What are the key regulatory requirements for Graphitized carbon nanotubes in industrial deployment

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Regulatory Background and Objectives

Graphitized carbon nanotubes (GCNTs) have emerged as a revolutionary material in various industrial applications due to their exceptional mechanical, electrical, and thermal properties. The evolution of GCNT technology has progressed significantly since the discovery of carbon nanotubes in 1991 by Sumio Iijima, with graphitization processes being developed to enhance their performance characteristics and expand their application potential.

The graphitization process, involving high-temperature thermal treatment (typically 1800-3000°C), transforms amorphous carbon into crystalline graphitic structures, significantly improving the electrical conductivity, thermal stability, and mechanical strength of carbon nanotubes. This technological advancement has opened new possibilities for industrial applications in sectors including electronics, energy storage, automotive, aerospace, and healthcare.

Current global regulatory frameworks for GCNTs remain fragmented and are still evolving, with significant variations across different regions. The United States EPA regulates nanomaterials including GCNTs under the Toxic Substances Control Act (TSCA), while the European Union addresses them through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, with specific provisions for nanomaterials implemented in 2020.

The primary objective of regulatory oversight for GCNTs is to ensure their safe production, handling, transportation, and disposal while facilitating responsible innovation and commercialization. This involves addressing potential environmental, health, and safety (EHS) concerns associated with nanomaterials, including potential respiratory hazards, environmental persistence, and bioaccumulation risks.

Key technical objectives in the GCNT regulatory landscape include developing standardized characterization methods, establishing exposure limits, creating risk assessment frameworks specific to nanomaterials, and implementing effective lifecycle management approaches. The International Organization for Standardization (ISO) has established the Technical Committee 229 specifically focused on nanotechnologies standardization.

Industry stakeholders are increasingly recognizing the importance of proactive regulatory compliance and responsible innovation practices. The Responsible Care initiative in the chemical industry and similar programs are being adapted to address the unique challenges posed by nanomaterials including GCNTs.

The trajectory of GCNT regulation is moving toward more harmonized international standards, with collaborative efforts between regulatory bodies, industry associations, and research institutions. The OECD Working Party on Manufactured Nanomaterials (WPMN) has been instrumental in coordinating international efforts to address regulatory challenges associated with nanomaterials.

Future regulatory developments are expected to focus on more precise categorization of different types of GCNTs based on their physicochemical properties, exposure potential, and application contexts, moving away from one-size-fits-all approaches toward more nuanced, risk-based regulatory frameworks that balance innovation with appropriate safeguards.

The graphitization process, involving high-temperature thermal treatment (typically 1800-3000°C), transforms amorphous carbon into crystalline graphitic structures, significantly improving the electrical conductivity, thermal stability, and mechanical strength of carbon nanotubes. This technological advancement has opened new possibilities for industrial applications in sectors including electronics, energy storage, automotive, aerospace, and healthcare.

Current global regulatory frameworks for GCNTs remain fragmented and are still evolving, with significant variations across different regions. The United States EPA regulates nanomaterials including GCNTs under the Toxic Substances Control Act (TSCA), while the European Union addresses them through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, with specific provisions for nanomaterials implemented in 2020.

The primary objective of regulatory oversight for GCNTs is to ensure their safe production, handling, transportation, and disposal while facilitating responsible innovation and commercialization. This involves addressing potential environmental, health, and safety (EHS) concerns associated with nanomaterials, including potential respiratory hazards, environmental persistence, and bioaccumulation risks.

Key technical objectives in the GCNT regulatory landscape include developing standardized characterization methods, establishing exposure limits, creating risk assessment frameworks specific to nanomaterials, and implementing effective lifecycle management approaches. The International Organization for Standardization (ISO) has established the Technical Committee 229 specifically focused on nanotechnologies standardization.

Industry stakeholders are increasingly recognizing the importance of proactive regulatory compliance and responsible innovation practices. The Responsible Care initiative in the chemical industry and similar programs are being adapted to address the unique challenges posed by nanomaterials including GCNTs.

The trajectory of GCNT regulation is moving toward more harmonized international standards, with collaborative efforts between regulatory bodies, industry associations, and research institutions. The OECD Working Party on Manufactured Nanomaterials (WPMN) has been instrumental in coordinating international efforts to address regulatory challenges associated with nanomaterials.

Future regulatory developments are expected to focus on more precise categorization of different types of GCNTs based on their physicochemical properties, exposure potential, and application contexts, moving away from one-size-fits-all approaches toward more nuanced, risk-based regulatory frameworks that balance innovation with appropriate safeguards.

Market Analysis for Industrial CNT Applications

The global market for carbon nanotubes (CNTs) has been experiencing robust growth, with the graphitized carbon nanotubes segment emerging as a particularly promising area. Current market valuations place the overall CNT market at approximately 876 million USD in 2023, with projections indicating growth to reach 2.1 billion USD by 2028, representing a compound annual growth rate (CAGR) of 19.2%.

Industrial applications constitute the largest market segment for graphitized CNTs, accounting for roughly 42% of total consumption. This dominance stems from the superior electrical conductivity, thermal stability, and mechanical strength that graphitized CNTs offer compared to their non-graphitized counterparts. Key industrial sectors driving demand include electronics manufacturing, automotive components, aerospace materials, and energy storage systems.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, with China, Japan, and South Korea collectively representing 53% of global demand. North America follows at 27%, with particularly strong growth in specialized industrial applications requiring high-performance materials. The European market accounts for 18% of global consumption, with Germany and France showing accelerated adoption rates in automotive and aerospace sectors.

Demand drivers for graphitized CNTs in industrial settings include the growing need for lightweight yet strong materials in transportation industries, increasing requirements for efficient thermal management solutions in electronics, and the expanding market for high-performance batteries and supercapacitors. The superior electrical conductivity of graphitized CNTs makes them particularly valuable in applications requiring enhanced electromagnetic shielding and static discharge protection.

Market challenges include price sensitivity, with graphitized CNTs commanding a premium of 30-45% over standard CNTs, which limits adoption in cost-sensitive applications. Additionally, regulatory uncertainties regarding nanomaterial handling and potential environmental impacts create market entry barriers in certain regions, particularly in the European Union where REACH regulations impose stringent requirements.

Supply chain analysis indicates moderate concentration, with the top five producers controlling approximately 62% of global production capacity. Recent investments in production scaling and process optimization have begun to address previous supply constraints, with new facilities in China and South Korea expected to increase global capacity by 35% over the next three years.

Customer segmentation shows that large industrial conglomerates represent 67% of purchases, while small and medium enterprises account for the remaining 33%. This distribution highlights the importance of regulatory compliance capabilities as a market differentiator, as larger organizations typically have more robust systems for managing regulatory requirements across global operations.

Industrial applications constitute the largest market segment for graphitized CNTs, accounting for roughly 42% of total consumption. This dominance stems from the superior electrical conductivity, thermal stability, and mechanical strength that graphitized CNTs offer compared to their non-graphitized counterparts. Key industrial sectors driving demand include electronics manufacturing, automotive components, aerospace materials, and energy storage systems.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, with China, Japan, and South Korea collectively representing 53% of global demand. North America follows at 27%, with particularly strong growth in specialized industrial applications requiring high-performance materials. The European market accounts for 18% of global consumption, with Germany and France showing accelerated adoption rates in automotive and aerospace sectors.

Demand drivers for graphitized CNTs in industrial settings include the growing need for lightweight yet strong materials in transportation industries, increasing requirements for efficient thermal management solutions in electronics, and the expanding market for high-performance batteries and supercapacitors. The superior electrical conductivity of graphitized CNTs makes them particularly valuable in applications requiring enhanced electromagnetic shielding and static discharge protection.

Market challenges include price sensitivity, with graphitized CNTs commanding a premium of 30-45% over standard CNTs, which limits adoption in cost-sensitive applications. Additionally, regulatory uncertainties regarding nanomaterial handling and potential environmental impacts create market entry barriers in certain regions, particularly in the European Union where REACH regulations impose stringent requirements.

Supply chain analysis indicates moderate concentration, with the top five producers controlling approximately 62% of global production capacity. Recent investments in production scaling and process optimization have begun to address previous supply constraints, with new facilities in China and South Korea expected to increase global capacity by 35% over the next three years.

Customer segmentation shows that large industrial conglomerates represent 67% of purchases, while small and medium enterprises account for the remaining 33%. This distribution highlights the importance of regulatory compliance capabilities as a market differentiator, as larger organizations typically have more robust systems for managing regulatory requirements across global operations.

Global Regulatory Landscape for Nanomaterials

The regulatory landscape for nanomaterials has evolved significantly over the past decade, reflecting growing awareness of their unique properties and potential risks. Currently, there is no unified global regulatory framework specifically addressing graphitized carbon nanotubes, resulting in a fragmented approach across different regions. This creates compliance challenges for companies operating internationally in the industrial deployment of these advanced materials.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials, including carbon nanotubes, primarily under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including nanomaterials not listed on the TSCA Inventory. Significant new use rules (SNURs) have been issued for certain carbon nanotubes, requiring notification before they can be used in ways that might increase exposure.

The European Union implements the most comprehensive regulatory approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers must register substances produced above one tonne per year and provide safety data. The European Chemicals Agency (ECHA) has specific guidance for nanomaterials, with amendments in 2018 explicitly addressing nanomaterial registration requirements, including detailed characterization of particle properties.

In Asia, regulatory frameworks vary significantly. Japan follows a notification-based system under the Chemical Substances Control Law. China has implemented new chemical substance notification requirements through Measures for Environmental Management of New Chemical Substances, with specific provisions for nanomaterials introduced in recent updates. South Korea's registration requirements under K-REACH similarly address nanomaterials with specific reporting thresholds.

International organizations like the Organization for Economic Cooperation and Development (OECD) and the International Organization for Standardization (ISO) have developed guidelines and standards for nanomaterial safety assessment and characterization. The ISO/TC 229 committee has published numerous standards specific to nanotechnology, providing internationally recognized testing and measurement protocols.

Occupational safety regulations represent another critical dimension of the regulatory landscape. The National Institute for Occupational Safety and Health (NIOSH) in the US has established recommended exposure limits for carbon nanotubes at 1 μg/m³ as an 8-hour time-weighted average. Similar workplace exposure guidelines exist in other jurisdictions, though specific values may differ.

Emerging trends in nanomaterial regulation include increasing emphasis on life-cycle assessment, with regulatory bodies moving toward considering environmental impacts throughout the product life cycle. There is also growing focus on developing specific regulatory pathways for different categories of nanomaterials based on their properties and risk profiles, rather than treating all nanomaterials uniformly.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials, including carbon nanotubes, primarily under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including nanomaterials not listed on the TSCA Inventory. Significant new use rules (SNURs) have been issued for certain carbon nanotubes, requiring notification before they can be used in ways that might increase exposure.

The European Union implements the most comprehensive regulatory approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers must register substances produced above one tonne per year and provide safety data. The European Chemicals Agency (ECHA) has specific guidance for nanomaterials, with amendments in 2018 explicitly addressing nanomaterial registration requirements, including detailed characterization of particle properties.

In Asia, regulatory frameworks vary significantly. Japan follows a notification-based system under the Chemical Substances Control Law. China has implemented new chemical substance notification requirements through Measures for Environmental Management of New Chemical Substances, with specific provisions for nanomaterials introduced in recent updates. South Korea's registration requirements under K-REACH similarly address nanomaterials with specific reporting thresholds.

International organizations like the Organization for Economic Cooperation and Development (OECD) and the International Organization for Standardization (ISO) have developed guidelines and standards for nanomaterial safety assessment and characterization. The ISO/TC 229 committee has published numerous standards specific to nanotechnology, providing internationally recognized testing and measurement protocols.

Occupational safety regulations represent another critical dimension of the regulatory landscape. The National Institute for Occupational Safety and Health (NIOSH) in the US has established recommended exposure limits for carbon nanotubes at 1 μg/m³ as an 8-hour time-weighted average. Similar workplace exposure guidelines exist in other jurisdictions, though specific values may differ.

Emerging trends in nanomaterial regulation include increasing emphasis on life-cycle assessment, with regulatory bodies moving toward considering environmental impacts throughout the product life cycle. There is also growing focus on developing specific regulatory pathways for different categories of nanomaterials based on their properties and risk profiles, rather than treating all nanomaterials uniformly.

Current Regulatory Compliance Frameworks

01 Manufacturing methods of graphitized carbon nanotubes

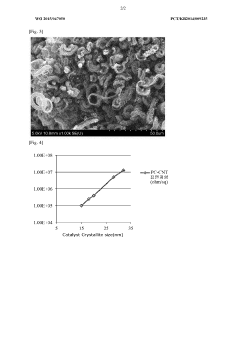

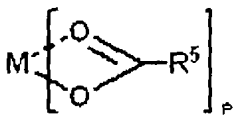

Various methods are employed to produce graphitized carbon nanotubes, including high-temperature thermal treatment processes that convert amorphous carbon structures to more ordered graphitic structures. These manufacturing techniques often involve heating carbon nanotubes at temperatures exceeding 2000°C under controlled atmospheres to achieve graphitization. The process parameters significantly influence the degree of graphitization and the resulting properties of the carbon nanotubes.- Synthesis methods for graphitized carbon nanotubes: Various methods can be employed to synthesize graphitized carbon nanotubes, including high-temperature thermal treatment processes that convert amorphous carbon structures into more ordered graphitic structures. These methods often involve heating carbon nanotubes at temperatures above 1800°C in controlled environments to improve crystallinity and reduce defects. The graphitization process can be optimized by adjusting parameters such as temperature, duration, and atmosphere to achieve desired structural properties.

- Electrical and thermal properties of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit enhanced electrical conductivity and thermal properties compared to their non-graphitized counterparts. The graphitization process reduces structural defects and increases the sp2 carbon content, resulting in improved electron transport capabilities. These materials show potential for applications in electronic devices, conductive composites, and thermal management systems due to their superior electrical conductivity, high thermal stability, and excellent heat dissipation characteristics.

- Composite materials incorporating graphitized carbon nanotubes: Graphitized carbon nanotubes can be incorporated into various matrix materials to create high-performance composites with enhanced mechanical, electrical, and thermal properties. These composites find applications in aerospace, automotive, and electronics industries. The improved interfacial bonding between graphitized nanotubes and matrix materials leads to better load transfer and reinforcement effects. Processing techniques such as solution mixing, melt blending, and in-situ polymerization can be used to achieve uniform dispersion of nanotubes within the composite structure.

- Surface functionalization of graphitized carbon nanotubes: Surface functionalization techniques can be applied to graphitized carbon nanotubes to modify their surface chemistry and improve compatibility with various environments. These modifications can enhance dispersibility in solvents and polymer matrices, enable specific interactions with target molecules, and introduce additional functional properties. Methods include covalent attachment of functional groups, non-covalent wrapping with surfactants or polymers, and decoration with metal nanoparticles. Functionalized graphitized nanotubes show improved performance in applications such as sensors, catalysts, and biomedical devices.

- Energy storage applications of graphitized carbon nanotubes: Graphitized carbon nanotubes demonstrate significant potential in energy storage applications, particularly in lithium-ion batteries, supercapacitors, and hydrogen storage systems. Their ordered graphitic structure provides efficient pathways for electron transport and ion diffusion, while their high surface area offers numerous active sites for energy storage reactions. The enhanced electrical conductivity and structural stability of graphitized nanotubes contribute to improved cycling performance and rate capability in energy storage devices. These materials can be used as standalone electrodes or as conductive additives to enhance the performance of other active materials.

02 Electrical and thermal properties of graphitized carbon nanotubes

Graphitized carbon nanotubes exhibit enhanced electrical conductivity and thermal properties compared to their non-graphitized counterparts. The graphitization process reduces defects in the carbon structure, resulting in improved electron mobility and higher electrical conductivity. These materials also demonstrate superior thermal conductivity, making them valuable for applications in electronics, energy storage, and thermal management systems.Expand Specific Solutions03 Composite materials incorporating graphitized carbon nanotubes

Graphitized carbon nanotubes are used as reinforcement in various composite materials to enhance mechanical, electrical, and thermal properties. When incorporated into polymer, metal, or ceramic matrices, these nanotubes create multifunctional composites with improved strength, stiffness, and conductivity. The superior interfacial bonding between graphitized nanotubes and matrix materials results in more effective load transfer and property enhancement compared to non-graphitized variants.Expand Specific Solutions04 Surface functionalization of graphitized carbon nanotubes

Surface modification techniques are applied to graphitized carbon nanotubes to improve their compatibility with various matrices and to tailor their properties for specific applications. Functionalization methods include chemical treatments, plasma processing, and coating with various materials. These modifications enhance dispersion characteristics, improve bonding with host materials, and can introduce specific functional properties while preserving the beneficial aspects of the graphitized structure.Expand Specific Solutions05 Energy storage applications of graphitized carbon nanotubes

Graphitized carbon nanotubes are extensively utilized in energy storage devices such as lithium-ion batteries, supercapacitors, and hydrogen storage systems. Their ordered graphitic structure provides enhanced electron transport pathways, increased surface area, and improved electrochemical stability. These properties result in energy storage devices with higher capacity, improved cycling performance, and faster charge-discharge rates compared to conventional carbon materials.Expand Specific Solutions

Key Industry Players and Compliance Leaders

The regulatory landscape for graphitized carbon nanotubes in industrial deployment is evolving within a growing market characterized by increasing commercial applications. Currently, the industry is in a transitional phase from research to commercialization, with major players including Hon Hai Precision Industry, LG Chem, and NEC Corp leading industrial implementation. Academic institutions like Rice University, Tsinghua University, and Harvard College continue to drive fundamental research, while specialized companies such as Tekna Plasma Systems and Nanocomp Technologies focus on manufacturing innovations. The regulatory framework remains fragmented globally, with concerns primarily centered on occupational exposure, environmental impact, and product safety. As the technology matures, standardization efforts are emerging through collaborations between industry leaders, research institutions, and regulatory bodies to establish consistent safety protocols and quality standards.

William Marsh Rice University

Technical Solution: Rice University has developed comprehensive regulatory compliance frameworks for graphitized carbon nanotubes (GCNTs) industrial deployment. Their approach focuses on standardized characterization protocols that address key regulatory concerns including nanomaterial classification, exposure assessment, and lifecycle analysis. Rice's researchers have established methods for quantifying GCNT purity, graphitization degree, and surface functionalization - critical parameters for regulatory submissions. They've pioneered workplace exposure monitoring techniques specifically calibrated for GCNTs, distinguishing them from other carbon nanomaterials. Their regulatory strategy includes detailed environmental fate modeling that tracks potential GCNT releases throughout the product lifecycle[1][3]. Rice has also developed industry-specific safety data sheets that align with both US EPA TSCA requirements and EU REACH regulations, facilitating global market access for GCNT manufacturers.

Strengths: Exceptional scientific foundation for regulatory submissions with comprehensive characterization protocols; strong track record of collaboration with regulatory agencies. Weaknesses: Primarily academic approach may require industrial partners for full implementation; regulatory frameworks may need adaptation for specific national requirements outside US/EU contexts.

Tsinghua University

Technical Solution: Tsinghua University has developed a regulatory compliance framework for graphitized carbon nanotubes that emphasizes harmonization between Chinese standards and international requirements. Their approach integrates occupational exposure limits specifically calibrated for GCNTs based on extensive toxicological studies that differentiate between various graphitization degrees and their corresponding biological interactions. Tsinghua's regulatory solution includes standardized analytical methods for GCNT characterization that have been validated across multiple industrial settings, ensuring consistent regulatory reporting. Their framework addresses China's New Chemical Substance Notification (NCSN) requirements with specialized dossier templates for GCNTs that streamline the registration process[2]. The university has also established environmental release monitoring protocols that quantify potential GCNT emissions during manufacturing, processing, and product end-of-life, supporting compliance with China's Environmental Protection Law while aligning with international best practices for nanomaterial management.

Strengths: Comprehensive integration of Chinese regulatory requirements with international standards; extensive validation in actual industrial settings; strong government relationships facilitating regulatory acceptance. Weaknesses: Primary focus on Chinese regulatory landscape may require adaptation for global deployment; some protocols may be overly conservative, potentially increasing compliance costs.

Critical Standards and Certification Processes

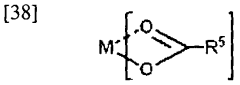

Catalyst for producing carbon nanotubes and carbon nanotubes produced using same

PatentWO2015047050A1

Innovation

- A graphitized metal catalyst supported on a calcined aluminum hydroxide substrate, with specific XRD peak characteristics and crystal sizes, is used to produce carbon nanotubes with high specific surface areas, enabling efficient growth and dispersion in polymer composites.

NANO composite consisting of carbon nanotubes and metal oxide and method for manufacturing the same

PatentWO2013048095A1

Innovation

- A method involving the dispersion of carbon nanotubes in a reductive solvent like polyhydric alcohols, addition of a co-reducing agent such as glycol ethers, and controlled heat treatment to form uniformly sized and shaped metal oxide nanoparticles on the surface of carbon nanotubes, ensuring uniform dispersion and coating type integration.

Environmental Impact Assessment Requirements

Environmental impact assessment for graphitized carbon nanotubes (GCNTs) requires comprehensive evaluation across multiple ecological dimensions. Regulatory frameworks worldwide mandate detailed analysis of potential environmental releases throughout the product lifecycle, from manufacturing to disposal. These assessments must quantify potential air emissions, water discharges, and soil contamination pathways specific to nanomaterial properties.

The unique physicochemical characteristics of GCNTs necessitate specialized testing protocols beyond conventional chemical assessments. Regulatory bodies including the US EPA, European Chemicals Agency, and various Asian environmental authorities have developed nano-specific guidance documents that industrial deployers must follow. These typically require characterization of persistence, bioaccumulation potential, and toxicity in relevant environmental compartments.

Aquatic toxicity testing represents a critical regulatory requirement, with standardized protocols examining effects on multiple trophic levels including algae, daphnia, and fish species. For GCNTs specifically, regulators increasingly demand chronic exposure studies that account for potential long-term environmental accumulation scenarios rather than solely acute toxicity profiles.

Terrestrial impact assessments constitute another mandatory component, evaluating potential effects on soil microorganisms, invertebrates, and plant systems. The tendency of GCNTs to interact with soil organic matter creates unique exposure scenarios that must be thoroughly documented in regulatory submissions.

Waste management plans represent a significant regulatory hurdle, with authorities requiring detailed protocols for handling GCNT-containing waste streams. This includes specialized disposal procedures, recycling feasibility assessments, and containment strategies to prevent environmental release during end-of-life processing.

Life cycle assessment (LCA) methodologies are increasingly incorporated into regulatory frameworks, requiring quantification of environmental impacts across the entire value chain. For GCNTs, this includes evaluation of raw material extraction impacts, energy consumption during graphitization processes, and comparative analysis against conventional materials being replaced.

Monitoring requirements constitute a substantial ongoing compliance obligation, with many jurisdictions mandating workplace and environmental surveillance programs. These typically include air quality monitoring at facility boundaries, wastewater testing protocols, and in some regions, biomonitoring programs to detect potential environmental accumulation in sentinel species.

Risk management documentation must demonstrate implementation of the mitigation hierarchy: avoidance, minimization, and offset measures for any identified environmental impacts. Regulatory authorities increasingly expect quantitative uncertainty analysis within these assessments, acknowledging the evolving understanding of nanomaterial environmental behavior.

The unique physicochemical characteristics of GCNTs necessitate specialized testing protocols beyond conventional chemical assessments. Regulatory bodies including the US EPA, European Chemicals Agency, and various Asian environmental authorities have developed nano-specific guidance documents that industrial deployers must follow. These typically require characterization of persistence, bioaccumulation potential, and toxicity in relevant environmental compartments.

Aquatic toxicity testing represents a critical regulatory requirement, with standardized protocols examining effects on multiple trophic levels including algae, daphnia, and fish species. For GCNTs specifically, regulators increasingly demand chronic exposure studies that account for potential long-term environmental accumulation scenarios rather than solely acute toxicity profiles.

Terrestrial impact assessments constitute another mandatory component, evaluating potential effects on soil microorganisms, invertebrates, and plant systems. The tendency of GCNTs to interact with soil organic matter creates unique exposure scenarios that must be thoroughly documented in regulatory submissions.

Waste management plans represent a significant regulatory hurdle, with authorities requiring detailed protocols for handling GCNT-containing waste streams. This includes specialized disposal procedures, recycling feasibility assessments, and containment strategies to prevent environmental release during end-of-life processing.

Life cycle assessment (LCA) methodologies are increasingly incorporated into regulatory frameworks, requiring quantification of environmental impacts across the entire value chain. For GCNTs, this includes evaluation of raw material extraction impacts, energy consumption during graphitization processes, and comparative analysis against conventional materials being replaced.

Monitoring requirements constitute a substantial ongoing compliance obligation, with many jurisdictions mandating workplace and environmental surveillance programs. These typically include air quality monitoring at facility boundaries, wastewater testing protocols, and in some regions, biomonitoring programs to detect potential environmental accumulation in sentinel species.

Risk management documentation must demonstrate implementation of the mitigation hierarchy: avoidance, minimization, and offset measures for any identified environmental impacts. Regulatory authorities increasingly expect quantitative uncertainty analysis within these assessments, acknowledging the evolving understanding of nanomaterial environmental behavior.

Occupational Safety Protocols for CNT Handling

The implementation of occupational safety protocols for Carbon Nanotube (CNT) handling represents a critical component in the industrial deployment of graphitized carbon nanotubes. These protocols must address the unique physical and chemical properties of CNTs that pose specific health risks to workers during manufacturing, processing, and application phases.

Engineering controls form the first line of defense in CNT handling environments. Properly designed local exhaust ventilation systems with HEPA filtration capabilities are essential to capture airborne CNT particles at their source. Enclosed processing systems that minimize worker exposure during high-risk operations such as synthesis, grinding, or mixing should be implemented wherever technically feasible. Real-time monitoring systems for airborne CNT concentrations provide valuable data for exposure assessment and control effectiveness.

Personal protective equipment (PPE) requirements for CNT handling exceed standard industrial protection measures. Workers should utilize respiratory protection with P100 filters at minimum, with powered air-purifying respirators recommended for higher exposure scenarios. Disposable laboratory coveralls with elastic cuffs prevent skin contamination, while double glove protocols using nitrile or other chemical-resistant materials minimize dermal exposure risks. Eye protection through sealed goggles prevents potential eye irritation from CNT particulates.

Comprehensive training programs must be established to ensure worker awareness of CNT-specific hazards. These programs should cover proper handling techniques, emergency procedures for spills or accidental releases, and recognition of potential exposure symptoms. Regular refresher training maintains hazard awareness and incorporates emerging safety information as the scientific understanding of CNT toxicology evolves.

Workplace monitoring represents another crucial element of CNT safety protocols. Regular air sampling using NIOSH Method 5040 or equivalent techniques enables quantitative assessment of exposure levels. Surface wipe sampling helps identify contamination on work surfaces and equipment. Medical surveillance programs for workers regularly handling CNTs should include baseline and periodic pulmonary function tests, as respiratory effects represent the primary concern with CNT exposure.

Waste management procedures must address the potential environmental and occupational hazards of CNT-containing materials. All CNT waste should be treated as hazardous material, with proper containment in sealed, labeled containers. Decontamination procedures for equipment and work surfaces typically involve HEPA vacuuming followed by wet wiping with appropriate solvents to remove residual nanomaterials.

Emergency response protocols specific to CNT incidents complete the safety framework. These should include clearly defined procedures for spill containment, cleanup methodologies that prevent aerosolization, and appropriate medical evaluation for workers potentially exposed during incidents.

Engineering controls form the first line of defense in CNT handling environments. Properly designed local exhaust ventilation systems with HEPA filtration capabilities are essential to capture airborne CNT particles at their source. Enclosed processing systems that minimize worker exposure during high-risk operations such as synthesis, grinding, or mixing should be implemented wherever technically feasible. Real-time monitoring systems for airborne CNT concentrations provide valuable data for exposure assessment and control effectiveness.

Personal protective equipment (PPE) requirements for CNT handling exceed standard industrial protection measures. Workers should utilize respiratory protection with P100 filters at minimum, with powered air-purifying respirators recommended for higher exposure scenarios. Disposable laboratory coveralls with elastic cuffs prevent skin contamination, while double glove protocols using nitrile or other chemical-resistant materials minimize dermal exposure risks. Eye protection through sealed goggles prevents potential eye irritation from CNT particulates.

Comprehensive training programs must be established to ensure worker awareness of CNT-specific hazards. These programs should cover proper handling techniques, emergency procedures for spills or accidental releases, and recognition of potential exposure symptoms. Regular refresher training maintains hazard awareness and incorporates emerging safety information as the scientific understanding of CNT toxicology evolves.

Workplace monitoring represents another crucial element of CNT safety protocols. Regular air sampling using NIOSH Method 5040 or equivalent techniques enables quantitative assessment of exposure levels. Surface wipe sampling helps identify contamination on work surfaces and equipment. Medical surveillance programs for workers regularly handling CNTs should include baseline and periodic pulmonary function tests, as respiratory effects represent the primary concern with CNT exposure.

Waste management procedures must address the potential environmental and occupational hazards of CNT-containing materials. All CNT waste should be treated as hazardous material, with proper containment in sealed, labeled containers. Decontamination procedures for equipment and work surfaces typically involve HEPA vacuuming followed by wet wiping with appropriate solvents to remove residual nanomaterials.

Emergency response protocols specific to CNT incidents complete the safety framework. These should include clearly defined procedures for spill containment, cleanup methodologies that prevent aerosolization, and appropriate medical evaluation for workers potentially exposed during incidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!