Comparing Microchannel Cooling and Vapor Chamber Technologies

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Evolution and Objectives

Thermal management technologies have evolved significantly over the past decades, driven by the increasing power densities and miniaturization trends in electronic devices. The journey began with passive cooling methods such as heat sinks and natural convection in the 1960s and 1970s, which provided adequate cooling for the relatively low-power electronics of that era. As transistor densities increased following Moore's Law, the 1980s and 1990s saw the introduction of forced-air cooling systems with fans and blowers to enhance heat dissipation capabilities.

The early 2000s marked a significant shift toward more advanced thermal solutions as power densities continued to rise dramatically in high-performance computing, telecommunications, and later in mobile devices. This period witnessed the commercial adoption of heat pipes, which utilize phase change principles to transport heat more efficiently than solid conduction. The thermal management landscape further evolved with the introduction of vapor chambers around 2005-2010, offering two-dimensional heat spreading capabilities that significantly outperformed traditional solutions.

Concurrently, liquid cooling technologies began gaining traction in high-performance applications, initially through closed-loop systems and eventually leading to the development of microchannel cooling technologies. Microchannels represent a significant advancement by allowing coolant to flow through microscale channels directly integrated into or positioned extremely close to heat-generating components, dramatically reducing thermal resistance.

The primary objective of modern thermal management is to maintain electronic components within their specified operating temperature ranges while minimizing system size, weight, power consumption, and acoustic noise. For high-performance computing and data centers, the goal extends to maximizing computational density while optimizing energy efficiency. In mobile and wearable devices, the focus shifts toward maintaining comfortable touch temperatures while preserving battery life and enabling thinner form factors.

Both microchannel cooling and vapor chamber technologies have emerged as promising solutions to address these objectives, albeit through fundamentally different approaches. Microchannel cooling offers superior heat transfer coefficients through direct liquid cooling, potentially handling heat fluxes exceeding 500 W/cm², while vapor chambers excel in spreading heat across larger surfaces with minimal temperature gradients. The selection between these technologies increasingly depends on specific application requirements, including heat flux density, spatial constraints, orientation sensitivity, and reliability considerations.

The evolution trajectory suggests a future convergence of these technologies, with hybrid solutions potentially offering the benefits of both approaches. Research is actively exploring materials innovations, manufacturing techniques, and working fluid optimizations to push the performance boundaries of both technologies while addressing their respective limitations.

The early 2000s marked a significant shift toward more advanced thermal solutions as power densities continued to rise dramatically in high-performance computing, telecommunications, and later in mobile devices. This period witnessed the commercial adoption of heat pipes, which utilize phase change principles to transport heat more efficiently than solid conduction. The thermal management landscape further evolved with the introduction of vapor chambers around 2005-2010, offering two-dimensional heat spreading capabilities that significantly outperformed traditional solutions.

Concurrently, liquid cooling technologies began gaining traction in high-performance applications, initially through closed-loop systems and eventually leading to the development of microchannel cooling technologies. Microchannels represent a significant advancement by allowing coolant to flow through microscale channels directly integrated into or positioned extremely close to heat-generating components, dramatically reducing thermal resistance.

The primary objective of modern thermal management is to maintain electronic components within their specified operating temperature ranges while minimizing system size, weight, power consumption, and acoustic noise. For high-performance computing and data centers, the goal extends to maximizing computational density while optimizing energy efficiency. In mobile and wearable devices, the focus shifts toward maintaining comfortable touch temperatures while preserving battery life and enabling thinner form factors.

Both microchannel cooling and vapor chamber technologies have emerged as promising solutions to address these objectives, albeit through fundamentally different approaches. Microchannel cooling offers superior heat transfer coefficients through direct liquid cooling, potentially handling heat fluxes exceeding 500 W/cm², while vapor chambers excel in spreading heat across larger surfaces with minimal temperature gradients. The selection between these technologies increasingly depends on specific application requirements, including heat flux density, spatial constraints, orientation sensitivity, and reliability considerations.

The evolution trajectory suggests a future convergence of these technologies, with hybrid solutions potentially offering the benefits of both approaches. Research is actively exploring materials innovations, manufacturing techniques, and working fluid optimizations to push the performance boundaries of both technologies while addressing their respective limitations.

Market Demand Analysis for Advanced Cooling Solutions

The global market for advanced cooling solutions is experiencing unprecedented growth, driven primarily by the increasing thermal management challenges in high-performance computing, data centers, and consumer electronics. Current market research indicates that the thermal management market is projected to reach $22.8 billion by 2025, with advanced cooling technologies representing the fastest-growing segment at a CAGR of 8.2%. This growth trajectory reflects the urgent need for more efficient heat dissipation solutions as electronic devices continue to shrink in size while simultaneously increasing in processing power.

Within this expanding market, microchannel cooling and vapor chamber technologies have emerged as two particularly promising solutions. The demand for these advanced cooling technologies is being fueled by several converging factors. First, the data center industry's rapid expansion, with global data center IP traffic exceeding 20.6 zettabytes annually, has created critical cooling challenges as power densities continue to rise. Traditional air cooling methods are increasingly inadequate for managing thermal loads in high-density server environments, creating a significant market opportunity for liquid-based cooling solutions like microchannels.

Consumer electronics represents another major demand driver, with smartphone manufacturers seeking thinner device profiles while managing the heat generated by more powerful processors. Market research shows that over 78% of smartphone users identify device overheating as a significant concern affecting user experience, creating strong consumer pull for devices with superior thermal management. Vapor chamber technology has gained particular traction in this segment due to its thin profile and efficient heat spreading capabilities.

The automotive industry, especially with the rise of electric vehicles, constitutes a rapidly growing market for advanced cooling solutions. Electric vehicle batteries generate substantial heat during charging and discharging cycles, requiring sophisticated thermal management systems to maintain optimal operating temperatures and extend battery life. Industry forecasts suggest that the EV thermal management market alone will grow at a CAGR of 13.4% through 2028.

Aerospace and defense applications represent a premium segment of the market, where reliability under extreme conditions is paramount. These sectors demand cooling solutions that can function effectively in environments with significant temperature fluctuations, high vibration, and limited space constraints. Both microchannel and vapor chamber technologies are being evaluated for these high-value applications.

Geographically, North America and Asia-Pacific dominate the market for advanced cooling technologies, with China, Japan, South Korea, and the United States leading in both production and consumption. The Asia-Pacific region is expected to witness the highest growth rate, driven by the concentration of electronics manufacturing and increasing adoption of high-performance computing solutions across various industries.

Within this expanding market, microchannel cooling and vapor chamber technologies have emerged as two particularly promising solutions. The demand for these advanced cooling technologies is being fueled by several converging factors. First, the data center industry's rapid expansion, with global data center IP traffic exceeding 20.6 zettabytes annually, has created critical cooling challenges as power densities continue to rise. Traditional air cooling methods are increasingly inadequate for managing thermal loads in high-density server environments, creating a significant market opportunity for liquid-based cooling solutions like microchannels.

Consumer electronics represents another major demand driver, with smartphone manufacturers seeking thinner device profiles while managing the heat generated by more powerful processors. Market research shows that over 78% of smartphone users identify device overheating as a significant concern affecting user experience, creating strong consumer pull for devices with superior thermal management. Vapor chamber technology has gained particular traction in this segment due to its thin profile and efficient heat spreading capabilities.

The automotive industry, especially with the rise of electric vehicles, constitutes a rapidly growing market for advanced cooling solutions. Electric vehicle batteries generate substantial heat during charging and discharging cycles, requiring sophisticated thermal management systems to maintain optimal operating temperatures and extend battery life. Industry forecasts suggest that the EV thermal management market alone will grow at a CAGR of 13.4% through 2028.

Aerospace and defense applications represent a premium segment of the market, where reliability under extreme conditions is paramount. These sectors demand cooling solutions that can function effectively in environments with significant temperature fluctuations, high vibration, and limited space constraints. Both microchannel and vapor chamber technologies are being evaluated for these high-value applications.

Geographically, North America and Asia-Pacific dominate the market for advanced cooling technologies, with China, Japan, South Korea, and the United States leading in both production and consumption. The Asia-Pacific region is expected to witness the highest growth rate, driven by the concentration of electronics manufacturing and increasing adoption of high-performance computing solutions across various industries.

Current State and Challenges in Thermal Management Technologies

Thermal management technologies have evolved significantly over the past decade, with microchannel cooling and vapor chamber solutions emerging as leading approaches for high-performance electronic devices. Currently, these technologies are being implemented across various industries including consumer electronics, data centers, aerospace, and automotive applications, where thermal challenges continue to intensify with increasing power densities.

Microchannel cooling technology has reached a mature implementation stage in specialized applications, achieving thermal performance of 500-1000 W/cm² in laboratory settings. Commercial implementations typically deliver 100-300 W/cm² cooling capacity with pressure drops ranging from 10-50 kPa. The primary challenge facing microchannel cooling remains the high manufacturing precision required for consistent channel dimensions, typically in the 50-500 μm range, which impacts production costs and scalability.

Vapor chamber technology has demonstrated thermal conductivities equivalent to 3000-5000 W/m·K, significantly outperforming solid copper (400 W/m·K). Current implementations achieve thickness profiles as thin as 0.3-0.6 mm for mobile applications while maintaining effective heat spreading capabilities. However, vapor chambers face limitations in their ability to manage extremely high heat fluxes above 500 W/cm² and struggle with orientation sensitivity in certain applications.

Both technologies confront similar challenges regarding integration complexity with existing thermal management systems. Manufacturing consistency remains problematic, with vapor chambers experiencing issues in wick structure uniformity and working fluid distribution, while microchannels face challenges in maintaining uniform channel dimensions and preventing clogging during operation.

Geographically, thermal management technology development shows distinct regional characteristics. North America leads in research innovation with significant contributions from universities and national laboratories. Asia dominates manufacturing capacity, particularly in Taiwan, South Korea, and China, where most commercial vapor chambers and microchannel solutions are produced. Europe contributes specialized applications in automotive and industrial sectors with emphasis on reliability and sustainability.

Material constraints represent another significant challenge, with both technologies requiring advanced materials that balance thermal conductivity, mechanical strength, and corrosion resistance. Copper remains dominant but adds weight penalties, while aluminum solutions offer weight advantages but with reduced thermal performance. Emerging composite materials show promise but face commercialization barriers due to cost and manufacturing complexity.

System-level integration presents ongoing challenges, particularly in managing pumping power requirements for microchannel systems and addressing the inherent limitations in heat transport capacity for vapor chambers when implemented in complex three-dimensional thermal architectures.

Microchannel cooling technology has reached a mature implementation stage in specialized applications, achieving thermal performance of 500-1000 W/cm² in laboratory settings. Commercial implementations typically deliver 100-300 W/cm² cooling capacity with pressure drops ranging from 10-50 kPa. The primary challenge facing microchannel cooling remains the high manufacturing precision required for consistent channel dimensions, typically in the 50-500 μm range, which impacts production costs and scalability.

Vapor chamber technology has demonstrated thermal conductivities equivalent to 3000-5000 W/m·K, significantly outperforming solid copper (400 W/m·K). Current implementations achieve thickness profiles as thin as 0.3-0.6 mm for mobile applications while maintaining effective heat spreading capabilities. However, vapor chambers face limitations in their ability to manage extremely high heat fluxes above 500 W/cm² and struggle with orientation sensitivity in certain applications.

Both technologies confront similar challenges regarding integration complexity with existing thermal management systems. Manufacturing consistency remains problematic, with vapor chambers experiencing issues in wick structure uniformity and working fluid distribution, while microchannels face challenges in maintaining uniform channel dimensions and preventing clogging during operation.

Geographically, thermal management technology development shows distinct regional characteristics. North America leads in research innovation with significant contributions from universities and national laboratories. Asia dominates manufacturing capacity, particularly in Taiwan, South Korea, and China, where most commercial vapor chambers and microchannel solutions are produced. Europe contributes specialized applications in automotive and industrial sectors with emphasis on reliability and sustainability.

Material constraints represent another significant challenge, with both technologies requiring advanced materials that balance thermal conductivity, mechanical strength, and corrosion resistance. Copper remains dominant but adds weight penalties, while aluminum solutions offer weight advantages but with reduced thermal performance. Emerging composite materials show promise but face commercialization barriers due to cost and manufacturing complexity.

System-level integration presents ongoing challenges, particularly in managing pumping power requirements for microchannel systems and addressing the inherent limitations in heat transport capacity for vapor chambers when implemented in complex three-dimensional thermal architectures.

Technical Comparison of Microchannel and Vapor Chamber Solutions

01 Microchannel cooling systems for electronic devices

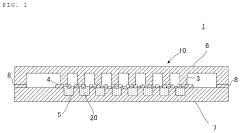

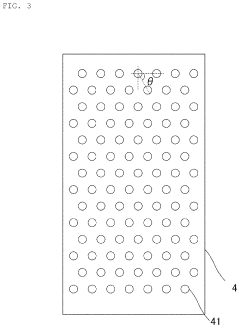

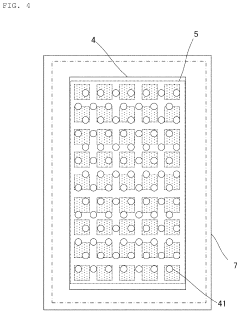

Microchannel cooling systems utilize small channels to circulate coolant directly through or adjacent to heat-generating components in electronic devices. These systems provide efficient heat transfer by maximizing surface area contact between the coolant and the heat source. The microchannels can be integrated into heat sinks or directly into semiconductor substrates, allowing for targeted cooling of high-power density components such as CPUs, GPUs, and power electronics. This approach significantly improves thermal management compared to conventional cooling methods.- Microchannel cooling systems for electronic devices: Microchannel cooling systems utilize small channels to circulate coolant directly through or adjacent to heat-generating components in electronic devices. These systems provide efficient heat dissipation by maximizing the surface area for heat exchange while minimizing the thermal resistance. The microchannels can be integrated into heat sinks or directly into semiconductor substrates, allowing for more effective cooling of high-power density components such as CPUs, GPUs, and power electronics.

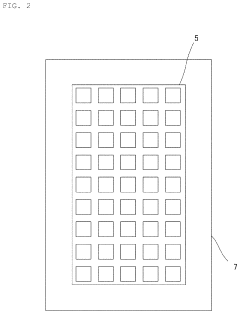

- Vapor chamber design and construction techniques: Vapor chambers are sealed, flat heat pipes that use phase change of a working fluid to efficiently transfer heat across their surface area. The internal structure typically includes a wick material that facilitates the return of condensed liquid to the evaporator section through capillary action. Advanced vapor chamber designs incorporate specialized wick structures, optimized working fluids, and thin-profile constructions to maximize thermal performance while minimizing space requirements. These technologies enable uniform heat spreading across larger surfaces, reducing hot spots in compact electronic devices.

- Integration of vapor chambers with microchannel cooling: Hybrid thermal management solutions combine vapor chambers with microchannel cooling to leverage the advantages of both technologies. The vapor chamber provides efficient heat spreading across a large area, while microchannels offer high heat flux capability at specific locations. This integration allows for more effective cooling of complex electronic systems with varying heat generation profiles. The combined approach can significantly reduce thermal resistance and improve overall system performance, particularly in applications with space constraints and high power densities.

- Advanced materials and manufacturing for thermal solutions: Novel materials and manufacturing techniques enhance the performance of microchannel and vapor chamber cooling technologies. These include the use of high thermal conductivity materials like copper, aluminum, and graphene composites, as well as advanced fabrication methods such as additive manufacturing, chemical etching, and micro-machining. Surface treatments and coatings can improve wettability and fluid flow characteristics within microchannels and vapor chambers. These material and manufacturing innovations lead to more efficient heat transfer, reduced thermal resistance, and improved reliability of cooling systems.

- Thermal management for specialized applications: Microchannel cooling and vapor chamber technologies are adapted for specialized applications with unique thermal challenges. These include high-performance computing systems, telecommunications equipment, power electronics, medical devices, and aerospace applications. Custom designs address specific requirements such as extreme temperature environments, limited space constraints, high reliability needs, or weight restrictions. The cooling solutions may incorporate additional features like redundant systems, passive operation capabilities, or integration with broader thermal management architectures to ensure optimal performance under application-specific conditions.

02 Vapor chamber design and construction techniques

Vapor chambers are sealed, flat heat pipes that use phase change of a working fluid to efficiently transfer heat from a source to a heat dissipation area. The internal structure typically includes a wick material that facilitates capillary action to return condensed liquid to the evaporation zone. Advanced vapor chamber designs incorporate specialized wick structures, optimized working fluids, and thin-profile constructions to maximize thermal performance while minimizing space requirements. These chambers can be integrated into various cooling solutions for electronics, providing uniform temperature distribution across surfaces.Expand Specific Solutions03 Integration of vapor chambers with heat sinks and cooling systems

Vapor chambers can be effectively integrated with traditional heat sinks, fans, and other cooling components to create hybrid thermal management solutions. By embedding vapor chambers into the base of heat sinks or between heat sources and cooling fins, heat can be rapidly spread across a larger surface area before being dissipated. This integration reduces thermal resistance and hotspots, allowing for more efficient cooling of high-power electronic components. Some designs incorporate multiple vapor chambers in layered configurations to manage complex thermal loads in compact devices.Expand Specific Solutions04 Advanced manufacturing techniques for microchannel and vapor chamber technologies

Manufacturing innovations have enabled more efficient and cost-effective production of microchannel cooling systems and vapor chambers. Techniques include precision etching, additive manufacturing, diffusion bonding, and micro-machining processes that create complex internal structures with high precision. Advanced materials such as copper, aluminum, and specialized alloys are used to optimize thermal conductivity. These manufacturing methods allow for mass production of customized cooling solutions with intricate internal geometries that maximize heat transfer efficiency while maintaining structural integrity.Expand Specific Solutions05 Application-specific cooling solutions using microchannel and vapor chamber technologies

Specialized cooling solutions have been developed for specific applications such as telecommunications equipment, data centers, automotive electronics, and medical devices. These solutions combine microchannel cooling and vapor chamber technologies tailored to the unique thermal requirements and space constraints of each application. Innovations include two-phase cooling systems, immersion cooling with microchannels, and hybrid approaches that integrate multiple cooling technologies. These application-specific designs optimize thermal performance while addressing factors such as reliability, maintenance, noise, and energy efficiency.Expand Specific Solutions

Key Industry Players in Advanced Thermal Management

The microchannel cooling and vapor chamber technology market is currently in a growth phase, with increasing adoption across electronics, automotive, and aerospace sectors. The global thermal management solutions market is estimated at $12-15 billion annually, with these advanced cooling technologies capturing a growing share due to increasing power densities in electronic devices. Technologically, companies like IBM, Samsung, and Intel lead in microchannel innovation with established intellectual property portfolios, while Fujitsu, Huawei, and Qualcomm have made significant advancements in vapor chamber implementations. Academic institutions including Xi'an Jiaotong University and EPFL are contributing breakthrough research, particularly in hybrid cooling solutions. The ecosystem shows a balanced mix of technology giants, specialized thermal management companies, and research institutions driving innovation through both competitive development and collaborative approaches.

International Business Machines Corp.

Technical Solution: IBM has pioneered advanced microchannel cooling technologies for high-performance computing systems and data centers. Their "Aquasar" and subsequent "SuperMUC" cooling systems utilize microchannels integrated directly into server components, with water flowing through channels approximately 100 microns wide. This approach has demonstrated the ability to remove heat fluxes exceeding 350 W/cm² while maintaining component temperatures below critical thresholds[7]. IBM's research has expanded to include two-phase cooling in microchannels, where the working fluid undergoes phase change from liquid to vapor, significantly enhancing heat transfer coefficients. Their patented "Thermal Conduction Module" incorporates microchannels with precisely engineered pin fin structures that increase surface area and induce beneficial flow turbulence. More recently, IBM has developed hierarchical microchannel networks that dynamically adjust flow distribution based on localized heating patterns, addressing the challenge of non-uniform heat generation in modern processors[8]. Their cooling solutions have demonstrated energy efficiency improvements of up to 40% compared to traditional air cooling methods in data center environments.

Strengths: Exceptional cooling capacity for high-density computing applications; significant energy efficiency improvements; enables higher performance computing. Weaknesses: System complexity requiring specialized maintenance; potential for coolant leakage concerns; higher initial implementation costs compared to conventional cooling.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary vapor chamber technology for thermal management in their mobile devices and consumer electronics. Their ultra-thin vapor chamber designs range from 0.35mm to 0.55mm in thickness and utilize a proprietary working fluid with optimized wick structures to maximize heat spreading capability[3]. Samsung's vapor chambers incorporate sintered copper powder wicks with multi-layer mesh structures that enhance capillary action and fluid return. For their flagship smartphones, Samsung has implemented stacked vapor chamber designs that can dissipate heat from multiple components simultaneously, achieving thermal resistance values below 0.1°C/W[4]. The company has also pioneered the integration of graphene layers within vapor chambers to improve thermal conductivity by approximately 20%. Samsung's latest vapor chamber technology features 3D contoured designs that conform to irregular device geometries, allowing for more efficient use of limited space in slim form factor devices while maintaining effective heat dissipation across the entire device footprint.

Strengths: Extremely thin form factor suitable for mobile devices; passive operation with no power consumption; uniform temperature distribution across surfaces. Weaknesses: Limited heat flux handling compared to active cooling solutions; performance dependent on orientation in some designs; manufacturing consistency challenges at scale.

Core Patents and Innovations in Cooling Technologies

Vapor chamber

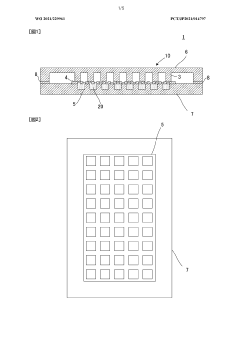

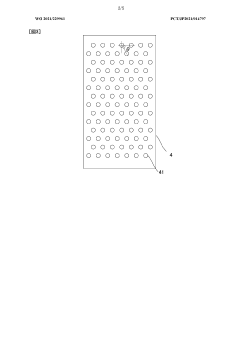

PatentWO2021229961A1

Innovation

- A vapor chamber design featuring a housing with a microchannel and a wick, where the contact area between the wick and microchannel is 5% to 40% of the internal space, with specific dimensions and configurations to ensure optimal heat transfer and capillary force, including a phosphor copper solder joining member and materials with high thermal conductivity.

Vapor chamber

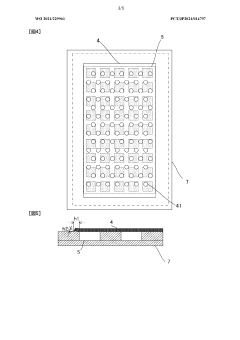

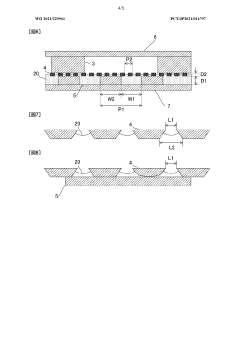

PatentActiveUS11585606B2

Innovation

- A vapor chamber configuration with a larger wick area than the microchannel area, where the wick is sandwiched between the lower casing sheet and a support, and the wick is adhesive-bonded to the microchannel, ensuring a strong capillary force and suitable heat conduction by maintaining contact with the microchannel despite potential shifting.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal management technologies has become increasingly important as electronic devices proliferate globally. When comparing microchannel cooling and vapor chamber technologies, several sustainability considerations emerge that influence their adoption and development trajectories.

Microchannel cooling systems typically require pumps and additional energy to circulate coolant through the system, resulting in higher operational energy consumption compared to passive solutions. However, their superior cooling efficiency can lead to overall energy savings in high-performance computing environments by allowing systems to operate at optimal temperatures with less thermal throttling. The manufacturing process for microchannels often involves precision machining or etching techniques that may utilize hazardous chemicals, raising concerns about production-related environmental impacts.

Vapor chambers, as passive cooling solutions, generally consume no operational energy beyond the initial heat input from the device being cooled. This characteristic makes them particularly attractive from an energy efficiency perspective. Their sealed nature also means minimal risk of coolant leakage or evaporation during the product lifecycle, reducing potential environmental contamination risks. However, vapor chambers typically contain working fluids that may include compounds with varying degrees of environmental impact if improperly disposed of at end-of-life.

Material selection represents a critical environmental consideration for both technologies. Copper, commonly used in both solutions for its excellent thermal conductivity, has significant mining and refining impacts. Alternative materials being explored include aluminum and various composites that may offer reduced environmental footprints. Additionally, the recyclability of these systems differs substantially—vapor chambers present challenges due to their sealed construction and mixed materials, while microchannel systems may be easier to disassemble and recycle.

Water consumption in manufacturing processes presents another environmental concern, particularly for microchannel fabrication which often requires substantial water for cleaning and processing steps. The semiconductor industry's approach to water recycling and conservation offers valuable lessons for sustainable manufacturing of these cooling technologies.

Lifecycle assessment studies indicate that the environmental impact of both technologies is heavily influenced by their operational lifespan and the energy efficiency improvements they enable in the host systems. Extended product lifespans through robust design and repairability can significantly reduce the cumulative environmental impact, particularly for vapor chambers which have fewer moving parts and potential failure points compared to active microchannel systems.

Microchannel cooling systems typically require pumps and additional energy to circulate coolant through the system, resulting in higher operational energy consumption compared to passive solutions. However, their superior cooling efficiency can lead to overall energy savings in high-performance computing environments by allowing systems to operate at optimal temperatures with less thermal throttling. The manufacturing process for microchannels often involves precision machining or etching techniques that may utilize hazardous chemicals, raising concerns about production-related environmental impacts.

Vapor chambers, as passive cooling solutions, generally consume no operational energy beyond the initial heat input from the device being cooled. This characteristic makes them particularly attractive from an energy efficiency perspective. Their sealed nature also means minimal risk of coolant leakage or evaporation during the product lifecycle, reducing potential environmental contamination risks. However, vapor chambers typically contain working fluids that may include compounds with varying degrees of environmental impact if improperly disposed of at end-of-life.

Material selection represents a critical environmental consideration for both technologies. Copper, commonly used in both solutions for its excellent thermal conductivity, has significant mining and refining impacts. Alternative materials being explored include aluminum and various composites that may offer reduced environmental footprints. Additionally, the recyclability of these systems differs substantially—vapor chambers present challenges due to their sealed construction and mixed materials, while microchannel systems may be easier to disassemble and recycle.

Water consumption in manufacturing processes presents another environmental concern, particularly for microchannel fabrication which often requires substantial water for cleaning and processing steps. The semiconductor industry's approach to water recycling and conservation offers valuable lessons for sustainable manufacturing of these cooling technologies.

Lifecycle assessment studies indicate that the environmental impact of both technologies is heavily influenced by their operational lifespan and the energy efficiency improvements they enable in the host systems. Extended product lifespans through robust design and repairability can significantly reduce the cumulative environmental impact, particularly for vapor chambers which have fewer moving parts and potential failure points compared to active microchannel systems.

Integration Challenges in Electronic Device Design

Integrating advanced cooling technologies like microchannel cooling and vapor chambers into electronic devices presents significant engineering challenges that require careful consideration during the design phase. The dimensional constraints of modern electronic devices, particularly in mobile and ultra-thin applications, create substantial spatial limitations for implementing these cooling solutions. Engineers must balance the need for effective thermal management with the consumer demand for increasingly compact and lightweight devices.

Material compatibility represents another critical challenge, as the integration of cooling systems often involves combining different materials with varying thermal expansion coefficients. This mismatch can lead to mechanical stress, potential delamination, and reliability issues over time, especially during thermal cycling. Additionally, the interface between the cooling system and heat-generating components must be optimized to minimize thermal resistance, often requiring specialized thermal interface materials and precise manufacturing tolerances.

Manufacturing complexity increases substantially with the introduction of these advanced cooling technologies. Microchannel cooling systems require precise micro-fabrication techniques to create uniform channels with optimal dimensions, while vapor chambers demand careful sealing and working fluid management. These requirements often necessitate specialized equipment and quality control processes that may not align with existing production capabilities.

Power requirements present another integration challenge, particularly for active microchannel cooling systems that require pumps or other fluid-driving mechanisms. These components not only consume power but also generate additional heat themselves, potentially offsetting some of the cooling benefits. The reliability of these active components becomes a critical factor in overall system dependability.

Maintenance and serviceability considerations further complicate integration efforts. Sealed systems like vapor chambers offer advantages in terms of maintenance-free operation but present challenges if repairs become necessary. Microchannel systems may be more susceptible to clogging or corrosion over time, potentially requiring periodic maintenance that must be accounted for in the design phase.

Cost implications of integrating these advanced cooling technologies remain significant, with both initial manufacturing expenses and potential lifecycle costs affecting commercial viability. Engineers must evaluate whether the thermal performance improvements justify the additional complexity and expense, particularly in consumer electronics where price sensitivity is high.

Material compatibility represents another critical challenge, as the integration of cooling systems often involves combining different materials with varying thermal expansion coefficients. This mismatch can lead to mechanical stress, potential delamination, and reliability issues over time, especially during thermal cycling. Additionally, the interface between the cooling system and heat-generating components must be optimized to minimize thermal resistance, often requiring specialized thermal interface materials and precise manufacturing tolerances.

Manufacturing complexity increases substantially with the introduction of these advanced cooling technologies. Microchannel cooling systems require precise micro-fabrication techniques to create uniform channels with optimal dimensions, while vapor chambers demand careful sealing and working fluid management. These requirements often necessitate specialized equipment and quality control processes that may not align with existing production capabilities.

Power requirements present another integration challenge, particularly for active microchannel cooling systems that require pumps or other fluid-driving mechanisms. These components not only consume power but also generate additional heat themselves, potentially offsetting some of the cooling benefits. The reliability of these active components becomes a critical factor in overall system dependability.

Maintenance and serviceability considerations further complicate integration efforts. Sealed systems like vapor chambers offer advantages in terms of maintenance-free operation but present challenges if repairs become necessary. Microchannel systems may be more susceptible to clogging or corrosion over time, potentially requiring periodic maintenance that must be accounted for in the design phase.

Cost implications of integrating these advanced cooling technologies remain significant, with both initial manufacturing expenses and potential lifecycle costs affecting commercial viability. Engineers must evaluate whether the thermal performance improvements justify the additional complexity and expense, particularly in consumer electronics where price sensitivity is high.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!