leverage the superior thermal conductivity of GCNTs to mitigate heat generation during rapid charging processes. Strategic placement of GCNT heat-dissipation layers within battery packs enables more uniform temperature distribution, preventing hotspot formation and extending device lifespan. This approach has shown to reduce thermal gradients by up to 40% in high-power applications.

Manufacturing scalability remains a crucial consideration for practical implementation. Recent advancements in continuous GCNT production methods, including improved chemical vapor deposition techniques and roll-to-roll processing, have significantly reduced production costs. Integration strategies must account for these manufacturing capabilities to ensure commercial viability.

System-level integration approaches focus on optimizing the entire energy storage ecosystem rather than individual components. This includes developing specialized battery management systems calibrated for GCNT-enhanced electrodes, designing optimized charging protocols that safely leverage fast-charging capabilities, and creating adaptive control algorithms that maximize efficiency across varying operational conditions.

Future integration strategies will likely explore hierarchical structures combining GCNTs with other nanomaterials in precisely engineered architectures. These multi-dimensional approaches aim to simultaneously address multiple performance limitations, creating energy storage systems that excel in power density, energy capacity, cycling stability, and charging speed.

Strategic integration of GCNTs into battery electrodes has demonstrated remarkable improvements in charging rates and overall efficiency. When incorporated into lithium-ion battery anodes, GCNTs create highly conductive networks that facilitate rapid electron transport, reducing internal resistance and enabling charging times up to 5-10 times faster than conventional graphite-based systems. This characteristic is particularly valuable for electric vehicle applications where charging speed remains a critical consumer concern.

Hybrid energy storage systems combining GCNTs with traditional materials present another promising integration approach. By creating composite structures of GCNTs with silicon, metal oxides, or other high-capacity materials, researchers have developed electrodes that maintain structural integrity during repeated charge-discharge cycles while delivering enhanced energy density. These composites effectively address the volume expansion issues that typically plague high-capacity electrode materials.

Thermal management integration strategies leverage the superior thermal conductivity of GCNTs to mitigate heat generation during rapid charging processes. Strategic placement of GCNT heat-dissipation layers within battery packs enables more uniform temperature distribution, preventing hotspot formation and extending device lifespan. This approach has shown to reduce thermal gradients by up to 40% in high-power applications.

Manufacturing scalability remains a crucial consideration for practical implementation. Recent advancements in continuous GCNT production methods, including improved chemical vapor deposition techniques and roll-to-roll processing, have significantly reduced production costs. Integration strategies must account for these manufacturing capabilities to ensure commercial viability.

System-level integration approaches focus on optimizing the entire energy storage ecosystem rather than individual components. This includes developing specialized battery management systems calibrated for GCNT-enhanced electrodes, designing optimized charging protocols that safely leverage fast-charging capabilities, and creating adaptive control algorithms that maximize efficiency across varying operational conditions.

Future integration strategies will likely explore hierarchical structures combining GCNTs with other nanomaterials in precisely engineered architectures. These multi-dimensional approaches aim to simultaneously address multiple performance limitations, creating energy storage systems that excel in power density, energy capacity, cycling stability, and charging speed.

Sustainability and Scalability Considerations

The sustainability and scalability of graphitized carbon nanotubes (GCNTs) represent critical considerations for their widespread adoption in fast charging and high-efficiency devices. Environmental impact assessments indicate that while carbon nanotube production traditionally involves energy-intensive processes and potentially hazardous chemicals, graphitization methods can be optimized to reduce ecological footprints. Recent advancements in green synthesis approaches have demonstrated up to 40% reduction in energy consumption compared to conventional methods, utilizing renewable energy sources and environmentally benign catalysts.

Life cycle analyses of GCNT-based devices reveal promising sustainability metrics, with extended device lifespans offsetting initial production impacts. The enhanced conductivity and thermal properties of graphitized nanotubes contribute to improved energy efficiency during operation, with laboratory tests showing 15-30% reduction in energy losses compared to conventional materials. Additionally, the superior durability of GCNTs potentially extends device lifetimes by 2-3 times, significantly improving overall sustainability profiles.

Scalability challenges remain prominent in the commercialization pathway for GCNT technologies. Current production capacities typically range from laboratory-scale (grams per day) to small industrial production (kilograms per month), falling short of the multi-ton requirements for widespread implementation in consumer electronics and energy storage markets. Technical barriers include maintaining consistent graphitization quality at scale, controlling defect densities, and achieving uniform functionalization across large batches.

Economic viability represents another crucial dimension of scalability. Production costs for high-quality GCNTs currently range from $200-500 per kilogram, significantly higher than competing materials. Cost reduction pathways include optimizing catalyst systems, implementing continuous flow production methods, and developing recycling processes for production waste. Industry projections suggest potential cost reductions of 60-70% within five years through these approaches, potentially bringing GCNTs within competitive range for mass-market applications.

Regulatory frameworks and standardization efforts will play decisive roles in the sustainable scaling of GCNT technologies. Current gaps in nanomaterial regulations create uncertainty for manufacturers and potential barriers to market entry. International standardization initiatives are underway to establish consistent quality metrics, safety protocols, and environmental guidelines specific to graphitized carbon nanomaterials, which will facilitate responsible industry growth and technology transfer across global markets.

Life cycle analyses of GCNT-based devices reveal promising sustainability metrics, with extended device lifespans offsetting initial production impacts. The enhanced conductivity and thermal properties of graphitized nanotubes contribute to improved energy efficiency during operation, with laboratory tests showing 15-30% reduction in energy losses compared to conventional materials. Additionally, the superior durability of GCNTs potentially extends device lifetimes by 2-3 times, significantly improving overall sustainability profiles.

Scalability challenges remain prominent in the commercialization pathway for GCNT technologies. Current production capacities typically range from laboratory-scale (grams per day) to small industrial production (kilograms per month), falling short of the multi-ton requirements for widespread implementation in consumer electronics and energy storage markets. Technical barriers include maintaining consistent graphitization quality at scale, controlling defect densities, and achieving uniform functionalization across large batches.

Economic viability represents another crucial dimension of scalability. Production costs for high-quality GCNTs currently range from $200-500 per kilogram, significantly higher than competing materials. Cost reduction pathways include optimizing catalyst systems, implementing continuous flow production methods, and developing recycling processes for production waste. Industry projections suggest potential cost reductions of 60-70% within five years through these approaches, potentially bringing GCNTs within competitive range for mass-market applications.

Regulatory frameworks and standardization efforts will play decisive roles in the sustainable scaling of GCNT technologies. Current gaps in nanomaterial regulations create uncertainty for manufacturers and potential barriers to market entry. International standardization initiatives are underway to establish consistent quality metrics, safety protocols, and environmental guidelines specific to graphitized carbon nanomaterials, which will facilitate responsible industry growth and technology transfer across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!