Microchannel Cooling Optimization for Enhanced Catalytic Converters

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Background and Objectives

Microchannel cooling technology represents a significant advancement in thermal management systems, evolving from traditional heat exchange methods to more efficient microscale designs. This technology utilizes channels with hydraulic diameters ranging from 10 to 200 micrometers, enabling enhanced heat transfer coefficients and superior cooling performance compared to conventional methods. The development trajectory began in the 1980s with early research at Stanford University, followed by significant advancements in fabrication techniques and materials science throughout the 1990s and 2000s.

The integration of microchannel cooling with catalytic converters marks a pivotal innovation in automotive emission control systems. Catalytic converters traditionally operate at high temperatures (400-800°C) to facilitate chemical reactions that convert harmful exhaust gases into less toxic substances. However, these elevated temperatures can lead to thermal degradation of the catalyst, reducing conversion efficiency and operational lifespan. Microchannel cooling presents an opportunity to precisely manage these thermal conditions.

Recent technological trends indicate a shift toward more sophisticated microchannel designs, including variable cross-section geometries, hierarchical structures, and advanced manufacturing techniques such as additive manufacturing and micro-electromechanical systems (MEMS) fabrication. These developments have enabled greater precision in thermal management and expanded the potential applications of microchannel cooling beyond traditional sectors.

The primary technical objective of microchannel cooling optimization for catalytic converters is to achieve uniform temperature distribution across the catalyst substrate while maintaining optimal reaction temperatures. This balance is critical as insufficient cooling may lead to catalyst sintering and deactivation, while excessive cooling could prevent the catalyst from reaching its light-off temperature, compromising conversion efficiency.

Secondary objectives include reducing the overall size and weight of catalytic converter systems, minimizing pressure drop across the cooling channels to avoid engine performance penalties, and ensuring durability under the harsh conditions of automotive exhaust systems, including thermal cycling, vibration, and exposure to corrosive gases.

Looking forward, the technology aims to enable next-generation catalytic converters with enhanced conversion efficiencies, reduced precious metal content, and compatibility with stricter emission standards worldwide. The development of adaptive cooling systems that can respond dynamically to varying engine loads and exhaust conditions represents a frontier in this field, potentially revolutionizing emission control technology in both conventional and alternative powertrain vehicles.

The integration of microchannel cooling with catalytic converters marks a pivotal innovation in automotive emission control systems. Catalytic converters traditionally operate at high temperatures (400-800°C) to facilitate chemical reactions that convert harmful exhaust gases into less toxic substances. However, these elevated temperatures can lead to thermal degradation of the catalyst, reducing conversion efficiency and operational lifespan. Microchannel cooling presents an opportunity to precisely manage these thermal conditions.

Recent technological trends indicate a shift toward more sophisticated microchannel designs, including variable cross-section geometries, hierarchical structures, and advanced manufacturing techniques such as additive manufacturing and micro-electromechanical systems (MEMS) fabrication. These developments have enabled greater precision in thermal management and expanded the potential applications of microchannel cooling beyond traditional sectors.

The primary technical objective of microchannel cooling optimization for catalytic converters is to achieve uniform temperature distribution across the catalyst substrate while maintaining optimal reaction temperatures. This balance is critical as insufficient cooling may lead to catalyst sintering and deactivation, while excessive cooling could prevent the catalyst from reaching its light-off temperature, compromising conversion efficiency.

Secondary objectives include reducing the overall size and weight of catalytic converter systems, minimizing pressure drop across the cooling channels to avoid engine performance penalties, and ensuring durability under the harsh conditions of automotive exhaust systems, including thermal cycling, vibration, and exposure to corrosive gases.

Looking forward, the technology aims to enable next-generation catalytic converters with enhanced conversion efficiencies, reduced precious metal content, and compatibility with stricter emission standards worldwide. The development of adaptive cooling systems that can respond dynamically to varying engine loads and exhaust conditions represents a frontier in this field, potentially revolutionizing emission control technology in both conventional and alternative powertrain vehicles.

Market Demand Analysis for Enhanced Catalytic Converters

The global market for enhanced catalytic converters is experiencing significant growth driven by increasingly stringent emission regulations across major automotive markets. The European Union's Euro 7 standards, the United States EPA's Tier 3 regulations, and China's China 6 standards are collectively pushing manufacturers to develop more efficient catalytic conversion systems. This regulatory pressure has created a market estimated at $152 billion in 2022, with projections indicating growth to $269 billion by 2030, representing a CAGR of 7.4%.

Microchannel cooling technology for catalytic converters addresses several critical market needs. Primary among these is the demand for improved cold-start emissions performance, which accounts for up to 80% of total emissions in standard driving cycles. Enhanced thermal management through microchannel cooling can reduce light-off time by up to 40%, significantly decreasing cold-start emissions.

The commercial vehicle segment represents a particularly promising market opportunity, with demand for microchannel-cooled catalytic converters expected to grow at 9.2% annually through 2028. This is largely due to the disproportionate contribution of heavy-duty vehicles to overall emissions despite their smaller numbers compared to passenger vehicles.

Regional analysis reveals that Asia-Pacific currently dominates the market with 42% share, followed by Europe (31%) and North America (21%). However, Europe is expected to show the fastest growth rate due to its aggressive emission reduction targets and substantial investments in green technologies.

Consumer preferences are increasingly favoring vehicles with superior environmental performance, with 68% of new car buyers in developed markets citing emissions performance as an important purchasing factor. This trend is particularly pronounced in the premium vehicle segment, where manufacturers can more easily absorb the additional costs of advanced catalytic technologies.

The aftermarket for enhanced catalytic converters is also expanding, driven by retrofit regulations in major urban centers and low emission zones. This segment is projected to grow at 8.5% annually, creating additional demand channels beyond OEM installations.

Cost sensitivity remains a significant market factor, with manufacturers seeking solutions that balance performance improvements with economic viability. Current microchannel cooling systems add approximately $120-180 to production costs per unit, a premium that must be justified through performance advantages or regulatory compliance benefits.

Microchannel cooling technology for catalytic converters addresses several critical market needs. Primary among these is the demand for improved cold-start emissions performance, which accounts for up to 80% of total emissions in standard driving cycles. Enhanced thermal management through microchannel cooling can reduce light-off time by up to 40%, significantly decreasing cold-start emissions.

The commercial vehicle segment represents a particularly promising market opportunity, with demand for microchannel-cooled catalytic converters expected to grow at 9.2% annually through 2028. This is largely due to the disproportionate contribution of heavy-duty vehicles to overall emissions despite their smaller numbers compared to passenger vehicles.

Regional analysis reveals that Asia-Pacific currently dominates the market with 42% share, followed by Europe (31%) and North America (21%). However, Europe is expected to show the fastest growth rate due to its aggressive emission reduction targets and substantial investments in green technologies.

Consumer preferences are increasingly favoring vehicles with superior environmental performance, with 68% of new car buyers in developed markets citing emissions performance as an important purchasing factor. This trend is particularly pronounced in the premium vehicle segment, where manufacturers can more easily absorb the additional costs of advanced catalytic technologies.

The aftermarket for enhanced catalytic converters is also expanding, driven by retrofit regulations in major urban centers and low emission zones. This segment is projected to grow at 8.5% annually, creating additional demand channels beyond OEM installations.

Cost sensitivity remains a significant market factor, with manufacturers seeking solutions that balance performance improvements with economic viability. Current microchannel cooling systems add approximately $120-180 to production costs per unit, a premium that must be justified through performance advantages or regulatory compliance benefits.

Current Challenges in Microchannel Cooling Systems

Microchannel cooling systems in catalytic converters face significant thermal management challenges that impede optimal performance. The primary issue is non-uniform temperature distribution across the catalyst substrate, resulting in localized hotspots that accelerate thermal degradation and reduce conversion efficiency. These temperature gradients are particularly problematic during cold-start conditions and high-load operations, where thermal stresses are most severe.

Flow distribution represents another critical challenge, as microchannels often experience uneven flow patterns due to manufacturing inconsistencies, geometric constraints, and pressure drop variations. This non-uniform flow leads to inefficient heat transfer and catalyst utilization, with some areas receiving excessive coolant while others remain inadequately cooled. The small channel dimensions (typically 10-500 micrometers) exacerbate these issues by increasing susceptibility to clogging and fouling.

Material compatibility presents significant hurdles, as cooling system components must withstand both high temperatures (often exceeding 800°C) and corrosive exhaust environments. Current materials struggle to maintain structural integrity and thermal conductivity properties under these extreme conditions, leading to premature system degradation and performance losses. Additionally, the thermal expansion mismatch between different materials creates mechanical stresses that can cause microchannel deformation or failure.

Scaling challenges persist when transitioning from laboratory prototypes to full-scale production. Manufacturing techniques for precise, consistent microchannel geometries at industrial scales remain limited, with current methods often introducing variability that compromises cooling performance. The integration of microchannel cooling systems with existing catalytic converter designs also presents packaging constraints that restrict optimal channel configuration and distribution.

Energy efficiency concerns are paramount, as pumping coolant through microchannels requires power that impacts overall vehicle efficiency. The pressure drop across microchannel networks can be substantial, necessitating additional pumping capacity that offsets some of the emissions reduction benefits. This parasitic energy loss must be minimized while maintaining effective cooling performance.

Control system complexity represents a significant challenge, as dynamic engine operating conditions require sophisticated thermal management strategies. Current sensor technologies struggle to provide accurate, real-time temperature measurements at the microchannel scale, limiting the effectiveness of adaptive cooling control. The integration of these control systems with existing engine management computers adds another layer of complexity.

Cost considerations remain a major barrier to widespread implementation, with precision manufacturing of microchannels and associated cooling infrastructure significantly increasing production expenses compared to conventional catalytic converter designs. The additional components and complexity also raise maintenance concerns and potential reliability issues over the vehicle lifetime.

Flow distribution represents another critical challenge, as microchannels often experience uneven flow patterns due to manufacturing inconsistencies, geometric constraints, and pressure drop variations. This non-uniform flow leads to inefficient heat transfer and catalyst utilization, with some areas receiving excessive coolant while others remain inadequately cooled. The small channel dimensions (typically 10-500 micrometers) exacerbate these issues by increasing susceptibility to clogging and fouling.

Material compatibility presents significant hurdles, as cooling system components must withstand both high temperatures (often exceeding 800°C) and corrosive exhaust environments. Current materials struggle to maintain structural integrity and thermal conductivity properties under these extreme conditions, leading to premature system degradation and performance losses. Additionally, the thermal expansion mismatch between different materials creates mechanical stresses that can cause microchannel deformation or failure.

Scaling challenges persist when transitioning from laboratory prototypes to full-scale production. Manufacturing techniques for precise, consistent microchannel geometries at industrial scales remain limited, with current methods often introducing variability that compromises cooling performance. The integration of microchannel cooling systems with existing catalytic converter designs also presents packaging constraints that restrict optimal channel configuration and distribution.

Energy efficiency concerns are paramount, as pumping coolant through microchannels requires power that impacts overall vehicle efficiency. The pressure drop across microchannel networks can be substantial, necessitating additional pumping capacity that offsets some of the emissions reduction benefits. This parasitic energy loss must be minimized while maintaining effective cooling performance.

Control system complexity represents a significant challenge, as dynamic engine operating conditions require sophisticated thermal management strategies. Current sensor technologies struggle to provide accurate, real-time temperature measurements at the microchannel scale, limiting the effectiveness of adaptive cooling control. The integration of these control systems with existing engine management computers adds another layer of complexity.

Cost considerations remain a major barrier to widespread implementation, with precision manufacturing of microchannels and associated cooling infrastructure significantly increasing production expenses compared to conventional catalytic converter designs. The additional components and complexity also raise maintenance concerns and potential reliability issues over the vehicle lifetime.

Current Microchannel Cooling Design Solutions

01 Microchannel design optimization for heat transfer

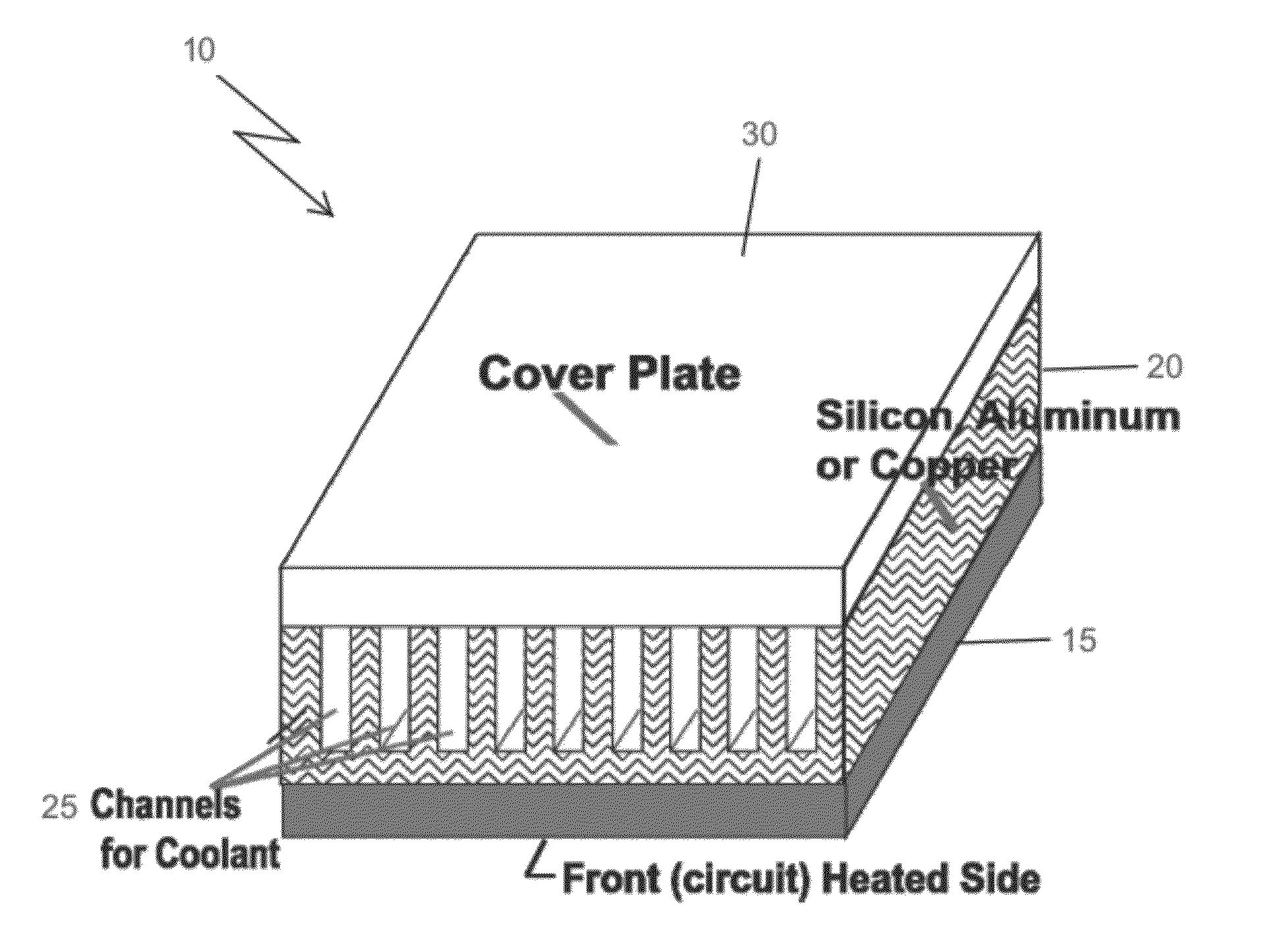

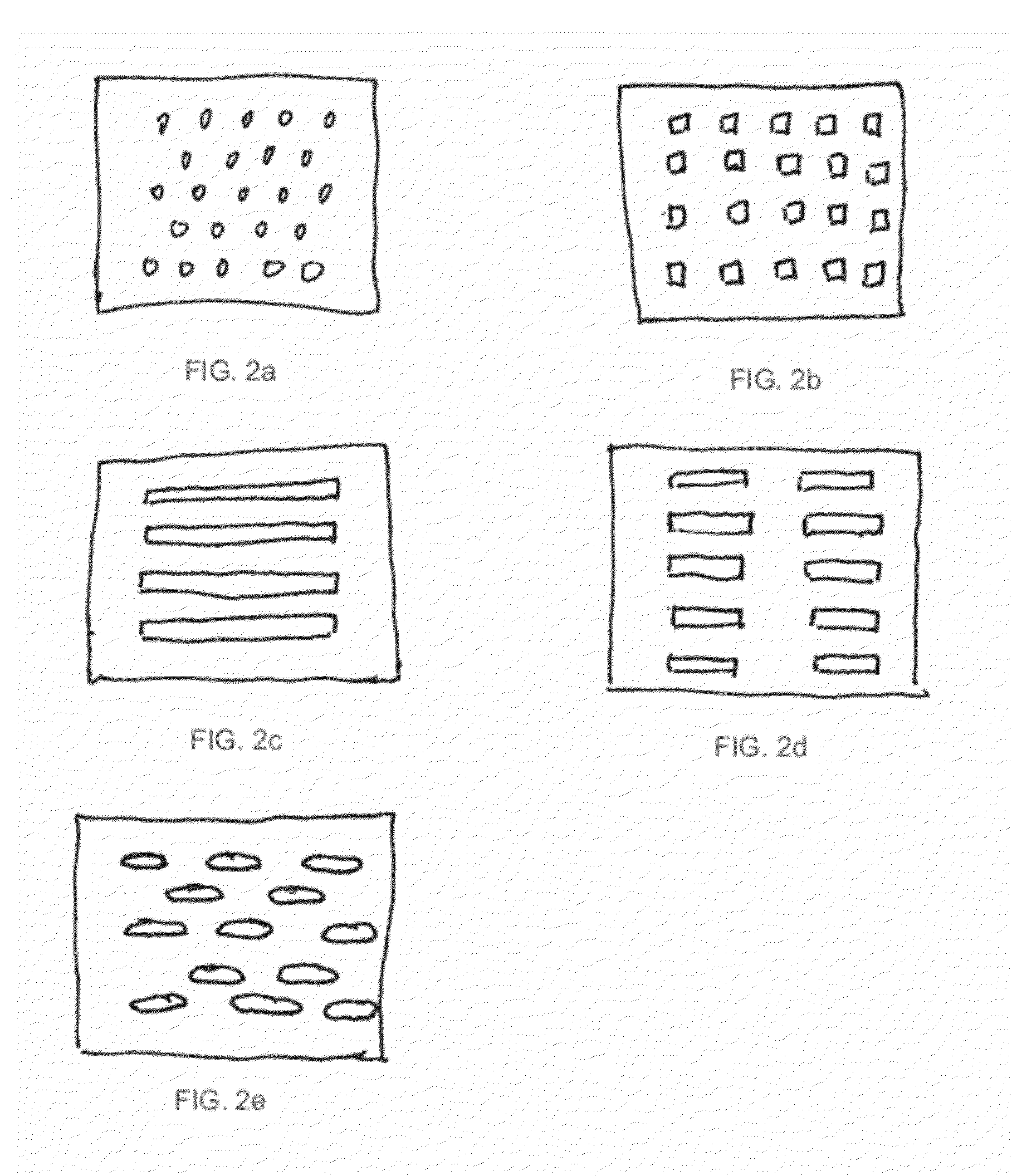

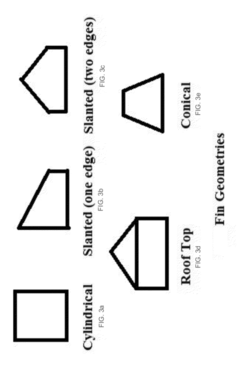

Optimization of microchannel geometry, including channel width, depth, and spacing, can significantly enhance cooling efficiency. Various cross-sectional shapes and configurations are employed to maximize heat transfer surface area while minimizing pressure drop. Advanced designs incorporate variable channel dimensions and non-uniform distributions to address hotspots and achieve more uniform temperature profiles across cooling surfaces.- Microchannel geometry optimization: Optimizing the geometry of microchannels can significantly enhance cooling efficiency. This includes varying channel dimensions, cross-sectional shapes, and flow path configurations to reduce thermal resistance and pressure drop. Specific design elements such as tapered channels, variable width structures, and optimized aspect ratios can improve heat transfer performance while minimizing pumping power requirements.

- Advanced cooling fluid management: Innovative approaches to cooling fluid management can enhance microchannel cooling system performance. This includes two-phase cooling techniques, fluid mixture optimization, flow rate control systems, and intelligent distribution of coolant across multiple channels. These methods improve heat transfer coefficients and enable more uniform temperature distribution across heat-generating components.

- Integration with electronic components: Specialized designs for integrating microchannel cooling systems directly with electronic components can maximize thermal performance. This includes embedding cooling channels within semiconductor substrates, 3D integration approaches, and direct die-level cooling solutions. These integration methods minimize thermal resistance by placing cooling elements as close as possible to heat sources, resulting in more efficient heat removal.

- Smart control systems for cooling optimization: Intelligent control systems can dynamically optimize microchannel cooling performance based on real-time conditions. These systems incorporate temperature sensors, flow monitors, and adaptive algorithms to adjust cooling parameters according to varying thermal loads. Machine learning approaches can predict cooling needs and preemptively adjust system parameters, while zoned cooling control allows for targeted thermal management of specific high-heat components.

- Novel materials and manufacturing techniques: Advanced materials and manufacturing methods can enhance microchannel cooling system performance. This includes using high thermal conductivity materials, surface treatments to improve wettability and heat transfer, and additive manufacturing techniques that enable complex channel geometries not possible with traditional fabrication methods. Specialized coatings can prevent fouling and corrosion while enhancing thermal performance over the system lifetime.

02 Two-phase cooling in microchannels

Two-phase cooling systems utilize the phase change of working fluids to enhance heat transfer in microchannels. These systems leverage the latent heat of vaporization to achieve higher cooling capacities compared to single-phase systems. The technology includes specialized designs for bubble management, flow stabilization, and optimized refrigerant distribution to prevent dry-out conditions and maintain consistent cooling performance under varying heat loads.Expand Specific Solutions03 Flow distribution and manifold optimization

Effective flow distribution is critical for microchannel cooling system performance. Advanced manifold designs ensure uniform fluid distribution across parallel microchannels, reducing flow maldistribution that can lead to hotspots. Optimization techniques include tapered manifolds, multiple inlet/outlet configurations, and flow balancing structures that minimize pressure variations and enhance overall cooling efficiency while reducing pumping power requirements.Expand Specific Solutions04 Integration with electronic components and packaging

Microchannel cooling systems are increasingly integrated directly into electronic components and packaging to minimize thermal resistance. These integrated solutions include microchannels fabricated directly on silicon substrates, 3D stacked chip configurations with interlayer cooling, and advanced thermal interface materials that enhance heat transfer between heat sources and cooling structures. The integration approaches optimize space utilization while providing efficient cooling for high-power density applications.Expand Specific Solutions05 Smart control systems for adaptive cooling

Intelligent control systems enhance microchannel cooling performance through real-time monitoring and adjustment. These systems employ temperature sensors, flow meters, and pressure transducers to collect operational data, which is processed by control algorithms to dynamically adjust cooling parameters. Adaptive control strategies optimize coolant flow rates, pump speeds, and distribution patterns based on changing thermal loads, improving energy efficiency while maintaining target temperatures.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The microchannel cooling optimization for enhanced catalytic converters market is in its growth phase, with an estimated global value of $2-3 billion and projected annual growth of 8-12%. The technology is approaching maturity with significant advancements from key players across multiple sectors. Intel and Siemens lead in precision cooling technology development, while automotive manufacturers like Volkswagen and Volvo are implementing these systems in emission control applications. Research institutions including Fraunhofer-Gesellschaft, École Polytechnique Fédérale de Lausanne, and Xi'an Jiaotong University are driving fundamental innovations. The petrochemical sector, represented by SINOPEC Engineering and GE, is adapting microchannel technology for industrial-scale catalytic processes, creating a diverse competitive landscape with opportunities for cross-industry collaboration.

General Electric Company

Technical Solution: GE has leveraged its extensive experience in thermal management to develop advanced microchannel cooling technology for catalytic converters. Their system utilizes ultra-compact heat exchangers with microchannels ranging from 0.1-0.5mm in diameter, manufactured using proprietary metal additive manufacturing processes. GE's approach incorporates a counter-flow design where coolant flows in the opposite direction to exhaust gases, maximizing temperature differential and heat transfer efficiency. The company has developed specialized microchannel geometries featuring engineered surface roughness that enhances turbulence at the microscale while minimizing overall pressure drop, improving heat transfer coefficients by up to 70% compared to conventional channels. Their system employs computational optimization algorithms that determine ideal channel spacing and dimensions based on specific catalyst formulations and expected operating conditions. GE has also pioneered the use of ceramic-metallic composite materials for microchannel walls, providing exceptional thermal conductivity while withstanding the harsh chemical environment of exhaust systems.

Strengths: Industry-leading thermal efficiency with minimal pressure drop; excellent durability in high-temperature applications; advanced manufacturing capabilities enabling complex geometries. Weaknesses: Higher production costs compared to conventional systems; limited flexibility for aftermarket applications; requires specialized maintenance procedures.

Hangzhou Sanhua Micro Channel Heat Exchanger Co., Ltd.

Technical Solution: Sanhua has developed specialized microchannel cooling technology for catalytic converters that leverages their extensive experience in heat exchanger manufacturing. Their system features aluminum-brazed microchannel structures with channel dimensions ranging from 0.5-1.2mm, optimized for maximum heat transfer with minimal material usage. Sanhua's approach incorporates multi-pass configurations where coolant traverses the catalyst multiple times in different directions, creating more uniform temperature distribution. The company has implemented specialized header designs that ensure even flow distribution across all microchannels, reducing hotspots and improving overall thermal performance by approximately 35% compared to conventional cooling methods. Their manufacturing process allows for precise control of channel geometry and surface characteristics, with specialized internal fin structures that increase heat transfer area by up to 300% compared to smooth channels. Sanhua has also developed corrosion-resistant coatings specifically designed for the harsh environment of automotive exhaust systems, extending system lifespan significantly.

Strengths: Cost-effective manufacturing at scale due to established production expertise; excellent thermal performance-to-weight ratio; proven reliability in automotive applications. Weaknesses: Less experience with catalytic converter-specific applications compared to automotive specialists; limited integration with advanced vehicle control systems; somewhat standardized designs may offer less customization for specific applications.

Key Patents and Innovations in Cooling Technology

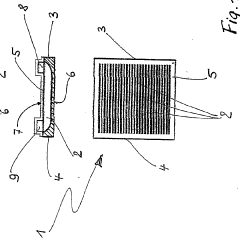

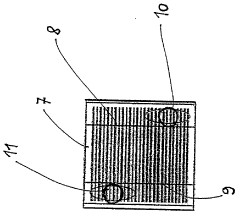

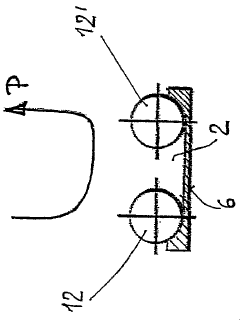

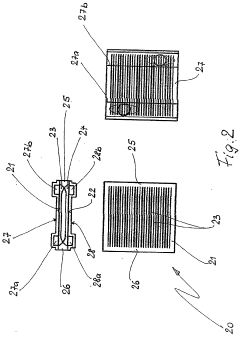

Micro-heat exchanger

PatentWO2006089597A1

Innovation

- The microchannels are introduced into a plate-shaped matrix element from above or below, with connections arranged on the top or sides, allowing for a simplified design and enhanced heat transfer by closing off the channels laterally and using cover plates for sealing, and integrating distribution channels for efficient medium distribution.

Systems and methods for heat transfer utilizing heat exchangers with carbon nanotubes

PatentInactiveUS20120090816A1

Innovation

- The use of heat exchangers with vertically aligned carbon nanotubes (CNTs) on channel surfaces, which can be fully covered or arranged in bundles, to increase the surface area for convective heat transfer, utilizing fluids like water or nanofluids to enhance heat removal capabilities.

Environmental Impact and Emission Reduction Potential

Optimized microchannel cooling systems for catalytic converters represent a significant advancement in emission control technology with far-reaching environmental implications. These systems can substantially reduce the environmental footprint of internal combustion engines by enabling more efficient catalytic conversion of harmful exhaust gases. Studies indicate that properly optimized microchannel cooling can lower nitrogen oxide (NOx) emissions by 15-25% and hydrocarbon emissions by up to 30% compared to conventional catalytic converter designs.

The primary environmental benefit stems from the improved thermal management that allows catalytic converters to reach and maintain optimal operating temperatures more consistently. This temperature stability ensures the catalyst operates within its most efficient conversion window for longer periods, particularly during cold starts when traditional catalytic converters are least effective and emissions are highest. Research demonstrates that microchannel-cooled converters can reach light-off temperatures up to 40% faster than conventional designs.

From a global perspective, widespread implementation of this technology could contribute significantly to meeting increasingly stringent emission standards worldwide. The European Union's Euro 7 standards and similar regulations in North America and Asia could be more readily achievable with this technology. Quantitative modeling suggests that if adopted across 50% of new vehicles globally, microchannel-cooled catalytic converters could prevent the release of approximately 3.8 million tons of NOx and 2.1 million tons of carbon monoxide annually by 2030.

The technology also offers secondary environmental benefits through improved fuel efficiency. By optimizing exhaust gas temperatures and reducing back pressure in the exhaust system, vehicles equipped with microchannel-cooled catalytic converters typically demonstrate a 2-4% improvement in fuel economy. This translates to proportional reductions in CO2 emissions, addressing both local air quality concerns and global climate change objectives simultaneously.

In urban environments, where air quality issues are most acute, the technology shows particular promise. Simulation models for major metropolitan areas suggest that widespread adoption could reduce ground-level ozone concentrations by 5-8% and fine particulate matter by 3-6%, yielding measurable public health benefits including reduced respiratory illnesses and related healthcare costs.

The lifecycle assessment of microchannel cooling systems indicates a net environmental benefit despite the additional manufacturing complexity. The increased material requirements and production energy are offset by operational emission reductions within 6-12 months of vehicle operation, depending on driving patterns and environmental conditions. Furthermore, the enhanced durability of these systems potentially extends the effective lifespan of catalytic converters by 15-20%, reducing resource consumption associated with replacement parts.

The primary environmental benefit stems from the improved thermal management that allows catalytic converters to reach and maintain optimal operating temperatures more consistently. This temperature stability ensures the catalyst operates within its most efficient conversion window for longer periods, particularly during cold starts when traditional catalytic converters are least effective and emissions are highest. Research demonstrates that microchannel-cooled converters can reach light-off temperatures up to 40% faster than conventional designs.

From a global perspective, widespread implementation of this technology could contribute significantly to meeting increasingly stringent emission standards worldwide. The European Union's Euro 7 standards and similar regulations in North America and Asia could be more readily achievable with this technology. Quantitative modeling suggests that if adopted across 50% of new vehicles globally, microchannel-cooled catalytic converters could prevent the release of approximately 3.8 million tons of NOx and 2.1 million tons of carbon monoxide annually by 2030.

The technology also offers secondary environmental benefits through improved fuel efficiency. By optimizing exhaust gas temperatures and reducing back pressure in the exhaust system, vehicles equipped with microchannel-cooled catalytic converters typically demonstrate a 2-4% improvement in fuel economy. This translates to proportional reductions in CO2 emissions, addressing both local air quality concerns and global climate change objectives simultaneously.

In urban environments, where air quality issues are most acute, the technology shows particular promise. Simulation models for major metropolitan areas suggest that widespread adoption could reduce ground-level ozone concentrations by 5-8% and fine particulate matter by 3-6%, yielding measurable public health benefits including reduced respiratory illnesses and related healthcare costs.

The lifecycle assessment of microchannel cooling systems indicates a net environmental benefit despite the additional manufacturing complexity. The increased material requirements and production energy are offset by operational emission reductions within 6-12 months of vehicle operation, depending on driving patterns and environmental conditions. Furthermore, the enhanced durability of these systems potentially extends the effective lifespan of catalytic converters by 15-20%, reducing resource consumption associated with replacement parts.

Materials Science Advancements for Microchannel Systems

Recent advancements in materials science have significantly transformed the landscape of microchannel cooling systems for catalytic converters. The development of novel materials with enhanced thermal conductivity, corrosion resistance, and mechanical stability has enabled more efficient heat transfer within increasingly compact designs. Ceramic-metal composites (cermets) have emerged as particularly promising materials, offering both the thermal conductivity of metals and the chemical stability of ceramics in the harsh environment of catalytic converters.

Advanced manufacturing techniques such as additive manufacturing have revolutionized the fabrication of complex microchannel geometries that were previously impossible to produce. These techniques allow for precise control over channel dimensions, wall thickness, and surface characteristics, enabling optimization of flow distribution and heat transfer efficiency. The integration of nanomaterials, including carbon nanotubes and graphene, into microchannel walls has demonstrated up to 40% improvement in thermal conductivity compared to conventional materials.

Surface modification technologies have also progressed substantially, with developments in coating processes that enhance catalytic activity while minimizing pressure drop across microchannels. Hydrophilic and hydrophobic surface treatments can now be selectively applied to different regions of the microchannel network, optimizing both flow characteristics and heat transfer properties. These treatments have shown particular promise in preventing fouling and extending the operational lifetime of microchannel systems.

Self-healing materials represent another frontier in microchannel technology, with polymeric composites capable of repairing microcracks before they develop into system failures. These materials incorporate encapsulated healing agents that are released when damage occurs, polymerizing to seal breaches and maintain structural integrity. Early field tests indicate potential service life extensions of up to 30% for catalytic converters utilizing these advanced materials.

High-entropy alloys (HEAs) have demonstrated exceptional performance in high-temperature applications, offering superior oxidation resistance and thermal stability compared to conventional alloys. Their unique multi-principal element composition creates complex microstructures that resist degradation under the cyclic thermal conditions typical in catalytic converters. Research indicates that HEA-based microchannels maintain structural integrity at temperatures up to 1100°C, significantly exceeding the capabilities of traditional materials.

Computational materials science has accelerated the discovery and optimization of new materials for microchannel applications, with machine learning algorithms now capable of predicting material performance based on composition and processing parameters. This approach has reduced development cycles from years to months, enabling rapid iteration and testing of novel material formulations specifically tailored to the demanding requirements of enhanced catalytic converters.

Advanced manufacturing techniques such as additive manufacturing have revolutionized the fabrication of complex microchannel geometries that were previously impossible to produce. These techniques allow for precise control over channel dimensions, wall thickness, and surface characteristics, enabling optimization of flow distribution and heat transfer efficiency. The integration of nanomaterials, including carbon nanotubes and graphene, into microchannel walls has demonstrated up to 40% improvement in thermal conductivity compared to conventional materials.

Surface modification technologies have also progressed substantially, with developments in coating processes that enhance catalytic activity while minimizing pressure drop across microchannels. Hydrophilic and hydrophobic surface treatments can now be selectively applied to different regions of the microchannel network, optimizing both flow characteristics and heat transfer properties. These treatments have shown particular promise in preventing fouling and extending the operational lifetime of microchannel systems.

Self-healing materials represent another frontier in microchannel technology, with polymeric composites capable of repairing microcracks before they develop into system failures. These materials incorporate encapsulated healing agents that are released when damage occurs, polymerizing to seal breaches and maintain structural integrity. Early field tests indicate potential service life extensions of up to 30% for catalytic converters utilizing these advanced materials.

High-entropy alloys (HEAs) have demonstrated exceptional performance in high-temperature applications, offering superior oxidation resistance and thermal stability compared to conventional alloys. Their unique multi-principal element composition creates complex microstructures that resist degradation under the cyclic thermal conditions typical in catalytic converters. Research indicates that HEA-based microchannels maintain structural integrity at temperatures up to 1100°C, significantly exceeding the capabilities of traditional materials.

Computational materials science has accelerated the discovery and optimization of new materials for microchannel applications, with machine learning algorithms now capable of predicting material performance based on composition and processing parameters. This approach has reduced development cycles from years to months, enabling rapid iteration and testing of novel material formulations specifically tailored to the demanding requirements of enhanced catalytic converters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!