Comparison of Microchannel Cooling and Heat Pipe Technologies

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel and Heat Pipe Cooling Background and Objectives

Thermal management has become a critical challenge in modern electronics as device miniaturization and increasing power densities continue to push the boundaries of conventional cooling methods. Microchannel cooling and heat pipe technologies represent two significant advancements in thermal management that have evolved over the past several decades to address these challenges. Both technologies have their roots in the aerospace and defense industries before finding widespread applications in consumer electronics, data centers, and industrial systems.

Microchannel cooling emerged in the early 1980s when researchers at Stanford University demonstrated the superior heat transfer capabilities of microscale fluid channels. This technology involves the circulation of coolant through channels with hydraulic diameters typically ranging from 10 to 500 micrometers. The evolution of microchannel technology has been marked by continuous improvements in channel geometry, surface modifications, and coolant formulations to enhance thermal performance.

Heat pipe technology, on the other hand, has a longer history dating back to the 1960s when it was developed for spacecraft thermal control systems. Heat pipes operate on a passive two-phase heat transfer principle, utilizing the latent heat of vaporization to transport thermal energy efficiently from a heat source to a heat sink. The technology has progressed through various generations, from conventional cylindrical designs to vapor chambers, pulsating heat pipes, and loop heat pipes, each offering specific advantages for different applications.

The market demand for both technologies has been driven by the exponential growth in computing power and the corresponding increase in heat generation. The global thermal management market is projected to reach $78.9 billion by 2026, with cooling solutions for electronics representing a significant portion of this market. Industries such as artificial intelligence, 5G telecommunications, and high-performance computing are particularly driving the need for advanced cooling solutions.

The technical objectives for both microchannel and heat pipe technologies focus on several key parameters: maximizing heat flux handling capability (currently targeting >500 W/cm²), minimizing thermal resistance, reducing system size and weight, enhancing reliability, and decreasing manufacturing costs. Additionally, environmental considerations have led to research into eco-friendly refrigerants for microchannels and working fluids for heat pipes.

Recent technological trends include the integration of these cooling methods with emerging materials such as graphene and carbon nanotubes, the development of hybrid cooling systems that combine multiple technologies, and the implementation of smart thermal management systems with embedded sensors and adaptive control mechanisms. The convergence of these technologies with artificial intelligence for predictive thermal management represents the frontier of research in this field.

Microchannel cooling emerged in the early 1980s when researchers at Stanford University demonstrated the superior heat transfer capabilities of microscale fluid channels. This technology involves the circulation of coolant through channels with hydraulic diameters typically ranging from 10 to 500 micrometers. The evolution of microchannel technology has been marked by continuous improvements in channel geometry, surface modifications, and coolant formulations to enhance thermal performance.

Heat pipe technology, on the other hand, has a longer history dating back to the 1960s when it was developed for spacecraft thermal control systems. Heat pipes operate on a passive two-phase heat transfer principle, utilizing the latent heat of vaporization to transport thermal energy efficiently from a heat source to a heat sink. The technology has progressed through various generations, from conventional cylindrical designs to vapor chambers, pulsating heat pipes, and loop heat pipes, each offering specific advantages for different applications.

The market demand for both technologies has been driven by the exponential growth in computing power and the corresponding increase in heat generation. The global thermal management market is projected to reach $78.9 billion by 2026, with cooling solutions for electronics representing a significant portion of this market. Industries such as artificial intelligence, 5G telecommunications, and high-performance computing are particularly driving the need for advanced cooling solutions.

The technical objectives for both microchannel and heat pipe technologies focus on several key parameters: maximizing heat flux handling capability (currently targeting >500 W/cm²), minimizing thermal resistance, reducing system size and weight, enhancing reliability, and decreasing manufacturing costs. Additionally, environmental considerations have led to research into eco-friendly refrigerants for microchannels and working fluids for heat pipes.

Recent technological trends include the integration of these cooling methods with emerging materials such as graphene and carbon nanotubes, the development of hybrid cooling systems that combine multiple technologies, and the implementation of smart thermal management systems with embedded sensors and adaptive control mechanisms. The convergence of these technologies with artificial intelligence for predictive thermal management represents the frontier of research in this field.

Market Demand Analysis for Advanced Thermal Management Solutions

The global thermal management market is experiencing robust growth, driven primarily by the increasing power densities in electronic devices and the miniaturization trend across multiple industries. Current market valuations place the advanced cooling solutions sector at approximately 15 billion USD in 2023, with projections indicating a compound annual growth rate of 8-10% through 2030. This growth trajectory is particularly evident in data centers, where cooling costs can represent up to 40% of total operational expenses, creating significant demand for more efficient thermal management technologies.

Microchannel cooling and heat pipe technologies are responding to specific market needs across various sectors. In the high-performance computing segment, the demand for solutions capable of dissipating heat loads exceeding 500 W/cm² is growing as processor architectures become more complex. The electric vehicle market represents another significant growth area, with thermal management systems being critical for battery performance, safety, and longevity. Industry reports indicate that the EV thermal management market alone is expected to reach 6.5 billion USD by 2027.

The aerospace and defense sectors are increasingly adopting advanced cooling technologies for avionics and power electronics, with requirements for solutions that can operate reliably under extreme conditions while maintaining minimal weight and volume. This sector values the high reliability and passive operation characteristics of heat pipes, while also exploring the higher cooling capacity of microchannel systems for next-generation equipment.

Consumer electronics manufacturers are seeking thermal solutions that enable thinner device profiles while managing the heat from increasingly powerful components. This market segment is particularly sensitive to cost considerations, with manufacturers looking for thermal management solutions that add no more than 3-5% to the total device cost while significantly enhancing performance and reliability.

Healthcare and medical device industries are emerging as new adopters of advanced cooling technologies, particularly for imaging equipment and portable diagnostic devices where precise temperature control is essential for accurate operation. The demand in this sector is growing at approximately 12% annually, faster than the overall market average.

Regional analysis reveals that Asia-Pacific dominates manufacturing capacity for both technologies, while North America leads in research and development investment. Europe shows strong adoption rates in automotive and renewable energy applications. The market is increasingly demanding integrated solutions that combine multiple cooling technologies to address complex thermal challenges, with over 60% of new system designs incorporating hybrid approaches rather than single-technology solutions.

Microchannel cooling and heat pipe technologies are responding to specific market needs across various sectors. In the high-performance computing segment, the demand for solutions capable of dissipating heat loads exceeding 500 W/cm² is growing as processor architectures become more complex. The electric vehicle market represents another significant growth area, with thermal management systems being critical for battery performance, safety, and longevity. Industry reports indicate that the EV thermal management market alone is expected to reach 6.5 billion USD by 2027.

The aerospace and defense sectors are increasingly adopting advanced cooling technologies for avionics and power electronics, with requirements for solutions that can operate reliably under extreme conditions while maintaining minimal weight and volume. This sector values the high reliability and passive operation characteristics of heat pipes, while also exploring the higher cooling capacity of microchannel systems for next-generation equipment.

Consumer electronics manufacturers are seeking thermal solutions that enable thinner device profiles while managing the heat from increasingly powerful components. This market segment is particularly sensitive to cost considerations, with manufacturers looking for thermal management solutions that add no more than 3-5% to the total device cost while significantly enhancing performance and reliability.

Healthcare and medical device industries are emerging as new adopters of advanced cooling technologies, particularly for imaging equipment and portable diagnostic devices where precise temperature control is essential for accurate operation. The demand in this sector is growing at approximately 12% annually, faster than the overall market average.

Regional analysis reveals that Asia-Pacific dominates manufacturing capacity for both technologies, while North America leads in research and development investment. Europe shows strong adoption rates in automotive and renewable energy applications. The market is increasingly demanding integrated solutions that combine multiple cooling technologies to address complex thermal challenges, with over 60% of new system designs incorporating hybrid approaches rather than single-technology solutions.

Current State and Technical Challenges in Cooling Technologies

Microchannel cooling and heat pipe technologies represent two of the most advanced thermal management solutions in today's electronics cooling landscape. Currently, these technologies are experiencing rapid development driven by the increasing thermal demands of high-performance computing, electric vehicles, aerospace applications, and telecommunications infrastructure.

Microchannel cooling systems have reached impressive heat flux dissipation capabilities exceeding 1000 W/cm² in laboratory settings, though commercial implementations typically achieve 300-500 W/cm². The technology has matured significantly over the past decade, with channel dimensions now routinely fabricated at sub-millimeter scales (50-500 μm). Recent advancements in manufacturing techniques, particularly additive manufacturing and precision etching, have enabled more complex and optimized channel geometries.

Heat pipe technology has similarly evolved, with ultra-thin vapor chambers now produced at thicknesses below 0.5 mm while maintaining thermal conductivities equivalent to 5000-10000 W/m·K. The working fluid selection has expanded beyond traditional water and ammonia to include engineered nanofluids that demonstrate enhanced thermal performance through suspended nanoparticles.

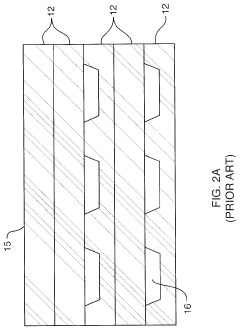

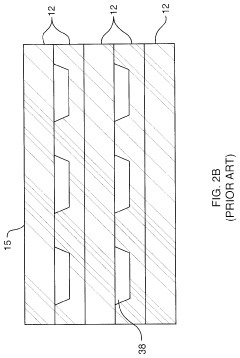

Despite these advancements, both technologies face significant technical challenges. For microchannel cooling, flow distribution uniformity remains problematic in larger arrays, with edge channels often experiencing up to 30% flow rate variation compared to central channels. Pressure drop concerns continue to limit practical implementation, as pumping power requirements increase exponentially with decreasing channel dimensions. Additionally, fouling and clogging present reliability issues, particularly in systems with expected lifespans exceeding 5-7 years.

Heat pipes face their own set of challenges, including operational orientation limitations that can reduce thermal performance by 40-60% in unfavorable positions. Working fluid compatibility with envelope materials continues to cause long-term reliability concerns, with some combinations experiencing performance degradation of 15-20% after 3-5 years of operation. Thermal interface resistance at evaporator and condenser sections remains a bottleneck, often accounting for 20-30% of the total thermal resistance in the system.

Geographically, microchannel cooling technology development is concentrated in North America and East Asia, with significant research clusters in Silicon Valley, Boston, Tokyo, and Shanghai. Heat pipe technology shows a more distributed development pattern, with strong research centers across Europe (particularly Germany and Finland), Asia (Japan, Taiwan, China), and North America.

The integration of these cooling technologies with emerging materials like graphene, diamond composites, and phase change materials represents the current frontier, with hybrid systems attempting to leverage the strengths of both approaches while mitigating their individual limitations.

Microchannel cooling systems have reached impressive heat flux dissipation capabilities exceeding 1000 W/cm² in laboratory settings, though commercial implementations typically achieve 300-500 W/cm². The technology has matured significantly over the past decade, with channel dimensions now routinely fabricated at sub-millimeter scales (50-500 μm). Recent advancements in manufacturing techniques, particularly additive manufacturing and precision etching, have enabled more complex and optimized channel geometries.

Heat pipe technology has similarly evolved, with ultra-thin vapor chambers now produced at thicknesses below 0.5 mm while maintaining thermal conductivities equivalent to 5000-10000 W/m·K. The working fluid selection has expanded beyond traditional water and ammonia to include engineered nanofluids that demonstrate enhanced thermal performance through suspended nanoparticles.

Despite these advancements, both technologies face significant technical challenges. For microchannel cooling, flow distribution uniformity remains problematic in larger arrays, with edge channels often experiencing up to 30% flow rate variation compared to central channels. Pressure drop concerns continue to limit practical implementation, as pumping power requirements increase exponentially with decreasing channel dimensions. Additionally, fouling and clogging present reliability issues, particularly in systems with expected lifespans exceeding 5-7 years.

Heat pipes face their own set of challenges, including operational orientation limitations that can reduce thermal performance by 40-60% in unfavorable positions. Working fluid compatibility with envelope materials continues to cause long-term reliability concerns, with some combinations experiencing performance degradation of 15-20% after 3-5 years of operation. Thermal interface resistance at evaporator and condenser sections remains a bottleneck, often accounting for 20-30% of the total thermal resistance in the system.

Geographically, microchannel cooling technology development is concentrated in North America and East Asia, with significant research clusters in Silicon Valley, Boston, Tokyo, and Shanghai. Heat pipe technology shows a more distributed development pattern, with strong research centers across Europe (particularly Germany and Finland), Asia (Japan, Taiwan, China), and North America.

The integration of these cooling technologies with emerging materials like graphene, diamond composites, and phase change materials represents the current frontier, with hybrid systems attempting to leverage the strengths of both approaches while mitigating their individual limitations.

Current Technical Solutions for High Heat Flux Applications

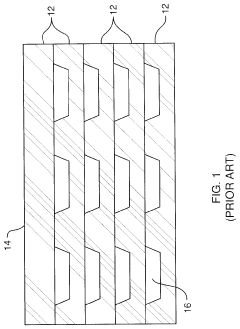

01 Microchannel design optimization for cooling efficiency

Optimizing the design of microchannels can significantly enhance cooling efficiency. This includes varying channel dimensions, shapes, and patterns to maximize heat transfer while minimizing pressure drop. Advanced microchannel designs incorporate features such as tapered channels, variable cross-sections, and optimized flow distribution networks to improve thermal performance. These design optimizations enable more efficient heat dissipation from high-power electronic components and systems.- Microchannel design optimization for cooling efficiency: Optimizing the design of microchannels can significantly enhance cooling efficiency. This includes considerations such as channel geometry, dimensions, and layout patterns. Specific design elements like varying channel widths, depths, and cross-sectional shapes can create turbulent flow that improves heat transfer. Advanced microchannel structures with tapered designs or variable cross-sections help distribute coolant flow more effectively, reducing hotspots and improving overall thermal management in electronic devices.

- Heat pipe integration with microchannel cooling systems: Combining heat pipes with microchannel cooling creates hybrid thermal management solutions with enhanced efficiency. Heat pipes efficiently transport heat away from critical components to microchannels for dissipation. This integration leverages the passive operation of heat pipes with the high heat transfer coefficients of microchannels. The synergistic effect results in more uniform temperature distribution, reduced thermal resistance, and improved cooling performance for high-power electronic devices and systems.

- Advanced materials for enhanced thermal conductivity: Utilizing advanced materials in microchannel and heat pipe technologies significantly improves cooling efficiency. Materials such as copper, aluminum alloys, and composite materials with high thermal conductivity enhance heat transfer rates. Novel materials including carbon nanotubes, graphene, and metal foams incorporated into channel walls or heat pipe wicks improve surface area and thermal conductivity. These material innovations enable more effective heat dissipation and contribute to overall cooling system performance.

- Working fluid optimization for heat pipes and microchannels: Selection and optimization of working fluids play a crucial role in cooling efficiency. Nanofluids containing suspended nanoparticles enhance thermal conductivity compared to conventional coolants. Phase-change materials and dielectric fluids enable two-phase cooling with higher heat transfer coefficients. The composition, flow rate, and pressure of working fluids can be adjusted to match specific thermal loads. Advanced fluid formulations with additives improve wettability and reduce flow resistance in microchannels and heat pipes.

- Integrated electronic cooling solutions with control systems: Comprehensive cooling solutions integrate microchannels and heat pipes with intelligent control systems for adaptive thermal management. These systems incorporate temperature sensors, flow regulators, and feedback mechanisms to adjust cooling performance based on real-time thermal loads. Smart cooling architectures can selectively activate different cooling pathways depending on operational conditions. The integration of pumps, fans, and other auxiliary components with microchannels and heat pipes creates complete thermal management solutions for high-performance electronics and power systems.

02 Heat pipe integration with microchannel cooling systems

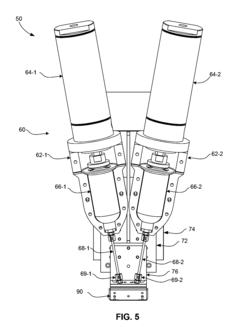

Combining heat pipe technology with microchannel cooling creates hybrid thermal management solutions with enhanced performance. Heat pipes efficiently transport heat from hot spots to microchannels, which then dissipate the heat more effectively. This integration leverages the passive operation of heat pipes with the high heat transfer coefficients of microchannels. Such hybrid systems provide more uniform temperature distribution and can handle higher heat fluxes than either technology alone.Expand Specific Solutions03 Working fluid selection and phase change enhancement

The selection of appropriate working fluids and enhancement of phase change processes are critical for both microchannel and heat pipe cooling technologies. Advanced working fluids, including nanofluids and engineered coolants, improve thermal conductivity and heat transfer coefficients. Surface modifications within microchannels and heat pipes promote nucleation and enhance phase change heat transfer. These innovations lead to more efficient cooling systems capable of managing higher heat loads with reduced pumping power requirements.Expand Specific Solutions04 Thermal management for electronic devices and high-power applications

Microchannel cooling and heat pipe technologies are increasingly applied to thermal management in electronic devices and high-power applications. These cooling solutions address the challenges of heat dissipation in compact electronic packages, data centers, and power electronics. By implementing these advanced cooling technologies, device performance can be improved while preventing thermal throttling and extending component lifespan. The integration of these cooling systems enables higher power densities and more compact designs in modern electronic systems.Expand Specific Solutions05 Manufacturing techniques and material innovations

Advanced manufacturing techniques and material innovations are enhancing the performance and cost-effectiveness of microchannel and heat pipe cooling systems. Additive manufacturing enables complex channel geometries that were previously impossible to fabricate. Novel materials with high thermal conductivity, such as graphene-enhanced composites and specialized metal alloys, improve heat transfer efficiency. These manufacturing and material advancements lead to more efficient cooling solutions with improved reliability and reduced production costs.Expand Specific Solutions

Key Industry Players in Advanced Cooling Solutions

Microchannel cooling and heat pipe technologies are currently in a growth phase, with the global thermal management market expected to reach $20 billion by 2025. Intel, IBM, and GlobalFoundries lead in microchannel cooling development for high-performance computing applications, while Vertiv and Carrier focus on commercial cooling solutions. Heat pipe technology sees significant advancement from universities like Xi'an Jiaotong University and Harbin Institute of Technology, alongside industrial players like Raytheon and The Aerospace Corporation. The technology maturity varies by application - heat pipes are more established in consumer electronics, while microchannel cooling is gaining traction in data centers and EV applications. Both technologies are converging in hybrid solutions as thermal management demands increase across industries.

Intel Corp.

Technical Solution: Intel has developed advanced microchannel cooling solutions for high-performance computing and data center applications. Their technology integrates microchannels directly into silicon interposers and heat spreaders, creating what they call "embedded multi-die interconnect bridges" (EMIB). This approach allows coolant to flow through microscopic channels etched directly into the chip packaging, removing heat much closer to its source. Intel's latest implementations feature channel widths of 50-100 microns with aspect ratios exceeding 10:1, enabling cooling capacities of over 1000 W/cm² in laboratory settings. They've also pioneered two-phase cooling in microchannels, where the working fluid undergoes phase change, significantly enhancing heat transfer coefficients. For data centers, Intel has developed rack-level microchannel cooling solutions that eliminate traditional heat sinks, reducing thermal resistance and enabling higher processor frequencies while maintaining safe operating temperatures.

Strengths: Superior thermal performance with ability to handle extremely high heat fluxes; enables continued processor miniaturization and performance scaling; integrates directly with semiconductor manufacturing processes. Weaknesses: Higher manufacturing complexity and cost; requires sophisticated fluid delivery systems; potential reliability concerns with fluid systems in electronic environments.

International Business Machines Corp.

Technical Solution: IBM has pioneered innovative cooling technologies for high-performance computing systems, developing both advanced microchannel and heat pipe solutions. Their microchannel cooling technology features "hierarchical manifold microchannel" designs that optimize coolant distribution across large chip areas. These systems employ parallel microchannels with widths of 25-75 microns arranged in multiple tiers, allowing coolant to reach all areas with minimal pressure drop. IBM's research has demonstrated cooling capacities exceeding 500 W/cm² using water-based coolants in these systems. For their enterprise servers, IBM has developed hybrid cooling solutions that combine microchannel cold plates with traditional air cooling for cost-effective thermal management. On the heat pipe front, IBM has created ultra-thin vapor chamber heat pipes specifically designed for high-density server environments, featuring proprietary wick structures that enhance capillary action and heat transfer. Their "Thermal Conduction Modules" incorporate multiple heat pipes in a single cooling assembly to manage heat from multiple components simultaneously.

Strengths: Extensive experience in enterprise-scale cooling implementation; solutions optimized for reliability in mission-critical systems; technologies tested in real-world high-performance computing environments. Weaknesses: Custom cooling solutions often tied to proprietary IBM hardware; higher implementation costs compared to conventional cooling; complex installation and maintenance requirements.

Core Innovations in Microchannel and Heat Pipe Technologies

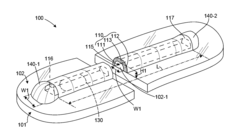

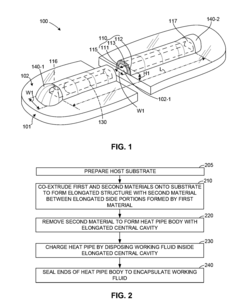

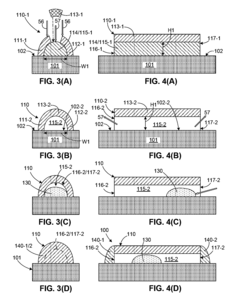

Co-Extruded Microchannel Heat Pipes

PatentActiveUS20150367462A1

Innovation

- A cost-effective method using co-extrusion to form microchannel heat pipes on a substrate, where a primary material and a secondary sacrificial material are extruded to create an elongated composite structure, with the secondary material later removed to form a central channel, and filled with a working fluid, allowing for efficient integration into ICs during or after fabrication.

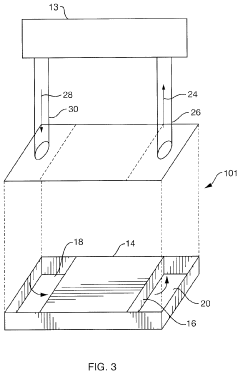

Microelectronics cooling system

PatentActiveUS20220136780A1

Innovation

- The use of microchannel heat exchangers as heat absorbers and sinks in heat pipes, with cross-sectional dimensions less than 1000 microns, and a passive system that employs a liquid working fluid to absorb heat, form vapor, and condense it outside the enclosure, allowing for high heat transfer rates without mechanically moving parts.

Material Science Advancements for Cooling Technologies

Material science innovations have significantly transformed the landscape of thermal management solutions, particularly in the realm of microchannel cooling and heat pipe technologies. Recent advancements in material engineering have introduced novel substrates with enhanced thermal conductivity properties, directly addressing the efficiency limitations of traditional cooling methods. Silicon carbide and diamond-based composites have emerged as promising materials for microchannel fabrication, offering thermal conductivity values up to five times higher than conventional aluminum alloys while maintaining structural integrity under extreme thermal conditions.

Nanomaterial integration represents another breakthrough area, with carbon nanotubes and graphene being incorporated into both microchannel walls and heat pipe wicks. These materials demonstrate exceptional thermal conductivity—graphene's theoretical thermal conductivity exceeds 5000 W/m·K, substantially surpassing copper's 400 W/m·K. When applied as coatings or embedded within existing structures, these nanomaterials can enhance heat transfer coefficients by 30-45% in experimental settings.

Surface modification techniques have evolved to address the critical challenge of contact resistance in cooling systems. Advanced plasma treatments and chemical vapor deposition methods now enable the creation of hydrophilic or hydrophobic surfaces with precisely controlled wettability characteristics. For microchannels, hydrophilic surfaces promote uniform fluid distribution and reduce flow resistance, while heat pipes benefit from tailored wicking structures that optimize capillary action and fluid return mechanisms.

Phase-change materials (PCMs) have been successfully integrated into both cooling technologies, providing thermal buffering capabilities during peak load conditions. Metal-organic frameworks and encapsulated paraffin compounds with melting points engineered for specific application temperature ranges offer energy storage densities of 200-300 J/g, effectively dampening thermal fluctuations in high-performance computing and power electronics applications.

Composite wick structures for heat pipes represent a significant material science advancement, combining multiple materials with complementary properties. Bi-porous structures featuring nano-scale secondary pores within conventional sintered copper matrices have demonstrated up to 70% improvement in capillary pumping capability while maintaining structural stability. Similarly, gradient porosity designs optimize fluid flow dynamics by strategically varying pore size and distribution throughout the heat pipe structure.

Corrosion-resistant and biocompatible materials are expanding application possibilities for both technologies in harsh environments and medical devices. Titanium alloys and specialized ceramic coatings provide exceptional chemical stability while maintaining thermal performance, enabling deployment in aggressive industrial settings and implantable medical cooling systems where traditional copper-based solutions would rapidly degrade.

Nanomaterial integration represents another breakthrough area, with carbon nanotubes and graphene being incorporated into both microchannel walls and heat pipe wicks. These materials demonstrate exceptional thermal conductivity—graphene's theoretical thermal conductivity exceeds 5000 W/m·K, substantially surpassing copper's 400 W/m·K. When applied as coatings or embedded within existing structures, these nanomaterials can enhance heat transfer coefficients by 30-45% in experimental settings.

Surface modification techniques have evolved to address the critical challenge of contact resistance in cooling systems. Advanced plasma treatments and chemical vapor deposition methods now enable the creation of hydrophilic or hydrophobic surfaces with precisely controlled wettability characteristics. For microchannels, hydrophilic surfaces promote uniform fluid distribution and reduce flow resistance, while heat pipes benefit from tailored wicking structures that optimize capillary action and fluid return mechanisms.

Phase-change materials (PCMs) have been successfully integrated into both cooling technologies, providing thermal buffering capabilities during peak load conditions. Metal-organic frameworks and encapsulated paraffin compounds with melting points engineered for specific application temperature ranges offer energy storage densities of 200-300 J/g, effectively dampening thermal fluctuations in high-performance computing and power electronics applications.

Composite wick structures for heat pipes represent a significant material science advancement, combining multiple materials with complementary properties. Bi-porous structures featuring nano-scale secondary pores within conventional sintered copper matrices have demonstrated up to 70% improvement in capillary pumping capability while maintaining structural stability. Similarly, gradient porosity designs optimize fluid flow dynamics by strategically varying pore size and distribution throughout the heat pipe structure.

Corrosion-resistant and biocompatible materials are expanding application possibilities for both technologies in harsh environments and medical devices. Titanium alloys and specialized ceramic coatings provide exceptional chemical stability while maintaining thermal performance, enabling deployment in aggressive industrial settings and implantable medical cooling systems where traditional copper-based solutions would rapidly degrade.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical considerations in thermal management system selection, particularly when comparing microchannel cooling and heat pipe technologies. Microchannel cooling systems typically require pumping power to circulate coolant through their narrow channels, which adds to the overall energy consumption. However, their superior heat transfer efficiency often results in lower operating temperatures for electronic components, potentially reducing the energy consumption of the cooled devices themselves. This creates an interesting energy trade-off that must be carefully evaluated based on specific application requirements.

Heat pipe technologies, in contrast, operate passively without requiring external power for fluid circulation, making them inherently more energy-efficient from an operational standpoint. This passive operation translates to zero direct energy consumption and reduced maintenance requirements over the system lifetime. The absence of moving parts also contributes to their reliability and longevity, further enhancing their sustainability profile.

From a manufacturing perspective, microchannel cooling systems generally require more complex fabrication processes, including precision machining or etching of channels and integration of pumping mechanisms. These processes can be energy-intensive and may involve environmentally concerning chemicals, particularly in semiconductor-grade microchannel manufacturing. Heat pipes, while also requiring specialized manufacturing techniques, typically have a simpler construction with fewer components and potentially lower embodied energy.

Material considerations also play a significant role in the sustainability assessment. Microchannel systems often utilize a variety of materials including metals, polymers, and sometimes specialized coolants that may have environmental implications if leaked or improperly disposed of. Heat pipes typically use working fluids such as water, methanol, or ammonia, each with different environmental profiles that must be considered in lifecycle assessments.

End-of-life management represents another important sustainability factor. The recyclability of materials used in both technologies varies significantly. Microchannel systems may contain more diverse materials that require separation for effective recycling, while heat pipes often have simpler material compositions. However, the working fluids in heat pipes may require special handling during decommissioning to prevent environmental contamination.

Overall lifecycle carbon footprint analysis reveals that while heat pipes may have advantages in operational energy efficiency, the total environmental impact depends heavily on application-specific factors including cooling requirements, operational lifetime, and integration with other systems. Recent research indicates that hybrid solutions combining aspects of both technologies may offer optimal energy efficiency and sustainability profiles for next-generation thermal management applications.

Heat pipe technologies, in contrast, operate passively without requiring external power for fluid circulation, making them inherently more energy-efficient from an operational standpoint. This passive operation translates to zero direct energy consumption and reduced maintenance requirements over the system lifetime. The absence of moving parts also contributes to their reliability and longevity, further enhancing their sustainability profile.

From a manufacturing perspective, microchannel cooling systems generally require more complex fabrication processes, including precision machining or etching of channels and integration of pumping mechanisms. These processes can be energy-intensive and may involve environmentally concerning chemicals, particularly in semiconductor-grade microchannel manufacturing. Heat pipes, while also requiring specialized manufacturing techniques, typically have a simpler construction with fewer components and potentially lower embodied energy.

Material considerations also play a significant role in the sustainability assessment. Microchannel systems often utilize a variety of materials including metals, polymers, and sometimes specialized coolants that may have environmental implications if leaked or improperly disposed of. Heat pipes typically use working fluids such as water, methanol, or ammonia, each with different environmental profiles that must be considered in lifecycle assessments.

End-of-life management represents another important sustainability factor. The recyclability of materials used in both technologies varies significantly. Microchannel systems may contain more diverse materials that require separation for effective recycling, while heat pipes often have simpler material compositions. However, the working fluids in heat pipes may require special handling during decommissioning to prevent environmental contamination.

Overall lifecycle carbon footprint analysis reveals that while heat pipes may have advantages in operational energy efficiency, the total environmental impact depends heavily on application-specific factors including cooling requirements, operational lifetime, and integration with other systems. Recent research indicates that hybrid solutions combining aspects of both technologies may offer optimal energy efficiency and sustainability profiles for next-generation thermal management applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!