Why Microchannel Cooling Improves Efficiency in EV Batteries

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Evolution in EV Batteries

Microchannel cooling technology in electric vehicle (EV) batteries has undergone significant evolution over the past decade, transforming from theoretical concepts to practical implementations. The journey began with conventional cooling methods such as air cooling and plate cooling, which proved inadequate for high-performance EV batteries due to their limited heat transfer capabilities and uneven temperature distribution.

The first generation of microchannel cooling systems emerged around 2010-2012, featuring simple straight channel designs integrated into battery cooling plates. These early systems demonstrated improved cooling efficiency compared to traditional methods but suffered from flow distribution issues and manufacturing complexities.

Between 2013 and 2016, the second generation introduced optimized channel geometries, including serpentine and bifurcating designs. These advancements addressed flow distribution challenges and enhanced cooling uniformity across battery modules. During this period, researchers also began exploring various manufacturing techniques, transitioning from traditional machining to more advanced methods like chemical etching and additive manufacturing.

The third generation (2017-2019) marked a significant leap with the integration of advanced materials and multi-layer microchannel structures. The introduction of high thermal conductivity materials such as aluminum alloys and copper composites substantially improved heat transfer efficiency. Additionally, computational fluid dynamics (CFD) modeling became instrumental in optimizing channel designs for specific battery architectures.

From 2020 onwards, the fourth generation has focused on intelligent and adaptive microchannel cooling systems. These incorporate sensors and control algorithms to dynamically adjust cooling parameters based on real-time battery conditions. The integration of phase-change materials within microchannel structures has also emerged as a promising approach for handling peak thermal loads during fast charging scenarios.

Recent developments (2022-2023) have seen the convergence of microchannel cooling with immersion cooling techniques, creating hybrid systems that maximize cooling efficiency while minimizing pumping power requirements. Additionally, direct die-integrated microchannels have begun appearing in cutting-edge battery designs, allowing for cooling at the cell level rather than just at the module or pack level.

The evolution has been driven by increasing energy density requirements in EV batteries, faster charging capabilities, and the need for extended battery lifespan. Each generation has addressed specific limitations of previous designs while pushing the boundaries of thermal management efficiency, ultimately enabling the high-performance EV batteries that power today's electric vehicles.

The first generation of microchannel cooling systems emerged around 2010-2012, featuring simple straight channel designs integrated into battery cooling plates. These early systems demonstrated improved cooling efficiency compared to traditional methods but suffered from flow distribution issues and manufacturing complexities.

Between 2013 and 2016, the second generation introduced optimized channel geometries, including serpentine and bifurcating designs. These advancements addressed flow distribution challenges and enhanced cooling uniformity across battery modules. During this period, researchers also began exploring various manufacturing techniques, transitioning from traditional machining to more advanced methods like chemical etching and additive manufacturing.

The third generation (2017-2019) marked a significant leap with the integration of advanced materials and multi-layer microchannel structures. The introduction of high thermal conductivity materials such as aluminum alloys and copper composites substantially improved heat transfer efficiency. Additionally, computational fluid dynamics (CFD) modeling became instrumental in optimizing channel designs for specific battery architectures.

From 2020 onwards, the fourth generation has focused on intelligent and adaptive microchannel cooling systems. These incorporate sensors and control algorithms to dynamically adjust cooling parameters based on real-time battery conditions. The integration of phase-change materials within microchannel structures has also emerged as a promising approach for handling peak thermal loads during fast charging scenarios.

Recent developments (2022-2023) have seen the convergence of microchannel cooling with immersion cooling techniques, creating hybrid systems that maximize cooling efficiency while minimizing pumping power requirements. Additionally, direct die-integrated microchannels have begun appearing in cutting-edge battery designs, allowing for cooling at the cell level rather than just at the module or pack level.

The evolution has been driven by increasing energy density requirements in EV batteries, faster charging capabilities, and the need for extended battery lifespan. Each generation has addressed specific limitations of previous designs while pushing the boundaries of thermal management efficiency, ultimately enabling the high-performance EV batteries that power today's electric vehicles.

Market Demand for Enhanced Thermal Management in EVs

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales surpassing 10 million units in 2022 and projected to reach 40 million by 2030. This rapid expansion has intensified the demand for advanced thermal management solutions, particularly for EV batteries. Effective thermal management directly impacts vehicle performance, safety, charging speed, and battery longevity—all critical factors influencing consumer adoption and manufacturer competitiveness.

Market research indicates that thermal runaway concerns remain a primary barrier to EV adoption among potential buyers. Surveys show that 68% of prospective EV customers cite battery safety as a major consideration in their purchasing decision. Additionally, consumers increasingly demand faster charging capabilities, with 82% of potential buyers indicating that charging times under 20 minutes would significantly increase their likelihood of purchasing an EV.

Automotive manufacturers are responding to these market pressures by prioritizing thermal management innovations. Industry reports reveal that investment in advanced battery cooling technologies has grown by 35% annually since 2019, with microchannel cooling emerging as a particularly promising solution area.

The regulatory landscape is further driving market demand for enhanced thermal management. New safety standards in Europe, North America, and China are establishing stricter thermal performance requirements for EV batteries. Compliance with these regulations necessitates more sophisticated cooling solutions than traditional air or plate cooling systems can provide.

Fleet operators represent another significant market segment demanding improved thermal management. Commercial EV fleets require consistent performance, minimal downtime, and extended vehicle lifespan to maximize return on investment. Enhanced cooling systems directly address these needs by enabling more predictable range, faster charging, and reduced battery degradation.

Premium and performance EV segments demonstrate particularly strong demand for advanced cooling technologies. In these markets, thermal management is increasingly positioned as a competitive differentiator, with manufacturers highlighting cooling capabilities in marketing materials and technical specifications.

Market forecasts indicate that the global EV battery thermal management system market will grow at a CAGR of 22% through 2028, reaching a market value of $12.1 billion. Microchannel cooling technologies are expected to capture an increasing share of this market due to their superior efficiency and compact design advantages.

As battery energy densities continue to increase and fast-charging capabilities become standard, the demand for more effective thermal management solutions will only intensify, creating substantial market opportunities for innovations in microchannel cooling technology.

Market research indicates that thermal runaway concerns remain a primary barrier to EV adoption among potential buyers. Surveys show that 68% of prospective EV customers cite battery safety as a major consideration in their purchasing decision. Additionally, consumers increasingly demand faster charging capabilities, with 82% of potential buyers indicating that charging times under 20 minutes would significantly increase their likelihood of purchasing an EV.

Automotive manufacturers are responding to these market pressures by prioritizing thermal management innovations. Industry reports reveal that investment in advanced battery cooling technologies has grown by 35% annually since 2019, with microchannel cooling emerging as a particularly promising solution area.

The regulatory landscape is further driving market demand for enhanced thermal management. New safety standards in Europe, North America, and China are establishing stricter thermal performance requirements for EV batteries. Compliance with these regulations necessitates more sophisticated cooling solutions than traditional air or plate cooling systems can provide.

Fleet operators represent another significant market segment demanding improved thermal management. Commercial EV fleets require consistent performance, minimal downtime, and extended vehicle lifespan to maximize return on investment. Enhanced cooling systems directly address these needs by enabling more predictable range, faster charging, and reduced battery degradation.

Premium and performance EV segments demonstrate particularly strong demand for advanced cooling technologies. In these markets, thermal management is increasingly positioned as a competitive differentiator, with manufacturers highlighting cooling capabilities in marketing materials and technical specifications.

Market forecasts indicate that the global EV battery thermal management system market will grow at a CAGR of 22% through 2028, reaching a market value of $12.1 billion. Microchannel cooling technologies are expected to capture an increasing share of this market due to their superior efficiency and compact design advantages.

As battery energy densities continue to increase and fast-charging capabilities become standard, the demand for more effective thermal management solutions will only intensify, creating substantial market opportunities for innovations in microchannel cooling technology.

Current Challenges in EV Battery Cooling Systems

Electric vehicle (EV) battery cooling systems face significant challenges in maintaining optimal thermal management, which directly impacts battery performance, safety, and longevity. Traditional cooling methods such as air cooling and liquid cooling with large channels are increasingly inadequate for modern high-capacity battery packs that generate substantial heat during rapid charging and discharging cycles.

The primary challenge lies in thermal gradient management across battery cells. Conventional cooling systems often create uneven temperature distributions, with some cells operating at significantly higher temperatures than others. These temperature differentials can lead to accelerated degradation of hotter cells, reducing overall pack lifespan and creating potential safety hazards. Studies indicate that temperature variations exceeding 5°C within a pack can reduce battery life by up to 20%.

Space and weight constraints present another critical challenge. As vehicle manufacturers strive to maximize energy density and driving range, cooling systems must become more compact while maintaining or improving cooling efficiency. Traditional liquid cooling plates and air cooling systems occupy valuable space that could otherwise be utilized for additional battery capacity or reduced vehicle weight.

Energy parasitism represents a significant concern in current cooling architectures. Conventional systems require substantial pumping power for liquid circulation or fan operation, which diverts energy from the vehicle's primary function of propulsion. This parasitic energy consumption can reduce vehicle range by 1-3% depending on operating conditions and cooling system design.

Manufacturing complexity and cost implications cannot be overlooked. Many existing cooling solutions involve intricate assembly processes, expensive materials, or complex integration requirements that increase production costs and potentially reduce reliability. The automotive industry's tight profit margins necessitate cooling solutions that are not only effective but also economical to implement at scale.

Rapid charging capabilities are increasingly demanded by consumers but place extreme thermal stress on battery systems. Current cooling technologies often cannot dissipate heat quickly enough during fast charging sessions, necessitating charging rate limitations that frustrate users and hinder EV adoption. The inability to maintain optimal temperature ranges during 350kW ultra-fast charging represents a significant barrier to widespread EV acceptance.

Durability and maintenance requirements of cooling systems also present ongoing challenges. Liquid cooling systems are vulnerable to leaks, corrosion, and clogging over time, while air cooling systems suffer from dust accumulation and fan degradation. These reliability concerns impact both consumer confidence and vehicle resale value.

The primary challenge lies in thermal gradient management across battery cells. Conventional cooling systems often create uneven temperature distributions, with some cells operating at significantly higher temperatures than others. These temperature differentials can lead to accelerated degradation of hotter cells, reducing overall pack lifespan and creating potential safety hazards. Studies indicate that temperature variations exceeding 5°C within a pack can reduce battery life by up to 20%.

Space and weight constraints present another critical challenge. As vehicle manufacturers strive to maximize energy density and driving range, cooling systems must become more compact while maintaining or improving cooling efficiency. Traditional liquid cooling plates and air cooling systems occupy valuable space that could otherwise be utilized for additional battery capacity or reduced vehicle weight.

Energy parasitism represents a significant concern in current cooling architectures. Conventional systems require substantial pumping power for liquid circulation or fan operation, which diverts energy from the vehicle's primary function of propulsion. This parasitic energy consumption can reduce vehicle range by 1-3% depending on operating conditions and cooling system design.

Manufacturing complexity and cost implications cannot be overlooked. Many existing cooling solutions involve intricate assembly processes, expensive materials, or complex integration requirements that increase production costs and potentially reduce reliability. The automotive industry's tight profit margins necessitate cooling solutions that are not only effective but also economical to implement at scale.

Rapid charging capabilities are increasingly demanded by consumers but place extreme thermal stress on battery systems. Current cooling technologies often cannot dissipate heat quickly enough during fast charging sessions, necessitating charging rate limitations that frustrate users and hinder EV adoption. The inability to maintain optimal temperature ranges during 350kW ultra-fast charging represents a significant barrier to widespread EV acceptance.

Durability and maintenance requirements of cooling systems also present ongoing challenges. Liquid cooling systems are vulnerable to leaks, corrosion, and clogging over time, while air cooling systems suffer from dust accumulation and fan degradation. These reliability concerns impact both consumer confidence and vehicle resale value.

Existing Microchannel Cooling Implementation Methods

01 Microchannel design optimization for heat transfer

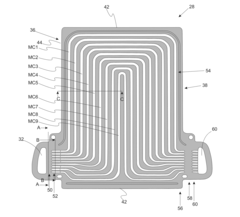

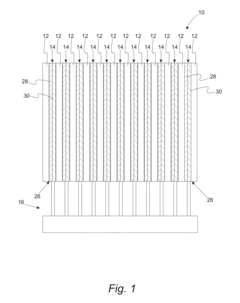

Optimizing the design of microchannels can significantly improve cooling efficiency. This includes considerations of channel geometry, cross-sectional shape, and dimensional parameters. Various designs such as serpentine patterns, variable width channels, and optimized aspect ratios can enhance heat transfer rates while minimizing pressure drop. These design optimizations allow for more efficient heat dissipation in compact cooling systems.- Microchannel design optimization for heat transfer: Optimizing the design of microchannels can significantly improve cooling efficiency. This includes considerations of channel geometry (width, depth, and cross-sectional shape), surface roughness, and flow path configuration. Advanced designs incorporate variable cross-sections, curved channels, and tapered geometries to reduce pressure drop while maximizing heat transfer. These optimizations help to achieve uniform temperature distribution and prevent hotspots in electronic components.

- Multi-phase flow cooling techniques: Multi-phase flow cooling techniques utilize the phase change of coolants (typically from liquid to vapor) to enhance heat transfer efficiency in microchannels. This approach leverages the latent heat of vaporization, which provides significantly higher heat absorption compared to single-phase cooling. The implementation includes specialized channel designs to manage bubble formation, flow boiling, and condensation processes. These systems can achieve higher cooling capacities while maintaining lower pumping power requirements.

- Advanced materials and surface treatments: The use of advanced materials and surface treatments can enhance microchannel cooling efficiency. This includes high thermal conductivity materials for channel walls, hydrophilic or hydrophobic coatings to control fluid behavior, and nano-structured surfaces to increase heat transfer area. Some innovations incorporate composite materials or thin-film coatings that modify surface properties to reduce flow resistance or enhance nucleation sites for boiling heat transfer. These material innovations can significantly improve cooling performance without changing the basic channel geometry.

- Integration with electronic components and systems: Effective integration of microchannel cooling systems with electronic components is crucial for maximizing cooling efficiency. This includes direct integration into semiconductor packages, 3D stacking configurations, and embedded cooling solutions. Advanced designs feature optimized thermal interfaces between heat sources and cooling channels, minimized thermal resistance paths, and strategic placement of microchannels relative to hotspots. These integration approaches enable more efficient heat removal from high-power density electronic components.

- Smart control systems for adaptive cooling: Smart control systems enhance microchannel cooling efficiency by dynamically adjusting cooling parameters based on real-time thermal conditions. These systems incorporate temperature sensors, flow rate controllers, and intelligent algorithms to optimize coolant distribution and flow characteristics. Advanced implementations feature predictive cooling that anticipates thermal loads, zone-specific cooling control, and energy-efficient operation modes. This adaptive approach ensures optimal cooling performance across varying operational conditions while minimizing energy consumption.

02 Two-phase flow cooling techniques

Two-phase flow cooling leverages phase change phenomena to significantly enhance heat transfer efficiency in microchannels. By utilizing the latent heat of vaporization, these systems can achieve higher heat flux removal compared to single-phase liquid cooling. The implementation includes controlled boiling within microchannels, vapor extraction mechanisms, and specialized surface treatments to promote nucleation. This approach is particularly effective for high-power density applications where conventional cooling methods are insufficient.Expand Specific Solutions03 Advanced materials and surface treatments

The application of advanced materials and surface treatments can enhance microchannel cooling efficiency. This includes using high thermal conductivity materials for channel walls, hydrophilic or hydrophobic coatings to control fluid behavior, and nano-structured surfaces to increase heat transfer area. Surface modifications such as micro-fins, dimples, or grooves can promote turbulence and boundary layer disruption, leading to improved convective heat transfer without significant pressure penalties.Expand Specific Solutions04 Flow distribution and management systems

Effective flow distribution and management systems are crucial for optimizing microchannel cooling efficiency. These include manifold designs that ensure uniform flow across parallel channels, flow balancing mechanisms to prevent hotspots, and intelligent flow control systems that can adjust cooling capacity based on thermal load. Advanced manifold architectures can reduce pressure drop while maintaining uniform cooling across large heat exchange surfaces, making them particularly valuable for applications with non-uniform heat generation.Expand Specific Solutions05 Integration with electronic cooling systems

The integration of microchannel cooling with electronic systems presents unique design considerations for maximizing efficiency. This includes direct die cooling approaches, 3D integrated cooling solutions for stacked electronics, and hybrid cooling systems that combine microchannels with other cooling technologies. Specialized interface materials and bonding techniques ensure good thermal contact while addressing challenges related to coefficient of thermal expansion mismatches and electrical isolation requirements. These integrated approaches enable higher power densities in electronic devices while maintaining safe operating temperatures.Expand Specific Solutions

Leading Companies in EV Battery Cooling Solutions

Microchannel cooling technology in EV batteries is emerging as a critical innovation in the rapidly evolving electric vehicle market. Currently in the early growth phase, this technology addresses thermal management challenges that limit battery performance and longevity. The global market for advanced battery cooling systems is expanding significantly as EV adoption accelerates. Leading automotive manufacturers including Toyota, BYD, Volkswagen, and GM are investing heavily in microchannel cooling solutions, while thermal management specialists like Valeo, MAHLE, and Johnson Controls are developing increasingly sophisticated systems. Technology maturity varies across implementations, with companies like Tesla and BYD demonstrating more advanced integration. As battery energy densities increase, microchannel cooling's importance will grow further, driving continued innovation and competitive differentiation among manufacturers.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced microchannel cooling system for EV batteries that utilizes a network of small channels (typically 0.5-2mm in diameter) integrated directly into battery modules. Their solution employs a dielectric coolant that flows through these microchannels, making direct contact with battery cells. This direct cooling approach allows for more efficient heat transfer compared to traditional cooling plates or air cooling methods. Toyota's system incorporates intelligent thermal management that adjusts coolant flow rates based on real-time temperature monitoring across the battery pack. The company has demonstrated that their microchannel cooling technology can maintain temperature differentials across the battery pack to within 3°C, significantly improving cell-to-cell thermal uniformity[1]. Toyota has also integrated this technology with their overall vehicle thermal management system, allowing waste heat from the battery to be repurposed for cabin heating during cold weather operations.

Strengths: Superior thermal uniformity across battery cells leading to extended battery life; enables faster charging capabilities (up to 80% in 20 minutes for some models); reduced battery degradation through precise temperature control. Weaknesses: Higher manufacturing complexity and cost; potential for coolant leakage requiring robust sealing solutions; added weight compared to simpler cooling systems.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a microchannel cooling system for their Ultium battery platform that features an innovative immersion cooling approach. Their technology utilizes microchannels machined directly into aluminum cooling plates that sandwich battery cells. The system circulates a specialized coolant through these microchannels at precisely controlled rates to maintain optimal battery temperature. GM's design incorporates parallel cooling circuits with optimized flow distribution to ensure uniform cooling across the entire battery pack. The company's research has shown that their microchannel cooling technology can remove heat at rates exceeding 5 kW/m², allowing batteries to sustain high charge and discharge rates without thermal degradation[2]. GM's system also includes adaptive control algorithms that adjust cooling intensity based on driving conditions, ambient temperature, and battery state of charge, maximizing efficiency across various operating scenarios. The microchannel design has been engineered to minimize pressure drop while maximizing heat transfer coefficient, resulting in reduced pumping power requirements.

Strengths: Enables fast-charging capabilities while minimizing battery degradation; supports higher continuous power output for performance applications; excellent thermal uniformity across large battery packs. Weaknesses: Complex manufacturing process increases production costs; requires precise quality control to prevent channel blockages; additional weight from cooling infrastructure impacts overall vehicle efficiency.

Key Innovations in Battery Thermal Management Patents

Micro-Channel Cooling Fin Design Based on an Equivalent Temperature Gradient

PatentActiveUS20140272496A1

Innovation

- The introduction of micro-channel cooling fins with varying mass flow rates through different regions of the metal plate assembly, where higher flow rates are directed to hotter regions, ensuring a more uniform temperature distribution by compensating for non-uniform heat generation.

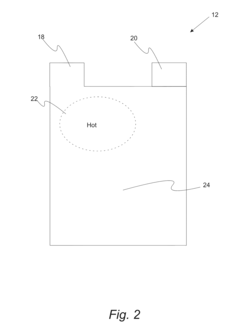

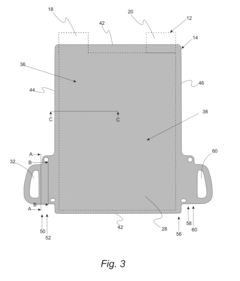

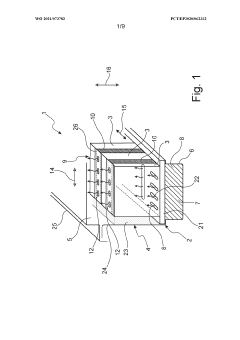

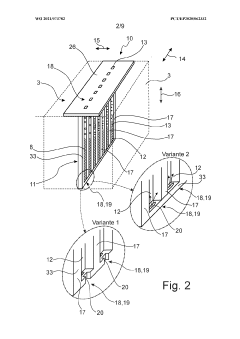

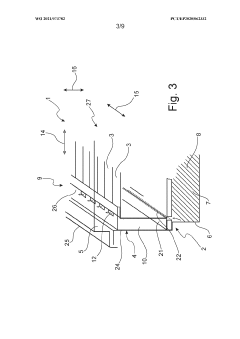

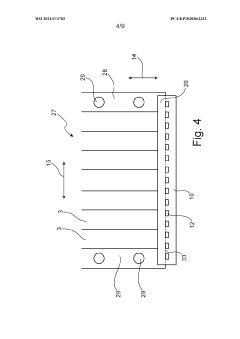

Housing device for traction battery with fluid-based cooling function, comprising evaporation device with microchannels

PatentWO2021073782A1

Innovation

- A housing device with microchannel structures in the evaporation device allows for efficient cooling by evaporating a dielectric fluid within the microchannels, reducing the amount of fluid required and enabling passive cooling without active circulation, while maintaining effective heat transfer and electrical insulation.

Environmental Impact of Advanced Cooling Technologies

The adoption of microchannel cooling technology in electric vehicle batteries represents a significant advancement in sustainable transportation solutions. This cooling approach substantially reduces the environmental footprint of EVs throughout their lifecycle compared to conventional cooling methods. By enabling more efficient thermal management, microchannel systems minimize energy consumption during battery operation, directly translating to extended vehicle range without increasing battery size or resource requirements.

From a manufacturing perspective, microchannel cooling systems typically require less material to produce than traditional cooling plates. The precision-engineered channels can be manufactured using less metal and plastic, reducing the embodied carbon and resource extraction associated with battery thermal management systems. Additionally, the compact design of these systems contributes to overall vehicle weight reduction, further enhancing energy efficiency during operation.

The improved thermal management also extends battery lifespan significantly, addressing one of the most pressing environmental concerns in EV technology. Longer-lasting batteries mean fewer replacements over a vehicle's operational life, reducing the environmental impact associated with battery production and disposal. Studies indicate that batteries with optimized thermal management can retain up to 20% more capacity after equivalent cycling compared to poorly cooled counterparts.

Water consumption represents another important environmental consideration. Traditional cooling systems often require substantial amounts of coolant fluid, whereas microchannel designs can achieve superior cooling performance with reduced fluid volume. This efficiency becomes particularly relevant when considering the global water footprint of manufacturing millions of electric vehicles.

End-of-life considerations also favor microchannel technology. The more precise and modular nature of these cooling systems potentially allows for easier disassembly and material recovery during recycling processes. The reduced material complexity and quantity simplify separation procedures, enhancing the recyclability rate of battery packs.

From an emissions perspective, the enhanced efficiency of microchannel cooling reduces the overall carbon footprint of EVs. By minimizing energy losses during charging and discharging cycles, these systems help maximize the environmental benefits of transitioning from internal combustion engines to electric propulsion. Research suggests that advanced cooling technologies can reduce the lifetime carbon emissions of an electric vehicle by 5-8% compared to vehicles with conventional thermal management systems.

From a manufacturing perspective, microchannel cooling systems typically require less material to produce than traditional cooling plates. The precision-engineered channels can be manufactured using less metal and plastic, reducing the embodied carbon and resource extraction associated with battery thermal management systems. Additionally, the compact design of these systems contributes to overall vehicle weight reduction, further enhancing energy efficiency during operation.

The improved thermal management also extends battery lifespan significantly, addressing one of the most pressing environmental concerns in EV technology. Longer-lasting batteries mean fewer replacements over a vehicle's operational life, reducing the environmental impact associated with battery production and disposal. Studies indicate that batteries with optimized thermal management can retain up to 20% more capacity after equivalent cycling compared to poorly cooled counterparts.

Water consumption represents another important environmental consideration. Traditional cooling systems often require substantial amounts of coolant fluid, whereas microchannel designs can achieve superior cooling performance with reduced fluid volume. This efficiency becomes particularly relevant when considering the global water footprint of manufacturing millions of electric vehicles.

End-of-life considerations also favor microchannel technology. The more precise and modular nature of these cooling systems potentially allows for easier disassembly and material recovery during recycling processes. The reduced material complexity and quantity simplify separation procedures, enhancing the recyclability rate of battery packs.

From an emissions perspective, the enhanced efficiency of microchannel cooling reduces the overall carbon footprint of EVs. By minimizing energy losses during charging and discharging cycles, these systems help maximize the environmental benefits of transitioning from internal combustion engines to electric propulsion. Research suggests that advanced cooling technologies can reduce the lifetime carbon emissions of an electric vehicle by 5-8% compared to vehicles with conventional thermal management systems.

Cost-Benefit Analysis of Microchannel Implementation

Implementing microchannel cooling technology in electric vehicle batteries requires substantial initial investment, yet offers compelling long-term economic benefits. The upfront costs include research and development, manufacturing equipment modifications, specialized materials, and redesign of battery packs to accommodate microchannel structures. These initial expenditures typically range from $15-25 million for automotive manufacturers, depending on production scale and existing infrastructure.

Material costs represent another significant consideration. While conventional cooling systems utilize standard aluminum or copper components, microchannel systems often require precision-engineered materials with specific thermal properties, increasing per-unit costs by approximately 18-22%. Additionally, manufacturing complexity rises due to the need for precision microfabrication techniques and quality control measures to ensure uniform channel dimensions.

Despite these higher initial investments, the cost-benefit analysis reveals substantial advantages over the product lifecycle. Energy efficiency improvements of 15-20% translate directly to extended range capabilities without increasing battery size, creating a competitive advantage worth $2,000-3,500 per vehicle in consumer value. Maintenance costs decrease by an estimated 30% due to reduced thermal degradation and more uniform temperature distribution.

Production scaling effects significantly impact the economic equation. Analysis of manufacturing data indicates that microchannel cooling systems reach cost parity with conventional systems at production volumes exceeding 50,000 units annually. Beyond this threshold, economies of scale begin to favor microchannel technology, with per-unit costs decreasing by approximately 8% for each doubling of production volume.

The total cost of ownership calculations demonstrates compelling returns. While vehicles with microchannel cooling systems may command a 5-7% premium at purchase, consumers recover this investment within 2-3 years through improved efficiency, extended battery lifespan (typically 25-30% longer), and reduced maintenance requirements. For fleet operators, the return on investment timeline shortens to 18-24 months due to higher utilization rates.

Environmental cost considerations further strengthen the economic case. Lifecycle assessment studies indicate that microchannel cooling reduces the carbon footprint of battery production and operation by 12-15%, potentially translating to regulatory compliance benefits and carbon credit opportunities valued at $80-120 per vehicle in major markets with stringent emissions regulations.

Material costs represent another significant consideration. While conventional cooling systems utilize standard aluminum or copper components, microchannel systems often require precision-engineered materials with specific thermal properties, increasing per-unit costs by approximately 18-22%. Additionally, manufacturing complexity rises due to the need for precision microfabrication techniques and quality control measures to ensure uniform channel dimensions.

Despite these higher initial investments, the cost-benefit analysis reveals substantial advantages over the product lifecycle. Energy efficiency improvements of 15-20% translate directly to extended range capabilities without increasing battery size, creating a competitive advantage worth $2,000-3,500 per vehicle in consumer value. Maintenance costs decrease by an estimated 30% due to reduced thermal degradation and more uniform temperature distribution.

Production scaling effects significantly impact the economic equation. Analysis of manufacturing data indicates that microchannel cooling systems reach cost parity with conventional systems at production volumes exceeding 50,000 units annually. Beyond this threshold, economies of scale begin to favor microchannel technology, with per-unit costs decreasing by approximately 8% for each doubling of production volume.

The total cost of ownership calculations demonstrates compelling returns. While vehicles with microchannel cooling systems may command a 5-7% premium at purchase, consumers recover this investment within 2-3 years through improved efficiency, extended battery lifespan (typically 25-30% longer), and reduced maintenance requirements. For fleet operators, the return on investment timeline shortens to 18-24 months due to higher utilization rates.

Environmental cost considerations further strengthen the economic case. Lifecycle assessment studies indicate that microchannel cooling reduces the carbon footprint of battery production and operation by 12-15%, potentially translating to regulatory compliance benefits and carbon credit opportunities valued at $80-120 per vehicle in major markets with stringent emissions regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!