Investigation of Microchannel Cooling's Impact on Thermal Cycles in HV Batteries

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Evolution and Objectives

Microchannel cooling technology has evolved significantly over the past three decades, transitioning from theoretical concepts to practical applications across various industries. Initially developed for microelectronics cooling in the 1980s, this technology has progressively expanded into automotive applications, particularly in the last decade as electric vehicles gained market prominence. The fundamental principle involves the use of small channels (typically 10μm-1mm in diameter) to circulate coolant directly through or adjacent to heat-generating components, enabling more efficient thermal management compared to conventional cooling methods.

The evolution of microchannel cooling for high-voltage batteries has been accelerated by the increasing energy density demands of modern electric vehicles. Early implementations focused primarily on plate-based designs with limited integration capabilities. However, recent advancements have shifted toward more sophisticated three-dimensional microchannel networks that can be directly integrated into battery modules and even individual cells.

Material science breakthroughs have played a crucial role in this technological progression. The transition from traditional metal-based microchannels to advanced polymer composites and ceramic materials has addressed previous limitations related to weight, corrosion resistance, and manufacturing complexity. These new materials offer improved thermal conductivity while maintaining structural integrity under the demanding conditions of battery operation.

Manufacturing techniques have similarly evolved from rudimentary etching processes to advanced additive manufacturing methods. This shift has enabled more complex geometries and reduced production costs, making microchannel cooling increasingly viable for mass-market applications. The integration of computational fluid dynamics in design processes has further optimized channel configurations for specific battery architectures.

The primary objective of microchannel cooling technology in high-voltage batteries is to achieve uniform temperature distribution across cell arrays, thereby minimizing thermal gradients that accelerate degradation. Secondary objectives include reducing thermal cycling amplitude, extending battery lifespan, enhancing fast-charging capabilities, and improving overall system safety by preventing thermal runaway conditions.

Current research aims to quantify the specific impact of microchannel cooling on thermal cycles in high-voltage batteries, with particular focus on cycle life extension, performance consistency under variable load conditions, and optimization of energy consumption for cooling systems. The technology seeks to balance the trade-offs between cooling efficiency, system complexity, manufacturing feasibility, and cost-effectiveness to enable widespread adoption in next-generation electric vehicles.

The evolution of microchannel cooling for high-voltage batteries has been accelerated by the increasing energy density demands of modern electric vehicles. Early implementations focused primarily on plate-based designs with limited integration capabilities. However, recent advancements have shifted toward more sophisticated three-dimensional microchannel networks that can be directly integrated into battery modules and even individual cells.

Material science breakthroughs have played a crucial role in this technological progression. The transition from traditional metal-based microchannels to advanced polymer composites and ceramic materials has addressed previous limitations related to weight, corrosion resistance, and manufacturing complexity. These new materials offer improved thermal conductivity while maintaining structural integrity under the demanding conditions of battery operation.

Manufacturing techniques have similarly evolved from rudimentary etching processes to advanced additive manufacturing methods. This shift has enabled more complex geometries and reduced production costs, making microchannel cooling increasingly viable for mass-market applications. The integration of computational fluid dynamics in design processes has further optimized channel configurations for specific battery architectures.

The primary objective of microchannel cooling technology in high-voltage batteries is to achieve uniform temperature distribution across cell arrays, thereby minimizing thermal gradients that accelerate degradation. Secondary objectives include reducing thermal cycling amplitude, extending battery lifespan, enhancing fast-charging capabilities, and improving overall system safety by preventing thermal runaway conditions.

Current research aims to quantify the specific impact of microchannel cooling on thermal cycles in high-voltage batteries, with particular focus on cycle life extension, performance consistency under variable load conditions, and optimization of energy consumption for cooling systems. The technology seeks to balance the trade-offs between cooling efficiency, system complexity, manufacturing feasibility, and cost-effectiveness to enable widespread adoption in next-generation electric vehicles.

Market Analysis for Advanced HV Battery Thermal Management

The global market for advanced thermal management systems in high-voltage (HV) batteries is experiencing robust growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Current market valuations indicate that the HV battery thermal management sector reached approximately 3.5 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 22% through 2030. This growth trajectory significantly outpaces many other automotive technology segments, highlighting the critical importance of thermal management in battery performance and longevity.

Microchannel cooling technology, specifically, represents one of the fastest-growing subsegments within this market. Industry reports indicate that liquid cooling systems, of which microchannel technology is an advanced variant, currently account for about 40% of the thermal management market share, with expectations to reach 55% by 2028 as manufacturers increasingly recognize its superior thermal cycling benefits.

Regional analysis reveals distinct market characteristics across different territories. Asia-Pacific dominates the market with approximately 45% share, led by China's massive EV manufacturing ecosystem and Japan's advanced technological capabilities. North America follows at 30%, with particularly strong research and development investments in microchannel cooling technologies from both established automakers and emerging EV startups. Europe accounts for 20% of the market, with stringent safety regulations driving adoption of advanced thermal management solutions.

Customer demand analysis indicates three primary market drivers for microchannel cooling technology in HV batteries: extended battery lifespan (cited by 78% of OEMs as "very important"), improved fast-charging capabilities (68%), and enhanced safety profiles (92%). These priorities align perfectly with microchannel cooling's demonstrated ability to maintain more consistent temperature profiles during thermal cycling events.

Market segmentation shows passenger vehicles currently represent the largest application segment (65%), followed by commercial vehicles (20%) and stationary energy storage systems (15%). However, the commercial vehicle segment is expected to grow at the highest rate (27% CAGR) as fleet electrification accelerates and the benefits of advanced thermal management become more widely recognized in heavy-duty applications where thermal cycling is particularly challenging.

Competitive analysis reveals that tier-one automotive suppliers are increasingly partnering with thermal management specialists to develop proprietary microchannel cooling solutions, recognizing this technology as a key differentiator in next-generation EV platforms. This trend has triggered significant merger and acquisition activity, with five major deals exceeding 100 million USD each announced in the past 18 months specifically targeting microchannel cooling intellectual property.

Microchannel cooling technology, specifically, represents one of the fastest-growing subsegments within this market. Industry reports indicate that liquid cooling systems, of which microchannel technology is an advanced variant, currently account for about 40% of the thermal management market share, with expectations to reach 55% by 2028 as manufacturers increasingly recognize its superior thermal cycling benefits.

Regional analysis reveals distinct market characteristics across different territories. Asia-Pacific dominates the market with approximately 45% share, led by China's massive EV manufacturing ecosystem and Japan's advanced technological capabilities. North America follows at 30%, with particularly strong research and development investments in microchannel cooling technologies from both established automakers and emerging EV startups. Europe accounts for 20% of the market, with stringent safety regulations driving adoption of advanced thermal management solutions.

Customer demand analysis indicates three primary market drivers for microchannel cooling technology in HV batteries: extended battery lifespan (cited by 78% of OEMs as "very important"), improved fast-charging capabilities (68%), and enhanced safety profiles (92%). These priorities align perfectly with microchannel cooling's demonstrated ability to maintain more consistent temperature profiles during thermal cycling events.

Market segmentation shows passenger vehicles currently represent the largest application segment (65%), followed by commercial vehicles (20%) and stationary energy storage systems (15%). However, the commercial vehicle segment is expected to grow at the highest rate (27% CAGR) as fleet electrification accelerates and the benefits of advanced thermal management become more widely recognized in heavy-duty applications where thermal cycling is particularly challenging.

Competitive analysis reveals that tier-one automotive suppliers are increasingly partnering with thermal management specialists to develop proprietary microchannel cooling solutions, recognizing this technology as a key differentiator in next-generation EV platforms. This trend has triggered significant merger and acquisition activity, with five major deals exceeding 100 million USD each announced in the past 18 months specifically targeting microchannel cooling intellectual property.

Current Challenges in Battery Thermal Cycling Management

The thermal management of high-voltage (HV) battery systems represents one of the most critical challenges in electric vehicle (EV) development. Current battery thermal cycling management faces several significant obstacles that limit performance, safety, and longevity of battery systems. Temperature gradients within battery packs remain a persistent issue, with variations of up to 10°C commonly observed across large-format battery modules. These gradients accelerate differential aging of cells and create thermal stress points that compromise structural integrity over time.

Conventional cooling systems struggle to maintain optimal operating temperatures (typically 20-40°C) during rapid charging and discharging cycles. During fast charging scenarios, heat generation can exceed 3W per cell, overwhelming traditional cooling architectures and triggering thermal throttling that extends charging times. This limitation directly impacts user experience and commercial viability of EVs in competitive markets.

Energy efficiency presents another major challenge, with current thermal management systems consuming 3-8% of total battery capacity. This parasitic loss significantly reduces vehicle range, particularly in extreme climate conditions where heating or cooling demands intensify. The industry lacks standardized thermal cycling protocols that accurately represent real-world usage patterns, making it difficult to compare solutions across platforms or predict long-term performance degradation.

Material constraints further complicate thermal management strategies. Current phase change materials (PCMs) exhibit limited heat absorption capacity and thermal conductivity, while traditional liquid cooling systems face challenges with uniform heat distribution across large battery arrays. The integration density of cooling channels remains insufficient for next-generation high-energy-density cells, which generate more heat in smaller volumes.

Sensor technology and control algorithms represent additional bottlenecks. Current temperature monitoring systems typically utilize 1-2 sensors per module, providing insufficient spatial resolution to detect localized hotspots. Predictive thermal management algorithms lack the sophistication to anticipate thermal loads based on driving conditions, route planning, and ambient factors, resulting in reactive rather than proactive cooling strategies.

Manufacturing complexity and cost considerations impose further constraints. Advanced cooling solutions like microchannel systems require precision manufacturing techniques that significantly increase production costs. The industry faces a critical trade-off between thermal performance and economic viability, particularly in mass-market vehicle segments where price sensitivity is high.

Regulatory requirements add another layer of complexity, with safety standards mandating thermal runaway prevention and containment capabilities that must be balanced against performance objectives. The absence of harmonized international standards creates market fragmentation and increases compliance costs for global manufacturers.

Conventional cooling systems struggle to maintain optimal operating temperatures (typically 20-40°C) during rapid charging and discharging cycles. During fast charging scenarios, heat generation can exceed 3W per cell, overwhelming traditional cooling architectures and triggering thermal throttling that extends charging times. This limitation directly impacts user experience and commercial viability of EVs in competitive markets.

Energy efficiency presents another major challenge, with current thermal management systems consuming 3-8% of total battery capacity. This parasitic loss significantly reduces vehicle range, particularly in extreme climate conditions where heating or cooling demands intensify. The industry lacks standardized thermal cycling protocols that accurately represent real-world usage patterns, making it difficult to compare solutions across platforms or predict long-term performance degradation.

Material constraints further complicate thermal management strategies. Current phase change materials (PCMs) exhibit limited heat absorption capacity and thermal conductivity, while traditional liquid cooling systems face challenges with uniform heat distribution across large battery arrays. The integration density of cooling channels remains insufficient for next-generation high-energy-density cells, which generate more heat in smaller volumes.

Sensor technology and control algorithms represent additional bottlenecks. Current temperature monitoring systems typically utilize 1-2 sensors per module, providing insufficient spatial resolution to detect localized hotspots. Predictive thermal management algorithms lack the sophistication to anticipate thermal loads based on driving conditions, route planning, and ambient factors, resulting in reactive rather than proactive cooling strategies.

Manufacturing complexity and cost considerations impose further constraints. Advanced cooling solutions like microchannel systems require precision manufacturing techniques that significantly increase production costs. The industry faces a critical trade-off between thermal performance and economic viability, particularly in mass-market vehicle segments where price sensitivity is high.

Regulatory requirements add another layer of complexity, with safety standards mandating thermal runaway prevention and containment capabilities that must be balanced against performance objectives. The absence of harmonized international standards creates market fragmentation and increases compliance costs for global manufacturers.

Existing Microchannel Cooling Implementation Strategies

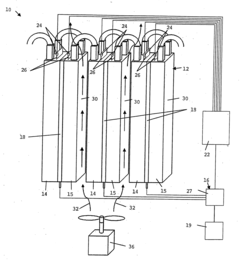

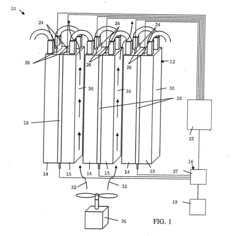

01 Microchannel heat exchangers for thermal cycling applications

Microchannel heat exchangers utilize small channels to enhance heat transfer efficiency in thermal cycling applications. These systems provide improved thermal management through increased surface area-to-volume ratios, allowing for rapid heating and cooling cycles. The microchannels facilitate efficient heat exchange between cooling fluids and heat-generating components, making them ideal for applications requiring precise temperature control during thermal cycling processes.- Microchannel heat exchangers for thermal cycling applications: Microchannel heat exchangers utilize small channels to enhance heat transfer efficiency in thermal cycling applications. These systems provide improved thermal management through increased surface area-to-volume ratios, allowing for rapid heating and cooling cycles. The microchannels facilitate efficient heat exchange between cooling fluids and heat-generating components, making them ideal for applications requiring precise temperature control during thermal cycles.

- Cooling systems for electronic components using microchannels: Microchannel cooling systems are specifically designed for electronic components that undergo thermal cycles during operation. These systems incorporate microchannels directly into or adjacent to electronic components to efficiently remove heat. The small channel dimensions allow for enhanced cooling performance while maintaining compact designs, which is crucial for modern electronics with high power densities and thermal cycling requirements.

- Phase change cooling in microchannel systems: Phase change cooling mechanisms in microchannel systems utilize the latent heat of vaporization to enhance cooling efficiency during thermal cycles. These systems employ working fluids that change phase within microchannels, absorbing significant amounts of heat during the process. This approach provides more effective temperature control during thermal cycling compared to single-phase cooling methods, making it suitable for applications with high heat flux and thermal cycling demands.

- Microchannel design optimization for thermal cycling: Optimized microchannel designs focus on enhancing heat transfer performance during thermal cycling while minimizing pressure drop. These designs consider channel geometry, surface treatments, and flow arrangements to improve thermal performance. Various configurations such as parallel, serpentine, or branching microchannels are employed to address specific thermal cycling requirements, with considerations for material expansion and contraction during temperature fluctuations.

- Integrated cooling solutions with microchannels for thermal management: Integrated cooling solutions combine microchannels with other cooling technologies to create comprehensive thermal management systems for applications undergoing thermal cycles. These hybrid approaches may incorporate heat pipes, thermoelectric coolers, or phase change materials alongside microchannels to optimize cooling performance. The integration enables more effective handling of varying thermal loads during cycling, providing stable temperature control across different operating conditions.

02 Thermal management systems for electronic components

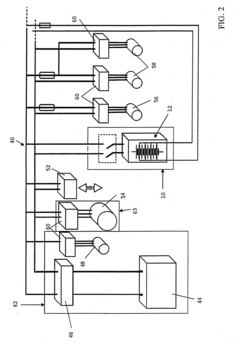

Microchannel cooling systems designed specifically for electronic components manage heat generated during operational thermal cycles. These systems incorporate microchannels directly into or adjacent to electronic components to provide localized cooling. The design allows for efficient heat dissipation from high-power density electronics, preventing thermal damage and maintaining optimal operating temperatures during repeated thermal cycles, which extends component lifespan and improves reliability.Expand Specific Solutions03 Phase change cooling in microchannel systems

Phase change cooling mechanisms in microchannel systems utilize the latent heat of vaporization to enhance cooling efficiency during thermal cycles. These systems employ working fluids that undergo phase transitions within microchannels, absorbing significant amounts of heat. This approach provides more effective temperature control during thermal cycling compared to single-phase cooling methods, making it suitable for applications with high heat flux requirements or those needing rapid temperature changes.Expand Specific Solutions04 Microchannel design optimization for thermal cycling

Optimized microchannel designs specifically engineered for thermal cycling applications focus on channel geometry, distribution patterns, and surface treatments. These designs consider factors such as flow distribution, pressure drop, and heat transfer coefficients to maximize cooling efficiency. Advanced manufacturing techniques enable complex channel configurations that can withstand repeated thermal expansion and contraction during cycling while maintaining structural integrity and consistent cooling performance.Expand Specific Solutions05 Integrated cooling systems with thermal cycle management

Integrated cooling systems combine microchannels with additional thermal management technologies to handle complex thermal cycling requirements. These systems may incorporate sensors, controllers, and multiple cooling zones to actively respond to changing thermal loads. The integration allows for precise temperature control during different phases of thermal cycles, making them suitable for applications in manufacturing processes, laboratory equipment, and advanced thermal testing where temperature uniformity and cycle repeatability are critical.Expand Specific Solutions

Leading Companies in Battery Cooling Solutions

Microchannel cooling technology for HV batteries is currently in the growth phase of its industry lifecycle, with an estimated market size of $1.2-1.5 billion and projected CAGR of 18-22% through 2030. The competitive landscape features established automotive manufacturers (Mercedes-Benz, Hyundai, Kia, Volkswagen, Audi) investing heavily in thermal management solutions, while specialized thermal systems providers like AVL List, Valeo Thermal Systems, and Johnson Controls are developing advanced microchannel technologies. Tech integration is being pursued by Intel and LG Energy Solution, focusing on smart thermal management systems. The technology is approaching maturity with commercial implementations, though optimization for various battery chemistries and form factors remains an active research area across academic institutions like Shandong University and Louisiana State University.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a microchannel cooling technology for their Ultium battery platform that features an innovative immersion cooling approach. Their system utilizes precision-engineered microchannels (typically 100-500 micrometers wide) embedded within the battery module base plate. The design employs a proprietary coolant formulation that flows through these channels at carefully controlled rates to maintain optimal thermal conditions. GM's research indicates this system can remove heat at rates exceeding 3 kW/m², significantly reducing thermal cycling effects. The technology incorporates pressure-optimized flow distribution to ensure uniform cooling across large battery packs, with sensors monitoring temperature at multiple points to enable dynamic flow adjustments. This approach has reportedly reduced battery degradation by up to 30% by minimizing thermal gradients and preventing hotspot formation during rapid charging and high-load operation.

Strengths: Exceptional heat transfer efficiency due to optimized microchannel geometry; integrated design reduces overall system complexity; demonstrated improvement in battery longevity through superior thermal management. Weaknesses: Requires precise manufacturing tolerances; higher initial implementation cost compared to conventional cooling systems; potential for channel clogging over extended vehicle lifetime.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a sophisticated microchannel cooling system for their EQ series electric vehicles that integrates directly with the battery module structure. Their approach utilizes a network of precisely engineered microchannels (typically 0.8-1.5mm in diameter) machined into cooling plates that sit between battery cells. The system employs a dual-circuit design that allows for both active cooling and heating of the battery pack, enabling optimal temperature management across extreme ambient conditions from -30°C to +50°C. Mercedes' technology incorporates variable flow rate control based on real-time thermal modeling, with their research showing the system can maintain cell-to-cell temperature variations below 2°C even during 350kW ultra-fast charging sessions. The cooling plates feature optimized flow path geometries that maximize surface contact while minimizing pressure drop, allowing for efficient coolant circulation with reduced pumping energy requirements.

Strengths: Exceptional temperature uniformity across large battery packs; integrated heating capability for cold weather performance; sophisticated thermal management algorithms optimize efficiency. Weaknesses: High manufacturing precision requirements increase production costs; complex system architecture requires additional components; slightly increased weight compared to simpler cooling solutions.

Critical Patents in Microchannel Cooling for HV Batteries

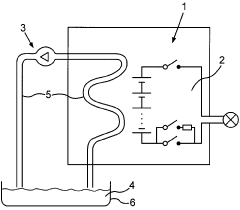

Battery temperature control method and assembly

PatentInactiveUS20110117463A1

Innovation

- A battery temperature control assembly utilizing positive thermal coefficient (PTC) resistive elements, configured to maintain a desired operating temperature by applying electrical power, with anomaly temperatures set below the maximum battery operating temperature to prevent overheating, and controlled by a system of temperature sensors and a controller to manage heat transfer.

liquid cooling system of a HV battery

PatentInactiveDE102013006755A1

Innovation

- A high-voltage battery device with a cooling circuit integrated collection container that collects cooling fluid, ensuring it is completely emptied when not in use, primarily through gravitational force or controlled venting, minimizing contact with live components.

Safety Standards and Compliance Requirements

The implementation of microchannel cooling systems in high-voltage battery applications necessitates strict adherence to comprehensive safety standards and compliance requirements. International standards such as IEC 62660 and ISO 6469 establish fundamental safety parameters for lithium-ion batteries in electric vehicles, with specific provisions addressing thermal management systems. These standards mandate rigorous testing protocols for thermal runaway prevention, electrical isolation, and coolant containment integrity.

Regulatory bodies including the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's ECE R100 regulation have established specific requirements for battery cooling systems. These regulations typically require manufacturers to demonstrate that cooling systems maintain battery temperatures within safe operating ranges under various conditions, including rapid charging, high-power discharge events, and extreme ambient temperatures.

UN 38.3 testing requirements for lithium battery transportation safety have implications for microchannel cooling designs, particularly regarding thermal shock resistance and structural integrity. Manufacturers must ensure that cooling channels and associated components maintain their functionality and safety characteristics throughout the battery's operational lifetime and under transportation stress conditions.

Material compatibility standards are particularly relevant for microchannel cooling implementations. ISO 19453-5 addresses automotive electronic component requirements for chemicals and fluids, while SAE J1739 provides guidelines for Design Failure Mode and Effects Analysis (DFMEA) that should be applied to cooling system design. Coolants used in microchannel systems must comply with environmental regulations such as the EU's REACH and RoHS directives, limiting the use of hazardous substances.

Electromagnetic compatibility (EMC) requirements outlined in IEC 61851 and ISO 11452 series must be considered, as cooling system components like pumps and sensors can potentially generate electromagnetic interference affecting battery management systems. The integration of sensors for temperature monitoring within microchannel cooling systems must comply with functional safety standards such as ISO 26262, particularly when these systems are part of thermal runaway prevention mechanisms.

Manufacturing quality standards including ISO 9001 and IATF 16949 apply to the production processes for microchannel cooling components, with special attention to leak testing protocols and quality control measures for microchannel fabrication. Emerging standards specifically addressing battery thermal management systems are being developed by organizations like SAE International and the International Electrotechnical Commission, with working groups focusing on standardized testing methodologies for cooling efficiency and thermal cycle impact assessment.

Compliance with these standards requires comprehensive documentation of design validation, risk assessment, and testing results throughout the development process of microchannel cooling systems for high-voltage batteries.

Regulatory bodies including the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's ECE R100 regulation have established specific requirements for battery cooling systems. These regulations typically require manufacturers to demonstrate that cooling systems maintain battery temperatures within safe operating ranges under various conditions, including rapid charging, high-power discharge events, and extreme ambient temperatures.

UN 38.3 testing requirements for lithium battery transportation safety have implications for microchannel cooling designs, particularly regarding thermal shock resistance and structural integrity. Manufacturers must ensure that cooling channels and associated components maintain their functionality and safety characteristics throughout the battery's operational lifetime and under transportation stress conditions.

Material compatibility standards are particularly relevant for microchannel cooling implementations. ISO 19453-5 addresses automotive electronic component requirements for chemicals and fluids, while SAE J1739 provides guidelines for Design Failure Mode and Effects Analysis (DFMEA) that should be applied to cooling system design. Coolants used in microchannel systems must comply with environmental regulations such as the EU's REACH and RoHS directives, limiting the use of hazardous substances.

Electromagnetic compatibility (EMC) requirements outlined in IEC 61851 and ISO 11452 series must be considered, as cooling system components like pumps and sensors can potentially generate electromagnetic interference affecting battery management systems. The integration of sensors for temperature monitoring within microchannel cooling systems must comply with functional safety standards such as ISO 26262, particularly when these systems are part of thermal runaway prevention mechanisms.

Manufacturing quality standards including ISO 9001 and IATF 16949 apply to the production processes for microchannel cooling components, with special attention to leak testing protocols and quality control measures for microchannel fabrication. Emerging standards specifically addressing battery thermal management systems are being developed by organizations like SAE International and the International Electrotechnical Commission, with working groups focusing on standardized testing methodologies for cooling efficiency and thermal cycle impact assessment.

Compliance with these standards requires comprehensive documentation of design validation, risk assessment, and testing results throughout the development process of microchannel cooling systems for high-voltage batteries.

Environmental Impact of Advanced Cooling Technologies

The environmental implications of microchannel cooling technology in high-voltage battery systems extend far beyond operational efficiency. As advanced cooling technologies evolve, their ecological footprint becomes increasingly significant in sustainability assessments. Microchannel cooling systems, while offering superior thermal management for HV batteries, present both environmental challenges and opportunities that warrant careful consideration.

The manufacturing process of microchannel cooling systems involves precision engineering of microscale channels, typically requiring specialized materials and fabrication techniques. These processes often consume substantial energy and may utilize rare earth metals or specialized alloys, raising concerns about resource depletion and mining impacts. However, compared to conventional cooling systems, the material efficiency of microchannels—using less coolant and smaller components—potentially reduces the overall environmental burden of raw material extraction.

Operational environmental benefits of microchannel cooling are substantial. By maintaining optimal temperature ranges more efficiently, these systems can extend battery lifespan by up to 30%, significantly reducing waste from premature battery replacement. This lifecycle extension directly translates to fewer batteries manufactured and disposed of, mitigating the environmental impact of battery production and end-of-life management.

Energy consumption patterns also shift favorably with microchannel implementation. Studies indicate that advanced microchannel cooling can reduce cooling-related energy consumption by 15-25% compared to traditional methods. This efficiency gain translates to lower greenhouse gas emissions throughout the battery's operational life, particularly important as the energy density and thermal management requirements of HV batteries continue to increase.

The coolant selection for microchannel systems presents another environmental consideration. While traditional coolants often contain environmentally harmful compounds, newer microchannel designs increasingly utilize biodegradable alternatives or closed-loop systems that minimize leakage risk. This transition reduces potential soil and water contamination hazards associated with coolant disposal or accidental release.

End-of-life considerations reveal additional environmental dimensions. The intricate integration of microchannel cooling systems with battery components may complicate recycling processes, potentially reducing recovery rates of valuable materials. Conversely, the precision engineering of these systems creates opportunities for component reuse and remanufacturing, potentially establishing circular economy pathways that conventional cooling technologies cannot support.

Climate impact modeling suggests that widespread adoption of microchannel cooling in electric vehicle batteries could reduce lifetime carbon emissions by 3-7% per vehicle, primarily through improved efficiency and extended battery life. This cumulative effect becomes significant when projected across global electric vehicle adoption forecasts, representing a meaningful contribution to transportation sector decarbonization efforts.

The manufacturing process of microchannel cooling systems involves precision engineering of microscale channels, typically requiring specialized materials and fabrication techniques. These processes often consume substantial energy and may utilize rare earth metals or specialized alloys, raising concerns about resource depletion and mining impacts. However, compared to conventional cooling systems, the material efficiency of microchannels—using less coolant and smaller components—potentially reduces the overall environmental burden of raw material extraction.

Operational environmental benefits of microchannel cooling are substantial. By maintaining optimal temperature ranges more efficiently, these systems can extend battery lifespan by up to 30%, significantly reducing waste from premature battery replacement. This lifecycle extension directly translates to fewer batteries manufactured and disposed of, mitigating the environmental impact of battery production and end-of-life management.

Energy consumption patterns also shift favorably with microchannel implementation. Studies indicate that advanced microchannel cooling can reduce cooling-related energy consumption by 15-25% compared to traditional methods. This efficiency gain translates to lower greenhouse gas emissions throughout the battery's operational life, particularly important as the energy density and thermal management requirements of HV batteries continue to increase.

The coolant selection for microchannel systems presents another environmental consideration. While traditional coolants often contain environmentally harmful compounds, newer microchannel designs increasingly utilize biodegradable alternatives or closed-loop systems that minimize leakage risk. This transition reduces potential soil and water contamination hazards associated with coolant disposal or accidental release.

End-of-life considerations reveal additional environmental dimensions. The intricate integration of microchannel cooling systems with battery components may complicate recycling processes, potentially reducing recovery rates of valuable materials. Conversely, the precision engineering of these systems creates opportunities for component reuse and remanufacturing, potentially establishing circular economy pathways that conventional cooling technologies cannot support.

Climate impact modeling suggests that widespread adoption of microchannel cooling in electric vehicle batteries could reduce lifetime carbon emissions by 3-7% per vehicle, primarily through improved efficiency and extended battery life. This cumulative effect becomes significant when projected across global electric vehicle adoption forecasts, representing a meaningful contribution to transportation sector decarbonization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!