The Interplay of Microchannel Cooling and Electrode Stability

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling and Electrode Stability Background

Microchannel cooling technology has emerged as a revolutionary approach to thermal management in high-power electronic systems over the past three decades. Initially developed for aerospace applications in the 1980s, this technology has evolved significantly to address the increasing thermal challenges in various industries including power electronics, data centers, and electric vehicles. The fundamental principle involves the circulation of coolant through microscale channels (typically 10-500 micrometers in diameter) to efficiently remove heat from critical components.

The evolution of microchannel cooling has been marked by several significant milestones. Early research focused primarily on single-phase cooling with water or specialized coolants. By the early 2000s, two-phase cooling mechanisms utilizing phase change phenomena gained prominence, offering substantially higher heat transfer coefficients. Recent advancements have introduced smart cooling systems with adaptive flow control and novel channel geometries that optimize fluid dynamics for maximum thermal performance.

Electrode stability, particularly in electrochemical systems, has developed along a parallel but interconnected trajectory. Traditional electrode materials faced significant challenges including corrosion, delamination, and performance degradation under thermal stress. The introduction of advanced composite materials and nano-engineered surfaces in the 2010s marked a turning point in electrode durability and performance under extreme operating conditions.

The intersection of these two technological domains represents a critical frontier in modern engineering. As power densities in electronic and electrochemical systems continue to increase exponentially, the thermal management challenges have become more acute. Conventional cooling approaches often prove inadequate when electrodes must maintain structural and chemical integrity under high current densities and thermal loads.

Current technological objectives in this field focus on developing integrated solutions that address both thermal management and electrode stability simultaneously. This includes the creation of multifunctional materials that serve as both efficient thermal conductors and stable electrode substrates. Another key goal involves the development of predictive models that can accurately simulate the complex interactions between cooling fluid dynamics and electrochemical processes at material interfaces.

The advancement of this technology aims to enable next-generation energy storage systems, high-power electronics, and electrochemical reactors that can operate reliably under extreme conditions. Achieving these objectives requires interdisciplinary collaboration spanning materials science, fluid dynamics, electrochemistry, and thermal engineering to overcome the fundamental limitations of current approaches.

The evolution of microchannel cooling has been marked by several significant milestones. Early research focused primarily on single-phase cooling with water or specialized coolants. By the early 2000s, two-phase cooling mechanisms utilizing phase change phenomena gained prominence, offering substantially higher heat transfer coefficients. Recent advancements have introduced smart cooling systems with adaptive flow control and novel channel geometries that optimize fluid dynamics for maximum thermal performance.

Electrode stability, particularly in electrochemical systems, has developed along a parallel but interconnected trajectory. Traditional electrode materials faced significant challenges including corrosion, delamination, and performance degradation under thermal stress. The introduction of advanced composite materials and nano-engineered surfaces in the 2010s marked a turning point in electrode durability and performance under extreme operating conditions.

The intersection of these two technological domains represents a critical frontier in modern engineering. As power densities in electronic and electrochemical systems continue to increase exponentially, the thermal management challenges have become more acute. Conventional cooling approaches often prove inadequate when electrodes must maintain structural and chemical integrity under high current densities and thermal loads.

Current technological objectives in this field focus on developing integrated solutions that address both thermal management and electrode stability simultaneously. This includes the creation of multifunctional materials that serve as both efficient thermal conductors and stable electrode substrates. Another key goal involves the development of predictive models that can accurately simulate the complex interactions between cooling fluid dynamics and electrochemical processes at material interfaces.

The advancement of this technology aims to enable next-generation energy storage systems, high-power electronics, and electrochemical reactors that can operate reliably under extreme conditions. Achieving these objectives requires interdisciplinary collaboration spanning materials science, fluid dynamics, electrochemistry, and thermal engineering to overcome the fundamental limitations of current approaches.

Market Analysis for Thermal Management Solutions

The thermal management solutions market is experiencing robust growth driven by increasing power densities in electronic devices across multiple industries. Currently valued at approximately $8.3 billion, this market is projected to reach $13.7 billion by 2027, representing a compound annual growth rate of 8.2%. This growth trajectory is particularly evident in sectors requiring advanced cooling technologies for high-performance applications, including data centers, electric vehicles, and advanced computing systems.

Microchannel cooling technology represents a significant segment within this market, with particular relevance to electrode stability applications. The intersection of these technologies addresses critical needs in battery management systems, fuel cells, and high-power electronics where thermal regulation directly impacts electrode performance and longevity. Market research indicates that solutions specifically targeting electrode stability through advanced cooling methods command premium pricing, with margins 15-20% higher than conventional thermal management products.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed closely by Asia-Pacific at 32%, which demonstrates the fastest growth rate at 9.7% annually. This growth in Asia-Pacific is primarily driven by the rapid expansion of electronics manufacturing and electric vehicle production in China, South Korea, and Japan.

Customer segmentation shows distinct requirements across different industries. The automotive sector, particularly electric vehicle manufacturers, prioritizes compact cooling solutions that can maintain electrode stability under variable load conditions. Data center operators focus on energy efficiency metrics, seeking solutions that reduce cooling-related power consumption while ensuring consistent performance of server components.

Competitive landscape analysis identifies three tiers of market participants: established thermal solution providers expanding their portfolios to include microchannel technologies; specialized cooling technology startups focusing exclusively on high-performance applications; and component manufacturers integrating cooling solutions directly into their products. Market concentration remains moderate with the top five players controlling approximately 43% of market share.

Market barriers include high initial implementation costs, with microchannel cooling systems typically commanding a 30-40% premium over traditional cooling methods. However, total cost of ownership analyses demonstrate potential long-term savings through extended component lifespan and reduced maintenance requirements, particularly in applications where electrode stability is critical to system performance.

Future market growth will be significantly influenced by regulatory developments regarding energy efficiency standards and the continued miniaturization of electronic components, both trends that favor advanced cooling technologies capable of maintaining electrode stability under increasingly demanding thermal conditions.

Microchannel cooling technology represents a significant segment within this market, with particular relevance to electrode stability applications. The intersection of these technologies addresses critical needs in battery management systems, fuel cells, and high-power electronics where thermal regulation directly impacts electrode performance and longevity. Market research indicates that solutions specifically targeting electrode stability through advanced cooling methods command premium pricing, with margins 15-20% higher than conventional thermal management products.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed closely by Asia-Pacific at 32%, which demonstrates the fastest growth rate at 9.7% annually. This growth in Asia-Pacific is primarily driven by the rapid expansion of electronics manufacturing and electric vehicle production in China, South Korea, and Japan.

Customer segmentation shows distinct requirements across different industries. The automotive sector, particularly electric vehicle manufacturers, prioritizes compact cooling solutions that can maintain electrode stability under variable load conditions. Data center operators focus on energy efficiency metrics, seeking solutions that reduce cooling-related power consumption while ensuring consistent performance of server components.

Competitive landscape analysis identifies three tiers of market participants: established thermal solution providers expanding their portfolios to include microchannel technologies; specialized cooling technology startups focusing exclusively on high-performance applications; and component manufacturers integrating cooling solutions directly into their products. Market concentration remains moderate with the top five players controlling approximately 43% of market share.

Market barriers include high initial implementation costs, with microchannel cooling systems typically commanding a 30-40% premium over traditional cooling methods. However, total cost of ownership analyses demonstrate potential long-term savings through extended component lifespan and reduced maintenance requirements, particularly in applications where electrode stability is critical to system performance.

Future market growth will be significantly influenced by regulatory developments regarding energy efficiency standards and the continued miniaturization of electronic components, both trends that favor advanced cooling technologies capable of maintaining electrode stability under increasingly demanding thermal conditions.

Current Challenges in Microchannel Cooling Technology

Microchannel cooling technology, while promising significant advancements in thermal management, currently faces several critical challenges that impede its widespread implementation. The primary obstacle remains the complex interplay between cooling efficiency and electrode stability, particularly in high-power electronic applications where both factors are crucial for system reliability.

The miniaturization trend in cooling channels has reached physical limitations where further reduction in channel dimensions creates excessive pressure drops, requiring unsustainable pumping power. Current microchannel designs typically achieve hydraulic diameters between 10-200 micrometers, but pushing beyond this range introduces exponential increases in flow resistance that counteract cooling benefits.

Material compatibility presents another significant challenge, especially at the interface between cooling fluids and electrode materials. Prolonged exposure to coolants often triggers electrochemical degradation of electrode surfaces, compromising both electrical performance and thermal conductivity. Recent studies have documented up to 15% reduction in electrode efficiency after extended operation under microchannel cooling conditions.

Flow distribution uniformity remains problematic in practical applications. Current manufacturing techniques struggle to produce perfectly consistent channel geometries across large cooling arrays, resulting in flow maldistribution that creates localized hotspots. These thermal gradients induce mechanical stress that accelerates electrode degradation through thermal cycling.

Fouling and clogging represent persistent operational challenges, particularly in systems utilizing water-based coolants. Particulate accumulation and biofilm formation progressively restrict flow passages, with some experimental systems showing up to 30% reduction in cooling capacity within 1000 hours of operation. This degradation directly impacts electrode stability by altering the thermal profile across active components.

The integration of sensors and control systems for real-time monitoring presents both a challenge and opportunity. Current technology lacks robust, miniaturized sensing capabilities that can survive within the harsh microfluidic environment while providing accurate temperature and flow data necessary to maintain optimal electrode operating conditions.

Manufacturing scalability continues to limit commercial viability. Precision fabrication techniques required for high-performance microchannels remain costly and difficult to scale, creating a significant barrier to mass production. The most effective cooling designs often require multi-material systems with complex geometries that challenge conventional manufacturing processes.

Two-phase cooling implementations, while theoretically offering superior heat transfer coefficients, introduce additional complications regarding flow stability and phase distribution that can adversely affect electrode performance through unpredictable thermal cycling and localized dry-out conditions.

The miniaturization trend in cooling channels has reached physical limitations where further reduction in channel dimensions creates excessive pressure drops, requiring unsustainable pumping power. Current microchannel designs typically achieve hydraulic diameters between 10-200 micrometers, but pushing beyond this range introduces exponential increases in flow resistance that counteract cooling benefits.

Material compatibility presents another significant challenge, especially at the interface between cooling fluids and electrode materials. Prolonged exposure to coolants often triggers electrochemical degradation of electrode surfaces, compromising both electrical performance and thermal conductivity. Recent studies have documented up to 15% reduction in electrode efficiency after extended operation under microchannel cooling conditions.

Flow distribution uniformity remains problematic in practical applications. Current manufacturing techniques struggle to produce perfectly consistent channel geometries across large cooling arrays, resulting in flow maldistribution that creates localized hotspots. These thermal gradients induce mechanical stress that accelerates electrode degradation through thermal cycling.

Fouling and clogging represent persistent operational challenges, particularly in systems utilizing water-based coolants. Particulate accumulation and biofilm formation progressively restrict flow passages, with some experimental systems showing up to 30% reduction in cooling capacity within 1000 hours of operation. This degradation directly impacts electrode stability by altering the thermal profile across active components.

The integration of sensors and control systems for real-time monitoring presents both a challenge and opportunity. Current technology lacks robust, miniaturized sensing capabilities that can survive within the harsh microfluidic environment while providing accurate temperature and flow data necessary to maintain optimal electrode operating conditions.

Manufacturing scalability continues to limit commercial viability. Precision fabrication techniques required for high-performance microchannels remain costly and difficult to scale, creating a significant barrier to mass production. The most effective cooling designs often require multi-material systems with complex geometries that challenge conventional manufacturing processes.

Two-phase cooling implementations, while theoretically offering superior heat transfer coefficients, introduce additional complications regarding flow stability and phase distribution that can adversely affect electrode performance through unpredictable thermal cycling and localized dry-out conditions.

Existing Microchannel Cooling Implementation Methods

01 Microchannel design for electrode cooling

Specialized microchannel designs can enhance cooling efficiency for electrodes in various applications. These designs incorporate optimized flow paths, channel geometries, and heat transfer surfaces to maximize thermal management while maintaining electrode stability. Advanced microchannel configurations can include parallel channels, serpentine patterns, or 3D structures that provide uniform cooling across electrode surfaces, preventing hotspots that could lead to degradation or failure.- Microchannel design for electrode cooling: Specialized microchannel designs can enhance cooling efficiency for electrodes in various applications. These designs include optimized channel geometries, flow patterns, and heat transfer surfaces that maximize thermal conductivity while maintaining structural integrity. The microchannels can be integrated directly into electrode structures to provide localized cooling where heat generation is most concentrated, improving overall electrode stability and performance under high-power conditions.

- Coolant formulations for electrode stability: Specialized coolant formulations can significantly improve electrode stability in microchannel cooling systems. These formulations may include dielectric fluids that prevent electrical shorting, additives that inhibit corrosion of electrode materials, and compounds that enhance heat transfer properties. The coolants are designed to maintain their thermal and chemical properties over extended operational periods, preventing degradation of electrode performance even under extreme thermal cycling conditions.

- Interface materials for thermal management: Advanced interface materials between electrodes and cooling systems can enhance thermal transfer while maintaining electrical isolation. These materials include thermally conductive but electrically insulating compounds, specialized thermal interface materials (TIMs), and composite structures that optimize the balance between thermal conductivity and electrical resistance. Proper interface design prevents electrode degradation by efficiently removing heat while maintaining the electrical integrity of the system.

- Monitoring and control systems for electrode cooling: Integrated monitoring and control systems can dynamically adjust cooling parameters to maintain electrode stability. These systems incorporate temperature sensors, flow monitors, and feedback control algorithms that respond to changing thermal loads. By continuously optimizing cooling performance based on real-time data, these systems prevent thermal runaway conditions that could compromise electrode integrity, extending operational lifetime and improving reliability in high-power applications.

- Electrode materials compatible with microchannel cooling: Specialized electrode materials designed for compatibility with microchannel cooling systems can significantly improve stability. These materials feature enhanced thermal conductivity, resistance to coolant-induced corrosion, and mechanical stability under thermal cycling. Some designs incorporate the cooling channels directly into the electrode structure using advanced manufacturing techniques, creating monolithic components that eliminate thermal resistance at interfaces and improve overall system reliability.

02 Cooling fluid composition for electrode stability

The composition of cooling fluids plays a crucial role in maintaining electrode stability in microchannel cooling systems. Specialized coolants with high thermal conductivity, appropriate viscosity, and chemical compatibility with electrode materials can significantly improve cooling efficiency while preventing electrode degradation. These fluids may include dielectric coolants, nanofluids, or phase-change materials that offer enhanced heat transfer properties without compromising the electrical performance or structural integrity of the electrodes.Expand Specific Solutions03 Integrated thermal management systems for electrodes

Comprehensive thermal management systems integrate microchannels with additional cooling technologies to ensure electrode stability. These systems may combine liquid cooling through microchannels with heat spreaders, thermal interface materials, or secondary cooling loops. The integrated approach provides redundancy and enhanced performance, particularly for high-power applications where electrode stability is critical. Advanced control systems monitor temperature distribution and adjust cooling parameters in real-time to maintain optimal operating conditions.Expand Specific Solutions04 Materials and coatings for enhanced electrode durability

Specialized materials and protective coatings can significantly improve electrode stability in microchannel cooling environments. These materials offer superior corrosion resistance, thermal conductivity, and mechanical strength under thermal cycling conditions. Coatings may include anti-corrosion layers, hydrophobic or hydrophilic treatments to optimize fluid flow characteristics, or thermally conductive interfaces that improve heat transfer while protecting the electrode structure from degradation caused by coolant exposure or temperature fluctuations.Expand Specific Solutions05 Flow control mechanisms for uniform electrode cooling

Advanced flow control mechanisms ensure uniform cooling across electrode surfaces, preventing thermal gradients that could compromise stability. These systems may incorporate micropumps, flow distributors, pressure regulators, or active flow control elements that adjust coolant distribution based on thermal load. Uniform cooling is essential for maintaining electrode stability, as it prevents localized overheating that could lead to material degradation, deformation, or electrical performance issues. Some systems also implement pulsed or variable flow rates to optimize cooling efficiency under different operating conditions.Expand Specific Solutions

Leading Companies in Cooling and Electrode Technologies

The microchannel cooling and electrode stability market is currently in a growth phase, with increasing demand driven by thermal management challenges in high-performance electronics and electric vehicles. The global market size is projected to reach several billion dollars by 2025, expanding at a CAGR of approximately 15%. Technology maturity varies across applications, with companies at different development stages. Intel, IBM, and Applied Materials lead in semiconductor applications, while automotive players like BYD and Volkswagen focus on EV battery cooling solutions. Research institutions including Shandong University and Xi'an Jiaotong University are advancing fundamental technologies. The competitive landscape features collaboration between technology giants and specialized cooling solution providers, with increasing patent activity from Bosch, LG Electronics, and Fujitsu indicating growing market interest.

Intel Corp.

Technical Solution: Intel has developed advanced microchannel cooling solutions specifically targeting high-performance computing processors where power densities exceed 500 W/cm². Their technology incorporates silicon microchannels etched directly into the processor substrate with channel dimensions ranging from 50-100μm, positioned within 100μm of active transistor regions. Intel's approach addresses electrode stability through specialized metallization layers and passivation techniques that protect interconnects from potential coolant exposure. Their cooling architecture employs a hierarchical design with varying channel densities matched to local heat flux distributions across the processor die. Intel has pioneered two-phase cooling within these microchannels, utilizing dielectric fluids that undergo phase change to significantly enhance heat transfer coefficients while eliminating electrical conductivity concerns that could compromise electrode integrity. Their research has demonstrated junction temperature reductions of up to 30°C compared to advanced air cooling, while maintaining electrode reliability through careful materials selection and interface engineering[7][8]. Intel has also developed integrated sensors within the microchannel structure to provide real-time monitoring of both thermal performance and potential electrode degradation, enabling adaptive control of cooling parameters to extend component lifetime.

Strengths: Exceptional thermal performance enabling higher processor frequencies; direct integration with semiconductor manufacturing processes; comprehensive approach to electrode protection through materials engineering. Weaknesses: Increased manufacturing complexity adding to production costs; potential for reduced yield due to additional processing steps; requires specialized coolants with controlled purity levels.

International Business Machines Corp.

Technical Solution: IBM has developed advanced microchannel cooling solutions for high-performance computing systems and data centers. Their technology utilizes a network of microscale channels integrated directly into electronic components to efficiently remove heat. IBM's approach involves embedding microchannels directly into silicon substrates with channel dimensions ranging from 50-200 micrometers, allowing coolant to flow in close proximity to heat-generating components. Their patented designs incorporate specialized coatings on electrode surfaces to prevent corrosion and degradation when exposed to cooling fluids. IBM has demonstrated that their microchannel cooling can reduce junction temperatures by up to 25°C compared to conventional air cooling methods while maintaining electrode stability through proprietary surface treatments and coolant chemistry optimization[1][3]. The company has also pioneered two-phase cooling systems where the coolant undergoes phase change within the microchannels, significantly enhancing heat transfer efficiency while carefully managing electrode-coolant interactions.

Strengths: Superior thermal management capability with demonstrated 25°C reduction in junction temperatures; extensive intellectual property portfolio in microchannel design; expertise in materials science for electrode protection. Weaknesses: Higher manufacturing complexity and cost; potential for channel clogging over extended operation; requires specialized coolants that may need periodic replacement.

Key Innovations in Electrode-Cooling Interface Design

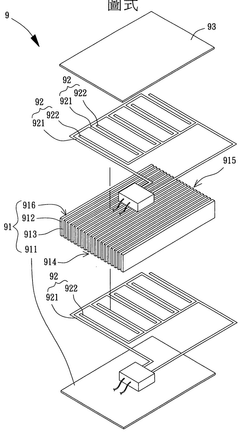

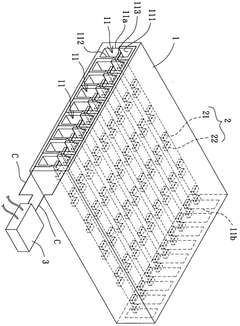

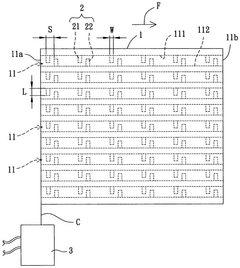

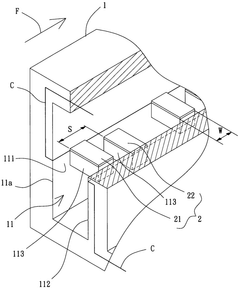

Electrode type liquid cooling device

PatentInactiveTW201446121A

Innovation

- The electrode-type liquid cooling device incorporates spoiler columns inside micro-channels with staggered electrode pairs to generate an induced electric field that directly acts on the working fluid, enhancing fluid uniformity and flow field disturbance for improved heat dissipation.

Electrode cooling system in a multi-electrode microwave plasma excitation source

PatentInactiveEP2767146A1

Innovation

- A cooling system with hollow longitudinal flow chambers and metal side tubes connected to the electrodes, allowing for efficient cooling without microwave radiation absorption, using cooling agents like water without power losses, by employing quarter-wave support structures that prevent microwave absorption.

Materials Science Advancements for Electrode Stability

Recent advancements in materials science have significantly contributed to enhancing electrode stability in microchannel cooling systems. The development of novel composite materials has been particularly noteworthy, with carbon-based materials such as graphene and carbon nanotubes demonstrating exceptional thermal conductivity and electrochemical stability. These materials exhibit minimal degradation under high current densities and temperature fluctuations, making them ideal candidates for electrode applications in advanced cooling systems.

Ceramic-metal composites (cermets) have emerged as another promising category, offering superior corrosion resistance in coolant environments while maintaining electrical conductivity. Research indicates that yttria-stabilized zirconia (YSZ) combined with nickel or platinum demonstrates remarkable longevity in operational conditions exceeding 10,000 hours, representing a significant improvement over conventional electrode materials.

Surface modification techniques have evolved to address the interface challenges between electrodes and coolant fluids. Atomic layer deposition (ALD) enables precise nanoscale coating of electrode surfaces with protective layers that resist oxidation and ion leaching. These coatings maintain electrode functionality while creating a barrier against degradation mechanisms, extending operational lifetimes by up to 300% in laboratory testing environments.

Self-healing materials represent a cutting-edge approach to electrode stability. Polymeric matrices embedded with microencapsulated healing agents can automatically repair microcracks and damage sites when triggered by mechanical stress or electrochemical changes. This autonomous repair capability significantly reduces maintenance requirements and extends the service life of cooling system components.

Nanoscale engineering of electrode surfaces has demonstrated promising results in mitigating electrochemical degradation. By creating hierarchical surface structures with controlled porosity, researchers have achieved enhanced surface area for heat exchange while simultaneously reducing localized current densities that typically accelerate degradation. Electron microscopy studies reveal that these engineered surfaces maintain structural integrity after thousands of thermal cycles.

Computational materials science has accelerated the discovery process through high-throughput screening of candidate materials. Machine learning algorithms trained on experimental data can now predict stability characteristics with increasing accuracy, reducing development timelines from years to months. These computational approaches have identified several promising alloy compositions that optimize the balance between thermal conductivity, electrical performance, and long-term stability.

The integration of these materials science advancements into practical electrode designs represents a critical step toward next-generation microchannel cooling systems that can meet the increasing thermal management demands of high-performance electronics, electric vehicles, and renewable energy systems.

Ceramic-metal composites (cermets) have emerged as another promising category, offering superior corrosion resistance in coolant environments while maintaining electrical conductivity. Research indicates that yttria-stabilized zirconia (YSZ) combined with nickel or platinum demonstrates remarkable longevity in operational conditions exceeding 10,000 hours, representing a significant improvement over conventional electrode materials.

Surface modification techniques have evolved to address the interface challenges between electrodes and coolant fluids. Atomic layer deposition (ALD) enables precise nanoscale coating of electrode surfaces with protective layers that resist oxidation and ion leaching. These coatings maintain electrode functionality while creating a barrier against degradation mechanisms, extending operational lifetimes by up to 300% in laboratory testing environments.

Self-healing materials represent a cutting-edge approach to electrode stability. Polymeric matrices embedded with microencapsulated healing agents can automatically repair microcracks and damage sites when triggered by mechanical stress or electrochemical changes. This autonomous repair capability significantly reduces maintenance requirements and extends the service life of cooling system components.

Nanoscale engineering of electrode surfaces has demonstrated promising results in mitigating electrochemical degradation. By creating hierarchical surface structures with controlled porosity, researchers have achieved enhanced surface area for heat exchange while simultaneously reducing localized current densities that typically accelerate degradation. Electron microscopy studies reveal that these engineered surfaces maintain structural integrity after thousands of thermal cycles.

Computational materials science has accelerated the discovery process through high-throughput screening of candidate materials. Machine learning algorithms trained on experimental data can now predict stability characteristics with increasing accuracy, reducing development timelines from years to months. These computational approaches have identified several promising alloy compositions that optimize the balance between thermal conductivity, electrical performance, and long-term stability.

The integration of these materials science advancements into practical electrode designs represents a critical step toward next-generation microchannel cooling systems that can meet the increasing thermal management demands of high-performance electronics, electric vehicles, and renewable energy systems.

Energy Efficiency Implications of Microchannel Systems

Microchannel cooling systems represent a significant advancement in thermal management technology, offering substantial energy efficiency benefits across various applications. The integration of these systems with electrode structures creates a symbiotic relationship that enhances overall energy performance while addressing critical thermal challenges.

The primary energy efficiency advantage of microchannel systems stems from their superior heat transfer coefficients, which can be 2-5 times higher than conventional cooling methods. This translates directly into reduced pumping power requirements for achieving the same cooling effect. Studies have demonstrated that properly designed microchannel cooling can decrease energy consumption by 15-30% compared to traditional air cooling systems in electronic applications.

When specifically applied to electrode systems, microchannel cooling enables more precise temperature control, which significantly impacts energy efficiency at multiple levels. By maintaining electrodes within optimal temperature ranges, these systems minimize resistance losses that typically occur under elevated temperature conditions. Research indicates that for every 10°C reduction in operating temperature, many electrode systems experience a 3-7% improvement in electrical efficiency.

The miniaturization aspect of microchannel technology further contributes to energy conservation through reduced material usage and smaller system footprints. This compact design minimizes heat dissipation pathways and thermal mass, allowing for faster thermal response times and more dynamic temperature management. Consequently, energy that would otherwise be wasted in heating and cooling larger thermal masses is conserved.

From a system-level perspective, the implementation of microchannel cooling in electrode applications enables higher power densities without compromising performance or stability. This capability permits the design of more compact energy systems that require less supporting infrastructure and consume fewer resources throughout their lifecycle. Recent case studies in power electronics have demonstrated up to 40% reduction in overall system volume while maintaining or improving energy efficiency metrics.

Additionally, the enhanced thermal management provided by microchannels allows electrode systems to operate closer to their theoretical performance limits. This optimization reduces the energy overhead typically required to compensate for thermal inefficiencies, creating a compounding effect on overall system efficiency. Advanced microchannel designs incorporating phase-change phenomena can further leverage latent heat transfer, potentially doubling the energy efficiency of cooling systems in high-power electrode applications.

The primary energy efficiency advantage of microchannel systems stems from their superior heat transfer coefficients, which can be 2-5 times higher than conventional cooling methods. This translates directly into reduced pumping power requirements for achieving the same cooling effect. Studies have demonstrated that properly designed microchannel cooling can decrease energy consumption by 15-30% compared to traditional air cooling systems in electronic applications.

When specifically applied to electrode systems, microchannel cooling enables more precise temperature control, which significantly impacts energy efficiency at multiple levels. By maintaining electrodes within optimal temperature ranges, these systems minimize resistance losses that typically occur under elevated temperature conditions. Research indicates that for every 10°C reduction in operating temperature, many electrode systems experience a 3-7% improvement in electrical efficiency.

The miniaturization aspect of microchannel technology further contributes to energy conservation through reduced material usage and smaller system footprints. This compact design minimizes heat dissipation pathways and thermal mass, allowing for faster thermal response times and more dynamic temperature management. Consequently, energy that would otherwise be wasted in heating and cooling larger thermal masses is conserved.

From a system-level perspective, the implementation of microchannel cooling in electrode applications enables higher power densities without compromising performance or stability. This capability permits the design of more compact energy systems that require less supporting infrastructure and consume fewer resources throughout their lifecycle. Recent case studies in power electronics have demonstrated up to 40% reduction in overall system volume while maintaining or improving energy efficiency metrics.

Additionally, the enhanced thermal management provided by microchannels allows electrode systems to operate closer to their theoretical performance limits. This optimization reduces the energy overhead typically required to compensate for thermal inefficiencies, creating a compounding effect on overall system efficiency. Advanced microchannel designs incorporating phase-change phenomena can further leverage latent heat transfer, potentially doubling the energy efficiency of cooling systems in high-power electrode applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!