Research on Graphitized carbon nanotubes for high voltage and high current applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Nanotube Technology Background and Objectives

Carbon nanotubes (CNTs) have emerged as one of the most promising nanomaterials since their discovery in 1991 by Sumio Iijima. These cylindrical structures composed of carbon atoms arranged in a hexagonal lattice have garnered significant attention due to their exceptional mechanical, thermal, and electrical properties. The evolution of CNT technology has progressed from initial laboratory curiosity to potential industrial applications, with graphitized carbon nanotubes representing a specialized advancement in this field.

Graphitization of carbon nanotubes involves high-temperature thermal treatment (typically above 2000°C) that enhances their crystallinity, reduces defects, and improves their electrical conductivity. This process transforms standard CNTs into materials particularly suitable for high voltage and high current applications, which is the focal point of our research. The historical trajectory shows a steady improvement in synthesis methods, from arc discharge and laser ablation to chemical vapor deposition (CVD), which now enables more controlled production of CNTs with specific properties.

The technological objectives for graphitized carbon nanotubes in high voltage and high current applications are multifaceted. Primary goals include developing CNTs with ultra-high current carrying capacity exceeding 10^9 A/cm², breakdown voltages above 10 kV/mm, and thermal stability at temperatures exceeding 200°C under continuous operation. Additionally, research aims to achieve uniform graphitization across large batches, scalable production methods, and integration techniques compatible with existing electrical infrastructure.

Current trends indicate a growing interest in hybrid systems that combine graphitized CNTs with traditional conductive materials to create composite solutions that leverage the strengths of both. The miniaturization of power electronics, increasing demand for efficient energy transmission, and the push toward electrification in transportation are driving forces behind the accelerated development of these advanced materials.

The technical evolution path suggests that next-generation graphitized CNTs will likely focus on controlled doping to further enhance conductivity, development of aligned CNT arrays for directional current flow, and surface functionalization to improve interface properties with other materials in electrical systems. These advancements are expected to enable breakthrough applications in power transmission, electric vehicles, aerospace systems, and next-generation electronics.

Research objectives also include understanding the fundamental mechanisms of electrical conduction in graphitized CNTs under extreme conditions, developing standardized testing protocols for high voltage and current applications, and establishing reliability metrics for long-term operation. The ultimate goal is to transition graphitized CNT technology from laboratory demonstrations to commercially viable products that can revolutionize high-power electrical systems.

Graphitization of carbon nanotubes involves high-temperature thermal treatment (typically above 2000°C) that enhances their crystallinity, reduces defects, and improves their electrical conductivity. This process transforms standard CNTs into materials particularly suitable for high voltage and high current applications, which is the focal point of our research. The historical trajectory shows a steady improvement in synthesis methods, from arc discharge and laser ablation to chemical vapor deposition (CVD), which now enables more controlled production of CNTs with specific properties.

The technological objectives for graphitized carbon nanotubes in high voltage and high current applications are multifaceted. Primary goals include developing CNTs with ultra-high current carrying capacity exceeding 10^9 A/cm², breakdown voltages above 10 kV/mm, and thermal stability at temperatures exceeding 200°C under continuous operation. Additionally, research aims to achieve uniform graphitization across large batches, scalable production methods, and integration techniques compatible with existing electrical infrastructure.

Current trends indicate a growing interest in hybrid systems that combine graphitized CNTs with traditional conductive materials to create composite solutions that leverage the strengths of both. The miniaturization of power electronics, increasing demand for efficient energy transmission, and the push toward electrification in transportation are driving forces behind the accelerated development of these advanced materials.

The technical evolution path suggests that next-generation graphitized CNTs will likely focus on controlled doping to further enhance conductivity, development of aligned CNT arrays for directional current flow, and surface functionalization to improve interface properties with other materials in electrical systems. These advancements are expected to enable breakthrough applications in power transmission, electric vehicles, aerospace systems, and next-generation electronics.

Research objectives also include understanding the fundamental mechanisms of electrical conduction in graphitized CNTs under extreme conditions, developing standardized testing protocols for high voltage and current applications, and establishing reliability metrics for long-term operation. The ultimate goal is to transition graphitized CNT technology from laboratory demonstrations to commercially viable products that can revolutionize high-power electrical systems.

Market Analysis for High Voltage Applications

The high voltage application market for graphitized carbon nanotubes (GCNTs) is experiencing robust growth, driven by increasing demand for advanced materials in power transmission, electronics, and renewable energy sectors. The global high voltage equipment market, where GCNTs can play a significant role, is projected to reach $24.7 billion by 2025, growing at a CAGR of 7.2% from 2020.

Power transmission and distribution infrastructure represents the largest market segment for high voltage applications of GCNTs. With aging grid infrastructure in developed nations and expanding electrification in developing regions, substantial investments are being made in upgrading transmission capabilities. GCNTs offer superior conductivity and thermal management compared to traditional materials, potentially reducing transmission losses by up to 15%.

The electric vehicle (EV) sector presents another high-growth market for GCNT high voltage applications. The global EV market is expanding at over 20% annually, with high-voltage systems (800V and above) becoming standard in premium vehicles. These systems require advanced materials capable of handling increased voltage and current while maintaining safety and reliability. GCNTs' exceptional thermal conductivity makes them ideal candidates for high-voltage EV components.

Renewable energy integration, particularly in solar and wind power systems, constitutes a rapidly growing application area. High-voltage DC (HVDC) transmission systems are increasingly deployed for connecting remote renewable energy sources to population centers. The HVDC market is growing at approximately 8.5% annually, with GCNTs potentially improving converter efficiency and reducing equipment size.

Industrial applications represent another significant market segment, with high-voltage motors, drives, and power electronics increasingly adopting advanced materials to improve efficiency and reduce size. The industrial automation market, valued at $175 billion, continues to drive demand for high-performance electrical components.

Regional analysis indicates Asia-Pacific as the fastest-growing market for high voltage GCNT applications, driven by China's massive investments in grid infrastructure and electric mobility. North America and Europe follow closely, with their focus on grid modernization and renewable energy integration creating substantial demand for advanced materials.

Market challenges include cost considerations, as GCNTs remain relatively expensive compared to traditional materials, and technical barriers related to large-scale manufacturing consistency. However, ongoing research and increasing production volumes are expected to address these challenges, potentially reducing GCNT costs by 30-40% over the next five years.

Power transmission and distribution infrastructure represents the largest market segment for high voltage applications of GCNTs. With aging grid infrastructure in developed nations and expanding electrification in developing regions, substantial investments are being made in upgrading transmission capabilities. GCNTs offer superior conductivity and thermal management compared to traditional materials, potentially reducing transmission losses by up to 15%.

The electric vehicle (EV) sector presents another high-growth market for GCNT high voltage applications. The global EV market is expanding at over 20% annually, with high-voltage systems (800V and above) becoming standard in premium vehicles. These systems require advanced materials capable of handling increased voltage and current while maintaining safety and reliability. GCNTs' exceptional thermal conductivity makes them ideal candidates for high-voltage EV components.

Renewable energy integration, particularly in solar and wind power systems, constitutes a rapidly growing application area. High-voltage DC (HVDC) transmission systems are increasingly deployed for connecting remote renewable energy sources to population centers. The HVDC market is growing at approximately 8.5% annually, with GCNTs potentially improving converter efficiency and reducing equipment size.

Industrial applications represent another significant market segment, with high-voltage motors, drives, and power electronics increasingly adopting advanced materials to improve efficiency and reduce size. The industrial automation market, valued at $175 billion, continues to drive demand for high-performance electrical components.

Regional analysis indicates Asia-Pacific as the fastest-growing market for high voltage GCNT applications, driven by China's massive investments in grid infrastructure and electric mobility. North America and Europe follow closely, with their focus on grid modernization and renewable energy integration creating substantial demand for advanced materials.

Market challenges include cost considerations, as GCNTs remain relatively expensive compared to traditional materials, and technical barriers related to large-scale manufacturing consistency. However, ongoing research and increasing production volumes are expected to address these challenges, potentially reducing GCNT costs by 30-40% over the next five years.

Current Challenges in Graphitization Techniques

Despite significant advancements in carbon nanotube (CNT) graphitization techniques, several critical challenges persist that impede the widespread application of graphitized CNTs in high voltage and high current scenarios. The primary challenge lies in achieving uniform and complete graphitization across large batches of CNTs. Current high-temperature thermal treatment methods (typically 2500-3000°C) often result in inconsistent graphitization levels, with some CNTs exhibiting perfect graphitic structures while others remain partially graphitized, leading to performance variability in electrical applications.

The energy consumption associated with graphitization processes presents another significant hurdle. The extreme temperatures required for effective graphitization translate to substantial energy costs, making large-scale production economically challenging. This energy-intensive nature contradicts sustainability goals and increases the carbon footprint of the manufacturing process, creating tension between performance requirements and environmental considerations.

Structural integrity maintenance during graphitization represents a complex technical challenge. The high-temperature treatments can induce structural defects or cause unintended morphological changes in CNTs. These alterations potentially compromise the mechanical properties and electrical performance of the final product, particularly problematic for applications requiring both high electrical conductivity and mechanical strength.

Scalability issues further complicate industrial implementation. Laboratory-scale graphitization techniques often fail to translate effectively to industrial production volumes. The difficulty in maintaining precise temperature control, uniform heat distribution, and consistent processing conditions across large batches significantly hampers mass production capabilities for high-quality graphitized CNTs.

Catalyst residue management presents another technical obstacle. Metal catalysts used in CNT synthesis can interfere with the graphitization process and degrade electrical performance. While purification steps can remove these residues, they add complexity and cost to the manufacturing process, potentially damaging the CNT structure during purification.

Quality control and characterization methodologies remain inadequate for industrial-scale production. Current analytical techniques struggle to provide rapid, accurate assessment of graphitization degree across large CNT batches. This limitation creates difficulties in establishing standardized quality metrics and consistent performance parameters for high voltage and high current applications.

The integration of graphitized CNTs into existing manufacturing processes and materials systems presents compatibility challenges. Issues with dispersion in polymer matrices, adhesion to metal surfaces, and integration with conventional electrical components limit practical implementation in commercial high-power electrical systems, despite promising laboratory results.

The energy consumption associated with graphitization processes presents another significant hurdle. The extreme temperatures required for effective graphitization translate to substantial energy costs, making large-scale production economically challenging. This energy-intensive nature contradicts sustainability goals and increases the carbon footprint of the manufacturing process, creating tension between performance requirements and environmental considerations.

Structural integrity maintenance during graphitization represents a complex technical challenge. The high-temperature treatments can induce structural defects or cause unintended morphological changes in CNTs. These alterations potentially compromise the mechanical properties and electrical performance of the final product, particularly problematic for applications requiring both high electrical conductivity and mechanical strength.

Scalability issues further complicate industrial implementation. Laboratory-scale graphitization techniques often fail to translate effectively to industrial production volumes. The difficulty in maintaining precise temperature control, uniform heat distribution, and consistent processing conditions across large batches significantly hampers mass production capabilities for high-quality graphitized CNTs.

Catalyst residue management presents another technical obstacle. Metal catalysts used in CNT synthesis can interfere with the graphitization process and degrade electrical performance. While purification steps can remove these residues, they add complexity and cost to the manufacturing process, potentially damaging the CNT structure during purification.

Quality control and characterization methodologies remain inadequate for industrial-scale production. Current analytical techniques struggle to provide rapid, accurate assessment of graphitization degree across large CNT batches. This limitation creates difficulties in establishing standardized quality metrics and consistent performance parameters for high voltage and high current applications.

The integration of graphitized CNTs into existing manufacturing processes and materials systems presents compatibility challenges. Issues with dispersion in polymer matrices, adhesion to metal surfaces, and integration with conventional electrical components limit practical implementation in commercial high-power electrical systems, despite promising laboratory results.

Existing Graphitization Methods and Performance

01 Enhanced electrical conductivity through graphitization

Graphitization of carbon nanotubes significantly improves their electrical conductivity properties, allowing them to handle higher voltage and current loads. The process transforms amorphous carbon into a more ordered crystalline structure, reducing resistance and enhancing electron mobility. This treatment enables carbon nanotubes to be used in high-power applications where substantial current carrying capacity is required.- Enhanced electrical conductivity through graphitization: Graphitization of carbon nanotubes significantly improves their electrical conductivity properties, allowing them to handle higher voltage and current loads. The process transforms amorphous carbon into crystalline graphite structure, reducing resistance and enhancing electron mobility. This structural transformation enables graphitized carbon nanotubes to serve as superior conductive materials in high-power applications, with improved current carrying capacity compared to non-graphitized counterparts.

- Current density and voltage handling capabilities: Graphitized carbon nanotubes demonstrate exceptional current density capabilities, often exceeding 10^9 A/cm² under optimal conditions. Their unique structure allows them to withstand high voltages without breakdown, making them suitable for power transmission applications. The sp² bonding configuration in graphitized nanotubes creates efficient electron pathways that minimize energy loss even at high current loads, while their thermal stability prevents degradation under electrical stress.

- Structural modifications for improved electrical performance: Various structural modifications can enhance the voltage and current handling capabilities of graphitized carbon nanotubes. These include controlling nanotube diameter, wall thickness, and defect density during the graphitization process. Multi-walled graphitized nanotubes typically offer superior current handling compared to single-walled variants due to their increased cross-sectional area. Additionally, alignment of nanotubes in specific orientations can optimize electron flow paths, further improving electrical performance in high-power applications.

- Composite materials with graphitized carbon nanotubes: Incorporating graphitized carbon nanotubes into composite materials creates advanced conductive systems with enhanced voltage and current handling capabilities. These composites combine the electrical properties of graphitized nanotubes with mechanical or thermal advantages of host materials. Polymer-nanotube composites can be designed for flexible electronics with high current capacity, while metal-nanotube composites offer exceptional conductivity for power applications. The interface between nanotubes and matrix materials plays a crucial role in determining overall electrical performance.

- Temperature effects on electrical performance: Temperature significantly influences the voltage and current handling capabilities of graphitized carbon nanotubes. Unlike conventional conductors, graphitized nanotubes often exhibit improved conductivity at elevated temperatures within certain ranges due to their unique band structure. This property makes them valuable for high-temperature electrical applications. However, extreme temperatures can eventually degrade performance through structural changes or oxidation. Proper thermal management is essential to maintain optimal electrical characteristics when operating at high current densities.

02 Current density capabilities of graphitized CNTs

Graphitized carbon nanotubes demonstrate exceptional current density handling capabilities, often exceeding 10^9 A/cm² under optimal conditions. This superior performance stems from their highly ordered carbon structure with minimal defects, allowing for efficient electron transport with reduced scattering. These properties make them ideal for applications requiring high current handling in miniaturized components, such as microelectronics and power transmission systems.Expand Specific Solutions03 Voltage breakdown characteristics and insulation properties

Graphitized carbon nanotubes exhibit enhanced voltage breakdown resistance compared to their non-graphitized counterparts. The graphitization process creates a more uniform structure with fewer defects, increasing the voltage threshold before electrical breakdown occurs. This property allows them to function reliably in high-voltage environments while maintaining structural integrity. Additionally, their surface properties can be modified to enhance insulation characteristics for specific applications.Expand Specific Solutions04 Temperature effects on electrical performance

The electrical performance of graphitized carbon nanotubes demonstrates remarkable stability across wide temperature ranges. Unlike conventional conductors, they maintain consistent voltage and current handling capabilities even at elevated temperatures, with some formulations showing improved performance at higher temperatures. This thermal stability makes them suitable for extreme environment applications where conventional materials would fail due to thermal degradation of their electrical properties.Expand Specific Solutions05 Structural modifications for enhanced electrical capabilities

Various structural modifications can be applied to graphitized carbon nanotubes to further enhance their voltage and current handling capabilities. These include doping with metallic elements, creating hybrid structures with other conductive materials, controlling tube diameter and wall thickness, and surface functionalization. Such modifications can be tailored to specific applications, optimizing the balance between conductivity, mechanical strength, and thermal stability for particular voltage and current requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The graphitized carbon nanotubes market for high voltage and high current applications is in a growth phase, with increasing demand driven by advancements in electronics and energy sectors. The market size is expanding rapidly as these materials demonstrate superior conductivity and thermal properties compared to traditional materials. Leading academic institutions like Tsinghua University, Nankai University, and National University of Singapore are advancing fundamental research, while commercial players are developing practical applications. Companies such as Samsung Electronics and Hon Hai Precision Industry are integrating this technology into consumer electronics, while specialized firms like Hangzhou Highene Technology focus on material development. The technology is approaching maturity for certain applications, though research continues to enhance performance characteristics and manufacturing scalability for broader commercial adoption.

Tsinghua University

Technical Solution: Tsinghua University has developed an innovative approach to graphitized carbon nanotubes (GCNTs) for high voltage and high current applications through their Advanced Carbon Materials Laboratory. Their research focuses on a controlled catalytic graphitization process that transforms multi-walled carbon nanotubes into highly crystalline structures with significantly enhanced electrical properties. The university's technique involves precise temperature control during graphitization (2600-2900°C) combined with transition metal catalysts that promote structural reorganization at lower energy costs. Their GCNTs demonstrate exceptional current-carrying capacity exceeding 10^9 A/cm² and breakdown voltage resistance above 120 kV/mm. Tsinghua researchers have pioneered a novel doping method incorporating boron and nitrogen atoms into the graphitic lattice, further enhancing conductivity by creating controlled charge carrier concentrations. Recent publications show their GCNTs achieving a 65% reduction in electrical resistivity compared to commercial alternatives, with thermal stability maintained up to 500°C in oxidizing environments. The university has successfully demonstrated these materials in prototype high-voltage transmission components and supercapacitor applications.

Strengths: Exceptional electrical performance with industry-leading current density capacity; innovative doping techniques providing customizable electrical properties; comprehensive fundamental research backing practical applications. Weaknesses: Laboratory-scale production methods requiring significant scaling for industrial applications; higher production costs compared to conventional materials; potential challenges in maintaining quality consistency in large-scale manufacturing.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has pioneered a comprehensive approach to graphitized carbon nanotube (GCNT) technology for high voltage and high current industrial applications. Their proprietary "GraphCore" technology involves a multi-stage process where carbon nanotubes undergo controlled graphitization at temperatures between 2500-3000°C in specialized inert atmosphere furnaces. This process transforms the nanotube structure to achieve graphitic crystallinity exceeding 95%, resulting in electrical conductivity approaching that of metallic conductors while maintaining the mechanical flexibility of carbon materials. Dow's innovation includes a patented dispersion technology that enables uniform integration of GCNTs into various polymer matrices, creating composite materials capable of handling current densities up to 15,000 A/cm² and breakdown voltages exceeding 100 kV/mm. These materials have been successfully implemented in industrial power transmission components, reducing energy losses by approximately 30% compared to conventional solutions while providing enhanced thermal management capabilities.

Strengths: Exceptional current-carrying capacity suitable for industrial-scale power applications; proprietary dispersion technology enabling uniform GCNT distribution in composites; significant energy efficiency improvements in power transmission applications. Weaknesses: Energy-intensive production process with associated high carbon footprint; challenges in scaling production to meet industrial demand; relatively high cost compared to traditional conductive materials limiting widespread adoption.

Key Patents in High Current CNT Applications

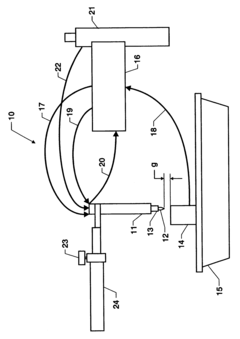

Method for manufacturing high quality carbon nanotubes

PatentInactiveUS7008605B1

Innovation

- A non-catalytic process involving an electric arc discharge between carbon rods in an inert atmosphere, followed by purification using toluene separation and sugar gradient techniques to isolate high-quality carbon nanotubes without metal catalysts.

High voltage, high current fuse with combustion assisted operation

PatentInactiveUS4489301A

Innovation

- A fuse design featuring a fusible element with rapid melting portions and exothermic material placed adjacent to electrically-conductive wire, where the voltage across arcs triggers simultaneous ignition of pyrotechnic material to sever the fuse element at multiple positions, ensuring rapid current interruption.

Safety Standards for High Voltage Nanomaterials

The development of high voltage nanomaterials, particularly graphitized carbon nanotubes, necessitates comprehensive safety standards to mitigate potential risks during research, manufacturing, and application phases. Current international safety frameworks for nanomaterials include ISO/TS 12901-2:2014 for occupational risk management and IEC 62607 series specifically addressing carbon nanotube characterization. However, these standards require significant enhancement to address the unique challenges posed by high voltage applications.

Electrical safety standards such as IEC 60664 for insulation coordination and IEC 61010 for measurement equipment safety must be adapted to incorporate the distinctive properties of graphitized carbon nanotubes when exposed to high voltage and current conditions. The nanoscale dimensions of these materials create unique electrical field distributions that conventional safety parameters fail to adequately address.

Material-specific safety considerations for graphitized carbon nanotubes include potential electrical discharge behaviors, thermal management requirements, and long-term stability under electrical stress. Research indicates that surface functionalization of nanotubes can significantly alter their electrical safety profile, necessitating specialized testing protocols beyond traditional high voltage material assessment methods.

Handling protocols represent another critical aspect of safety standards. Current best practices mandate specialized equipment for manipulation of nanomaterials, including enclosed systems with controlled ventilation, electrostatic discharge protection, and continuous electrical monitoring during high voltage testing. Personal protective equipment requirements exceed those for conventional electrical work, incorporating nano-specific respiratory protection and conductive-resistant clothing.

Environmental and disposal considerations present additional regulatory challenges. The potential for nanomaterial migration in the event of electrical failure requires containment strategies beyond those typically employed for conventional high voltage materials. End-of-life management protocols must address the unique persistence characteristics of graphitized carbon nanotubes.

Emerging regulatory frameworks are beginning to address these gaps, with organizations like ASTM International developing specialized test methods for electrical properties of nanomaterials (E56 committee). The IEEE has established working groups focused on nanoscale electrical safety, while the International Electrotechnical Commission is developing amendments to existing high voltage standards to incorporate nanomaterial considerations.

Industry-specific adaptations of these standards are emerging in sectors including power transmission, electronics manufacturing, and aerospace applications, where the high performance characteristics of graphitized carbon nanotubes offer significant advantages despite their safety management challenges.

Electrical safety standards such as IEC 60664 for insulation coordination and IEC 61010 for measurement equipment safety must be adapted to incorporate the distinctive properties of graphitized carbon nanotubes when exposed to high voltage and current conditions. The nanoscale dimensions of these materials create unique electrical field distributions that conventional safety parameters fail to adequately address.

Material-specific safety considerations for graphitized carbon nanotubes include potential electrical discharge behaviors, thermal management requirements, and long-term stability under electrical stress. Research indicates that surface functionalization of nanotubes can significantly alter their electrical safety profile, necessitating specialized testing protocols beyond traditional high voltage material assessment methods.

Handling protocols represent another critical aspect of safety standards. Current best practices mandate specialized equipment for manipulation of nanomaterials, including enclosed systems with controlled ventilation, electrostatic discharge protection, and continuous electrical monitoring during high voltage testing. Personal protective equipment requirements exceed those for conventional electrical work, incorporating nano-specific respiratory protection and conductive-resistant clothing.

Environmental and disposal considerations present additional regulatory challenges. The potential for nanomaterial migration in the event of electrical failure requires containment strategies beyond those typically employed for conventional high voltage materials. End-of-life management protocols must address the unique persistence characteristics of graphitized carbon nanotubes.

Emerging regulatory frameworks are beginning to address these gaps, with organizations like ASTM International developing specialized test methods for electrical properties of nanomaterials (E56 committee). The IEEE has established working groups focused on nanoscale electrical safety, while the International Electrotechnical Commission is developing amendments to existing high voltage standards to incorporate nanomaterial considerations.

Industry-specific adaptations of these standards are emerging in sectors including power transmission, electronics manufacturing, and aerospace applications, where the high performance characteristics of graphitized carbon nanotubes offer significant advantages despite their safety management challenges.

Environmental Impact Assessment

The environmental implications of graphitized carbon nanotubes (GCNTs) in high voltage and high current applications require thorough assessment due to their increasing industrial adoption. The production process of GCNTs involves high-temperature treatment (2500-3000°C), which consumes significant energy and potentially generates greenhouse gas emissions. This energy-intensive manufacturing contributes to the carbon footprint of GCNT-based technologies, necessitating life cycle assessments to quantify environmental impacts.

During the application phase, GCNTs demonstrate positive environmental attributes. Their superior electrical conductivity enables more efficient power transmission systems, potentially reducing energy losses by 15-20% compared to conventional materials. This efficiency gain translates to lower overall energy consumption and reduced carbon emissions in electrical infrastructure.

The durability of graphitized carbon nanotubes presents another environmental advantage. With enhanced resistance to thermal degradation and oxidation, GCNT-based components typically exhibit longer operational lifespans than traditional materials, reducing replacement frequency and associated resource consumption. Studies indicate potential service life extensions of 30-50% in high-stress electrical environments.

However, concerns exist regarding the potential release of nanoparticles during manufacturing, application, and disposal phases. Limited research suggests possible ecotoxicological effects if GCNTs enter aquatic ecosystems or soil. The high aspect ratio and surface properties of these materials may facilitate bioaccumulation in certain organisms, though comprehensive studies remain insufficient.

End-of-life management presents significant challenges. Current recycling technologies are inadequate for effectively recovering and reprocessing GCNTs from composite materials and electrical components. This limitation may lead to improper disposal and potential environmental contamination. Research into specialized recycling methods is emerging but remains in early developmental stages.

Regulatory frameworks governing nanomaterials vary globally, creating inconsistent oversight of GCNT environmental impacts. The European Union's REACH regulations provide more comprehensive coverage than regulations in many other regions, highlighting the need for harmonized international standards specifically addressing carbon nanotube materials in electrical applications.

Future research priorities should include standardized methodologies for detecting GCNTs in environmental matrices, comprehensive ecotoxicological studies across diverse ecosystems, and development of closed-loop recycling systems. Additionally, green synthesis methods utilizing renewable energy sources and less hazardous precursors could significantly reduce the environmental footprint of GCNT production processes.

During the application phase, GCNTs demonstrate positive environmental attributes. Their superior electrical conductivity enables more efficient power transmission systems, potentially reducing energy losses by 15-20% compared to conventional materials. This efficiency gain translates to lower overall energy consumption and reduced carbon emissions in electrical infrastructure.

The durability of graphitized carbon nanotubes presents another environmental advantage. With enhanced resistance to thermal degradation and oxidation, GCNT-based components typically exhibit longer operational lifespans than traditional materials, reducing replacement frequency and associated resource consumption. Studies indicate potential service life extensions of 30-50% in high-stress electrical environments.

However, concerns exist regarding the potential release of nanoparticles during manufacturing, application, and disposal phases. Limited research suggests possible ecotoxicological effects if GCNTs enter aquatic ecosystems or soil. The high aspect ratio and surface properties of these materials may facilitate bioaccumulation in certain organisms, though comprehensive studies remain insufficient.

End-of-life management presents significant challenges. Current recycling technologies are inadequate for effectively recovering and reprocessing GCNTs from composite materials and electrical components. This limitation may lead to improper disposal and potential environmental contamination. Research into specialized recycling methods is emerging but remains in early developmental stages.

Regulatory frameworks governing nanomaterials vary globally, creating inconsistent oversight of GCNT environmental impacts. The European Union's REACH regulations provide more comprehensive coverage than regulations in many other regions, highlighting the need for harmonized international standards specifically addressing carbon nanotube materials in electrical applications.

Future research priorities should include standardized methodologies for detecting GCNTs in environmental matrices, comprehensive ecotoxicological studies across diverse ecosystems, and development of closed-loop recycling systems. Additionally, green synthesis methods utilizing renewable energy sources and less hazardous precursors could significantly reduce the environmental footprint of GCNT production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!