Analysis of Microchannel Cooling in Aerospace Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Evolution and Objectives

Microchannel cooling technology emerged in the early 1980s when researchers at the University of California, Berkeley, first demonstrated the enhanced heat transfer capabilities of microchannels. This breakthrough innovation marked a significant departure from conventional cooling methods, offering unprecedented thermal management efficiency in compact systems. The evolution of this technology has been driven by the increasing thermal demands in aerospace applications, where weight, space, and power constraints are particularly stringent.

Throughout the 1990s, microchannel cooling research expanded from theoretical models to practical implementations, with aerospace engineers recognizing its potential for high-heat-flux applications such as avionics cooling and rocket engine thermal management. The miniaturization trend in aerospace electronics further accelerated the development of microchannel cooling systems, as traditional air cooling methods became inadequate for dissipating concentrated heat loads.

The early 2000s witnessed significant advancements in microchannel fabrication techniques, including precision etching, micro-machining, and additive manufacturing processes. These manufacturing innovations enabled more complex channel geometries and optimized flow patterns, substantially improving cooling performance while reducing pressure drop penalties. Concurrently, computational fluid dynamics (CFD) modeling capabilities evolved, allowing engineers to predict and optimize microchannel performance with greater accuracy.

Recent technological developments have focused on enhancing microchannel cooling through surface modifications, two-phase flow implementation, and smart control systems. The integration of nanofluids and phase-change materials has pushed the boundaries of heat transfer coefficients achievable in aerospace cooling applications. Additionally, the development of self-regulating microchannel systems has addressed flow distribution challenges in complex cooling networks.

The primary objectives of microchannel cooling technology in aerospace applications include maximizing heat dissipation capacity while minimizing system mass, volume, and power consumption. Engineers aim to achieve uniform temperature distribution across critical components, prevent localized hotspots, and ensure reliable operation under extreme environmental conditions. Another crucial goal is to develop systems capable of handling transient thermal loads characteristic of aerospace mission profiles.

Looking forward, the technology roadmap for microchannel cooling in aerospace applications emphasizes further miniaturization, integration with structural components, and adaptability to varying operational conditions. Research efforts are increasingly directed toward multi-functional cooling systems that combine thermal management with other functionalities such as structural support or electromagnetic shielding, maximizing the efficiency of aerospace systems where every gram and cubic centimeter matters.

Throughout the 1990s, microchannel cooling research expanded from theoretical models to practical implementations, with aerospace engineers recognizing its potential for high-heat-flux applications such as avionics cooling and rocket engine thermal management. The miniaturization trend in aerospace electronics further accelerated the development of microchannel cooling systems, as traditional air cooling methods became inadequate for dissipating concentrated heat loads.

The early 2000s witnessed significant advancements in microchannel fabrication techniques, including precision etching, micro-machining, and additive manufacturing processes. These manufacturing innovations enabled more complex channel geometries and optimized flow patterns, substantially improving cooling performance while reducing pressure drop penalties. Concurrently, computational fluid dynamics (CFD) modeling capabilities evolved, allowing engineers to predict and optimize microchannel performance with greater accuracy.

Recent technological developments have focused on enhancing microchannel cooling through surface modifications, two-phase flow implementation, and smart control systems. The integration of nanofluids and phase-change materials has pushed the boundaries of heat transfer coefficients achievable in aerospace cooling applications. Additionally, the development of self-regulating microchannel systems has addressed flow distribution challenges in complex cooling networks.

The primary objectives of microchannel cooling technology in aerospace applications include maximizing heat dissipation capacity while minimizing system mass, volume, and power consumption. Engineers aim to achieve uniform temperature distribution across critical components, prevent localized hotspots, and ensure reliable operation under extreme environmental conditions. Another crucial goal is to develop systems capable of handling transient thermal loads characteristic of aerospace mission profiles.

Looking forward, the technology roadmap for microchannel cooling in aerospace applications emphasizes further miniaturization, integration with structural components, and adaptability to varying operational conditions. Research efforts are increasingly directed toward multi-functional cooling systems that combine thermal management with other functionalities such as structural support or electromagnetic shielding, maximizing the efficiency of aerospace systems where every gram and cubic centimeter matters.

Aerospace Thermal Management Market Analysis

The aerospace thermal management market is experiencing robust growth driven by increasing demand for advanced cooling solutions in modern aircraft and spacecraft systems. Currently valued at approximately 8.2 billion USD in 2023, the market is projected to reach 12.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.7%. This growth trajectory is primarily fueled by the rising complexity of avionics systems and the integration of more electronic components in aerospace applications, which generate significant heat loads requiring efficient management solutions.

The market segmentation reveals distinct categories based on application areas. Military aircraft account for the largest market share at 42%, followed by commercial aircraft at 35%, spacecraft at 15%, and unmanned aerial vehicles (UAVs) at 8%. This distribution reflects the intensive thermal management requirements in military applications where advanced electronic warfare systems and high-performance avionics generate substantial heat loads.

Geographically, North America dominates the aerospace thermal management market with approximately 45% share, attributed to the presence of major aerospace manufacturers and substantial defense spending. Europe follows with 28%, while Asia-Pacific represents the fastest-growing region with a 12% annual growth rate, driven by expanding aerospace industries in China, India, and Japan.

The microchannel cooling technology segment specifically is witnessing accelerated adoption, currently representing about 18% of the overall aerospace thermal management market. This segment is expected to grow at a CAGR of 11.3% through 2028, outpacing the broader market due to its superior thermal performance characteristics and compact design advantages.

Key market drivers include the trend toward more electric aircraft (MEA) architectures, increasing power densities in avionics systems, and stringent regulations regarding fuel efficiency and emissions that necessitate more efficient thermal management. Additionally, the growing deployment of advanced materials in aerospace applications is creating new opportunities for innovative thermal management solutions.

Market challenges primarily revolve around high implementation costs, weight considerations, and integration complexities with existing systems. The average cost of implementing advanced microchannel cooling systems ranges from $75,000 to $250,000 per aircraft, depending on the complexity and scale of application, representing a significant investment for aerospace manufacturers.

Customer demand patterns indicate a growing preference for integrated thermal management systems that offer reduced weight, enhanced reliability, and lower maintenance requirements. This trend is particularly evident in next-generation aircraft programs where thermal management is considered a critical design parameter from the earliest development stages.

The market segmentation reveals distinct categories based on application areas. Military aircraft account for the largest market share at 42%, followed by commercial aircraft at 35%, spacecraft at 15%, and unmanned aerial vehicles (UAVs) at 8%. This distribution reflects the intensive thermal management requirements in military applications where advanced electronic warfare systems and high-performance avionics generate substantial heat loads.

Geographically, North America dominates the aerospace thermal management market with approximately 45% share, attributed to the presence of major aerospace manufacturers and substantial defense spending. Europe follows with 28%, while Asia-Pacific represents the fastest-growing region with a 12% annual growth rate, driven by expanding aerospace industries in China, India, and Japan.

The microchannel cooling technology segment specifically is witnessing accelerated adoption, currently representing about 18% of the overall aerospace thermal management market. This segment is expected to grow at a CAGR of 11.3% through 2028, outpacing the broader market due to its superior thermal performance characteristics and compact design advantages.

Key market drivers include the trend toward more electric aircraft (MEA) architectures, increasing power densities in avionics systems, and stringent regulations regarding fuel efficiency and emissions that necessitate more efficient thermal management. Additionally, the growing deployment of advanced materials in aerospace applications is creating new opportunities for innovative thermal management solutions.

Market challenges primarily revolve around high implementation costs, weight considerations, and integration complexities with existing systems. The average cost of implementing advanced microchannel cooling systems ranges from $75,000 to $250,000 per aircraft, depending on the complexity and scale of application, representing a significant investment for aerospace manufacturers.

Customer demand patterns indicate a growing preference for integrated thermal management systems that offer reduced weight, enhanced reliability, and lower maintenance requirements. This trend is particularly evident in next-generation aircraft programs where thermal management is considered a critical design parameter from the earliest development stages.

Current Microchannel Cooling Capabilities and Barriers

Microchannel cooling technology in aerospace applications has evolved significantly over the past two decades, with current capabilities reaching impressive thermal management performance levels. Modern microchannel heat exchangers can achieve heat flux dissipation rates of 500-1000 W/cm², making them suitable for cooling high-power electronics and propulsion systems in aerospace vehicles. The channel dimensions typically range from 10-500 micrometers, with aspect ratios between 1:1 and 10:1, allowing for optimization based on specific cooling requirements.

Despite these advancements, several significant barriers limit the widespread implementation of microchannel cooling in aerospace applications. Manufacturing challenges remain prominent, particularly in producing consistent channel geometries at scale with aerospace-grade materials. Current precision manufacturing techniques often struggle to maintain uniform channel dimensions across large cooling arrays, leading to flow maldistribution and reduced thermal performance.

Material compatibility presents another major obstacle. Aerospace environments demand materials that can withstand extreme temperature fluctuations, high pressures, and exposure to various working fluids while maintaining structural integrity. Current microchannel systems often utilize aluminum, copper, or silicon, each with limitations in aerospace contexts where weight, corrosion resistance, and thermal cycling endurance are critical factors.

Pressure drop considerations continue to constrain microchannel cooling system design. The inherently high pressure drops in microchannels necessitate powerful pumping systems, which add weight, complexity, and power consumption—all critical concerns in aerospace applications. Current systems typically operate with pressure drops of 0.5-2 bar across the microchannel heat exchanger, requiring significant pumping power.

Fouling and clogging represent persistent operational challenges. The small dimensions of microchannels make them particularly susceptible to blockage from particulates or biological growth in the cooling fluid. Current filtration systems add complexity and maintenance requirements, while chemical treatments may introduce compatibility issues with channel materials.

Integration with existing aerospace thermal management systems remains problematic. Microchannel cooling must interface with conventional cooling loops, power systems, and structural elements, often requiring complex manifolding and connection designs. Current solutions frequently involve custom interfaces that add weight and potential failure points.

Reliability and maintenance concerns further limit adoption. The aerospace industry's stringent reliability requirements demand cooling systems with predictable performance over thousands of operational hours. Current microchannel systems lack sufficient long-term operational data in relevant aerospace environments, particularly regarding thermal cycling effects, vibration resistance, and maintenance accessibility.

Despite these advancements, several significant barriers limit the widespread implementation of microchannel cooling in aerospace applications. Manufacturing challenges remain prominent, particularly in producing consistent channel geometries at scale with aerospace-grade materials. Current precision manufacturing techniques often struggle to maintain uniform channel dimensions across large cooling arrays, leading to flow maldistribution and reduced thermal performance.

Material compatibility presents another major obstacle. Aerospace environments demand materials that can withstand extreme temperature fluctuations, high pressures, and exposure to various working fluids while maintaining structural integrity. Current microchannel systems often utilize aluminum, copper, or silicon, each with limitations in aerospace contexts where weight, corrosion resistance, and thermal cycling endurance are critical factors.

Pressure drop considerations continue to constrain microchannel cooling system design. The inherently high pressure drops in microchannels necessitate powerful pumping systems, which add weight, complexity, and power consumption—all critical concerns in aerospace applications. Current systems typically operate with pressure drops of 0.5-2 bar across the microchannel heat exchanger, requiring significant pumping power.

Fouling and clogging represent persistent operational challenges. The small dimensions of microchannels make them particularly susceptible to blockage from particulates or biological growth in the cooling fluid. Current filtration systems add complexity and maintenance requirements, while chemical treatments may introduce compatibility issues with channel materials.

Integration with existing aerospace thermal management systems remains problematic. Microchannel cooling must interface with conventional cooling loops, power systems, and structural elements, often requiring complex manifolding and connection designs. Current solutions frequently involve custom interfaces that add weight and potential failure points.

Reliability and maintenance concerns further limit adoption. The aerospace industry's stringent reliability requirements demand cooling systems with predictable performance over thousands of operational hours. Current microchannel systems lack sufficient long-term operational data in relevant aerospace environments, particularly regarding thermal cycling effects, vibration resistance, and maintenance accessibility.

State-of-the-Art Microchannel Cooling Implementations

01 Microchannel heat sink designs for electronic cooling

Microchannel heat sinks are designed specifically for cooling electronic components by efficiently transferring heat away from high-power density devices. These designs incorporate small channels that maximize surface area for heat exchange while minimizing the required coolant volume. The microchannels can be integrated directly into electronic packaging to provide more effective cooling compared to traditional methods, enabling higher performance in compact electronic devices.- Microchannel heat sink designs for electronic cooling: Microchannel heat sinks provide efficient cooling for electronic components by using small channels to increase surface area for heat transfer. These designs incorporate optimized channel geometries, flow patterns, and materials to maximize thermal performance while minimizing pressure drop. Advanced microchannel structures can be integrated directly with electronic components to provide localized cooling where heat generation is highest.

- Two-phase cooling systems with microchannels: Two-phase cooling systems utilize the phase change of a working fluid (typically from liquid to vapor) within microchannels to achieve enhanced heat transfer. These systems leverage the latent heat of vaporization to remove large amounts of heat while maintaining relatively uniform temperatures. The design includes specialized inlet/outlet manifolds, flow distribution structures, and surface treatments to promote efficient boiling and condensation processes within the microchannels.

- Microchannel cooling for high-power electronics and data centers: Specialized microchannel cooling solutions designed for high-power electronics and data center applications focus on handling extreme heat loads while maintaining reliability. These systems often incorporate redundant cooling paths, advanced thermal management controls, and integration with facility-level cooling infrastructure. The designs prioritize energy efficiency, compact form factors, and the ability to cool high-density computing environments.

- Additive manufacturing and novel fabrication methods for microchannels: Advanced manufacturing techniques, particularly additive manufacturing, enable the creation of complex microchannel geometries that were previously impossible to fabricate. These methods allow for optimized channel cross-sections, integrated manifolds, and conformal cooling solutions that follow the contours of heat-generating components. Novel fabrication approaches also incorporate multi-material systems and hierarchical structures to enhance cooling performance.

- Modular and scalable microchannel cooling systems: Modular microchannel cooling designs allow for scalable thermal management solutions that can be adapted to various applications and heat loads. These systems feature standardized interfaces, quick-connect fittings, and interchangeable components that facilitate maintenance and upgrades. The modular approach enables efficient cooling of distributed heat sources and allows for system expansion without complete redesign.

02 Two-phase cooling systems in microchannels

Two-phase cooling systems utilize the phase change of coolants (from liquid to vapor) within microchannels to enhance heat transfer efficiency. This approach leverages the latent heat of vaporization to absorb significantly more thermal energy than single-phase systems. The design allows for uniform temperature distribution across the cooling surface and can handle high heat flux applications while maintaining lower pumping power requirements compared to conventional cooling methods.Expand Specific Solutions03 Microchannel cooling for power electronics and batteries

Microchannel cooling systems are specifically designed for power electronics and battery thermal management. These systems provide direct cooling to high-power components through precisely engineered microchannels that efficiently remove heat from critical areas. The cooling architecture helps maintain optimal operating temperatures for batteries and power modules, extending their lifespan and improving performance while preventing thermal runaway in high-load conditions.Expand Specific Solutions04 Advanced manufacturing techniques for microchannel coolers

Advanced manufacturing techniques enable the production of complex microchannel cooling structures with enhanced performance characteristics. These methods include additive manufacturing, precision etching, and micro-machining processes that create optimized channel geometries not possible with conventional manufacturing. The techniques allow for the integration of features such as variable channel dimensions, custom flow patterns, and embedded sensors to monitor cooling performance in real-time.Expand Specific Solutions05 Coolant flow optimization in microchannel systems

Optimization of coolant flow in microchannel systems involves the strategic design of channel geometry, manifold configurations, and flow distribution to maximize heat transfer efficiency. These designs address issues such as flow maldistribution, pressure drop, and thermal boundary layers through techniques like tapered channels, split flows, and engineered surface structures. The optimized flow patterns ensure uniform cooling across the entire heat-generating surface while minimizing pumping power requirements.Expand Specific Solutions

Leading Aerospace Thermal Management Solution Providers

Microchannel cooling in aerospace applications is currently in a growth phase, with the market expanding as aerospace manufacturers seek more efficient thermal management solutions. The global market size is estimated to reach several billion dollars by 2025, driven by increasing power densities in aircraft electronics and propulsion systems. Technologically, the field is advancing from early adoption to mainstream implementation, with varying maturity levels across companies. Intel and IBM lead in microchannel fabrication technology, while aerospace specialists like The Aerospace Corp., Airbus Operations, and Rolls-Royce are advancing application-specific implementations. Academic institutions including Northwestern Polytechnical University and Beihang University contribute significant research. GE and United Technologies are leveraging their aerospace expertise to develop integrated cooling solutions, while specialized firms like Forced Physics focus on novel cooling approaches.

General Electric Company

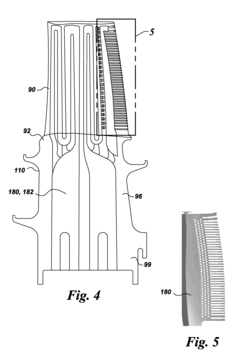

Technical Solution: General Electric has developed advanced microchannel cooling systems specifically for aerospace applications, focusing on high-performance jet engines and aircraft systems. Their technology utilizes an integrated network of microchannels (typically 10-500 micrometers in width) embedded directly into critical components like turbine blades and electronic systems. GE's approach employs a dual-phase cooling mechanism where the working fluid transitions between liquid and vapor states, extracting significantly more heat than single-phase systems. Their proprietary surface treatments enhance nucleate boiling and reduce pressure drops across the microchannels, achieving heat flux capabilities exceeding 500 W/cm² in some applications. GE has also pioneered additive manufacturing techniques to create complex internal cooling geometries previously impossible with traditional manufacturing, allowing for optimized flow distribution and reduced thermal gradients. Their systems incorporate smart sensors for real-time monitoring of cooling performance and predictive maintenance capabilities.

Strengths: Superior thermal management in extreme aerospace environments; integration with existing aircraft systems; proven reliability in commercial aviation applications. Weaknesses: Higher initial manufacturing costs; increased system complexity requiring specialized maintenance; weight considerations for aerospace implementation.

The Aerospace Corp.

Technical Solution: The Aerospace Corporation has developed a sophisticated microchannel cooling technology specifically designed for satellite thermal management and space-based electronics. Their approach utilizes an array of precisely engineered microchannels (typically 50-200 microns in diameter) fabricated directly into spacecraft components using advanced etching and bonding techniques. The system employs a closed-loop cooling architecture with specialized working fluids that maintain performance in zero-gravity environments and extreme temperature fluctuations. A key innovation is their oscillating heat pipe design integrated with microchannels, which eliminates the need for mechanical pumps, reducing system weight and improving reliability. The technology incorporates radiation-hardened materials and redundant flow paths to ensure continued operation even after partial system damage. Their cooling systems have demonstrated heat flux management capabilities of 300+ W/cm² while maintaining tight temperature control (±2°C) across critical components, essential for sensitive optical and electronic systems in space applications.

Strengths: Exceptional reliability in harsh space environments; passive operation reducing power requirements; radiation-hardened design for extended mission lifetimes. Weaknesses: Higher production costs compared to conventional cooling; limited scalability for very large thermal loads; specialized manufacturing requirements.

Critical Patents and Research in Aerospace Cooling

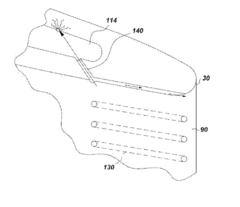

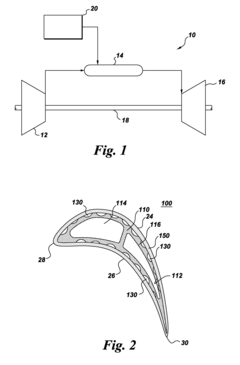

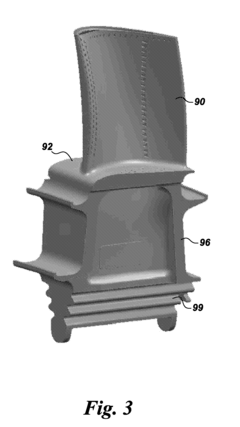

Methods of forming cooling channels using backstrike protection

PatentActiveUS20150367460A1

Innovation

- The use of a ceramic core as a backstop material within the component's interior space to absorb and disperse the energy of the abrasive liquid jet, preventing back-strike and facilitating the formation of access holes and grooves for coolant channels, while allowing for the subsequent removal of the core using leaching processes.

Material Science Advancements for Cooling Efficiency

The evolution of material science has been pivotal in advancing microchannel cooling technologies for aerospace applications. Traditional materials like aluminum and copper, while effective heat conductors, present limitations in weight, corrosion resistance, and thermal expansion that are particularly problematic in aerospace environments. Recent advancements in composite materials have introduced carbon-fiber reinforced polymers (CFRPs) with embedded metallic microchannels, offering superior strength-to-weight ratios while maintaining adequate thermal conductivity.

Nanomaterials represent another frontier in cooling efficiency enhancement. Carbon nanotubes (CNTs) and graphene, with thermal conductivities exceeding 3000 W/m·K, significantly outperform conventional metals. When incorporated into microchannel walls or coolant fluids as nanoparticles, these materials can increase heat transfer rates by 15-40% compared to standard configurations. Silicon carbide (SiC) and diamond-like carbon (DLC) coatings have also emerged as promising solutions, providing wear resistance and reduced friction in microchannel systems.

Additive manufacturing techniques have revolutionized the fabrication of complex microchannel geometries that were previously impossible to produce. Direct metal laser sintering (DMLS) and electron beam melting (EBM) enable the creation of intricate internal cooling passages with optimized flow patterns. These techniques allow for the integration of variable channel dimensions and custom surface textures that enhance turbulence and heat transfer without significant pressure drop penalties.

Smart materials with phase-change capabilities offer dynamic thermal management solutions. Microencapsulated phase change materials (PCMs) integrated into channel structures can absorb excess heat during peak thermal loads and release it during lower demand periods, effectively dampening thermal fluctuations. Shape memory alloys (SMAs) are being explored for adaptive cooling systems that can modify channel geometries in response to temperature changes, optimizing flow characteristics based on real-time thermal conditions.

Ceramic matrix composites (CMCs) have demonstrated exceptional performance in high-temperature aerospace applications. Materials such as silicon carbide/silicon carbide (SiC/SiC) composites maintain structural integrity and thermal conductivity at temperatures exceeding 1200°C, making them ideal for cooling systems in hypersonic vehicles and rocket engines. These materials exhibit minimal degradation under thermal cycling and are resistant to oxidation in extreme environments.

Bioinspired materials design approaches are yielding novel solutions based on natural cooling systems. Hierarchical channel networks mimicking leaf venation patterns or lung bronchioles optimize fluid distribution and heat exchange efficiency. Self-healing materials incorporating microcapsules with repair agents can automatically address microcracks and erosion damage in cooling channels, extending system lifespan in the harsh conditions of aerospace operation.

Nanomaterials represent another frontier in cooling efficiency enhancement. Carbon nanotubes (CNTs) and graphene, with thermal conductivities exceeding 3000 W/m·K, significantly outperform conventional metals. When incorporated into microchannel walls or coolant fluids as nanoparticles, these materials can increase heat transfer rates by 15-40% compared to standard configurations. Silicon carbide (SiC) and diamond-like carbon (DLC) coatings have also emerged as promising solutions, providing wear resistance and reduced friction in microchannel systems.

Additive manufacturing techniques have revolutionized the fabrication of complex microchannel geometries that were previously impossible to produce. Direct metal laser sintering (DMLS) and electron beam melting (EBM) enable the creation of intricate internal cooling passages with optimized flow patterns. These techniques allow for the integration of variable channel dimensions and custom surface textures that enhance turbulence and heat transfer without significant pressure drop penalties.

Smart materials with phase-change capabilities offer dynamic thermal management solutions. Microencapsulated phase change materials (PCMs) integrated into channel structures can absorb excess heat during peak thermal loads and release it during lower demand periods, effectively dampening thermal fluctuations. Shape memory alloys (SMAs) are being explored for adaptive cooling systems that can modify channel geometries in response to temperature changes, optimizing flow characteristics based on real-time thermal conditions.

Ceramic matrix composites (CMCs) have demonstrated exceptional performance in high-temperature aerospace applications. Materials such as silicon carbide/silicon carbide (SiC/SiC) composites maintain structural integrity and thermal conductivity at temperatures exceeding 1200°C, making them ideal for cooling systems in hypersonic vehicles and rocket engines. These materials exhibit minimal degradation under thermal cycling and are resistant to oxidation in extreme environments.

Bioinspired materials design approaches are yielding novel solutions based on natural cooling systems. Hierarchical channel networks mimicking leaf venation patterns or lung bronchioles optimize fluid distribution and heat exchange efficiency. Self-healing materials incorporating microcapsules with repair agents can automatically address microcracks and erosion damage in cooling channels, extending system lifespan in the harsh conditions of aerospace operation.

Aerospace Certification and Safety Standards

Aerospace certification and safety standards represent a critical framework governing the implementation of microchannel cooling technologies in aircraft and spacecraft systems. The Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other international regulatory bodies maintain stringent requirements that all thermal management systems must meet before deployment in aerospace applications.

For microchannel cooling systems specifically, DO-160 Environmental Conditions and Test Procedures for Airborne Equipment provides essential guidelines regarding thermal cycling, vibration resistance, and electromagnetic compatibility. These systems must demonstrate resilience under extreme temperature variations ranging from -55°C to over 125°C while maintaining structural integrity and performance.

The SAE Aerospace Standards (AS) series, particularly AS4073 and AS4076, outline requirements for fluid systems in aircraft, directly impacting microchannel design parameters including material selection, pressure ratings, and leak prevention mechanisms. Compliance with these standards necessitates extensive documentation of manufacturing processes, quality control procedures, and material traceability.

Risk assessment frameworks such as MIL-STD-882E require comprehensive analysis of potential failure modes in microchannel cooling systems. This includes evaluation of coolant leakage scenarios, channel blockage possibilities, and corrosion risks that could compromise aircraft safety. Manufacturers must implement redundancy measures and fault detection capabilities to mitigate these risks.

Material certification represents another significant hurdle, with aerospace-grade materials requiring compliance with standards like AMS 4911 for titanium alloys or AMS 4027 for aluminum alloys commonly used in microchannel fabrication. These materials must demonstrate specific mechanical properties while maintaining compatibility with coolants under operational conditions.

The certification process typically involves multiple testing phases, including component-level testing, subsystem integration testing, and full-system verification. Environmental qualification testing subjects microchannel cooling systems to simulated flight conditions including rapid pressure changes, humidity cycling, and salt fog exposure to verify long-term reliability.

Recent updates to aerospace standards have begun addressing advanced manufacturing techniques relevant to microchannel production, including additive manufacturing guidelines in AS9100D and specialized requirements for micro-scale heat exchangers in emerging standards. These evolving frameworks aim to balance innovation with the paramount concern of flight safety.

For microchannel cooling systems specifically, DO-160 Environmental Conditions and Test Procedures for Airborne Equipment provides essential guidelines regarding thermal cycling, vibration resistance, and electromagnetic compatibility. These systems must demonstrate resilience under extreme temperature variations ranging from -55°C to over 125°C while maintaining structural integrity and performance.

The SAE Aerospace Standards (AS) series, particularly AS4073 and AS4076, outline requirements for fluid systems in aircraft, directly impacting microchannel design parameters including material selection, pressure ratings, and leak prevention mechanisms. Compliance with these standards necessitates extensive documentation of manufacturing processes, quality control procedures, and material traceability.

Risk assessment frameworks such as MIL-STD-882E require comprehensive analysis of potential failure modes in microchannel cooling systems. This includes evaluation of coolant leakage scenarios, channel blockage possibilities, and corrosion risks that could compromise aircraft safety. Manufacturers must implement redundancy measures and fault detection capabilities to mitigate these risks.

Material certification represents another significant hurdle, with aerospace-grade materials requiring compliance with standards like AMS 4911 for titanium alloys or AMS 4027 for aluminum alloys commonly used in microchannel fabrication. These materials must demonstrate specific mechanical properties while maintaining compatibility with coolants under operational conditions.

The certification process typically involves multiple testing phases, including component-level testing, subsystem integration testing, and full-system verification. Environmental qualification testing subjects microchannel cooling systems to simulated flight conditions including rapid pressure changes, humidity cycling, and salt fog exposure to verify long-term reliability.

Recent updates to aerospace standards have begun addressing advanced manufacturing techniques relevant to microchannel production, including additive manufacturing guidelines in AS9100D and specialized requirements for micro-scale heat exchangers in emerging standards. These evolving frameworks aim to balance innovation with the paramount concern of flight safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!