Patents in Microchannel Cooling Technology for Automotive Innovations

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Evolution and Objectives

Microchannel cooling technology has evolved significantly over the past three decades, transitioning from theoretical concepts to practical applications in various industries. The fundamental principles were first explored in the 1980s when researchers began investigating the enhanced heat transfer capabilities of microchannels compared to conventional cooling methods. By the early 1990s, initial patents emerged focusing on basic microchannel heat exchanger designs, primarily for electronics cooling applications.

The automotive industry's interest in microchannel cooling technology began to accelerate in the early 2000s, driven by increasing power densities in vehicle electronics and the need for more efficient thermal management solutions. This period marked a shift from simple heat sink designs to more complex integrated cooling systems specifically engineered for automotive environments.

A significant technological leap occurred between 2010 and 2015 when advanced manufacturing techniques enabled the mass production of microchannel cooling systems with increasingly complex geometries. Patents during this period demonstrate a clear focus on optimizing channel dimensions, flow distribution, and material selection to maximize cooling efficiency while minimizing pressure drop and pumping power requirements.

The emergence of electric vehicles (EVs) around 2015 created new imperatives for thermal management, particularly for battery systems and power electronics. This catalyzed another wave of innovation in microchannel cooling technology, with patents increasingly addressing the unique cooling requirements of high-voltage battery packs, inverters, and electric motors.

Recent patent activity (2018-present) reveals a growing emphasis on integrating microchannel cooling with broader vehicle thermal management systems. Modern patents frequently describe intelligent cooling solutions that can dynamically adjust flow rates and cooling capacity based on real-time thermal demands across multiple vehicle subsystems.

The primary objectives driving microchannel cooling innovation in automotive applications include: enhancing cooling efficiency to manage increasingly power-dense components; reducing system weight and volume to support vehicle lightweighting efforts; improving reliability under extreme operating conditions; enabling faster charging capabilities for EVs; and developing manufacturing processes suitable for high-volume automotive production.

Looking forward, the technology trajectory suggests continued refinement of microchannel geometries through computational optimization, integration of advanced materials like ceramics and metal-matrix composites, and the development of multi-functional cooling systems that can simultaneously manage thermal loads across diverse vehicle components with varying temperature requirements.

The automotive industry's interest in microchannel cooling technology began to accelerate in the early 2000s, driven by increasing power densities in vehicle electronics and the need for more efficient thermal management solutions. This period marked a shift from simple heat sink designs to more complex integrated cooling systems specifically engineered for automotive environments.

A significant technological leap occurred between 2010 and 2015 when advanced manufacturing techniques enabled the mass production of microchannel cooling systems with increasingly complex geometries. Patents during this period demonstrate a clear focus on optimizing channel dimensions, flow distribution, and material selection to maximize cooling efficiency while minimizing pressure drop and pumping power requirements.

The emergence of electric vehicles (EVs) around 2015 created new imperatives for thermal management, particularly for battery systems and power electronics. This catalyzed another wave of innovation in microchannel cooling technology, with patents increasingly addressing the unique cooling requirements of high-voltage battery packs, inverters, and electric motors.

Recent patent activity (2018-present) reveals a growing emphasis on integrating microchannel cooling with broader vehicle thermal management systems. Modern patents frequently describe intelligent cooling solutions that can dynamically adjust flow rates and cooling capacity based on real-time thermal demands across multiple vehicle subsystems.

The primary objectives driving microchannel cooling innovation in automotive applications include: enhancing cooling efficiency to manage increasingly power-dense components; reducing system weight and volume to support vehicle lightweighting efforts; improving reliability under extreme operating conditions; enabling faster charging capabilities for EVs; and developing manufacturing processes suitable for high-volume automotive production.

Looking forward, the technology trajectory suggests continued refinement of microchannel geometries through computational optimization, integration of advanced materials like ceramics and metal-matrix composites, and the development of multi-functional cooling systems that can simultaneously manage thermal loads across diverse vehicle components with varying temperature requirements.

Automotive Market Demand for Advanced Thermal Management

The automotive industry is experiencing a significant shift towards advanced thermal management solutions, driven primarily by the electrification trend and increasing power densities in vehicle systems. Market research indicates that the global automotive thermal management system market is projected to grow substantially through 2030, with microchannel cooling technology emerging as a critical component of this growth trajectory.

Electric vehicles (EVs) represent the most substantial driver for advanced cooling solutions. As battery capacities increase and fast-charging capabilities become standard features, thermal management has evolved from a secondary consideration to a primary design constraint. The market demand is particularly acute for cooling solutions that can maintain optimal battery temperatures between 20-40°C, as temperature excursions beyond this range significantly impact battery longevity and safety profiles.

High-performance computing systems in modern vehicles constitute another major demand vector. Advanced driver assistance systems (ADAS), autonomous driving capabilities, and sophisticated infotainment systems generate substantial heat loads that conventional cooling approaches struggle to dissipate effectively. Industry analysts report that computing hardware in premium vehicles now generates heat comparable to small desktop computers, necessitating cooling solutions with superior thermal efficiency.

Power electronics represent the third significant market demand area. With the transition to higher voltage architectures (400V and 800V systems), inverters, converters, and on-board chargers operate at unprecedented power densities. These components require cooling solutions capable of managing localized heat fluxes exceeding 500 W/cm² in some applications—a technical challenge that microchannel cooling is uniquely positioned to address.

Market segmentation analysis reveals differentiated demands across vehicle categories. The luxury and performance segments demonstrate willingness to adopt premium cooling solutions that offer weight reduction and packaging advantages, while mass-market manufacturers prioritize cost-effective solutions that can be implemented at scale without significant manufacturing complexity.

Regional market analysis indicates that demand for advanced thermal management is strongest in regions with aggressive electrification targets and stringent emissions regulations. European and Chinese markets show particularly strong growth trajectories, with North American demand accelerating as EV adoption increases.

The aftermarket segment also presents emerging opportunities, particularly for retrofit cooling solutions that can address thermal management limitations in first-generation electric vehicles. This segment values solutions that can be implemented without major vehicle redesigns while delivering meaningful improvements in charging speeds and battery thermal stability.

Electric vehicles (EVs) represent the most substantial driver for advanced cooling solutions. As battery capacities increase and fast-charging capabilities become standard features, thermal management has evolved from a secondary consideration to a primary design constraint. The market demand is particularly acute for cooling solutions that can maintain optimal battery temperatures between 20-40°C, as temperature excursions beyond this range significantly impact battery longevity and safety profiles.

High-performance computing systems in modern vehicles constitute another major demand vector. Advanced driver assistance systems (ADAS), autonomous driving capabilities, and sophisticated infotainment systems generate substantial heat loads that conventional cooling approaches struggle to dissipate effectively. Industry analysts report that computing hardware in premium vehicles now generates heat comparable to small desktop computers, necessitating cooling solutions with superior thermal efficiency.

Power electronics represent the third significant market demand area. With the transition to higher voltage architectures (400V and 800V systems), inverters, converters, and on-board chargers operate at unprecedented power densities. These components require cooling solutions capable of managing localized heat fluxes exceeding 500 W/cm² in some applications—a technical challenge that microchannel cooling is uniquely positioned to address.

Market segmentation analysis reveals differentiated demands across vehicle categories. The luxury and performance segments demonstrate willingness to adopt premium cooling solutions that offer weight reduction and packaging advantages, while mass-market manufacturers prioritize cost-effective solutions that can be implemented at scale without significant manufacturing complexity.

Regional market analysis indicates that demand for advanced thermal management is strongest in regions with aggressive electrification targets and stringent emissions regulations. European and Chinese markets show particularly strong growth trajectories, with North American demand accelerating as EV adoption increases.

The aftermarket segment also presents emerging opportunities, particularly for retrofit cooling solutions that can address thermal management limitations in first-generation electric vehicles. This segment values solutions that can be implemented without major vehicle redesigns while delivering meaningful improvements in charging speeds and battery thermal stability.

Current Microchannel Cooling Landscape and Barriers

Microchannel cooling technology has emerged as a promising solution for thermal management in automotive applications, particularly for electric vehicles (EVs) and high-performance internal combustion engines. The current landscape reveals significant advancements in patent filings across major automotive markets including North America, Europe, and Asia, with a compound annual growth rate of approximately 18% over the past five years.

Leading automotive manufacturers have established robust patent portfolios in this domain, with Tesla, Toyota, and BMW demonstrating particular strength in microchannel cooling innovations for battery thermal management systems. Tier-1 suppliers like Bosch, Denso, and Valeo have also made substantial investments in developing proprietary microchannel cooling solutions, creating a competitive ecosystem.

The technological landscape is characterized by three primary approaches: traditional straight microchannels, enhanced surface microchannels with various geometrical modifications, and advanced manifold microchannel heat sinks. Patent analysis indicates a clear trend toward the latter two categories, which offer superior heat transfer coefficients and reduced pressure drops compared to conventional designs.

Despite promising developments, several significant barriers impede widespread adoption of microchannel cooling technology in automotive applications. Manufacturing complexity represents a primary challenge, as the production of high-precision microchannels with dimensions typically ranging from 10-500 micrometers requires specialized equipment and processes that are not fully compatible with traditional automotive manufacturing infrastructure.

Cost considerations present another substantial barrier. The precision manufacturing requirements and specialized materials needed for microchannel cooling systems currently result in production costs approximately 30-40% higher than conventional cooling solutions, creating adoption resistance in the price-sensitive automotive sector.

Reliability and durability concerns also persist, particularly regarding channel clogging and fouling over the vehicle's operational lifetime. Patent analysis reveals ongoing efforts to address these issues through self-cleaning designs and anti-fouling surface treatments, though fully validated long-term solutions remain elusive.

Integration challenges with existing vehicle architectures constitute another significant barrier. The compact nature of microchannels offers theoretical space advantages, but the associated pumping systems, manifolds, and control infrastructure often negate these benefits in practical implementations. Patents addressing holistic system integration approaches remain relatively sparse compared to component-level innovations.

Standardization represents a final key barrier, with the absence of industry-wide standards for microchannel cooling systems hampering interoperability and creating hesitancy among OEMs to commit to proprietary solutions that may face obsolescence risks. Recent consortium efforts among major manufacturers suggest movement toward addressing this gap, though concrete standardization remains in early stages.

Leading automotive manufacturers have established robust patent portfolios in this domain, with Tesla, Toyota, and BMW demonstrating particular strength in microchannel cooling innovations for battery thermal management systems. Tier-1 suppliers like Bosch, Denso, and Valeo have also made substantial investments in developing proprietary microchannel cooling solutions, creating a competitive ecosystem.

The technological landscape is characterized by three primary approaches: traditional straight microchannels, enhanced surface microchannels with various geometrical modifications, and advanced manifold microchannel heat sinks. Patent analysis indicates a clear trend toward the latter two categories, which offer superior heat transfer coefficients and reduced pressure drops compared to conventional designs.

Despite promising developments, several significant barriers impede widespread adoption of microchannel cooling technology in automotive applications. Manufacturing complexity represents a primary challenge, as the production of high-precision microchannels with dimensions typically ranging from 10-500 micrometers requires specialized equipment and processes that are not fully compatible with traditional automotive manufacturing infrastructure.

Cost considerations present another substantial barrier. The precision manufacturing requirements and specialized materials needed for microchannel cooling systems currently result in production costs approximately 30-40% higher than conventional cooling solutions, creating adoption resistance in the price-sensitive automotive sector.

Reliability and durability concerns also persist, particularly regarding channel clogging and fouling over the vehicle's operational lifetime. Patent analysis reveals ongoing efforts to address these issues through self-cleaning designs and anti-fouling surface treatments, though fully validated long-term solutions remain elusive.

Integration challenges with existing vehicle architectures constitute another significant barrier. The compact nature of microchannels offers theoretical space advantages, but the associated pumping systems, manifolds, and control infrastructure often negate these benefits in practical implementations. Patents addressing holistic system integration approaches remain relatively sparse compared to component-level innovations.

Standardization represents a final key barrier, with the absence of industry-wide standards for microchannel cooling systems hampering interoperability and creating hesitancy among OEMs to commit to proprietary solutions that may face obsolescence risks. Recent consortium efforts among major manufacturers suggest movement toward addressing this gap, though concrete standardization remains in early stages.

Contemporary Microchannel Cooling Implementations

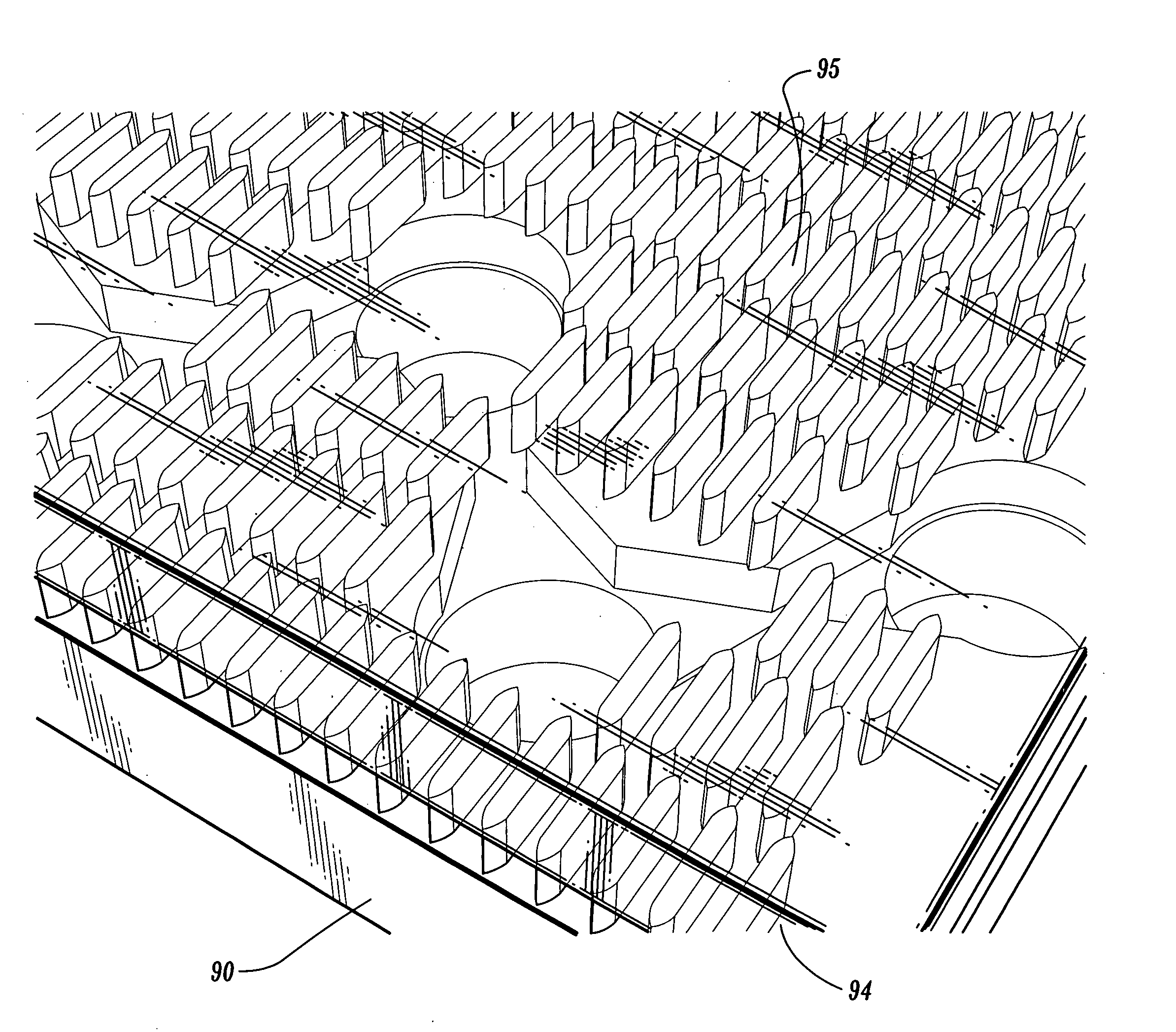

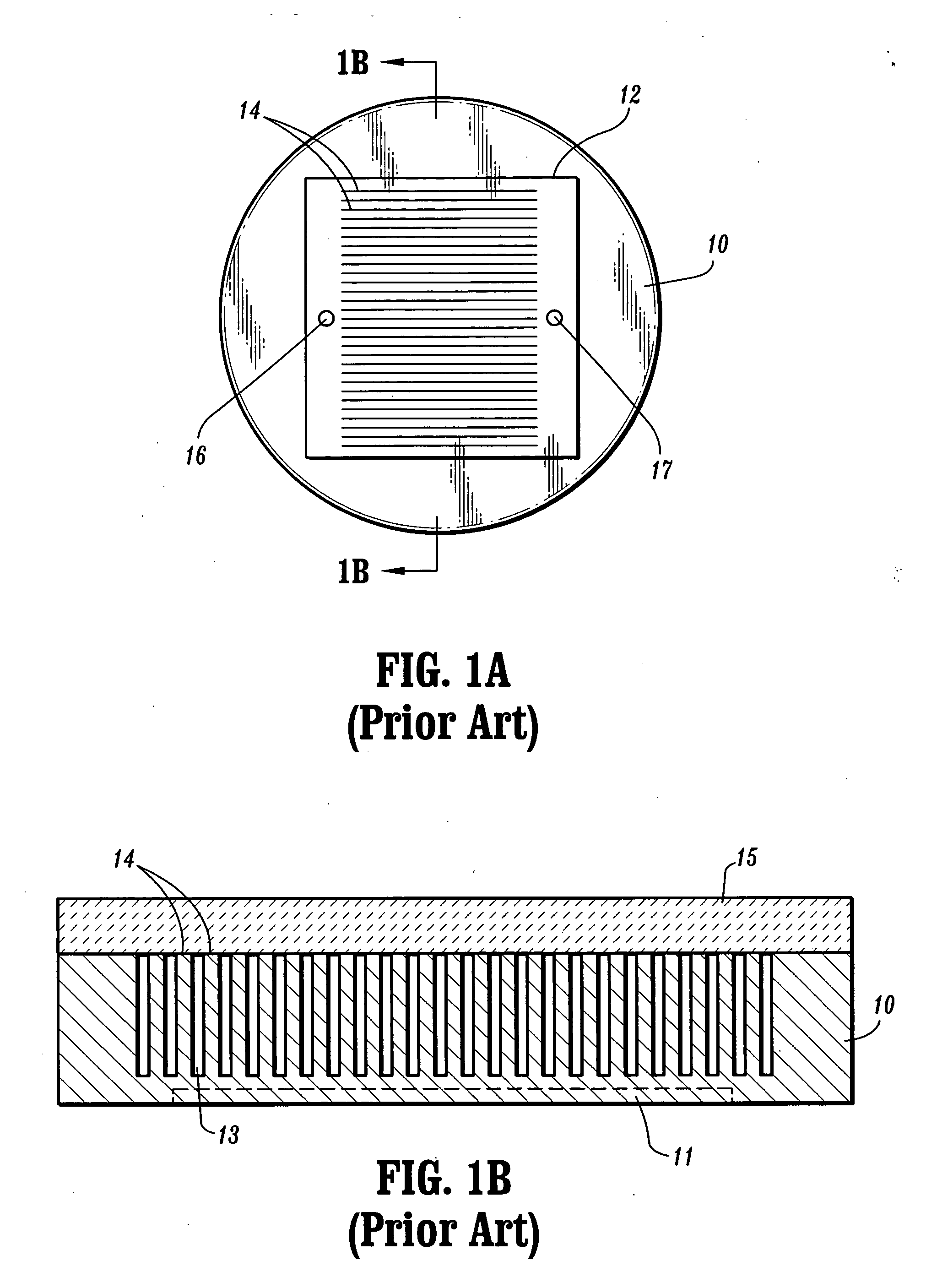

01 Microchannel design for electronic cooling

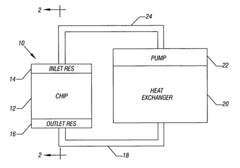

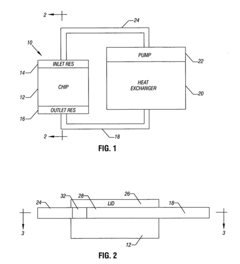

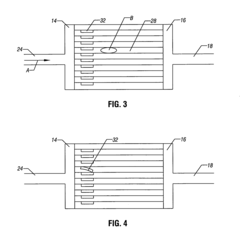

Microchannel cooling systems are designed specifically for electronic components to efficiently dissipate heat. These designs incorporate small channels that allow coolant to flow close to heat-generating components, maximizing thermal transfer. The microchannels can be integrated directly into electronic packaging or heat sinks, providing effective cooling for high-power density applications such as processors, power modules, and other electronic devices.- Microchannel design for electronic cooling: Microchannel cooling systems are designed specifically for electronic components to efficiently dissipate heat. These designs incorporate small channels that allow coolant to flow directly across or through heat-generating components. The microchannels can be integrated into heat sinks, cold plates, or directly into electronic packaging to maximize thermal transfer efficiency. Various geometries and configurations are employed to optimize cooling performance while minimizing space requirements.

- Advanced materials for microchannel fabrication: The development of advanced materials has enhanced microchannel cooling technology. Materials with high thermal conductivity, such as specialized metals, alloys, and composites, are used to fabricate microchannels. These materials improve heat transfer efficiency while maintaining structural integrity under thermal stress. Some innovations include the use of porous media, phase-change materials, and surface treatments to enhance cooling performance and prevent corrosion or fouling within the microchannels.

- Two-phase cooling in microchannels: Two-phase cooling systems utilize the phase change of the coolant (typically from liquid to vapor) to enhance heat transfer in microchannels. This approach leverages the latent heat of vaporization to achieve higher cooling capacity compared to single-phase systems. The technology includes specialized designs to manage vapor formation, bubble dynamics, and flow instabilities. Innovations in this area focus on optimizing channel geometry, surface characteristics, and flow control to maximize the benefits of two-phase heat transfer.

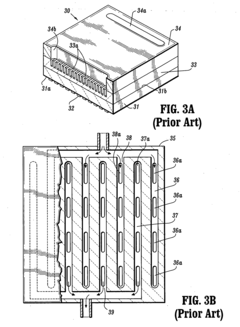

- Integration of microchannels in complex cooling systems: Microchannel technology is integrated into larger, more complex cooling systems to address thermal management challenges in various applications. These integrated systems may combine microchannels with other cooling technologies such as heat pipes, vapor chambers, or traditional air cooling. The integration enables efficient heat transfer from multiple heat sources to heat sinks or external cooling loops. Advanced designs incorporate sensors, controllers, and pumps to create adaptive cooling solutions that respond to changing thermal loads.

- Manufacturing techniques for microchannel cooling systems: Specialized manufacturing techniques have been developed to produce microchannel cooling systems with precise dimensions and complex geometries. These include advanced etching processes, additive manufacturing (3D printing), micro-machining, and bonding technologies. The manufacturing methods enable the creation of high-aspect-ratio channels, intricate flow patterns, and multi-layer structures. Innovations in this area focus on improving production efficiency, reducing costs, and enabling mass production while maintaining tight tolerances required for optimal cooling performance.

02 Advanced materials for microchannel fabrication

Various advanced materials are used in the fabrication of microchannel cooling systems to enhance thermal performance. These materials include high thermal conductivity metals, ceramics, and composite materials that improve heat transfer efficiency. Some implementations use specialized coatings or surface treatments to prevent corrosion, reduce friction, or enhance wettability within the microchannels, leading to improved cooling performance and system longevity.Expand Specific Solutions03 Two-phase cooling in microchannels

Two-phase cooling technology utilizes the phase change of the cooling fluid (typically from liquid to vapor) within microchannels to significantly enhance heat transfer capabilities. This approach leverages the latent heat of vaporization to remove large amounts of heat while maintaining relatively uniform temperatures. The technology enables higher heat flux cooling compared to single-phase systems and is particularly effective for high-power density applications where traditional cooling methods are insufficient.Expand Specific Solutions04 Microchannel cooling system integration

Integration strategies for microchannel cooling systems focus on incorporating cooling functionality directly into device packaging or system architecture. These approaches include embedding microchannels in substrates, creating 3D cooling structures, and developing modular cooling solutions that can be retrofitted to existing systems. Advanced integration techniques minimize thermal resistance between heat sources and cooling channels while addressing challenges related to fluid connections, sealing, and system reliability.Expand Specific Solutions05 Flow control and optimization in microchannel systems

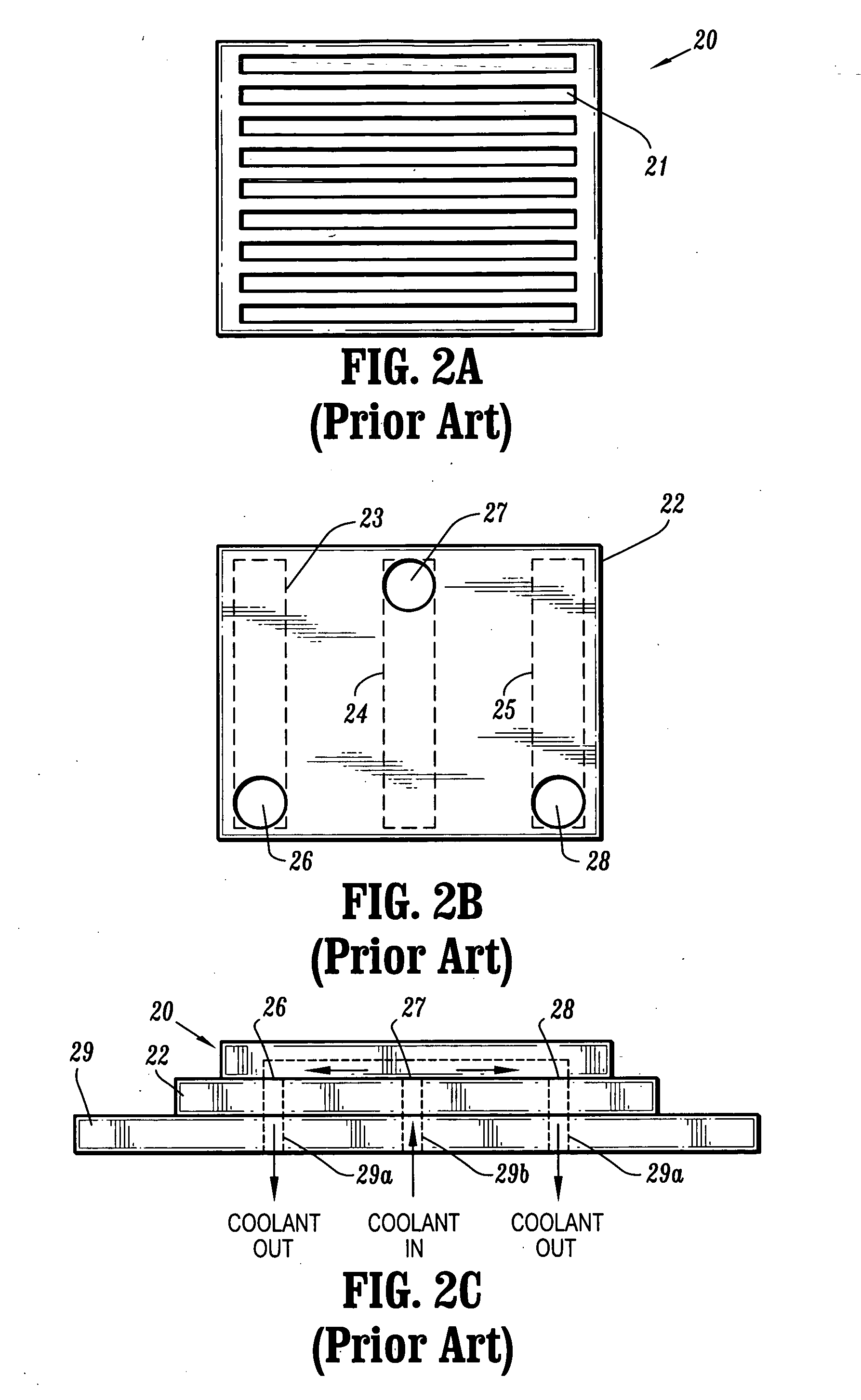

Flow control and optimization techniques are employed in microchannel cooling systems to enhance cooling efficiency and uniformity. These include the use of manifolds for flow distribution, variable channel geometries to optimize pressure drop and heat transfer, and active flow control mechanisms. Advanced designs incorporate computational fluid dynamics modeling to optimize channel dimensions, flow rates, and coolant properties for specific thermal management requirements, resulting in more efficient and effective cooling solutions.Expand Specific Solutions

Leading Companies in Automotive Thermal Management

Microchannel cooling technology for automotive innovations is currently in a growth phase, with the market expanding rapidly due to increasing demand for efficient thermal management in electric vehicles and high-performance combustion engines. The global market size is projected to reach significant scale as automotive manufacturers seek solutions for power electronics cooling and battery thermal management. From a technological maturity perspective, industry leaders like Intel, Ford Global Technologies, GM Global Technology Operations, and Samsung Electronics have established strong patent portfolios, while companies such as Johnson Controls and Marelli are developing specialized automotive applications. Academic institutions including Rochester Institute of Technology and South China University of Technology are contributing fundamental research, indicating a collaborative ecosystem where both established players and new entrants are actively innovating to address thermal challenges in next-generation vehicles.

Intel Corp.

Technical Solution: Intel has developed innovative microchannel cooling solutions primarily focused on high-performance computing applications that have been adapted for automotive electronics. Their patented technology features silicon-based microchannels etched directly into semiconductor substrates, creating integrated cooling pathways with dimensions as small as 50-100 micrometers. These microchannels utilize a closed-loop liquid cooling system with specialized non-conductive fluids that can safely operate in proximity to sensitive electronics. Intel's patents cover both the physical microchannel structures and the control systems that dynamically adjust coolant flow rates based on computational loads and thermal conditions. Their most advanced implementations incorporate machine learning algorithms that predict thermal loads and preemptively adjust cooling parameters to maintain optimal operating temperatures. For automotive applications, Intel has adapted this technology to handle the harsh vibration and temperature cycling environments found in vehicles, with specialized sealing and connection technologies that ensure zero-leak performance over the vehicle's lifetime.

Strengths: Extremely high cooling efficiency with heat flux capabilities exceeding 1000 W/cm²; minimal thermal resistance between heat source and coolant; compact integration with existing semiconductor manufacturing processes. Weaknesses: Higher system complexity requiring additional pumps and heat exchangers; potential reliability concerns in automotive environments; higher cost compared to traditional cooling solutions.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced microchannel cooling systems specifically designed for electric vehicle battery thermal management. Their patented technology utilizes an array of precisely engineered microchannels (typically 0.5-2mm in diameter) integrated directly into battery module structures. These systems employ a two-phase cooling approach where refrigerant changes state from liquid to vapor while absorbing heat, providing significantly higher heat transfer coefficients compared to traditional liquid cooling. Ford's patents cover specialized microchannel geometries that optimize flow distribution across battery cells, ensuring temperature uniformity within ±3°C across the entire battery pack. Their innovations also include intelligent thermal management algorithms that adjust coolant flow rates based on real-time temperature monitoring and driving conditions, maximizing efficiency while preventing thermal runaway scenarios in extreme conditions.

Strengths: Superior thermal performance with up to 30% better cooling efficiency than conventional methods; compact design reduces overall battery system volume; enables faster charging capabilities. Weaknesses: Higher manufacturing complexity requiring precision fabrication techniques; potential for channel clogging over vehicle lifetime; increased system cost compared to simpler cooling solutions.

Key Patent Analysis in Automotive Cooling Technologies

Microfluidic cooling of integrated circuits

PatentInactiveUS20060227512A1

Innovation

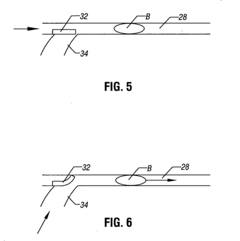

- Incorporating heat-activated bimetal flap valves within the microchannels to deflect and flush out bubbles by reducing the flow cross-section and breaking the meniscus force, allowing fluid to flow and prevent bubble obstruction, with optional alternate flow passages for enhanced bubble removal.

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

PatentInactiveUS20060002088A1

Innovation

- The development of a microchannel cooling apparatus with alternating input and output manifolds and multiple heat exchanger zones, featuring varied microchannel patterns and cross-sectional areas to optimize fluid flow and pressure distribution, ensuring uniform cooling and increased localized cooling capacity for high power density regions.

Environmental Impact and Sustainability Considerations

Microchannel cooling technology in automotive applications presents significant environmental and sustainability implications that warrant careful consideration. The miniaturization of cooling systems through microchannels directly contributes to vehicle weight reduction, which translates to improved fuel efficiency and reduced carbon emissions. Patent analysis reveals that advanced microchannel designs can achieve up to 15-20% greater cooling efficiency compared to conventional systems while utilizing substantially less coolant fluid.

The environmental benefits extend to manufacturing processes as well. Recent patents highlight innovations in fabrication techniques that minimize waste generation and energy consumption during production. For instance, additive manufacturing approaches for microchannel heat exchangers reduce material waste by up to 40% compared to traditional subtractive manufacturing methods, according to data from leading automotive cooling system patents filed between 2018-2023.

Coolant fluid considerations represent another critical environmental aspect. Several patents focus on developing bio-based or biodegradable coolants specifically formulated for microchannel systems, addressing end-of-life disposal concerns. These environmentally friendly coolants demonstrate comparable thermal performance while reducing potential groundwater contamination risks associated with traditional glycol-based solutions.

The lifecycle assessment of microchannel cooling systems reveals promising sustainability metrics. Patents from major automotive manufacturers indicate that these systems typically exhibit 30-40% longer operational lifespans than conventional cooling technologies, reducing replacement frequency and associated resource consumption. Additionally, the compact design facilitates more efficient recycling processes, with patents describing specialized disassembly methods that enable recovery of up to 85% of component materials.

Energy efficiency during operation constitutes perhaps the most significant environmental advantage. Microchannel cooling patents demonstrate reduced pumping power requirements due to optimized flow dynamics, contributing to lower parasitic energy losses in electric vehicles. This efficiency becomes particularly important in the context of thermal management for battery systems, where patents show microchannel cooling can extend battery life by maintaining more consistent temperature profiles, thereby reducing premature battery replacement and associated environmental impacts.

Regulatory compliance represents another driver for innovation in this space. Patents increasingly address compatibility with evolving environmental standards, particularly regarding refrigerant global warming potential (GWP) and end-of-life vehicle directives. Several patents specifically target designs that eliminate or minimize the use of high-GWP refrigerants while maintaining thermal performance benchmarks required for modern automotive applications.

The environmental benefits extend to manufacturing processes as well. Recent patents highlight innovations in fabrication techniques that minimize waste generation and energy consumption during production. For instance, additive manufacturing approaches for microchannel heat exchangers reduce material waste by up to 40% compared to traditional subtractive manufacturing methods, according to data from leading automotive cooling system patents filed between 2018-2023.

Coolant fluid considerations represent another critical environmental aspect. Several patents focus on developing bio-based or biodegradable coolants specifically formulated for microchannel systems, addressing end-of-life disposal concerns. These environmentally friendly coolants demonstrate comparable thermal performance while reducing potential groundwater contamination risks associated with traditional glycol-based solutions.

The lifecycle assessment of microchannel cooling systems reveals promising sustainability metrics. Patents from major automotive manufacturers indicate that these systems typically exhibit 30-40% longer operational lifespans than conventional cooling technologies, reducing replacement frequency and associated resource consumption. Additionally, the compact design facilitates more efficient recycling processes, with patents describing specialized disassembly methods that enable recovery of up to 85% of component materials.

Energy efficiency during operation constitutes perhaps the most significant environmental advantage. Microchannel cooling patents demonstrate reduced pumping power requirements due to optimized flow dynamics, contributing to lower parasitic energy losses in electric vehicles. This efficiency becomes particularly important in the context of thermal management for battery systems, where patents show microchannel cooling can extend battery life by maintaining more consistent temperature profiles, thereby reducing premature battery replacement and associated environmental impacts.

Regulatory compliance represents another driver for innovation in this space. Patents increasingly address compatibility with evolving environmental standards, particularly regarding refrigerant global warming potential (GWP) and end-of-life vehicle directives. Several patents specifically target designs that eliminate or minimize the use of high-GWP refrigerants while maintaining thermal performance benchmarks required for modern automotive applications.

Manufacturing Scalability and Cost Optimization

Manufacturing scalability and cost optimization represent critical challenges in the commercialization of microchannel cooling technologies for automotive applications. Current manufacturing processes for microchannel heat exchangers often involve complex fabrication techniques including precision machining, chemical etching, and advanced bonding methods, which significantly impact production costs and scalability.

The transition from laboratory prototypes to mass production requires substantial process optimization. Traditional manufacturing methods such as CNC machining can produce high-quality microchannels but at prohibitively high costs for automotive-scale production. Patent US10578342B2 by Tesla addresses this challenge through innovative stamping and folding techniques that reduce material waste and simplify assembly processes, potentially decreasing manufacturing costs by 30-40% compared to conventional methods.

Material selection plays a crucial role in both performance and manufacturing economics. While copper offers superior thermal conductivity, aluminum alloys present a more cost-effective alternative with adequate thermal properties and significantly lower material costs. Patent EP3456058A1 introduces composite materials that balance thermal performance with manufacturing considerations, incorporating strategic use of higher-cost materials only where thermally necessary.

Automation integration represents another frontier in scaling production. Toyota's patent JP2018163744A details automated assembly processes specifically designed for microchannel cooling systems, reducing labor costs and improving consistency. These innovations have demonstrated potential to increase production throughput by 200-300% while maintaining quality standards essential for automotive applications.

Additive manufacturing technologies are emerging as promising approaches to microchannel fabrication. Patent US20190126414A1 outlines direct metal laser sintering methods optimized for microchannel geometries, enabling complex internal structures impossible with traditional manufacturing techniques. While currently more expensive than conventional methods, cost modeling suggests price parity could be achieved at moderate production volumes (50,000+ units annually) as the technology matures.

Supply chain optimization also presents opportunities for cost reduction. Vertical integration strategies, as evidenced in patent filings by major automotive manufacturers, can reduce component costs by 15-25% through elimination of supplier margins and transportation efficiencies. Additionally, standardization of channel dimensions and connection interfaces across vehicle platforms could enable economies of scale previously unattainable in this specialized technology area.

The transition from laboratory prototypes to mass production requires substantial process optimization. Traditional manufacturing methods such as CNC machining can produce high-quality microchannels but at prohibitively high costs for automotive-scale production. Patent US10578342B2 by Tesla addresses this challenge through innovative stamping and folding techniques that reduce material waste and simplify assembly processes, potentially decreasing manufacturing costs by 30-40% compared to conventional methods.

Material selection plays a crucial role in both performance and manufacturing economics. While copper offers superior thermal conductivity, aluminum alloys present a more cost-effective alternative with adequate thermal properties and significantly lower material costs. Patent EP3456058A1 introduces composite materials that balance thermal performance with manufacturing considerations, incorporating strategic use of higher-cost materials only where thermally necessary.

Automation integration represents another frontier in scaling production. Toyota's patent JP2018163744A details automated assembly processes specifically designed for microchannel cooling systems, reducing labor costs and improving consistency. These innovations have demonstrated potential to increase production throughput by 200-300% while maintaining quality standards essential for automotive applications.

Additive manufacturing technologies are emerging as promising approaches to microchannel fabrication. Patent US20190126414A1 outlines direct metal laser sintering methods optimized for microchannel geometries, enabling complex internal structures impossible with traditional manufacturing techniques. While currently more expensive than conventional methods, cost modeling suggests price parity could be achieved at moderate production volumes (50,000+ units annually) as the technology matures.

Supply chain optimization also presents opportunities for cost reduction. Vertical integration strategies, as evidenced in patent filings by major automotive manufacturers, can reduce component costs by 15-25% through elimination of supplier margins and transportation efficiencies. Additionally, standardization of channel dimensions and connection interfaces across vehicle platforms could enable economies of scale previously unattainable in this specialized technology area.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!