Microchannel Cooling in Antenna Systems: Optimization and Regulation

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Background and Objectives

Microchannel cooling technology has evolved significantly over the past three decades, originating from the semiconductor industry's need for more efficient thermal management solutions. Initially developed in the 1980s for integrated circuit cooling, this technology has progressively expanded into various applications including power electronics, laser diodes, and more recently, antenna systems. The fundamental principle involves the use of small channels with hydraulic diameters typically ranging from 10 to 500 micrometers to enhance heat transfer through increased surface area-to-volume ratios.

The evolution of microchannel cooling has been marked by several key advancements, including the development of more sophisticated channel geometries, improved manufacturing techniques, and the integration of smart control systems. Recent research has particularly focused on optimizing flow distribution, reducing pressure drops, and enhancing heat transfer coefficients through novel channel designs and surface modifications.

In the context of antenna systems, thermal management has become increasingly critical as modern communication technologies demand higher power densities and operational reliability. Traditional cooling methods such as air cooling and conventional liquid cooling systems have proven inadequate for addressing the thermal challenges posed by advanced antenna arrays, particularly in applications involving high-frequency operations and phased array systems.

The primary technical objective of microchannel cooling in antenna systems is to achieve uniform temperature distribution across antenna elements while minimizing the overall system footprint. This is essential for maintaining consistent electrical performance, as temperature variations can lead to frequency shifts, impedance mismatches, and ultimately, degraded signal quality. Additionally, effective thermal management aims to extend the operational lifespan of antenna components by preventing thermal stress and related failure mechanisms.

Current research trends indicate a growing interest in adaptive cooling solutions that can dynamically respond to varying thermal loads during antenna operation. This includes the development of intelligent flow regulation mechanisms, integration of temperature sensors, and implementation of predictive thermal management algorithms. The goal is to create systems that can optimize cooling performance based on real-time operational conditions.

Looking forward, the technology trajectory suggests potential convergence with other emerging technologies such as additive manufacturing, which offers new possibilities for creating complex channel geometries, and advanced materials science, which may provide enhanced thermal conductivity and reduced flow resistance. The integration of artificial intelligence for predictive thermal management represents another promising direction for future development.

The ultimate technological aim is to develop microchannel cooling systems for antennas that are compact, energy-efficient, reliable, and capable of supporting next-generation communication technologies including 5G, 6G, and beyond, where thermal management will be even more critical due to increased power densities and operational frequencies.

The evolution of microchannel cooling has been marked by several key advancements, including the development of more sophisticated channel geometries, improved manufacturing techniques, and the integration of smart control systems. Recent research has particularly focused on optimizing flow distribution, reducing pressure drops, and enhancing heat transfer coefficients through novel channel designs and surface modifications.

In the context of antenna systems, thermal management has become increasingly critical as modern communication technologies demand higher power densities and operational reliability. Traditional cooling methods such as air cooling and conventional liquid cooling systems have proven inadequate for addressing the thermal challenges posed by advanced antenna arrays, particularly in applications involving high-frequency operations and phased array systems.

The primary technical objective of microchannel cooling in antenna systems is to achieve uniform temperature distribution across antenna elements while minimizing the overall system footprint. This is essential for maintaining consistent electrical performance, as temperature variations can lead to frequency shifts, impedance mismatches, and ultimately, degraded signal quality. Additionally, effective thermal management aims to extend the operational lifespan of antenna components by preventing thermal stress and related failure mechanisms.

Current research trends indicate a growing interest in adaptive cooling solutions that can dynamically respond to varying thermal loads during antenna operation. This includes the development of intelligent flow regulation mechanisms, integration of temperature sensors, and implementation of predictive thermal management algorithms. The goal is to create systems that can optimize cooling performance based on real-time operational conditions.

Looking forward, the technology trajectory suggests potential convergence with other emerging technologies such as additive manufacturing, which offers new possibilities for creating complex channel geometries, and advanced materials science, which may provide enhanced thermal conductivity and reduced flow resistance. The integration of artificial intelligence for predictive thermal management represents another promising direction for future development.

The ultimate technological aim is to develop microchannel cooling systems for antennas that are compact, energy-efficient, reliable, and capable of supporting next-generation communication technologies including 5G, 6G, and beyond, where thermal management will be even more critical due to increased power densities and operational frequencies.

Market Analysis for Thermal Management in Antenna Systems

The thermal management market for antenna systems is experiencing significant growth driven by the increasing deployment of 5G networks and advanced communication technologies. As these systems operate at higher frequencies and power levels, they generate more heat, necessitating effective cooling solutions. The global thermal management market for electronics was valued at approximately $8.6 billion in 2020 and is projected to reach $12.8 billion by 2025, growing at a CAGR of 8.2%.

Within this broader market, antenna thermal management represents a specialized segment with unique requirements. The demand is particularly strong in telecommunications, aerospace, defense, and automotive sectors. Telecommunications alone accounts for nearly 40% of the market share, primarily due to the rapid expansion of 5G infrastructure worldwide.

Regional analysis shows North America currently leads the market with approximately 35% share, followed closely by Asia-Pacific at 32%. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 9.7% through 2025, driven by massive telecommunications infrastructure development in China, South Korea, and Japan.

The market for microchannel cooling specifically is projected to grow from $1.2 billion in 2020 to $2.5 billion by 2025, representing a CAGR of 15.8%. This accelerated growth compared to the overall thermal management market indicates the increasing preference for microchannel solutions due to their superior performance in high-power density applications.

Key market drivers include the miniaturization of antenna systems, increasing power densities, and the need for more reliable performance in extreme environments. The trend toward integrated antenna arrays and MIMO (Multiple-Input Multiple-Output) systems in 5G applications has further intensified cooling requirements, creating new market opportunities.

Customer requirements are evolving toward solutions that offer not just effective cooling but also reduced weight, smaller footprint, and lower energy consumption. This has created a premium segment for advanced microchannel cooling systems that can deliver up to 40% better thermal performance while reducing the overall system weight by 25-30%.

Market challenges include the high initial cost of advanced cooling solutions, with microchannel systems typically commanding a 30-50% price premium over traditional cooling methods. Additionally, integration complexities and maintenance considerations present barriers to adoption in certain applications, particularly in remote or difficult-to-access installations.

The competitive landscape features both specialized thermal management companies and larger electronics manufacturers developing in-house solutions. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this technology, with transaction values increasing by approximately 25% in the past three years.

Within this broader market, antenna thermal management represents a specialized segment with unique requirements. The demand is particularly strong in telecommunications, aerospace, defense, and automotive sectors. Telecommunications alone accounts for nearly 40% of the market share, primarily due to the rapid expansion of 5G infrastructure worldwide.

Regional analysis shows North America currently leads the market with approximately 35% share, followed closely by Asia-Pacific at 32%. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 9.7% through 2025, driven by massive telecommunications infrastructure development in China, South Korea, and Japan.

The market for microchannel cooling specifically is projected to grow from $1.2 billion in 2020 to $2.5 billion by 2025, representing a CAGR of 15.8%. This accelerated growth compared to the overall thermal management market indicates the increasing preference for microchannel solutions due to their superior performance in high-power density applications.

Key market drivers include the miniaturization of antenna systems, increasing power densities, and the need for more reliable performance in extreme environments. The trend toward integrated antenna arrays and MIMO (Multiple-Input Multiple-Output) systems in 5G applications has further intensified cooling requirements, creating new market opportunities.

Customer requirements are evolving toward solutions that offer not just effective cooling but also reduced weight, smaller footprint, and lower energy consumption. This has created a premium segment for advanced microchannel cooling systems that can deliver up to 40% better thermal performance while reducing the overall system weight by 25-30%.

Market challenges include the high initial cost of advanced cooling solutions, with microchannel systems typically commanding a 30-50% price premium over traditional cooling methods. Additionally, integration complexities and maintenance considerations present barriers to adoption in certain applications, particularly in remote or difficult-to-access installations.

The competitive landscape features both specialized thermal management companies and larger electronics manufacturers developing in-house solutions. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this technology, with transaction values increasing by approximately 25% in the past three years.

Current Challenges in Antenna Thermal Regulation

Despite significant advancements in antenna system design, thermal regulation remains one of the most critical challenges facing modern antenna systems. As power densities increase and form factors shrink, heat dissipation has become a limiting factor in system performance and reliability. Current antenna systems, particularly in 5G and emerging 6G applications, generate substantial heat during operation due to higher frequencies and increased power requirements, with some advanced systems producing heat fluxes exceeding 500 W/cm².

Traditional cooling methods such as heat sinks, fans, and conventional liquid cooling systems are increasingly inadequate for these demanding thermal loads. The primary limitation stems from their inability to efficiently remove heat from localized hotspots that can reach temperatures above 120°C, potentially causing signal degradation, component failure, and reduced system lifespan. This is particularly problematic in phased array antennas where multiple transmit/receive modules are densely packed.

Spatial constraints present another significant challenge. Modern antenna systems, especially in mobile and aerospace applications, face severe space limitations that restrict the implementation of bulky cooling solutions. The trend toward miniaturization conflicts directly with cooling requirements, creating a fundamental design paradox that engineers must navigate.

Power consumption of cooling systems themselves has become a critical concern. In remote installations and battery-powered applications, cooling systems that consume excessive power undermine the overall energy efficiency of the antenna system. Current cooling technologies often require 15-30% of the total system power budget, which is unsustainable for many applications.

Environmental factors further complicate thermal regulation. Antenna systems deployed in extreme environments face temperature variations from -40°C to +85°C, humidity fluctuations, and exposure to contaminants that can compromise cooling system performance. These conditions demand robust thermal management solutions that maintain effectiveness across diverse operating scenarios.

The integration complexity between cooling systems and antenna components presents additional challenges. Current cooling solutions often require complex manufacturing processes and may interfere with electromagnetic performance. The need for non-metallic cooling components in proximity to radiating elements to avoid signal interference creates material selection constraints that limit thermal conductivity options.

Reliability and maintenance requirements also pose significant challenges. Cooling systems with moving parts or fluid circulation introduce potential failure points and maintenance requirements that are problematic for remote or inaccessible installations. The mean time between failures (MTBF) for cooling systems is often significantly lower than for the antenna components themselves, creating a system reliability bottleneck.

Traditional cooling methods such as heat sinks, fans, and conventional liquid cooling systems are increasingly inadequate for these demanding thermal loads. The primary limitation stems from their inability to efficiently remove heat from localized hotspots that can reach temperatures above 120°C, potentially causing signal degradation, component failure, and reduced system lifespan. This is particularly problematic in phased array antennas where multiple transmit/receive modules are densely packed.

Spatial constraints present another significant challenge. Modern antenna systems, especially in mobile and aerospace applications, face severe space limitations that restrict the implementation of bulky cooling solutions. The trend toward miniaturization conflicts directly with cooling requirements, creating a fundamental design paradox that engineers must navigate.

Power consumption of cooling systems themselves has become a critical concern. In remote installations and battery-powered applications, cooling systems that consume excessive power undermine the overall energy efficiency of the antenna system. Current cooling technologies often require 15-30% of the total system power budget, which is unsustainable for many applications.

Environmental factors further complicate thermal regulation. Antenna systems deployed in extreme environments face temperature variations from -40°C to +85°C, humidity fluctuations, and exposure to contaminants that can compromise cooling system performance. These conditions demand robust thermal management solutions that maintain effectiveness across diverse operating scenarios.

The integration complexity between cooling systems and antenna components presents additional challenges. Current cooling solutions often require complex manufacturing processes and may interfere with electromagnetic performance. The need for non-metallic cooling components in proximity to radiating elements to avoid signal interference creates material selection constraints that limit thermal conductivity options.

Reliability and maintenance requirements also pose significant challenges. Cooling systems with moving parts or fluid circulation introduce potential failure points and maintenance requirements that are problematic for remote or inaccessible installations. The mean time between failures (MTBF) for cooling systems is often significantly lower than for the antenna components themselves, creating a system reliability bottleneck.

Current Microchannel Cooling Implementation Methods

01 Microchannel geometry optimization

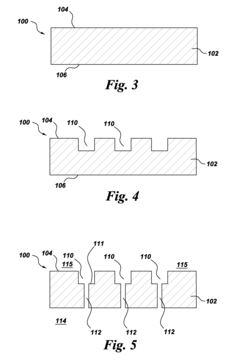

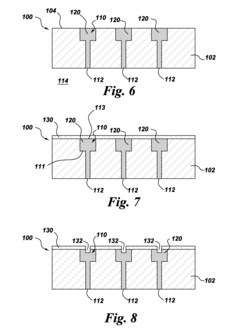

The design and optimization of microchannel geometries significantly impact cooling efficiency. Various cross-sectional shapes, dimensions, and arrangements can be engineered to enhance heat transfer rates while minimizing pressure drop. Advanced computational fluid dynamics modeling helps determine optimal channel width-to-height ratios, spacing, and flow path configurations to maximize thermal performance for specific applications. These optimizations can include tapered channels, variable cross-sections, and strategic placement of fins or obstacles to promote turbulence.- Microchannel geometry optimization: Optimization of microchannel geometry parameters such as channel width, depth, aspect ratio, and cross-sectional shape significantly impacts cooling efficiency. Advanced designs incorporate variable cross-sections, tapered channels, and optimized flow path configurations to reduce pressure drop while maximizing heat transfer. These geometric optimizations help balance the trade-off between thermal performance and pumping power requirements in cooling systems.

- Flow regulation and control systems: Intelligent flow regulation systems dynamically adjust coolant flow rates based on real-time thermal demands. These systems incorporate sensors, valves, and control algorithms to maintain optimal operating temperatures while minimizing energy consumption. Advanced regulation techniques include zoned cooling approaches, pulsed flow mechanisms, and adaptive control strategies that respond to changing heat loads, ensuring efficient thermal management across various operating conditions.

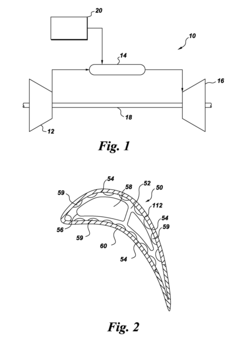

- Enhanced surface treatments and structures: Surface modifications within microchannels enhance heat transfer performance through increased surface area and improved fluid-surface interactions. Techniques include micro-fin structures, engineered roughness patterns, hydrophilic/hydrophobic coatings, and porous media inserts. These surface treatments promote turbulence, reduce thermal boundary layers, and enhance nucleate boiling in two-phase cooling applications, significantly improving overall thermal performance without substantial increases in pumping power.

- Two-phase cooling implementations: Two-phase cooling systems leverage the latent heat of vaporization to achieve superior cooling performance compared to single-phase systems. These implementations incorporate specialized microchannel designs that facilitate controlled phase change, vapor extraction, and condensate return. Advanced designs address challenges such as flow instability, dry-out prevention, and vapor management through optimized channel geometries, inlet/outlet configurations, and pressure control mechanisms to maintain consistent cooling performance.

- Integration with electronic systems and thermal management: Holistic integration of microchannel cooling with electronic systems involves optimized thermal interfaces, strategic placement of cooling structures, and comprehensive thermal management approaches. These solutions address hotspot mitigation, thermal gradient management, and system-level efficiency through techniques such as embedded cooling, 3D integration of cooling channels, and hierarchical thermal management architectures. Advanced designs consider manufacturing constraints, reliability factors, and maintenance requirements while maximizing cooling performance.

02 Flow regulation and control systems

Sophisticated flow regulation mechanisms are essential for maintaining optimal cooling performance across varying thermal loads. These systems incorporate sensors, valves, and control algorithms to dynamically adjust coolant flow rates and distribution patterns. Feedback control loops monitor temperature differentials and adjust pumping parameters accordingly, ensuring efficient heat removal while conserving energy. Advanced systems may employ predictive models to anticipate thermal loads and preemptively adjust flow characteristics, preventing temperature spikes and maintaining stable operating conditions.Expand Specific Solutions03 Enhanced coolant formulations

Specialized coolant formulations can significantly improve microchannel cooling efficiency. These advanced fluids may incorporate nanoparticles, phase-change materials, or additives that enhance thermal conductivity and heat capacity. Some formulations are designed to modify surface tension or viscosity characteristics to optimize flow behavior within microchannels. Temperature-responsive coolants can adapt their properties based on thermal conditions, providing more efficient heat transfer at different operating points while preventing issues like channel clogging or corrosion.Expand Specific Solutions04 Multi-layer and 3D microchannel architectures

Advanced cooling solutions utilize three-dimensional and multi-layer microchannel architectures to maximize cooling capacity within limited spaces. These designs feature stacked or interleaved channel networks that can target specific hotspots while maintaining uniform temperature distribution. Vertical integration allows coolant to flow through multiple layers, significantly increasing the effective heat transfer surface area. Some implementations incorporate varying channel dimensions at different layers to optimize flow distribution and pressure gradients throughout the system.Expand Specific Solutions05 Smart thermal management systems

Intelligent thermal management systems integrate sensors, microcontrollers, and machine learning algorithms to optimize microchannel cooling performance in real-time. These systems continuously monitor multiple parameters including temperature distribution, flow rates, pressure differentials, and system load to make dynamic adjustments. Predictive models can anticipate thermal requirements based on usage patterns and environmental conditions, proactively adjusting cooling parameters for optimal efficiency. Some advanced implementations incorporate self-diagnostic capabilities to detect flow restrictions, coolant degradation, or other potential issues before they impact system performance.Expand Specific Solutions

Leading Companies in Antenna Thermal Management

Microchannel cooling in antenna systems is currently in a growth phase, with the market expanding due to increasing demand for thermal management solutions in high-power communication systems. The global market is estimated to reach significant value as 5G deployment accelerates, creating opportunities for thermal regulation technologies. From a technical maturity perspective, the field shows varying levels of advancement among key players. Companies like Raytheon, Huawei, and ZTE have developed sophisticated microchannel solutions for military and commercial applications, while Ericsson and GLOBALFOUNDRIES are advancing miniaturization techniques. Academic institutions such as Xi'an Jiaotong University are contributing fundamental research, collaborating with industry leaders to optimize cooling efficiency and reduce power consumption in next-generation antenna systems.

Raytheon Co.

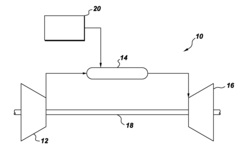

Technical Solution: Raytheon has developed advanced microchannel cooling solutions specifically for high-power radar and antenna systems. Their approach utilizes a network of precisely engineered microchannels (typically 10-500 μm in diameter) integrated directly into antenna substrates. These channels circulate dielectric coolants that efficiently remove heat from critical components while maintaining electromagnetic performance. Raytheon's system incorporates adaptive flow control mechanisms that adjust coolant flow rates based on real-time thermal monitoring, optimizing cooling efficiency during different operational modes. Their technology employs computational fluid dynamics (CFD) modeling to predict hotspots and optimize channel geometry accordingly. For military applications, Raytheon has implemented redundant cooling loops and fault-tolerant control systems to ensure continuous operation in mission-critical scenarios. Their latest systems achieve thermal resistance values below 0.1°C/W, enabling significantly higher power handling capabilities for advanced phased array systems.

Strengths: Superior integration with military-grade radar systems; exceptional reliability in harsh environments; proven performance in high-power density applications. Weaknesses: Higher implementation costs compared to conventional cooling; proprietary nature limits broader industry adoption; requires specialized manufacturing processes.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has pioneered microchannel cooling technology for 5G base station antenna systems through their "iCooling" solution. This approach integrates ultra-thin microchannels (typically 50-200μm wide) directly into antenna PCB substrates, creating a highly efficient thermal management system. The technology employs a two-phase cooling mechanism where the working fluid undergoes phase change within the microchannels, significantly enhancing heat transfer efficiency. Huawei's implementation includes intelligent pressure regulation systems that optimize coolant flow based on real-time thermal loads and environmental conditions. Their solution incorporates AI-driven predictive thermal management that anticipates hotspots before they form and adjusts cooling parameters accordingly. For outdoor deployments, Huawei has developed specialized coolant formulations that maintain performance across extreme temperature ranges (-40°C to +55°C). The system achieves cooling capacities exceeding 200 W/cm² while maintaining minimal temperature gradients across antenna arrays, crucial for maintaining signal integrity and beam forming accuracy.

Strengths: Exceptional integration with 5G infrastructure; AI-enhanced thermal management provides adaptive cooling; significantly reduced energy consumption compared to conventional cooling methods. Weaknesses: Complex manufacturing process increases production costs; requires specialized maintenance expertise; potential reliability concerns in extremely humid environments.

Key Patents and Research in Microchannel Heat Transfer

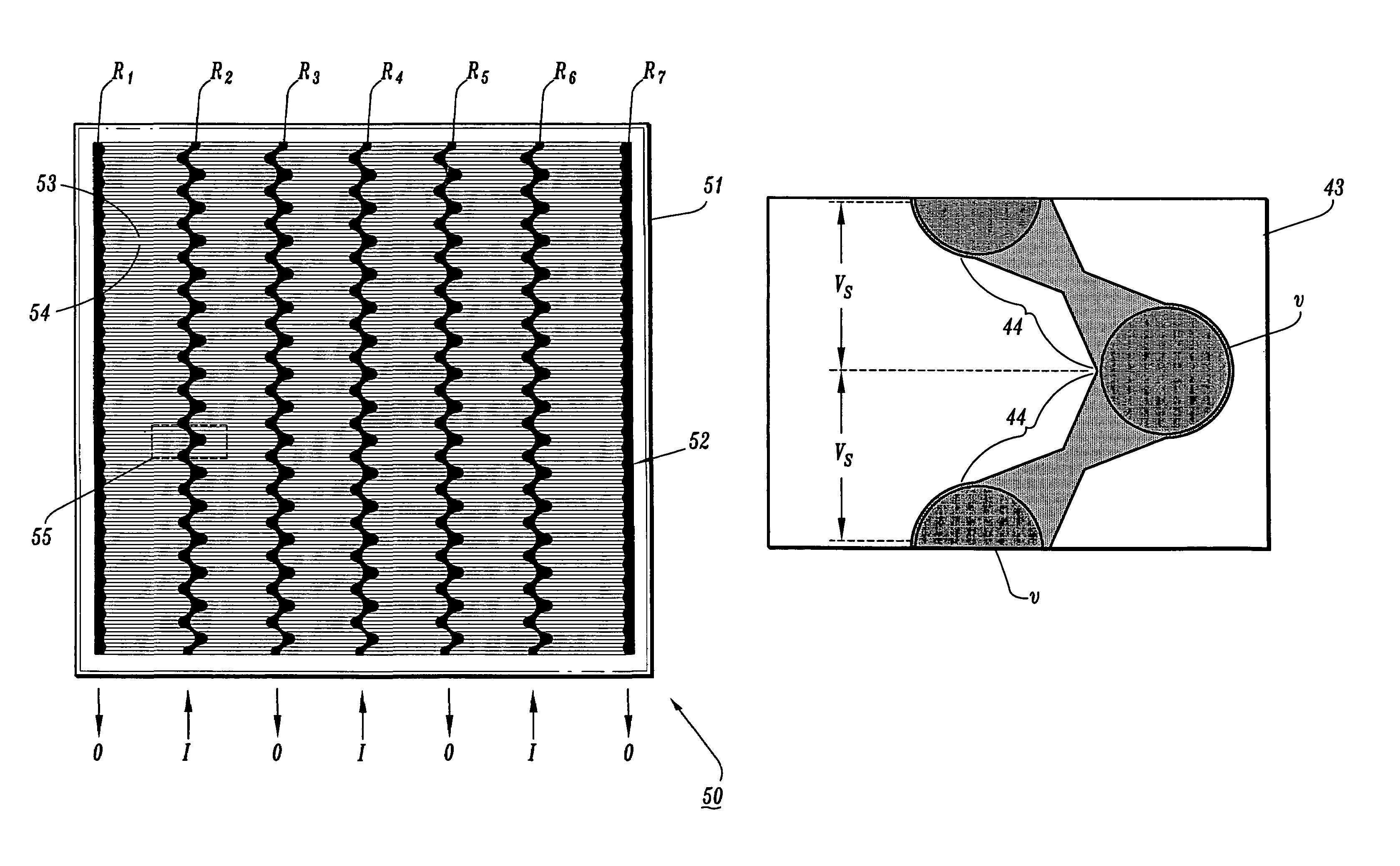

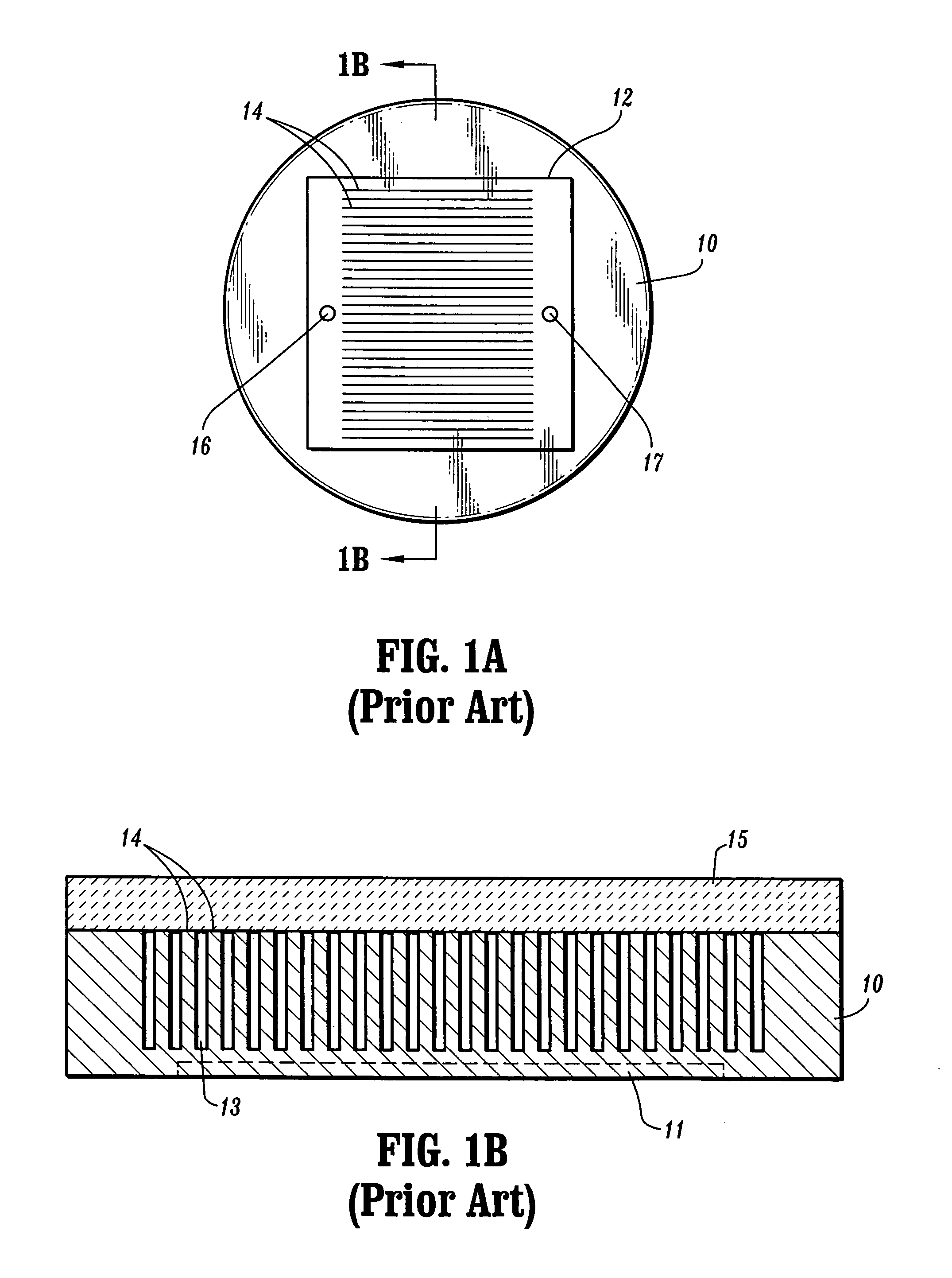

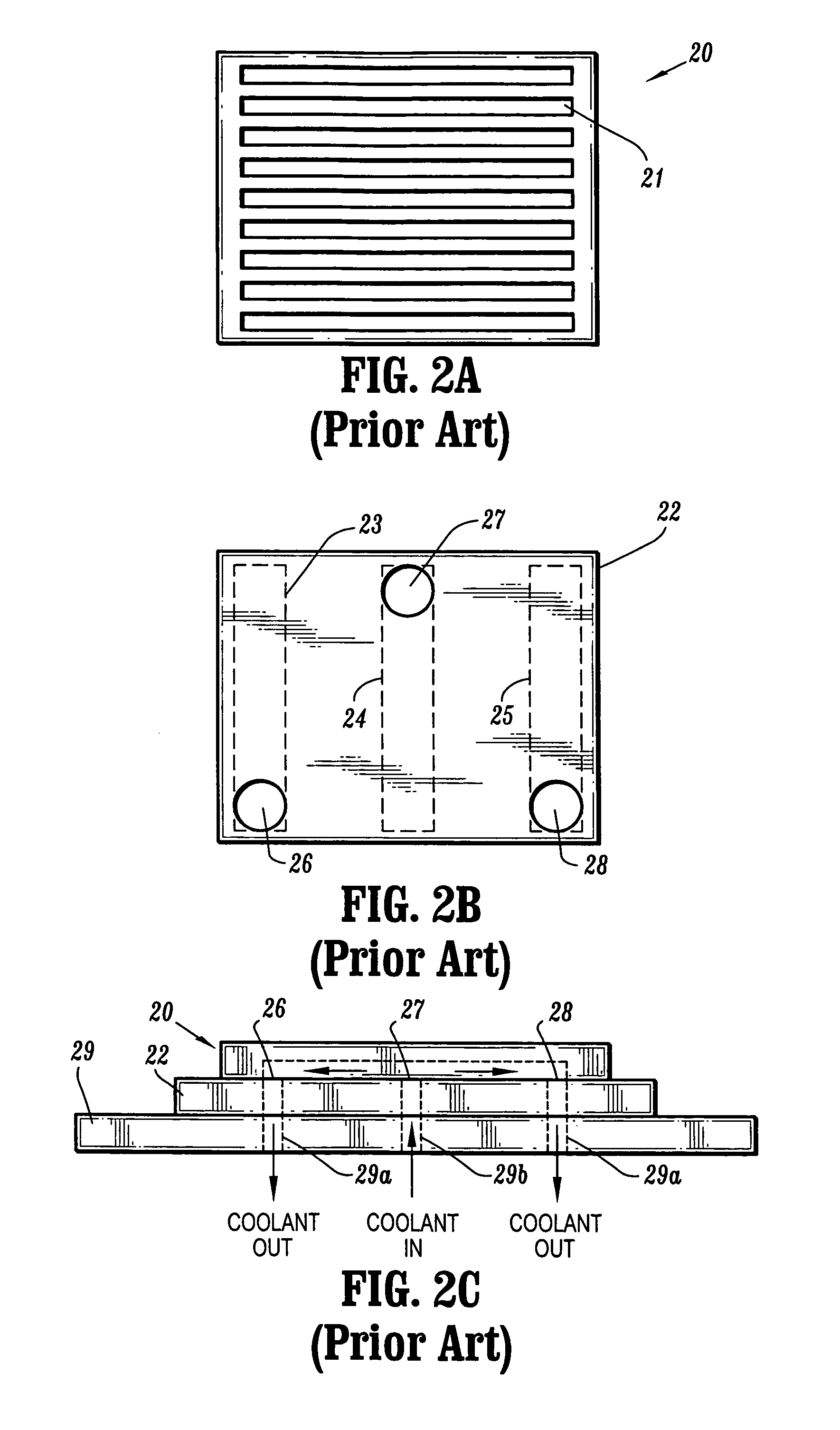

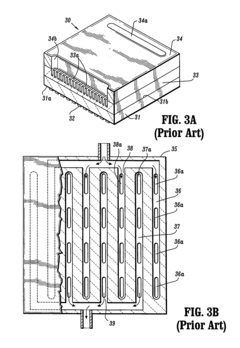

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

PatentInactiveUS7190580B2

Innovation

- The development of an integrated microchannel cooler device with a manifold plate and microchannel plate thermally bonded together, featuring alternating input and output manifolds with zig-zag patterns and varying cross-sectional areas, along with microfins that define microchannels, to ensure uniform coolant flow and minimize pressure drops.

Cooling channel systems for high-temperature components covered by coatings, and related processes

PatentActiveUS20120163984A1

Innovation

- A method involving the formation of microchannels and coolant passage holes, followed by filling with a sacrificial material, applying a metallic structural coating, creating passive cooling holes or slots, and removing the filler material, with additional coating layers to enhance coolant flow and protect against TBC failure.

Environmental Impact and Sustainability Considerations

The implementation of microchannel cooling systems in antenna technologies presents significant environmental and sustainability implications that warrant careful consideration. These systems, while offering enhanced thermal management capabilities, consume resources and energy throughout their lifecycle. The manufacturing processes for microchannels often involve energy-intensive precision machining or etching techniques, potentially utilizing harmful chemicals and generating waste materials. Minimizing these environmental impacts requires adopting cleaner production methods, such as water-based etching solutions or additive manufacturing approaches that reduce material waste.

Energy efficiency represents a critical sustainability factor in microchannel cooling systems. While these systems require power for coolant circulation, they typically demonstrate superior efficiency compared to conventional cooling methods, potentially reducing overall energy consumption by 30-45% in high-power antenna applications. This efficiency gain translates directly to reduced carbon emissions and operational costs over the system's lifetime. Furthermore, implementing smart control algorithms that dynamically adjust cooling parameters based on actual thermal loads can further optimize energy usage.

The selection of coolant materials presents another significant environmental consideration. Traditional coolants often contain environmentally harmful compounds with high global warming potential. The transition toward eco-friendly alternatives such as water-based solutions, biodegradable fluids, or dielectric coolants with minimal environmental impact represents an important sustainability advancement. Additionally, closed-loop cooling designs that minimize coolant loss and contamination risk substantially reduce environmental hazards associated with potential leakage.

From a lifecycle perspective, microchannel cooling systems offer notable sustainability advantages through their contribution to extended antenna system longevity. By maintaining optimal operating temperatures, these cooling solutions prevent premature component degradation, potentially extending equipment lifespan by 40-60% compared to conventionally cooled systems. This extension significantly reduces electronic waste generation and conserves the resources required for manufacturing replacement equipment.

End-of-life considerations must also factor into sustainability assessments. Designing microchannel systems with material recovery in mind facilitates the reclamation of valuable metals and components. Modular designs that allow for component replacement rather than complete system disposal further enhance sustainability. Additionally, standardizing materials and connection interfaces can simplify recycling processes and increase recovery rates of critical materials.

The water consumption implications of microchannel cooling systems deserve particular attention in regions facing water scarcity. While closed-loop systems minimize ongoing water requirements, the initial filling and occasional replenishment needs must be evaluated within local water resource contexts. Implementing water recovery systems and exploring alternative cooling mediums can mitigate these impacts in water-stressed environments.

Energy efficiency represents a critical sustainability factor in microchannel cooling systems. While these systems require power for coolant circulation, they typically demonstrate superior efficiency compared to conventional cooling methods, potentially reducing overall energy consumption by 30-45% in high-power antenna applications. This efficiency gain translates directly to reduced carbon emissions and operational costs over the system's lifetime. Furthermore, implementing smart control algorithms that dynamically adjust cooling parameters based on actual thermal loads can further optimize energy usage.

The selection of coolant materials presents another significant environmental consideration. Traditional coolants often contain environmentally harmful compounds with high global warming potential. The transition toward eco-friendly alternatives such as water-based solutions, biodegradable fluids, or dielectric coolants with minimal environmental impact represents an important sustainability advancement. Additionally, closed-loop cooling designs that minimize coolant loss and contamination risk substantially reduce environmental hazards associated with potential leakage.

From a lifecycle perspective, microchannel cooling systems offer notable sustainability advantages through their contribution to extended antenna system longevity. By maintaining optimal operating temperatures, these cooling solutions prevent premature component degradation, potentially extending equipment lifespan by 40-60% compared to conventionally cooled systems. This extension significantly reduces electronic waste generation and conserves the resources required for manufacturing replacement equipment.

End-of-life considerations must also factor into sustainability assessments. Designing microchannel systems with material recovery in mind facilitates the reclamation of valuable metals and components. Modular designs that allow for component replacement rather than complete system disposal further enhance sustainability. Additionally, standardizing materials and connection interfaces can simplify recycling processes and increase recovery rates of critical materials.

The water consumption implications of microchannel cooling systems deserve particular attention in regions facing water scarcity. While closed-loop systems minimize ongoing water requirements, the initial filling and occasional replenishment needs must be evaluated within local water resource contexts. Implementing water recovery systems and exploring alternative cooling mediums can mitigate these impacts in water-stressed environments.

Reliability and Performance Testing Methodologies

Reliability and performance testing methodologies for microchannel cooling systems in antenna applications require comprehensive protocols to ensure consistent operation under diverse conditions. These methodologies must evaluate both the thermal management capabilities and the impact on antenna performance metrics.

Standard testing begins with baseline thermal characterization, measuring heat dissipation rates across various power loads and ambient temperatures. This includes thermal resistance mapping, temperature uniformity assessment, and response time evaluation under dynamic thermal loads. For antenna-specific applications, these tests must be conducted while simultaneously monitoring signal integrity parameters to establish correlation between thermal conditions and RF performance.

Accelerated life testing represents a critical component of reliability assessment, subjecting microchannel cooling systems to extreme operating conditions that simulate years of operation within compressed timeframes. These tests typically include thermal cycling (between -40°C and 85°C), high-temperature operation (sustained 100+ hours at maximum rated temperature), and thermal shock testing to evaluate material integrity and connection reliability.

Environmental testing protocols must address the specific deployment scenarios for antenna systems. This includes salt fog exposure for maritime applications, sand and dust testing for desert environments, and vibration testing that simulates transportation and installation conditions. Humidity cycling tests are particularly important for evaluating potential condensation issues within the cooling channels that could affect flow dynamics.

Flow characterization testing measures pressure drop across the microchannel network under various flow rates, identifying potential flow restrictions or imbalances. Particle contamination testing evaluates the system's susceptibility to clogging and the effectiveness of filtration mechanisms. These tests typically involve introducing standardized contaminant particles and monitoring system performance degradation over time.

Long-term reliability assessment includes continuous operation testing under nominal conditions for 1000+ hours, with periodic performance measurements to detect gradual degradation. Failure mode analysis techniques such as computational fluid dynamics simulation and thermal imaging are employed to identify potential weak points before physical testing begins.

Statistical validation methodologies must be implemented across all testing protocols, with sufficient sample sizes to establish confidence intervals for key performance metrics. This data forms the foundation for mean time between failure (MTBF) calculations and service life predictions that are essential for commercial deployment of microchannel cooling technology in mission-critical antenna systems.

Standard testing begins with baseline thermal characterization, measuring heat dissipation rates across various power loads and ambient temperatures. This includes thermal resistance mapping, temperature uniformity assessment, and response time evaluation under dynamic thermal loads. For antenna-specific applications, these tests must be conducted while simultaneously monitoring signal integrity parameters to establish correlation between thermal conditions and RF performance.

Accelerated life testing represents a critical component of reliability assessment, subjecting microchannel cooling systems to extreme operating conditions that simulate years of operation within compressed timeframes. These tests typically include thermal cycling (between -40°C and 85°C), high-temperature operation (sustained 100+ hours at maximum rated temperature), and thermal shock testing to evaluate material integrity and connection reliability.

Environmental testing protocols must address the specific deployment scenarios for antenna systems. This includes salt fog exposure for maritime applications, sand and dust testing for desert environments, and vibration testing that simulates transportation and installation conditions. Humidity cycling tests are particularly important for evaluating potential condensation issues within the cooling channels that could affect flow dynamics.

Flow characterization testing measures pressure drop across the microchannel network under various flow rates, identifying potential flow restrictions or imbalances. Particle contamination testing evaluates the system's susceptibility to clogging and the effectiveness of filtration mechanisms. These tests typically involve introducing standardized contaminant particles and monitoring system performance degradation over time.

Long-term reliability assessment includes continuous operation testing under nominal conditions for 1000+ hours, with periodic performance measurements to detect gradual degradation. Failure mode analysis techniques such as computational fluid dynamics simulation and thermal imaging are employed to identify potential weak points before physical testing begins.

Statistical validation methodologies must be implemented across all testing protocols, with sufficient sample sizes to establish confidence intervals for key performance metrics. This data forms the foundation for mean time between failure (MTBF) calculations and service life predictions that are essential for commercial deployment of microchannel cooling technology in mission-critical antenna systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!