How Microchannel Cooling Optimizes Heat Rejection in HVAC Systems

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Background and Objectives

Microchannel cooling technology represents a significant advancement in heat transfer mechanisms, evolving from traditional fin-and-tube heat exchangers that have dominated HVAC systems for decades. This technology originated in the automotive industry during the 1980s and has gradually expanded into commercial and residential HVAC applications over the past twenty years. The fundamental principle involves replacing conventional refrigerant tubes with multiple parallel microchannels, typically with hydraulic diameters ranging from 0.2 to 3 millimeters.

The evolution of microchannel technology has been driven by increasing demands for energy efficiency, space optimization, and refrigerant charge reduction in cooling systems. Early implementations faced challenges with distribution, manufacturing precision, and corrosion resistance. However, continuous refinement has addressed many of these limitations, leading to broader adoption across various thermal management applications.

Current technological trends indicate a shift toward even smaller channel dimensions, advanced manufacturing techniques including 3D printing of microchannel structures, and integration with smart control systems for dynamic performance optimization. The convergence of microchannel cooling with IoT capabilities represents the next frontier in this technology's development trajectory.

The primary technical objectives for microchannel cooling in HVAC systems center around maximizing heat rejection capacity while minimizing system footprint and material usage. Specifically, research aims to achieve 20-30% higher heat transfer coefficients compared to conventional technologies, reduce refrigerant charge by 30-40%, and decrease air-side pressure drop by 15-25% to lower fan power consumption.

Additional objectives include enhancing system durability through improved corrosion resistance, developing cost-effective manufacturing processes to reduce the price premium currently associated with microchannel technology, and optimizing refrigerant distribution to ensure uniform cooling across the entire heat exchanger surface. These improvements collectively target a 10-15% reduction in overall system energy consumption.

Long-term technological goals involve the development of adaptive microchannel geometries that can modify their configuration based on operating conditions, integration with low-GWP refrigerants to meet environmental regulations, and the creation of hybrid systems that combine microchannel technology with other emerging cooling approaches such as membrane-based dehumidification or thermoelectric cooling.

The intersection of microchannel cooling with broader industry trends toward decarbonization and electrification presents opportunities for revolutionary rather than evolutionary advancements. As building systems increasingly shift toward heat pump technologies and all-electric solutions, microchannel heat exchangers are positioned to become a cornerstone technology enabling higher efficiency and smaller equipment footprints in next-generation HVAC systems.

The evolution of microchannel technology has been driven by increasing demands for energy efficiency, space optimization, and refrigerant charge reduction in cooling systems. Early implementations faced challenges with distribution, manufacturing precision, and corrosion resistance. However, continuous refinement has addressed many of these limitations, leading to broader adoption across various thermal management applications.

Current technological trends indicate a shift toward even smaller channel dimensions, advanced manufacturing techniques including 3D printing of microchannel structures, and integration with smart control systems for dynamic performance optimization. The convergence of microchannel cooling with IoT capabilities represents the next frontier in this technology's development trajectory.

The primary technical objectives for microchannel cooling in HVAC systems center around maximizing heat rejection capacity while minimizing system footprint and material usage. Specifically, research aims to achieve 20-30% higher heat transfer coefficients compared to conventional technologies, reduce refrigerant charge by 30-40%, and decrease air-side pressure drop by 15-25% to lower fan power consumption.

Additional objectives include enhancing system durability through improved corrosion resistance, developing cost-effective manufacturing processes to reduce the price premium currently associated with microchannel technology, and optimizing refrigerant distribution to ensure uniform cooling across the entire heat exchanger surface. These improvements collectively target a 10-15% reduction in overall system energy consumption.

Long-term technological goals involve the development of adaptive microchannel geometries that can modify their configuration based on operating conditions, integration with low-GWP refrigerants to meet environmental regulations, and the creation of hybrid systems that combine microchannel technology with other emerging cooling approaches such as membrane-based dehumidification or thermoelectric cooling.

The intersection of microchannel cooling with broader industry trends toward decarbonization and electrification presents opportunities for revolutionary rather than evolutionary advancements. As building systems increasingly shift toward heat pump technologies and all-electric solutions, microchannel heat exchangers are positioned to become a cornerstone technology enabling higher efficiency and smaller equipment footprints in next-generation HVAC systems.

HVAC Market Demand Analysis for Advanced Cooling Solutions

The HVAC market is experiencing a significant shift towards more efficient and environmentally friendly cooling solutions, driven by increasing energy costs, stringent regulations, and growing environmental awareness. The global HVAC market was valued at approximately $135.6 billion in 2021 and is projected to reach $208.5 billion by 2028, with a compound annual growth rate of 6.3%. Within this expanding market, advanced cooling technologies, particularly microchannel cooling systems, are gaining substantial traction.

Commercial buildings represent the largest segment demanding advanced cooling solutions, accounting for nearly 40% of the market share. This is primarily due to the increasing construction of energy-efficient green buildings and the retrofitting of existing structures to meet new environmental standards. Data centers form another rapidly growing segment, with cooling requirements expected to increase by 15% annually through 2026, driven by the expansion of cloud computing and big data applications.

The healthcare sector presents a specialized market for precision cooling systems, where stable temperature control is critical for medical equipment and patient comfort. This sector is expected to grow at 7.2% annually in terms of HVAC system adoption. Additionally, the residential sector is showing increased interest in high-efficiency cooling solutions, with consumer willingness to pay premium prices for systems that offer long-term energy savings.

Geographically, Asia-Pacific represents the fastest-growing market for advanced cooling technologies, with China and India leading the demand due to rapid urbanization and increasing disposable incomes. North America and Europe remain significant markets, primarily driven by replacement demand and stringent energy efficiency regulations.

Market research indicates that consumers are increasingly prioritizing energy efficiency, with 68% of commercial building owners citing energy cost reduction as their primary motivation for upgrading HVAC systems. The demand for systems with lower environmental impact is also rising, with 53% of new installations in developed markets featuring low-GWP refrigerants.

Microchannel cooling technology specifically addresses these market demands by offering 20-30% higher energy efficiency compared to traditional cooling methods. The technology's compact design also meets the growing market need for space-efficient solutions in urban environments where real estate premiums are high.

Industry surveys reveal that 72% of HVAC contractors report increased customer inquiries about advanced cooling technologies, with microchannel systems mentioned specifically in 45% of these inquiries. This indicates growing market awareness and interest in this technology's benefits, suggesting a robust demand trajectory for microchannel cooling solutions in the coming years.

Commercial buildings represent the largest segment demanding advanced cooling solutions, accounting for nearly 40% of the market share. This is primarily due to the increasing construction of energy-efficient green buildings and the retrofitting of existing structures to meet new environmental standards. Data centers form another rapidly growing segment, with cooling requirements expected to increase by 15% annually through 2026, driven by the expansion of cloud computing and big data applications.

The healthcare sector presents a specialized market for precision cooling systems, where stable temperature control is critical for medical equipment and patient comfort. This sector is expected to grow at 7.2% annually in terms of HVAC system adoption. Additionally, the residential sector is showing increased interest in high-efficiency cooling solutions, with consumer willingness to pay premium prices for systems that offer long-term energy savings.

Geographically, Asia-Pacific represents the fastest-growing market for advanced cooling technologies, with China and India leading the demand due to rapid urbanization and increasing disposable incomes. North America and Europe remain significant markets, primarily driven by replacement demand and stringent energy efficiency regulations.

Market research indicates that consumers are increasingly prioritizing energy efficiency, with 68% of commercial building owners citing energy cost reduction as their primary motivation for upgrading HVAC systems. The demand for systems with lower environmental impact is also rising, with 53% of new installations in developed markets featuring low-GWP refrigerants.

Microchannel cooling technology specifically addresses these market demands by offering 20-30% higher energy efficiency compared to traditional cooling methods. The technology's compact design also meets the growing market need for space-efficient solutions in urban environments where real estate premiums are high.

Industry surveys reveal that 72% of HVAC contractors report increased customer inquiries about advanced cooling technologies, with microchannel systems mentioned specifically in 45% of these inquiries. This indicates growing market awareness and interest in this technology's benefits, suggesting a robust demand trajectory for microchannel cooling solutions in the coming years.

Current Microchannel Heat Exchanger Technologies and Challenges

Microchannel heat exchangers (MCHEs) represent a significant advancement in HVAC thermal management technology, offering substantial improvements over conventional fin-and-tube heat exchangers. Current MCHE designs typically feature aluminum extrusions with multiple parallel channels ranging from 0.5mm to 2mm in hydraulic diameter, allowing for enhanced heat transfer coefficients and reduced refrigerant charge requirements.

The primary commercial MCHE technologies include parallel flow condensers, evaporators, and oil coolers, with market penetration most advanced in automotive air conditioning and increasingly in residential and commercial HVAC systems. Leading manufacturers have developed proprietary manufacturing techniques for channel formation, header design, and brazing processes that significantly impact performance characteristics.

Despite their advantages, MCHEs face several critical challenges that limit broader adoption. Refrigerant maldistribution remains a persistent issue, particularly in evaporator applications, where non-uniform flow across parallel channels can reduce thermal efficiency by up to 30%. Current header designs struggle to achieve optimal flow distribution, especially under variable load conditions.

Manufacturing complexity presents another significant hurdle. The production of MCHEs requires precise extrusion processes, complex brazing techniques, and specialized tooling that increases production costs compared to traditional heat exchangers. Tolerance control during manufacturing directly impacts channel uniformity and subsequent performance.

Fouling susceptibility represents a substantial operational challenge for MCHEs. The narrow channels are particularly vulnerable to particulate accumulation and biological growth, with research indicating performance degradation of 15-25% after extended operation in typical commercial environments. Current cleaning protocols often prove inadequate for restoring full performance without risking damage to the delicate channel structures.

Pressure drop considerations also present design challenges. While smaller channels enhance heat transfer, they simultaneously increase fluid resistance. Engineers must carefully balance thermal performance against pumping power requirements, with current designs typically operating at 20-40% higher pressure drops than conventional heat exchangers for equivalent capacity.

Material compatibility issues further complicate MCHE implementation, particularly with newer refrigerants. Aluminum channels can experience accelerated corrosion with certain refrigerant-oil combinations, while copper alternatives increase cost and manufacturing complexity. Current research focuses on developing corrosion-resistant coatings and alternative materials to address these limitations.

Freeze resistance remains problematic in certain applications, as the small hydraulic diameter channels are more susceptible to blockage from ice formation. This vulnerability has limited MCHE adoption in low-temperature refrigeration systems and heat pumps operating in cold climates.

The primary commercial MCHE technologies include parallel flow condensers, evaporators, and oil coolers, with market penetration most advanced in automotive air conditioning and increasingly in residential and commercial HVAC systems. Leading manufacturers have developed proprietary manufacturing techniques for channel formation, header design, and brazing processes that significantly impact performance characteristics.

Despite their advantages, MCHEs face several critical challenges that limit broader adoption. Refrigerant maldistribution remains a persistent issue, particularly in evaporator applications, where non-uniform flow across parallel channels can reduce thermal efficiency by up to 30%. Current header designs struggle to achieve optimal flow distribution, especially under variable load conditions.

Manufacturing complexity presents another significant hurdle. The production of MCHEs requires precise extrusion processes, complex brazing techniques, and specialized tooling that increases production costs compared to traditional heat exchangers. Tolerance control during manufacturing directly impacts channel uniformity and subsequent performance.

Fouling susceptibility represents a substantial operational challenge for MCHEs. The narrow channels are particularly vulnerable to particulate accumulation and biological growth, with research indicating performance degradation of 15-25% after extended operation in typical commercial environments. Current cleaning protocols often prove inadequate for restoring full performance without risking damage to the delicate channel structures.

Pressure drop considerations also present design challenges. While smaller channels enhance heat transfer, they simultaneously increase fluid resistance. Engineers must carefully balance thermal performance against pumping power requirements, with current designs typically operating at 20-40% higher pressure drops than conventional heat exchangers for equivalent capacity.

Material compatibility issues further complicate MCHE implementation, particularly with newer refrigerants. Aluminum channels can experience accelerated corrosion with certain refrigerant-oil combinations, while copper alternatives increase cost and manufacturing complexity. Current research focuses on developing corrosion-resistant coatings and alternative materials to address these limitations.

Freeze resistance remains problematic in certain applications, as the small hydraulic diameter channels are more susceptible to blockage from ice formation. This vulnerability has limited MCHE adoption in low-temperature refrigeration systems and heat pumps operating in cold climates.

Current Microchannel Implementation Strategies for Heat Rejection

01 Microchannel heat exchanger design for electronic cooling

Microchannel heat exchangers are designed specifically for cooling electronic components, featuring small hydraulic diameter channels that enhance heat transfer efficiency. These designs incorporate optimized channel geometries, flow distributions, and surface area-to-volume ratios to maximize cooling performance while minimizing space requirements. The microchannels facilitate efficient heat rejection from high-power density electronic components such as processors, power modules, and other heat-generating devices.- Microchannel heat exchanger design for electronic cooling: Microchannel heat exchangers are designed specifically for electronic cooling applications, featuring small hydraulic diameter channels that enhance heat transfer efficiency. These designs incorporate optimized channel geometries, flow arrangements, and surface treatments to maximize thermal performance while minimizing pressure drop. The compact nature of these heat exchangers allows for effective cooling of high-power density electronic components such as processors, power modules, and LED arrays.

- Two-phase cooling systems with microchannels: Two-phase cooling systems utilize microchannels to achieve enhanced heat rejection through phase change processes. These systems leverage the latent heat of vaporization of working fluids to remove large amounts of heat while maintaining relatively uniform temperatures. The microchannel structures are designed to promote controlled boiling and condensation, with specialized surface features to manage vapor formation and liquid distribution. This approach enables significantly higher heat flux capabilities compared to single-phase liquid cooling methods.

- Integrated microchannel cooling for power electronics: Integrated microchannel cooling solutions are specifically designed for power electronics applications, where they are directly incorporated into semiconductor packages or substrates. These systems feature microchannels etched or fabricated into the device substrate or attached as close as possible to the heat source. The integration minimizes thermal resistance and allows for efficient heat removal from high-power components such as IGBTs, MOSFETs, and power converters, enabling higher power densities and improved reliability.

- Advanced manufacturing techniques for microchannel heat sinks: Advanced manufacturing techniques enable the production of complex microchannel heat sink geometries that would be difficult or impossible to create using conventional methods. These techniques include additive manufacturing, chemical etching, micro-machining, and advanced bonding processes. The resulting structures can incorporate optimized channel cross-sections, variable channel dimensions, and integrated manifolds to distribute flow evenly. These manufacturing approaches allow for customized thermal solutions that maximize heat rejection while minimizing material usage and weight.

- Hybrid cooling systems with microchannels: Hybrid cooling systems combine microchannel technology with other cooling methods to achieve enhanced thermal performance across varying operating conditions. These systems may integrate microchannels with air cooling, thermoelectric elements, phase change materials, or jet impingement cooling. The hybrid approach allows for adaptive thermal management that can respond to changing heat loads and environmental conditions. Such systems often incorporate intelligent control mechanisms to optimize the operation of each cooling mode, resulting in improved energy efficiency and thermal performance.

02 Two-phase cooling systems with microchannels

Two-phase cooling systems utilize microchannels to enhance heat rejection through phase change processes. These systems employ working fluids that evaporate within the microchannels, absorbing significant heat through latent heat transfer. The vapor is then condensed in a separate section, and the liquid is returned to the evaporator section, creating a continuous cooling cycle. This approach provides higher heat transfer coefficients compared to single-phase systems, making it particularly effective for high heat flux applications.Expand Specific Solutions03 Integration of microchannels with heat sinks and cold plates

Microchannel structures are integrated with traditional heat sinks and cold plates to create hybrid cooling solutions. These designs combine the high heat transfer efficiency of microchannels with the robustness and reliability of conventional cooling methods. The integration involves embedding microchannel structures within larger heat sink bodies or creating modular systems where microchannel cold plates interface with heat-generating components. This approach allows for targeted cooling of high heat flux areas while maintaining overall system thermal management.Expand Specific Solutions04 Microchannel cooling for power electronics and high-performance computing

Specialized microchannel cooling solutions are developed for power electronics and high-performance computing applications that generate significant heat. These systems feature customized channel geometries, flow distributions, and manifold designs tailored to the specific thermal requirements of power semiconductors, high-performance processors, and data center equipment. The cooling solutions address both steady-state and transient thermal loads, ensuring reliable operation under varying computational or power conversion demands.Expand Specific Solutions05 Advanced manufacturing techniques for microchannel cooling systems

Novel manufacturing methods enable the production of complex microchannel cooling systems with enhanced performance characteristics. These techniques include additive manufacturing, chemical etching, micro-machining, and advanced bonding processes that allow for the creation of intricate channel geometries and multi-layer structures. The manufacturing approaches facilitate the integration of microchannels with different materials and components, enabling cost-effective production of high-performance cooling solutions with optimized thermal-hydraulic characteristics.Expand Specific Solutions

Leading Manufacturers and Competitors in Microchannel HVAC Market

Microchannel cooling technology in HVAC systems is currently in a growth phase, with the market expected to expand significantly due to increasing demand for energy-efficient thermal management solutions. The global market size for microchannel heat exchangers is projected to reach several billion dollars by 2025, driven by stringent energy regulations and sustainability initiatives. Technologically, the field shows varying maturity levels across players. Industry leaders like Gree Electric Appliances and Haier Smart Home have commercialized advanced microchannel solutions in residential and commercial air conditioning, while Intel and Fujitsu are pioneering applications in electronics cooling. Research institutions including École Polytechnique Fédérale de Lausanne, Xi'an Jiaotong University, and HRL Laboratories are advancing fundamental innovations through experimental prototypes and computational modeling, bridging the gap between theoretical concepts and practical implementation.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed advanced microchannel heat exchangers (MCHE) for their HVAC systems that utilize aluminum flat tubes with multiple small parallel channels (typically 0.5-2mm in diameter). Their technology implements optimized refrigerant distribution systems that ensure uniform flow across all microchannels, significantly improving heat transfer efficiency. Gree's approach includes specialized header designs that minimize flow maldistribution issues common in microchannel systems. Their R&D has focused on surface enhancement techniques within the microchannels, incorporating micro-fins and specialized geometries that increase turbulence and heat transfer area while maintaining manageable pressure drops. Gree has also developed proprietary manufacturing processes for their MCHE that allow for cost-effective mass production while maintaining tight tolerances necessary for optimal performance.

Strengths: Superior thermal efficiency with up to 30% higher heat transfer coefficients compared to traditional fin-tube designs; reduced refrigerant charge requirements (40-50% less); compact design allowing for smaller HVAC footprints. Weaknesses: Higher manufacturing precision requirements leading to increased production costs; greater susceptibility to fouling and blockage in certain operating environments; more complex defrosting requirements in heating mode applications.

Advanced Liquid Cooling Technologies, Inc.

Technical Solution: Advanced Liquid Cooling Technologies (ALCT) has developed a specialized microchannel cooling solution specifically optimized for HVAC applications. Their proprietary technology utilizes high-precision microchannels ranging from 100-500 micrometers in width, fabricated using advanced manufacturing techniques including selective laser sintering and precision CNC micromachining. ALCT's innovation centers on their patented "flow oscillation" design that creates controlled turbulence within microchannels to disrupt thermal boundary layers while minimizing pressure penalties. Their systems incorporate specialized manifold designs that ensure uniform flow distribution across parallel microchannel arrays, addressing the common challenge of flow maldistribution. ALCT has also developed specialized surface treatments for the internal microchannel walls that enhance nucleate boiling in evaporator applications, with engineered nucleation sites that promote efficient phase change. Their comprehensive approach includes integrated sensors and control systems that dynamically adjust flow parameters based on real-time heat load conditions.

Strengths: Exceptional thermal performance with heat transfer coefficients up to 3 times higher than conventional technologies; compact design enabling significant space savings in HVAC installations; precise temperature control capabilities with ±0.5°C accuracy. Weaknesses: Significantly higher manufacturing costs compared to traditional cooling technologies; requires more sophisticated filtration systems to prevent channel clogging; limited scalability for very large HVAC applications due to manufacturing constraints of high-precision microchannels.

Key Patents and Innovations in Microchannel Cooling Technology

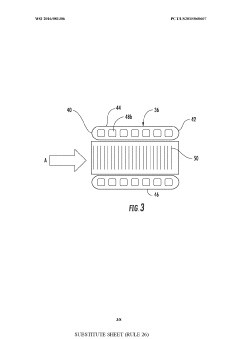

Frost tolerant microchannel heat exchanger

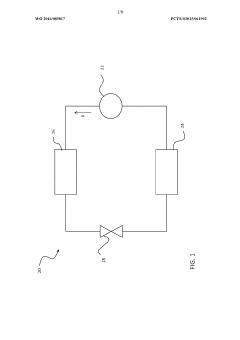

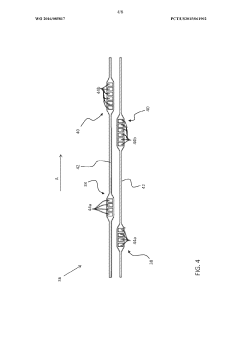

PatentWO2016085817A2

Innovation

- The design incorporates asymmetrical heat exchange tube segments with varying cross-sectional flow areas and a bend configuration that allows for sequential fluid flow and airflow direction changes, optimizing refrigerant flow to minimize frost accumulation by using superheated vapor in larger tubes and liquid or liquid-vapor mixtures in smaller tubes.

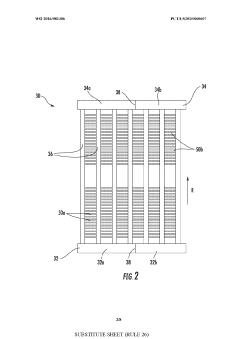

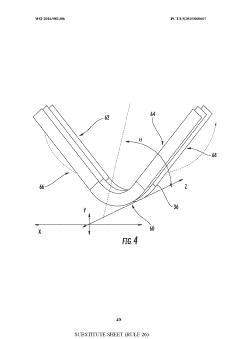

Multi-pass and multi-slab folded microchannel heat exchanger

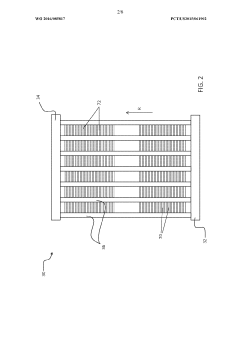

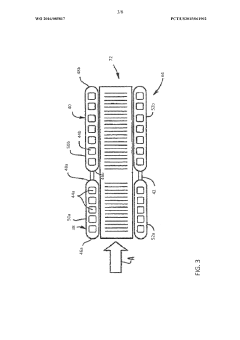

PatentWO2016081306A1

Innovation

- A multi-pass and multi-slab folded microchannel heat exchanger design with a bend forming a first and second slab at an angle, featuring a distributor for even refrigerant distribution and varying numbers of tube segments in each pass to reduce frost formation, allowing for improved airflow orientations such as cross-parallel and cross-counter flow configurations.

Energy Efficiency and Sustainability Impacts of Microchannel Technology

Microchannel technology represents a significant advancement in HVAC system design, offering substantial energy efficiency improvements and sustainability benefits compared to conventional cooling technologies. The implementation of microchannel heat exchangers in HVAC systems has demonstrated energy consumption reductions of 15-30% across various applications, directly translating to lower operational costs and reduced carbon footprints for commercial and residential buildings.

The enhanced heat transfer efficiency of microchannel technology enables HVAC systems to achieve the same cooling capacity while consuming significantly less energy. This efficiency gain stems from the optimized refrigerant flow distribution and increased heat transfer surface area per unit volume, allowing for more effective heat rejection with reduced fan power requirements. Studies have shown that microchannel condensers can operate with up to 40% less refrigerant charge compared to traditional fin-and-tube heat exchangers.

From a sustainability perspective, microchannel technology contributes to environmental conservation through multiple pathways. The reduced refrigerant charge directly minimizes the potential for harmful refrigerant leakage into the atmosphere, addressing concerns related to global warming potential (GWP) and ozone depletion. Additionally, the compact design of microchannel heat exchangers requires fewer raw materials for manufacturing, reducing the embodied energy and carbon footprint associated with production processes.

The lightweight and compact nature of microchannel components further enhances sustainability by reducing transportation emissions and facilitating easier installation and maintenance. These factors extend the lifecycle benefits beyond mere operational efficiency to encompass the entire product lifecycle from manufacturing to disposal.

When integrated into comprehensive building management systems, microchannel-based HVAC solutions enable more precise temperature control and zoning capabilities, further optimizing energy usage based on occupancy patterns and thermal load requirements. This smart integration capability positions microchannel technology as a key enabler for next-generation green buildings and smart city infrastructure.

Economic analyses indicate that despite higher initial investment costs (typically 10-15% premium over conventional systems), microchannel HVAC installations achieve payback periods of 2-4 years in most commercial applications through energy savings alone. When factoring in additional benefits such as reduced maintenance requirements and extended system lifespan, the total cost of ownership demonstrates clear advantages for building operators committed to sustainable operations.

As regulatory frameworks increasingly emphasize energy efficiency standards and carbon emission reductions, microchannel technology provides a viable pathway for HVAC manufacturers and building operators to achieve compliance while maintaining or improving performance metrics. This alignment with global sustainability goals positions microchannel cooling as a strategic technology for addressing climate change challenges within the built environment sector.

The enhanced heat transfer efficiency of microchannel technology enables HVAC systems to achieve the same cooling capacity while consuming significantly less energy. This efficiency gain stems from the optimized refrigerant flow distribution and increased heat transfer surface area per unit volume, allowing for more effective heat rejection with reduced fan power requirements. Studies have shown that microchannel condensers can operate with up to 40% less refrigerant charge compared to traditional fin-and-tube heat exchangers.

From a sustainability perspective, microchannel technology contributes to environmental conservation through multiple pathways. The reduced refrigerant charge directly minimizes the potential for harmful refrigerant leakage into the atmosphere, addressing concerns related to global warming potential (GWP) and ozone depletion. Additionally, the compact design of microchannel heat exchangers requires fewer raw materials for manufacturing, reducing the embodied energy and carbon footprint associated with production processes.

The lightweight and compact nature of microchannel components further enhances sustainability by reducing transportation emissions and facilitating easier installation and maintenance. These factors extend the lifecycle benefits beyond mere operational efficiency to encompass the entire product lifecycle from manufacturing to disposal.

When integrated into comprehensive building management systems, microchannel-based HVAC solutions enable more precise temperature control and zoning capabilities, further optimizing energy usage based on occupancy patterns and thermal load requirements. This smart integration capability positions microchannel technology as a key enabler for next-generation green buildings and smart city infrastructure.

Economic analyses indicate that despite higher initial investment costs (typically 10-15% premium over conventional systems), microchannel HVAC installations achieve payback periods of 2-4 years in most commercial applications through energy savings alone. When factoring in additional benefits such as reduced maintenance requirements and extended system lifespan, the total cost of ownership demonstrates clear advantages for building operators committed to sustainable operations.

As regulatory frameworks increasingly emphasize energy efficiency standards and carbon emission reductions, microchannel technology provides a viable pathway for HVAC manufacturers and building operators to achieve compliance while maintaining or improving performance metrics. This alignment with global sustainability goals positions microchannel cooling as a strategic technology for addressing climate change challenges within the built environment sector.

Manufacturing Processes and Material Science Advancements

The manufacturing processes for microchannel heat exchangers have evolved significantly to meet the demanding requirements of HVAC applications. Traditional fabrication methods involved complex brazing processes that limited design flexibility and increased production costs. Recent advancements have introduced precision extrusion techniques that allow for the creation of aluminum profiles with multiple parallel microchannels, dramatically improving thermal efficiency while reducing material usage by up to 40% compared to conventional heat exchangers.

Automated manufacturing lines now incorporate advanced CNC machining and laser welding technologies, enabling the production of microchannel components with channel dimensions as small as 0.5mm while maintaining tight tolerances. These manufacturing improvements have reduced production defects by approximately 30% and lowered assembly time by 25%, contributing to overall cost reductions in high-volume production scenarios.

Material science innovations have played a crucial role in enhancing microchannel cooling performance. The development of corrosion-resistant aluminum alloys (particularly the 3000 and 6000 series) has addressed durability concerns in HVAC applications. These specialized alloys demonstrate improved thermal conductivity (up to 237 W/m·K) while maintaining structural integrity under varying temperature and pressure conditions.

Surface treatment technologies have also advanced significantly, with hydrophilic coatings that improve condensate drainage and reduce air-side pressure drop by up to 15%. Additionally, antimicrobial surface treatments have been developed to address hygiene concerns in HVAC applications, inhibiting biofilm formation that could otherwise reduce heat transfer efficiency over time.

Composite materials are emerging as promising alternatives to traditional metals in microchannel applications. Polymer-metal hybrids and carbon-reinforced composites offer reduced weight (up to 60% lighter than all-metal equivalents) while maintaining thermal performance. These materials also provide greater design flexibility, allowing for more complex geometries that can further optimize fluid dynamics within the microchannels.

Additive manufacturing techniques, particularly selective laser melting and direct metal laser sintering, are revolutionizing microchannel production capabilities. These processes enable the creation of previously impossible internal geometries that maximize heat transfer surface area while minimizing fluid flow resistance. Though currently limited to smaller production runs due to cost considerations, these technologies are rapidly advancing toward broader commercial viability in HVAC manufacturing.

Automated manufacturing lines now incorporate advanced CNC machining and laser welding technologies, enabling the production of microchannel components with channel dimensions as small as 0.5mm while maintaining tight tolerances. These manufacturing improvements have reduced production defects by approximately 30% and lowered assembly time by 25%, contributing to overall cost reductions in high-volume production scenarios.

Material science innovations have played a crucial role in enhancing microchannel cooling performance. The development of corrosion-resistant aluminum alloys (particularly the 3000 and 6000 series) has addressed durability concerns in HVAC applications. These specialized alloys demonstrate improved thermal conductivity (up to 237 W/m·K) while maintaining structural integrity under varying temperature and pressure conditions.

Surface treatment technologies have also advanced significantly, with hydrophilic coatings that improve condensate drainage and reduce air-side pressure drop by up to 15%. Additionally, antimicrobial surface treatments have been developed to address hygiene concerns in HVAC applications, inhibiting biofilm formation that could otherwise reduce heat transfer efficiency over time.

Composite materials are emerging as promising alternatives to traditional metals in microchannel applications. Polymer-metal hybrids and carbon-reinforced composites offer reduced weight (up to 60% lighter than all-metal equivalents) while maintaining thermal performance. These materials also provide greater design flexibility, allowing for more complex geometries that can further optimize fluid dynamics within the microchannels.

Additive manufacturing techniques, particularly selective laser melting and direct metal laser sintering, are revolutionizing microchannel production capabilities. These processes enable the creation of previously impossible internal geometries that maximize heat transfer surface area while minimizing fluid flow resistance. Though currently limited to smaller production runs due to cost considerations, these technologies are rapidly advancing toward broader commercial viability in HVAC manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!