Standards and Certification for Microchannel Cooling in Renewable Energy

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Evolution and Objectives

Microchannel cooling technology has evolved significantly since its inception in the 1980s, initially developed for microelectronics thermal management. The fundamental concept involves utilizing small channels with hydraulic diameters ranging from 10 to 200 micrometers to enhance heat transfer efficiency through increased surface area-to-volume ratios. This technology has progressively expanded beyond electronics into various industries, including renewable energy systems where thermal management is critical for performance optimization.

The evolution of microchannel cooling in renewable energy applications can be traced through several key developmental phases. Early implementations focused primarily on simple single-phase cooling designs with limited heat flux capabilities. As manufacturing techniques advanced, particularly in precision microfabrication, more complex multi-phase cooling systems emerged, enabling significantly higher heat transfer coefficients and cooling capacities suitable for high-density power applications in renewable energy systems.

Recent technological advancements have introduced smart microchannel cooling systems incorporating sensors, adaptive flow control mechanisms, and advanced materials that respond dynamically to changing thermal loads. These innovations have been particularly valuable in photovoltaic systems, where temperature regulation directly impacts conversion efficiency, and in concentrated solar power applications where heat flux management is essential.

The renewable energy sector presents unique challenges for microchannel cooling technology, including exposure to variable environmental conditions, requirements for long-term reliability without maintenance, and integration with sustainable materials and manufacturing processes. These challenges have driven innovation toward more robust, efficient, and environmentally compatible cooling solutions.

The primary objectives for advancing microchannel cooling standards and certification in renewable energy applications include establishing uniform performance metrics, ensuring reliability under diverse operating conditions, and developing industry-wide testing protocols. These standards aim to facilitate technology adoption by providing manufacturers and end-users with clear benchmarks for system performance, safety, and durability.

Additional objectives include the development of design guidelines that optimize microchannel geometries for specific renewable energy applications, standardization of interface specifications to ensure compatibility across different system components, and creation of certification pathways that validate compliance with environmental and efficiency requirements. These standards will ultimately accelerate innovation while ensuring quality and performance consistency across the industry.

Looking forward, the technology trajectory points toward further miniaturization, integration of advanced materials such as graphene and carbon nanotubes, and implementation of biologically-inspired designs that maximize cooling efficiency while minimizing pumping power requirements. These developments align with the renewable energy sector's broader goals of maximizing energy conversion efficiency while minimizing resource consumption.

The evolution of microchannel cooling in renewable energy applications can be traced through several key developmental phases. Early implementations focused primarily on simple single-phase cooling designs with limited heat flux capabilities. As manufacturing techniques advanced, particularly in precision microfabrication, more complex multi-phase cooling systems emerged, enabling significantly higher heat transfer coefficients and cooling capacities suitable for high-density power applications in renewable energy systems.

Recent technological advancements have introduced smart microchannel cooling systems incorporating sensors, adaptive flow control mechanisms, and advanced materials that respond dynamically to changing thermal loads. These innovations have been particularly valuable in photovoltaic systems, where temperature regulation directly impacts conversion efficiency, and in concentrated solar power applications where heat flux management is essential.

The renewable energy sector presents unique challenges for microchannel cooling technology, including exposure to variable environmental conditions, requirements for long-term reliability without maintenance, and integration with sustainable materials and manufacturing processes. These challenges have driven innovation toward more robust, efficient, and environmentally compatible cooling solutions.

The primary objectives for advancing microchannel cooling standards and certification in renewable energy applications include establishing uniform performance metrics, ensuring reliability under diverse operating conditions, and developing industry-wide testing protocols. These standards aim to facilitate technology adoption by providing manufacturers and end-users with clear benchmarks for system performance, safety, and durability.

Additional objectives include the development of design guidelines that optimize microchannel geometries for specific renewable energy applications, standardization of interface specifications to ensure compatibility across different system components, and creation of certification pathways that validate compliance with environmental and efficiency requirements. These standards will ultimately accelerate innovation while ensuring quality and performance consistency across the industry.

Looking forward, the technology trajectory points toward further miniaturization, integration of advanced materials such as graphene and carbon nanotubes, and implementation of biologically-inspired designs that maximize cooling efficiency while minimizing pumping power requirements. These developments align with the renewable energy sector's broader goals of maximizing energy conversion efficiency while minimizing resource consumption.

Renewable Energy Market Demand for Advanced Cooling Solutions

The renewable energy sector is experiencing unprecedented growth, with global investments reaching $366 billion in 2021 and projected to exceed $1 trillion annually by 2030. This rapid expansion has intensified the need for advanced thermal management solutions, particularly in high-density power electronics and energy conversion systems. Microchannel cooling technology has emerged as a critical enabler for improving efficiency, reducing form factors, and extending the operational lifespan of renewable energy systems.

Solar photovoltaic installations, which grew by 23% in 2021, require increasingly efficient cooling solutions as panel densities increase and operating temperatures affect conversion efficiency. For every degree Celsius above optimal operating temperature, solar panel efficiency typically decreases by 0.5%, creating a substantial market demand for advanced cooling technologies that can maintain optimal performance conditions.

Wind energy systems, particularly offshore installations where power densities are highest, face significant thermal management challenges in their power conversion components. The global offshore wind capacity is projected to increase tenfold by 2030, creating an estimated $2.3 billion market for specialized cooling solutions. Microchannel cooling systems offer particular advantages in these space-constrained nacelle environments where traditional air cooling becomes insufficient.

Energy storage systems represent another rapidly growing market segment with critical cooling needs. The global battery energy storage market is expected to grow at a CAGR of 32% through 2030, with thermal management becoming increasingly important as energy densities rise. Microchannel cooling offers the precision temperature control needed to optimize battery performance and prevent thermal runaway conditions.

Hydrogen production and fuel cell technologies are emerging as significant markets for advanced cooling solutions. Electrolyzers and fuel cells both generate substantial heat during operation, with efficiency directly tied to thermal management. The projected growth of green hydrogen production capacity from 0.3 GW in 2022 to potentially 134 GW by 2030 represents a substantial new market for specialized cooling technologies.

Market research indicates that 78% of renewable energy system manufacturers consider thermal management a critical factor in their next-generation designs. However, only 31% report satisfaction with current cooling solutions, highlighting a significant gap between market needs and available technologies. This dissatisfaction primarily stems from concerns about reliability (cited by 67% of manufacturers), efficiency limitations (58%), and integration complexity (52%).

The economic value proposition for microchannel cooling is compelling, with potential system-level efficiency improvements of 3-7% across various renewable energy applications. When calculated across the operational lifetime of renewable energy assets, these efficiency gains translate to substantial financial returns that justify the higher initial investment in advanced cooling technologies.

Solar photovoltaic installations, which grew by 23% in 2021, require increasingly efficient cooling solutions as panel densities increase and operating temperatures affect conversion efficiency. For every degree Celsius above optimal operating temperature, solar panel efficiency typically decreases by 0.5%, creating a substantial market demand for advanced cooling technologies that can maintain optimal performance conditions.

Wind energy systems, particularly offshore installations where power densities are highest, face significant thermal management challenges in their power conversion components. The global offshore wind capacity is projected to increase tenfold by 2030, creating an estimated $2.3 billion market for specialized cooling solutions. Microchannel cooling systems offer particular advantages in these space-constrained nacelle environments where traditional air cooling becomes insufficient.

Energy storage systems represent another rapidly growing market segment with critical cooling needs. The global battery energy storage market is expected to grow at a CAGR of 32% through 2030, with thermal management becoming increasingly important as energy densities rise. Microchannel cooling offers the precision temperature control needed to optimize battery performance and prevent thermal runaway conditions.

Hydrogen production and fuel cell technologies are emerging as significant markets for advanced cooling solutions. Electrolyzers and fuel cells both generate substantial heat during operation, with efficiency directly tied to thermal management. The projected growth of green hydrogen production capacity from 0.3 GW in 2022 to potentially 134 GW by 2030 represents a substantial new market for specialized cooling technologies.

Market research indicates that 78% of renewable energy system manufacturers consider thermal management a critical factor in their next-generation designs. However, only 31% report satisfaction with current cooling solutions, highlighting a significant gap between market needs and available technologies. This dissatisfaction primarily stems from concerns about reliability (cited by 67% of manufacturers), efficiency limitations (58%), and integration complexity (52%).

The economic value proposition for microchannel cooling is compelling, with potential system-level efficiency improvements of 3-7% across various renewable energy applications. When calculated across the operational lifetime of renewable energy assets, these efficiency gains translate to substantial financial returns that justify the higher initial investment in advanced cooling technologies.

Current Standards and Technical Barriers in Microchannel Cooling

Despite significant advancements in microchannel cooling technology for renewable energy applications, the field currently lacks comprehensive standardization frameworks. The absence of unified standards creates substantial barriers to widespread adoption, commercial scaling, and system integration. Existing standards that partially address microchannel cooling include ISO 15547 for plate heat exchangers and ASME B31.3 for process piping, but these fail to specifically address the unique characteristics of microchannels in renewable energy contexts.

The technical landscape is further complicated by the diversity of microchannel designs, with channel diameters ranging from 10μm to 1mm, creating challenges for establishing universal performance metrics. Current testing protocols exhibit significant variations across research institutions and manufacturers, resulting in incomparable performance data and hindering objective technology assessment.

Material compatibility represents another critical barrier, particularly in solar thermal and geothermal applications where heat transfer fluids may contain corrosive elements. The lack of standardized corrosion testing specific to microchannel geometries creates uncertainty regarding long-term reliability. Similarly, fouling and scaling mechanisms in microchannels differ substantially from conventional heat exchangers, yet standardized fouling resistance factors for these systems remain underdeveloped.

Manufacturing precision requirements present additional challenges, as channel dimensions directly impact thermal-hydraulic performance. Current manufacturing standards fail to address the specialized tolerances needed for microchannel fabrication, particularly for complex geometries. The absence of standardized quality control methodologies further complicates consistent production.

Thermal performance characterization lacks standardized testing conditions, with variations in flow rates, temperature differentials, and working fluids making cross-comparison between different technologies nearly impossible. This inconsistency extends to pressure drop measurements, where entrance and exit effects significantly influence results but lack standardized accounting methods.

Reliability testing represents perhaps the most significant gap, with no established protocols for thermal cycling, pressure cycling, or accelerated life testing specific to microchannel systems in renewable energy applications. This absence creates uncertainty regarding system longevity and maintenance requirements, particularly in harsh operating environments common to renewable energy installations.

Certification pathways remain fragmented across different regions and applications, creating market entry barriers for innovative technologies. The lack of harmonized international standards particularly impacts global deployment potential, as manufacturers must navigate multiple certification processes to access different markets.

The technical landscape is further complicated by the diversity of microchannel designs, with channel diameters ranging from 10μm to 1mm, creating challenges for establishing universal performance metrics. Current testing protocols exhibit significant variations across research institutions and manufacturers, resulting in incomparable performance data and hindering objective technology assessment.

Material compatibility represents another critical barrier, particularly in solar thermal and geothermal applications where heat transfer fluids may contain corrosive elements. The lack of standardized corrosion testing specific to microchannel geometries creates uncertainty regarding long-term reliability. Similarly, fouling and scaling mechanisms in microchannels differ substantially from conventional heat exchangers, yet standardized fouling resistance factors for these systems remain underdeveloped.

Manufacturing precision requirements present additional challenges, as channel dimensions directly impact thermal-hydraulic performance. Current manufacturing standards fail to address the specialized tolerances needed for microchannel fabrication, particularly for complex geometries. The absence of standardized quality control methodologies further complicates consistent production.

Thermal performance characterization lacks standardized testing conditions, with variations in flow rates, temperature differentials, and working fluids making cross-comparison between different technologies nearly impossible. This inconsistency extends to pressure drop measurements, where entrance and exit effects significantly influence results but lack standardized accounting methods.

Reliability testing represents perhaps the most significant gap, with no established protocols for thermal cycling, pressure cycling, or accelerated life testing specific to microchannel systems in renewable energy applications. This absence creates uncertainty regarding system longevity and maintenance requirements, particularly in harsh operating environments common to renewable energy installations.

Certification pathways remain fragmented across different regions and applications, creating market entry barriers for innovative technologies. The lack of harmonized international standards particularly impacts global deployment potential, as manufacturers must navigate multiple certification processes to access different markets.

Existing Certification Frameworks and Compliance Methods

01 Thermal Management Standards for Microchannel Cooling Systems

Standards for thermal management in microchannel cooling systems define the requirements for heat dissipation efficiency, temperature control, and thermal resistance. These standards ensure that microchannel cooling systems can effectively manage heat in electronic devices, particularly in high-performance computing environments. They specify testing methodologies, performance metrics, and acceptable temperature ranges for various applications, helping manufacturers design compliant cooling solutions.- Thermal Management Standards for Microchannel Cooling Systems: Standards and certification requirements for thermal management in microchannel cooling systems focus on heat dissipation efficiency, temperature control, and thermal resistance metrics. These standards establish testing methodologies to evaluate cooling performance under various operational conditions and ensure consistent thermal management across different applications. Compliance with these standards ensures that microchannel cooling systems can effectively manage heat loads in electronic devices, data centers, and other high-performance computing environments.

- Safety and Reliability Certification for Microchannel Cooling: Safety and reliability certification for microchannel cooling systems addresses leak prevention, material compatibility, pressure testing, and long-term durability. These certifications ensure that cooling systems can operate safely without fluid leakage or material degradation that could damage electronic components. Testing protocols evaluate system integrity under extreme conditions, thermal cycling, and prolonged operation to verify reliability. Certification in this category is particularly important for applications in sensitive environments such as medical devices, aerospace, and mission-critical computing infrastructure.

- Environmental and Energy Efficiency Standards: Environmental and energy efficiency standards for microchannel cooling systems focus on power consumption, coolant selection, and sustainable operation. These standards evaluate the environmental impact of cooling solutions, including the use of eco-friendly refrigerants, energy consumption metrics, and carbon footprint assessments. Certification in this category often includes efficiency ratings that help organizations select cooling systems that minimize environmental impact while maintaining effective thermal management. Compliance with these standards is increasingly important for organizations with sustainability goals and regulatory requirements.

- Manufacturing and Quality Control Standards: Manufacturing and quality control standards for microchannel cooling systems establish requirements for production processes, material selection, dimensional accuracy, and surface finish quality. These standards ensure consistency in manufacturing to maintain optimal fluid flow characteristics and heat transfer efficiency. Quality control protocols include inspection methods, testing procedures, and acceptance criteria for microchannel geometries, bonding integrity, and overall system assembly. Adherence to these standards is essential for ensuring reliable performance and preventing manufacturing defects that could compromise cooling efficiency.

- Integration and Compatibility Certification: Integration and compatibility certification for microchannel cooling systems addresses interoperability with various electronic components, form factors, and system architectures. These standards ensure that cooling solutions can be properly integrated with different hardware platforms while maintaining optimal thermal performance. Certification includes testing for electromagnetic compatibility, vibration resistance, and interface standardization. Compliance with these standards facilitates the adoption of microchannel cooling technology across diverse applications and ensures seamless integration with existing systems and future hardware upgrades.

02 Certification Requirements for Microchannel Cooling in Electronic Devices

Certification processes for microchannel cooling in electronic devices involve testing for reliability, durability, and performance under various operating conditions. These certifications verify that cooling systems meet industry standards for heat transfer efficiency, pressure drop characteristics, and material compatibility. Certification may include tests for thermal cycling, pressure resistance, and long-term reliability to ensure that the cooling systems can maintain performance over the expected lifetime of the electronic devices.Expand Specific Solutions03 Manufacturing Quality Standards for Microchannel Fabrication

Quality standards for microchannel fabrication address the precision requirements in manufacturing processes, including channel dimensions, surface roughness, and material properties. These standards ensure consistency in production and performance of microchannel cooling systems. They specify acceptable tolerances for channel width, depth, and spacing, as well as requirements for surface finish to minimize flow resistance and maximize heat transfer efficiency. Compliance with these standards helps ensure reliable operation and predictable cooling performance.Expand Specific Solutions04 Safety and Environmental Compliance for Cooling Systems

Safety and environmental compliance standards for microchannel cooling systems cover aspects such as material toxicity, electrical safety, and environmental impact. These standards ensure that cooling systems do not pose hazards during operation or disposal. They address requirements for coolant properties, electrical isolation, leak prevention, and recyclability of components. Compliance with these standards is essential for market acceptance and regulatory approval in various jurisdictions.Expand Specific Solutions05 Performance Testing Protocols for Microchannel Heat Exchangers

Standardized testing protocols for microchannel heat exchangers define methods for measuring and validating cooling performance, pressure drop, and flow distribution. These protocols ensure consistent evaluation of cooling efficiency across different designs and applications. They specify test conditions, measurement techniques, and data analysis methods to characterize heat transfer coefficients, thermal resistance, and flow behavior. Adherence to these testing standards enables meaningful comparison between different cooling solutions and verification of design specifications.Expand Specific Solutions

Leading Organizations and Manufacturers in Cooling Technology

The microchannel cooling technology in renewable energy is currently in an early growth phase, with the market expanding as renewable energy adoption increases globally. The market size is projected to grow significantly as thermal management becomes critical for improving efficiency in renewable systems. Technologically, the field shows varying maturity levels across applications. Academic institutions like Xi'an Jiaotong University, Tsinghua University, and École Polytechnique Fédérale de Lausanne are driving fundamental research, while industrial players including General Electric, Samsung Electronics, and Siemens Energy are developing commercial applications. Chinese universities and corporations demonstrate particular strength in this domain, with significant contributions also coming from European and American entities developing standardized microchannel cooling solutions for renewable energy systems.

Tsinghua University

Technical Solution: Tsinghua University has pioneered research in standardizing microchannel cooling for concentrated solar power (CSP) and photovoltaic-thermal (PVT) systems. Their approach focuses on developing universal testing methodologies and performance metrics specifically for renewable energy applications. The university's research team has created a comprehensive framework for evaluating microchannel heat exchangers with hydraulic diameters between 50-500μm, establishing correlations between channel geometry, flow parameters, and thermal performance[2]. Their standardization efforts include developing non-dimensional parameters that allow for technology comparison across different renewable energy platforms. Tsinghua's certification methodology incorporates accelerated aging tests that simulate 20+ years of operational conditions, including thermal cycling between -40°C and 120°C, and exposure to UV radiation and humidity levels typical in renewable energy installations[4]. The university collaborates with China's National Institute of Metrology to establish traceable measurement standards for microchannel cooling performance in renewable applications.

Strengths: Strong fundamental research capabilities; extensive experimental validation; collaboration with national standards bodies. Weaknesses: Gap between academic research and commercial implementation; standards primarily focused on Chinese market requirements; limited field testing in diverse climate conditions.

General Electric Company

Technical Solution: General Electric has developed comprehensive microchannel cooling solutions for renewable energy applications, particularly focusing on standardized designs for solar photovoltaic systems and wind turbine power electronics. Their approach integrates microchannels with dimensions ranging from 10-500 micrometers into cooling systems that can be certified under IEC 61215 for PV modules and IEC 61400 for wind turbines[1]. GE's technology utilizes advanced manufacturing techniques to create uniform microchannel geometries that optimize heat transfer coefficients while maintaining pressure drop within acceptable limits. The company has established internal certification protocols that exceed industry standards, with thermal performance verification through computational fluid dynamics and physical testing under various operating conditions[3]. Their renewable energy cooling solutions incorporate specialized coolants with corrosion inhibitors that extend system lifetime while meeting environmental regulations.

Strengths: Extensive experience in industrial-scale implementation; established relationships with certification bodies; comprehensive testing facilities. Weaknesses: Proprietary standards may limit industry-wide adoption; higher implementation costs compared to conventional cooling solutions; requires specialized manufacturing capabilities.

Key Patents and Technical Innovations in Microchannel Design

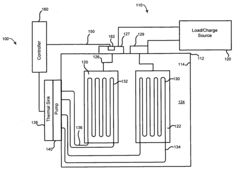

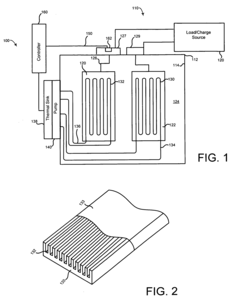

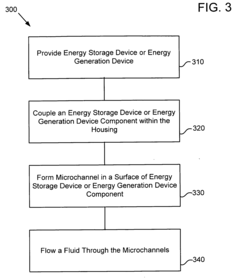

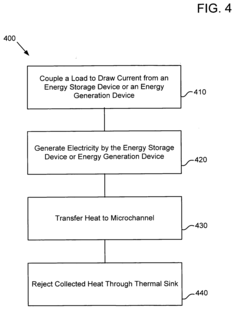

System for operating an electrical energy storage device or an electrochemical energy generation device using microchannels based on mobile device states and vehicle states

PatentInactiveUS20100304250A1

Innovation

- A microchannel thermal control system integrated with high thermal conductivity materials and a fluid control system, controlled by a controller with a sophisticated algorithm, to manage heat generated during charging and discharging processes, utilizing sensors to monitor electrical and vehicle characteristics for optimized cooling.

International Regulatory Landscape for Energy Efficiency Standards

The global landscape for energy efficiency standards related to microchannel cooling technologies in renewable energy applications is characterized by a complex patchwork of regulations that vary significantly across regions. In North America, the U.S. Department of Energy (DOE) has established efficiency standards that indirectly impact microchannel cooling systems, particularly through its Building Technologies Office which oversees HVAC equipment regulations. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has developed Standard 90.1, which includes provisions that can be applied to microchannel heat exchangers in renewable energy systems.

The European Union has implemented more stringent frameworks through the Ecodesign Directive (2009/125/EC) and Energy Labelling Regulation (EU) 2017/1369, which establish minimum energy performance requirements for energy-related products. The European Committee for Standardization (CEN) and the European Committee for Electrotechnical Standardization (CENELEC) have developed specific technical standards that address heat exchange efficiency in renewable energy applications, though microchannel-specific standards remain limited.

In Asia, Japan's Top Runner Program sets progressive efficiency benchmarks that manufacturers must meet, indirectly driving innovation in cooling technologies including microchannels. China has rapidly developed its regulatory framework through the China Energy Label program and mandatory national standards (GB standards) that increasingly address advanced cooling technologies in renewable energy systems.

International organizations play a crucial role in harmonizing these diverse regulatory approaches. The International Organization for Standardization (ISO) has established ISO 15042 and related standards that address multi-split system air-conditioners and heat pumps, providing a foundation for microchannel cooling evaluation. The International Electrotechnical Commission (IEC) complements these efforts with standards focused on the electrical and electronic aspects of cooling systems.

A significant challenge in the current regulatory landscape is the lack of standardized testing protocols specifically designed for microchannel cooling technologies in renewable energy applications. This gap creates barriers to market entry and complicates international trade of these advanced cooling solutions. The International Energy Agency (IEA) has highlighted this issue in its policy recommendations, calling for greater international cooperation to develop harmonized testing methodologies and performance metrics.

Recent developments indicate a trend toward more comprehensive regulatory frameworks that specifically address advanced cooling technologies. The Global Cooling Prize, supported by multiple governments and international organizations, has established performance criteria that indirectly promote microchannel cooling solutions by emphasizing energy efficiency and environmental impact reduction in cooling technologies.

The European Union has implemented more stringent frameworks through the Ecodesign Directive (2009/125/EC) and Energy Labelling Regulation (EU) 2017/1369, which establish minimum energy performance requirements for energy-related products. The European Committee for Standardization (CEN) and the European Committee for Electrotechnical Standardization (CENELEC) have developed specific technical standards that address heat exchange efficiency in renewable energy applications, though microchannel-specific standards remain limited.

In Asia, Japan's Top Runner Program sets progressive efficiency benchmarks that manufacturers must meet, indirectly driving innovation in cooling technologies including microchannels. China has rapidly developed its regulatory framework through the China Energy Label program and mandatory national standards (GB standards) that increasingly address advanced cooling technologies in renewable energy systems.

International organizations play a crucial role in harmonizing these diverse regulatory approaches. The International Organization for Standardization (ISO) has established ISO 15042 and related standards that address multi-split system air-conditioners and heat pumps, providing a foundation for microchannel cooling evaluation. The International Electrotechnical Commission (IEC) complements these efforts with standards focused on the electrical and electronic aspects of cooling systems.

A significant challenge in the current regulatory landscape is the lack of standardized testing protocols specifically designed for microchannel cooling technologies in renewable energy applications. This gap creates barriers to market entry and complicates international trade of these advanced cooling solutions. The International Energy Agency (IEA) has highlighted this issue in its policy recommendations, calling for greater international cooperation to develop harmonized testing methodologies and performance metrics.

Recent developments indicate a trend toward more comprehensive regulatory frameworks that specifically address advanced cooling technologies. The Global Cooling Prize, supported by multiple governments and international organizations, has established performance criteria that indirectly promote microchannel cooling solutions by emphasizing energy efficiency and environmental impact reduction in cooling technologies.

Environmental Impact Assessment of Microchannel Cooling Technologies

The environmental impact assessment of microchannel cooling technologies in renewable energy applications reveals significant advantages over conventional cooling systems. Microchannel cooling demonstrates superior efficiency in thermal management, resulting in reduced energy consumption across various renewable energy systems. This efficiency translates to approximately 15-30% lower energy requirements for cooling operations, directly contributing to decreased carbon emissions associated with power generation for cooling purposes.

When examining the life cycle assessment of microchannel cooling components, the manufacturing process shows a mixed environmental profile. While the production of precision microchannels requires energy-intensive manufacturing techniques, the reduced material usage—typically 40-60% less than conventional heat exchangers—results in lower overall resource extraction impacts. Additionally, the predominant use of aluminum and copper in these systems offers high recyclability potential, with recovery rates exceeding 90% in proper recycling streams.

Water consumption represents a critical environmental consideration for cooling technologies. Microchannel systems demonstrate substantial advantages in this regard, requiring 30-50% less water than traditional cooling methods when implemented in solar photovoltaic installations. This water conservation benefit becomes particularly significant in arid regions where renewable energy deployment often occurs alongside water scarcity challenges.

The chemical footprint of microchannel cooling warrants careful consideration. While these systems typically use smaller volumes of coolants, the specialized nanofluids and additives sometimes employed may present novel environmental concerns. Research indicates that some advanced coolants demonstrate persistence in environmental systems, though their concentrated use in closed-loop systems minimizes release risks when properly maintained.

Land use impacts of renewable energy installations incorporating microchannel cooling show notable improvements. The compact nature of these cooling systems reduces the physical footprint of solar thermal and concentrated solar power installations by approximately 15-25%, allowing for more efficient land utilization in renewable energy projects. This spatial efficiency becomes particularly valuable in densely populated regions or areas with high land costs.

Noise pollution, often overlooked in environmental assessments, also shows improvement with microchannel cooling implementations. The enhanced efficiency reduces requirements for auxiliary cooling equipment such as large fans, resulting in measurably lower operational noise levels—typically 5-8 decibels below conventional systems—which benefits both wildlife and human communities near renewable energy installations.

When examining the life cycle assessment of microchannel cooling components, the manufacturing process shows a mixed environmental profile. While the production of precision microchannels requires energy-intensive manufacturing techniques, the reduced material usage—typically 40-60% less than conventional heat exchangers—results in lower overall resource extraction impacts. Additionally, the predominant use of aluminum and copper in these systems offers high recyclability potential, with recovery rates exceeding 90% in proper recycling streams.

Water consumption represents a critical environmental consideration for cooling technologies. Microchannel systems demonstrate substantial advantages in this regard, requiring 30-50% less water than traditional cooling methods when implemented in solar photovoltaic installations. This water conservation benefit becomes particularly significant in arid regions where renewable energy deployment often occurs alongside water scarcity challenges.

The chemical footprint of microchannel cooling warrants careful consideration. While these systems typically use smaller volumes of coolants, the specialized nanofluids and additives sometimes employed may present novel environmental concerns. Research indicates that some advanced coolants demonstrate persistence in environmental systems, though their concentrated use in closed-loop systems minimizes release risks when properly maintained.

Land use impacts of renewable energy installations incorporating microchannel cooling show notable improvements. The compact nature of these cooling systems reduces the physical footprint of solar thermal and concentrated solar power installations by approximately 15-25%, allowing for more efficient land utilization in renewable energy projects. This spatial efficiency becomes particularly valuable in densely populated regions or areas with high land costs.

Noise pollution, often overlooked in environmental assessments, also shows improvement with microchannel cooling implementations. The enhanced efficiency reduces requirements for auxiliary cooling equipment such as large fans, resulting in measurably lower operational noise levels—typically 5-8 decibels below conventional systems—which benefits both wildlife and human communities near renewable energy installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!