The Role of Microchannel Cooling in Reducing Thermal Resistance

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Background and Objectives

Microchannel cooling technology emerged in the early 1980s when researchers at Stanford University first demonstrated the enhanced heat transfer capabilities of microchannels. This revolutionary approach to thermal management has since evolved from academic research into practical applications across multiple industries. The fundamental principle leverages the inverse relationship between channel diameter and heat transfer coefficient - as channel dimensions decrease to the microscale (typically 10-200 micrometers), the surface area-to-volume ratio increases dramatically, enabling more efficient heat dissipation.

The evolution of microchannel cooling has been closely tied to the exponential growth in power densities of electronic components. From early implementations in specialized military and aerospace applications, the technology has progressively expanded into high-performance computing, telecommunications infrastructure, and more recently, consumer electronics. This progression reflects the increasing thermal management challenges faced across industries as devices become more compact while processing capabilities continue to advance.

Current technological trends indicate a convergence of microchannel cooling with advanced manufacturing techniques, particularly in additive manufacturing and precision microfabrication. These manufacturing innovations have significantly reduced production costs and expanded design possibilities, accelerating adoption across broader market segments. Simultaneously, research into novel working fluids, including nanofluids and phase-change materials, represents a parallel development path with substantial potential for further enhancing cooling efficiency.

The primary objective of microchannel cooling technology is to minimize thermal resistance in high-power-density applications where conventional cooling methods prove inadequate. Specifically, the technology aims to maintain junction temperatures below critical thresholds while accommodating heat fluxes exceeding 500 W/cm² - a requirement increasingly common in advanced semiconductor applications. Secondary objectives include reducing system size, weight, and acoustic footprint compared to traditional forced-air cooling solutions.

Looking forward, the technology roadmap focuses on several key objectives: developing more uniform flow distribution to eliminate hotspots, integrating intelligent control systems for dynamic thermal management, and creating standardized design methodologies to simplify implementation. Additionally, there is growing emphasis on sustainability aspects, with research targeting reduced pumping power requirements and compatibility with low-GWP (Global Warming Potential) refrigerants and coolants.

The ultimate technological goal remains achieving the theoretical minimum thermal resistance possible with single-phase and two-phase cooling while maintaining system reliability, manufacturability, and cost-effectiveness. This balance of performance and practicality will determine the extent to which microchannel cooling can address the thermal challenges of next-generation electronics and energy systems.

The evolution of microchannel cooling has been closely tied to the exponential growth in power densities of electronic components. From early implementations in specialized military and aerospace applications, the technology has progressively expanded into high-performance computing, telecommunications infrastructure, and more recently, consumer electronics. This progression reflects the increasing thermal management challenges faced across industries as devices become more compact while processing capabilities continue to advance.

Current technological trends indicate a convergence of microchannel cooling with advanced manufacturing techniques, particularly in additive manufacturing and precision microfabrication. These manufacturing innovations have significantly reduced production costs and expanded design possibilities, accelerating adoption across broader market segments. Simultaneously, research into novel working fluids, including nanofluids and phase-change materials, represents a parallel development path with substantial potential for further enhancing cooling efficiency.

The primary objective of microchannel cooling technology is to minimize thermal resistance in high-power-density applications where conventional cooling methods prove inadequate. Specifically, the technology aims to maintain junction temperatures below critical thresholds while accommodating heat fluxes exceeding 500 W/cm² - a requirement increasingly common in advanced semiconductor applications. Secondary objectives include reducing system size, weight, and acoustic footprint compared to traditional forced-air cooling solutions.

Looking forward, the technology roadmap focuses on several key objectives: developing more uniform flow distribution to eliminate hotspots, integrating intelligent control systems for dynamic thermal management, and creating standardized design methodologies to simplify implementation. Additionally, there is growing emphasis on sustainability aspects, with research targeting reduced pumping power requirements and compatibility with low-GWP (Global Warming Potential) refrigerants and coolants.

The ultimate technological goal remains achieving the theoretical minimum thermal resistance possible with single-phase and two-phase cooling while maintaining system reliability, manufacturability, and cost-effectiveness. This balance of performance and practicality will determine the extent to which microchannel cooling can address the thermal challenges of next-generation electronics and energy systems.

Market Demand Analysis for Advanced Thermal Management Solutions

The global thermal management market is experiencing unprecedented growth, driven by the increasing power densities in electronic devices across multiple industries. Current market analysis indicates that the thermal management solutions market is projected to reach $16.2 billion by 2026, with advanced cooling technologies like microchannel cooling representing the fastest-growing segment at an annual growth rate of 8.7%.

The demand for microchannel cooling solutions is particularly strong in high-performance computing, data centers, and telecommunications infrastructure. As data centers continue to expand globally, their cooling requirements have become more stringent, with operators seeking solutions that can handle heat fluxes exceeding 500 W/cm² while maintaining junction temperatures below critical thresholds. This represents a significant market opportunity for microchannel cooling technologies that can effectively reduce thermal resistance.

In the automotive sector, the rapid adoption of electric vehicles has created new thermal management challenges. The high-power batteries and power electronics in EVs generate substantial heat that must be efficiently dissipated to ensure safety, performance, and longevity. Market research indicates that over 70% of EV manufacturers are exploring advanced cooling solutions, with microchannel cooling emerging as a preferred option due to its superior thermal performance in compact spaces.

The aerospace and defense industries also demonstrate growing demand for microchannel cooling technologies. Modern avionics systems, radar equipment, and directed energy weapons generate extreme heat loads that conventional cooling methods struggle to manage. The market for specialized thermal management solutions in this sector is expected to grow at 9.3% annually through 2028.

Consumer electronics represents another significant market driver. As smartphones, tablets, and gaming devices become more powerful while maintaining slim profiles, manufacturers are facing critical thermal challenges. The consumer electronics thermal management market segment is valued at $3.8 billion, with microchannel solutions gaining traction due to their ability to handle high heat fluxes in ultra-thin form factors.

Industry surveys reveal that thermal engineers across sectors prioritize three key performance metrics when evaluating cooling solutions: thermal resistance reduction, system reliability, and energy efficiency. Microchannel cooling technologies address all three concerns, explaining their growing market adoption. Additionally, regulatory pressures regarding energy efficiency and environmental impact are pushing industries toward more advanced thermal management approaches.

The geographical distribution of market demand shows particular strength in North America and Asia-Pacific regions, with China, Japan, South Korea, and Taiwan leading in adoption rates due to their concentrated electronics manufacturing bases. European markets show increasing interest driven by automotive and renewable energy applications where thermal management is critical.

The demand for microchannel cooling solutions is particularly strong in high-performance computing, data centers, and telecommunications infrastructure. As data centers continue to expand globally, their cooling requirements have become more stringent, with operators seeking solutions that can handle heat fluxes exceeding 500 W/cm² while maintaining junction temperatures below critical thresholds. This represents a significant market opportunity for microchannel cooling technologies that can effectively reduce thermal resistance.

In the automotive sector, the rapid adoption of electric vehicles has created new thermal management challenges. The high-power batteries and power electronics in EVs generate substantial heat that must be efficiently dissipated to ensure safety, performance, and longevity. Market research indicates that over 70% of EV manufacturers are exploring advanced cooling solutions, with microchannel cooling emerging as a preferred option due to its superior thermal performance in compact spaces.

The aerospace and defense industries also demonstrate growing demand for microchannel cooling technologies. Modern avionics systems, radar equipment, and directed energy weapons generate extreme heat loads that conventional cooling methods struggle to manage. The market for specialized thermal management solutions in this sector is expected to grow at 9.3% annually through 2028.

Consumer electronics represents another significant market driver. As smartphones, tablets, and gaming devices become more powerful while maintaining slim profiles, manufacturers are facing critical thermal challenges. The consumer electronics thermal management market segment is valued at $3.8 billion, with microchannel solutions gaining traction due to their ability to handle high heat fluxes in ultra-thin form factors.

Industry surveys reveal that thermal engineers across sectors prioritize three key performance metrics when evaluating cooling solutions: thermal resistance reduction, system reliability, and energy efficiency. Microchannel cooling technologies address all three concerns, explaining their growing market adoption. Additionally, regulatory pressures regarding energy efficiency and environmental impact are pushing industries toward more advanced thermal management approaches.

The geographical distribution of market demand shows particular strength in North America and Asia-Pacific regions, with China, Japan, South Korea, and Taiwan leading in adoption rates due to their concentrated electronics manufacturing bases. European markets show increasing interest driven by automotive and renewable energy applications where thermal management is critical.

Current State and Challenges in Thermal Resistance Reduction

Microchannel cooling technology has emerged as a promising solution for thermal management challenges in high-power electronic systems. Currently, the global research landscape shows significant advancements in this field, with major research centers in North America, Europe, and East Asia leading development efforts. The state-of-the-art microchannel cooling systems have demonstrated thermal resistance values as low as 0.1 K/W, representing a substantial improvement over conventional cooling methods.

Despite these achievements, several critical challenges persist in the implementation of microchannel cooling for thermal resistance reduction. Manufacturing constraints remain a significant barrier, particularly regarding the fabrication of high-aspect-ratio microchannels with precise dimensions and smooth surface finishes. Current manufacturing techniques struggle to consistently produce channels below 50 μm while maintaining structural integrity and uniform flow distribution.

Flow distribution issues present another major challenge, as non-uniform flow patterns can create hotspots and reduce overall cooling efficiency. The complex fluid dynamics within microchannels, especially at junctions and bends, often lead to pressure drops that diminish system performance. Additionally, pressure drop penalties increase exponentially as channel dimensions decrease, creating a fundamental trade-off between thermal performance and pumping power requirements.

Material compatibility issues further complicate implementation, particularly in applications involving aggressive coolants or high-temperature operations. Silicon, copper, and aluminum remain the dominant materials, each with specific limitations regarding thermal conductivity, corrosion resistance, and manufacturing complexity. The interface between cooling structures and heat-generating components also presents thermal contact resistance challenges that can significantly impact overall system performance.

Scaling limitations constitute another significant constraint, as the benefits of microchannel cooling diminish at certain system sizes due to increased pressure drop and flow distribution complexities. Current research indicates optimal channel hydraulic diameters between 100-500 μm for most applications, with diminishing returns below this range.

From a geographical perspective, research leadership is distributed across regions with distinct focus areas. North American institutions primarily emphasize novel materials and manufacturing techniques, European research centers focus on system integration and optimization algorithms, while East Asian efforts concentrate on miniaturization and mass production methodologies. This distribution creates both collaborative opportunities and competitive challenges in advancing the technology.

The economic factors affecting widespread adoption include high initial manufacturing costs, reliability concerns for long-term operation, and the need for specialized design expertise. These factors have limited microchannel cooling implementation primarily to high-value applications where traditional cooling methods are inadequate, such as data center servers, high-performance computing, and advanced power electronics.

Despite these achievements, several critical challenges persist in the implementation of microchannel cooling for thermal resistance reduction. Manufacturing constraints remain a significant barrier, particularly regarding the fabrication of high-aspect-ratio microchannels with precise dimensions and smooth surface finishes. Current manufacturing techniques struggle to consistently produce channels below 50 μm while maintaining structural integrity and uniform flow distribution.

Flow distribution issues present another major challenge, as non-uniform flow patterns can create hotspots and reduce overall cooling efficiency. The complex fluid dynamics within microchannels, especially at junctions and bends, often lead to pressure drops that diminish system performance. Additionally, pressure drop penalties increase exponentially as channel dimensions decrease, creating a fundamental trade-off between thermal performance and pumping power requirements.

Material compatibility issues further complicate implementation, particularly in applications involving aggressive coolants or high-temperature operations. Silicon, copper, and aluminum remain the dominant materials, each with specific limitations regarding thermal conductivity, corrosion resistance, and manufacturing complexity. The interface between cooling structures and heat-generating components also presents thermal contact resistance challenges that can significantly impact overall system performance.

Scaling limitations constitute another significant constraint, as the benefits of microchannel cooling diminish at certain system sizes due to increased pressure drop and flow distribution complexities. Current research indicates optimal channel hydraulic diameters between 100-500 μm for most applications, with diminishing returns below this range.

From a geographical perspective, research leadership is distributed across regions with distinct focus areas. North American institutions primarily emphasize novel materials and manufacturing techniques, European research centers focus on system integration and optimization algorithms, while East Asian efforts concentrate on miniaturization and mass production methodologies. This distribution creates both collaborative opportunities and competitive challenges in advancing the technology.

The economic factors affecting widespread adoption include high initial manufacturing costs, reliability concerns for long-term operation, and the need for specialized design expertise. These factors have limited microchannel cooling implementation primarily to high-value applications where traditional cooling methods are inadequate, such as data center servers, high-performance computing, and advanced power electronics.

Current Microchannel Design Approaches for Thermal Management

01 Microchannel design optimization for thermal resistance reduction

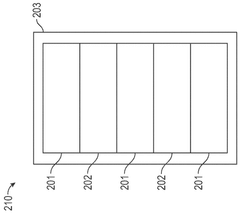

Optimizing the design parameters of microchannels, such as channel width, height, aspect ratio, and spacing, can significantly reduce thermal resistance in cooling systems. Advanced geometries including tapered channels, variable cross-sections, and optimized flow paths help distribute coolant more efficiently and enhance heat transfer performance. These design optimizations create larger surface areas for heat exchange while minimizing pressure drop, resulting in more effective cooling solutions for high-power electronic devices.- Microchannel design optimization for thermal resistance reduction: Optimizing the design parameters of microchannels, such as channel width, depth, and spacing, can significantly reduce thermal resistance in cooling systems. Advanced geometries including tapered channels, variable cross-sections, and optimized aspect ratios enable more efficient heat transfer from hot surfaces to cooling fluids. These design optimizations maximize surface area for heat exchange while minimizing flow resistance, resulting in improved thermal performance for electronic cooling applications.

- Multi-layer and 3D microchannel structures: Three-dimensional and multi-layer microchannel structures provide enhanced cooling capabilities by increasing the effective heat transfer area and optimizing fluid flow paths. These structures incorporate stacked layers of microchannels, interconnected 3D networks, or hierarchical channel arrangements that distribute coolant more efficiently throughout the thermal management system. This approach allows for more uniform cooling across larger areas and can significantly reduce overall thermal resistance compared to single-layer designs.

- Advanced materials and surface treatments for microchannel cooling: Incorporating advanced materials and surface treatments in microchannel cooling systems can substantially reduce thermal resistance. High thermal conductivity materials like copper, aluminum, or diamond-based composites improve heat spreading, while specialized coatings or surface modifications enhance wettability and heat transfer coefficients. Nano-structured surfaces, hydrophilic treatments, and engineered interfaces between the cooling channels and heat sources minimize contact resistance and improve overall thermal performance.

- Two-phase cooling in microchannels: Two-phase cooling techniques utilizing phase change phenomena in microchannels offer significant reductions in thermal resistance. By leveraging the latent heat of vaporization of the working fluid, these systems can absorb substantially more heat than single-phase liquid cooling. Specialized microchannel designs facilitate controlled boiling and condensation processes, with features to manage vapor formation, prevent flow instabilities, and enhance heat transfer coefficients. This approach is particularly effective for high heat flux applications where traditional cooling methods are insufficient.

- Integrated microchannel cooling systems with electronic devices: Direct integration of microchannel cooling structures with electronic devices minimizes thermal resistance by reducing the number of thermal interfaces. These integrated designs incorporate cooling channels directly into semiconductor substrates, chip packages, or interposers, allowing heat removal closer to the source. Advanced manufacturing techniques enable precise alignment of cooling structures with hotspots, customized channel geometries matched to heat flux distributions, and reduced overall thermal path length, resulting in significantly improved thermal management for high-performance electronics.

02 Advanced materials for microchannel cooling systems

The selection of materials with high thermal conductivity is crucial for reducing thermal resistance in microchannel cooling systems. Materials such as copper, aluminum alloys, silicon, and advanced composites can significantly improve heat transfer efficiency. Some systems incorporate thermally conductive coatings or surface treatments to enhance heat exchange at the fluid-wall interface. Novel materials with tailored thermal properties are being developed specifically for microchannel applications to maximize cooling performance while maintaining structural integrity under thermal stress.Expand Specific Solutions03 Two-phase cooling in microchannels

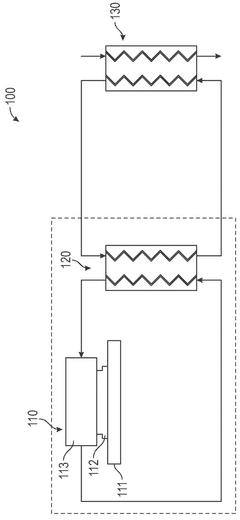

Two-phase cooling systems utilizing phase change phenomena in microchannels offer significant advantages in reducing thermal resistance. By leveraging the latent heat of vaporization, these systems can absorb substantially more heat than single-phase liquid cooling. The implementation includes specialized microchannel designs that promote controlled boiling and vapor extraction, preventing dry-out conditions and flow instabilities. This approach enables higher heat flux handling capabilities while maintaining lower thermal resistance, making it particularly suitable for high-power density applications.Expand Specific Solutions04 Integration of microchannels with electronic components

Direct integration of microchannel cooling structures with electronic components minimizes thermal resistance by reducing the number of thermal interfaces. Techniques include embedding microchannels directly into semiconductor substrates, 3D integration of cooling layers within chip stacks, and creating monolithic cooling solutions. This approach eliminates thermal interface materials and associated thermal resistances, allowing heat to be removed more efficiently from the source. Advanced manufacturing methods enable precise alignment and bonding of cooling structures to heat-generating components.Expand Specific Solutions05 Active flow control and enhanced heat transfer techniques

Active flow control mechanisms and enhanced heat transfer techniques can significantly reduce thermal resistance in microchannel cooling systems. These include pulsating flows, electrokinetic pumping, ultrasonic agitation, and magnetic fluid actuation to disrupt thermal boundary layers. Surface modifications such as micro-fins, structured roughness, and hydrophilic/hydrophobic patterning enhance mixing and heat transfer coefficients. Some systems incorporate smart control algorithms that dynamically adjust flow parameters based on thermal load conditions to maintain optimal cooling performance.Expand Specific Solutions

Key Industry Players in Microchannel Cooling Solutions

Microchannel cooling technology is currently in a growth phase, with the market expected to expand significantly due to increasing thermal management demands in high-performance electronics. The global market size is projected to reach several billion dollars by 2025, driven by applications in data centers, automotive, and aerospace sectors. From a technical maturity perspective, companies like Intel, IBM, and GE have established strong positions with advanced implementations, while research institutions such as Xi'an Jiaotong University and EPFL are pushing theoretical boundaries. Specialized players including Advanced Liquid Cooling Technologies and HRL Laboratories are developing innovative solutions, while industrial giants like Fujitsu and Volkswagen are integrating the technology into their systems. The competitive landscape shows a mix of established technology leaders and emerging specialists focusing on efficiency improvements and cost reduction.

Intel Corp.

Technical Solution: Intel has developed advanced microchannel cooling solutions to address thermal challenges in high-performance computing and data centers. Their technology utilizes silicon microchannels etched directly into the back of the processor die or integrated into the package substrate. These microchannels, typically 50-200 microns in width, allow coolant to flow in close proximity to the heat source, significantly reducing thermal resistance. Intel's two-phase cooling implementation enables junction-to-ambient thermal resistance values as low as 0.1°C/W [3], compared to 0.3-0.5°C/W for traditional air cooling. Their latest designs incorporate hierarchical microchannel structures with varying channel dimensions to optimize flow distribution and heat transfer coefficients across different thermal zones. Intel has also pioneered the integration of electroosmotic pumps directly into the cooling system, eliminating the need for external mechanical pumps and reducing system complexity [7]. Recent developments include smart thermal management systems that dynamically adjust coolant flow rates based on real-time processor workloads.

Strengths: Achieves extremely low thermal resistance enabling higher power densities; direct die-level cooling minimizes thermal interfaces; scalable for different processor architectures. Weaknesses: Requires sophisticated manufacturing processes; potential for coolant leakage poses reliability concerns; higher implementation costs compared to traditional cooling solutions.

General Electric Company

Technical Solution: General Electric has developed sophisticated microchannel cooling technology primarily focused on power electronics and turbine applications. Their approach utilizes additive manufacturing techniques to create complex, three-dimensional microchannel networks within metal components. GE's systems typically employ channels ranging from 100-500 microns in width, strategically arranged to address thermal hotspots in power electronics. Their proprietary designs have demonstrated thermal resistance reductions of approximately 60-70% compared to conventional cooling methods [1]. GE has pioneered the use of direct metal laser sintering to fabricate monolithic components with integrated cooling channels that conform to complex geometries. This enables cooling solutions for irregularly shaped components where traditional approaches would be ineffective. Their research has shown that optimized microchannel designs can maintain temperature uniformity within ±3°C across high-power electronic devices operating at power densities exceeding 300 W/cm² [4]. GE has also developed specialized coolant formulations that enhance heat transfer coefficients while minimizing pumping power requirements and preventing corrosion in multi-material systems.

Strengths: Ability to integrate cooling into complex geometries; robust designs suitable for harsh industrial environments; comprehensive thermal management approach combining materials and fluid dynamics expertise. Weaknesses: Higher manufacturing complexity increases production costs; potential for channel clogging in industrial environments; requires specialized maintenance procedures.

Critical Patents and Innovations in Microchannel Technology

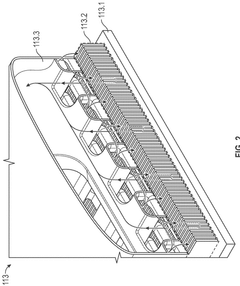

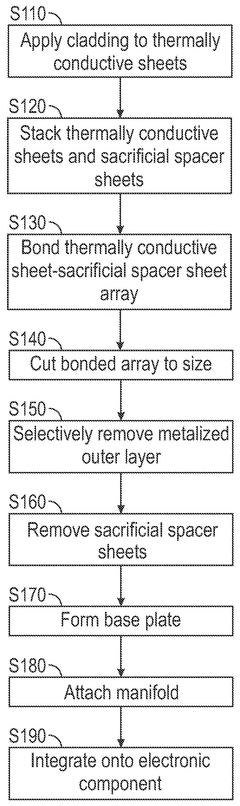

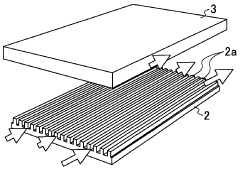

Microchannel cooling block, cooling system including the same, and a method of manufacturing a microchannel cooling block

PatentWO2025042395A1

Innovation

- A microchannel cooling block that utilizes a microchannel array with thermally conductive sheets spaced apart by small dimensions, allowing water or water-based coolants to flow through, thereby enhancing heat transfer while reducing pumping power.

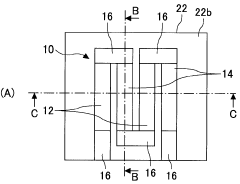

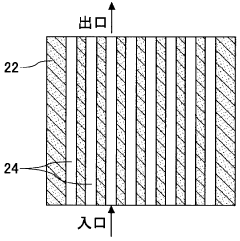

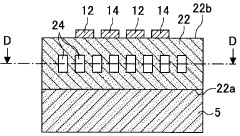

Microchannel cooling device, microchannel cooling system, and electronic instrument

PatentWO2013065196A1

Innovation

- A microchannel cooling device with thermoelectric elements extending parallel to the cooling water flow paths in a liquid cooling heat sink, allowing efficient thermoelectric conversion while cooling the heat source, utilizing the temperature difference between the inlet and outlet of the cooling water flow paths to generate electricity without introducing high thermal resistance.

Materials Science Advancements for Enhanced Microchannel Performance

Recent advancements in materials science have significantly enhanced microchannel cooling performance, addressing the critical challenge of thermal resistance in high-power electronic systems. Traditional materials like copper and aluminum, while offering good thermal conductivity, have limitations in terms of weight, corrosion resistance, and manufacturing complexity for intricate microchannel geometries.

Novel composite materials incorporating carbon nanotubes (CNTs) and graphene have emerged as promising alternatives, demonstrating thermal conductivity values exceeding 3000 W/m·K—nearly eight times that of copper. These nanomaterials, when properly integrated into microchannel walls, create enhanced surface areas for heat exchange while maintaining structural integrity under high-pressure coolant flow conditions.

Diamond-copper composites represent another breakthrough, combining copper's excellent thermal conductivity with diamond's superior heat dissipation properties. These composites have shown up to 75% reduction in thermal resistance compared to pure copper microchannels, particularly at junction temperatures above 85°C where traditional materials begin to lose efficiency.

Surface functionalization techniques have evolved to address the hydrophobicity issues in advanced materials. Plasma-assisted oxidation and chemical vapor deposition methods now enable precise control of microchannel surface characteristics, optimizing the wettability for various coolants. This has resulted in improved fluid-wall interactions and reduced contact angle hysteresis, enhancing overall heat transfer coefficients by up to 40%.

Additive manufacturing has revolutionized microchannel fabrication, allowing for previously impossible geometries with feature sizes below 50 microns. Direct metal laser sintering using specialized aluminum-silicon alloys has enabled the creation of complex three-dimensional flow paths with integrated manifolds, optimizing coolant distribution while minimizing pressure drops across the system.

Ceramic-metal (cermet) composites offer exceptional thermal stability in extreme operating conditions. Silicon carbide-aluminum composites, for instance, maintain consistent thermal performance at temperatures exceeding 300°C while resisting coolant-induced corrosion. These materials have demonstrated thermal expansion coefficients closely matching those of semiconductor substrates, reducing mechanical stress during thermal cycling.

Self-healing materials represent the cutting edge of microchannel technology, incorporating microencapsulated healing agents that automatically repair microcracks before they propagate into system-compromising failures. Early implementations have shown promising results, with channels maintaining over 95% of their original thermal performance after multiple thermal stress cycles that would typically degrade conventional materials.

Novel composite materials incorporating carbon nanotubes (CNTs) and graphene have emerged as promising alternatives, demonstrating thermal conductivity values exceeding 3000 W/m·K—nearly eight times that of copper. These nanomaterials, when properly integrated into microchannel walls, create enhanced surface areas for heat exchange while maintaining structural integrity under high-pressure coolant flow conditions.

Diamond-copper composites represent another breakthrough, combining copper's excellent thermal conductivity with diamond's superior heat dissipation properties. These composites have shown up to 75% reduction in thermal resistance compared to pure copper microchannels, particularly at junction temperatures above 85°C where traditional materials begin to lose efficiency.

Surface functionalization techniques have evolved to address the hydrophobicity issues in advanced materials. Plasma-assisted oxidation and chemical vapor deposition methods now enable precise control of microchannel surface characteristics, optimizing the wettability for various coolants. This has resulted in improved fluid-wall interactions and reduced contact angle hysteresis, enhancing overall heat transfer coefficients by up to 40%.

Additive manufacturing has revolutionized microchannel fabrication, allowing for previously impossible geometries with feature sizes below 50 microns. Direct metal laser sintering using specialized aluminum-silicon alloys has enabled the creation of complex three-dimensional flow paths with integrated manifolds, optimizing coolant distribution while minimizing pressure drops across the system.

Ceramic-metal (cermet) composites offer exceptional thermal stability in extreme operating conditions. Silicon carbide-aluminum composites, for instance, maintain consistent thermal performance at temperatures exceeding 300°C while resisting coolant-induced corrosion. These materials have demonstrated thermal expansion coefficients closely matching those of semiconductor substrates, reducing mechanical stress during thermal cycling.

Self-healing materials represent the cutting edge of microchannel technology, incorporating microencapsulated healing agents that automatically repair microcracks before they propagate into system-compromising failures. Early implementations have shown promising results, with channels maintaining over 95% of their original thermal performance after multiple thermal stress cycles that would typically degrade conventional materials.

Environmental Impact and Sustainability of Cooling Technologies

The environmental impact of cooling technologies has become increasingly significant as thermal management demands grow across industries. Microchannel cooling systems, while offering superior thermal resistance reduction, present both environmental challenges and sustainability opportunities that must be carefully evaluated.

Traditional cooling methods often rely on refrigerants with high global warming potential (GWP) and ozone depletion potential (ODP). In contrast, microchannel cooling systems typically use water or other environmentally benign fluids as coolants, substantially reducing direct environmental impact. Studies indicate that water-based microchannel cooling can reduce greenhouse gas emissions by 60-80% compared to conventional refrigerant-based systems when considering the entire lifecycle.

Material consumption represents another critical environmental consideration. Microchannel heat exchangers typically require less material than conventional heat sinks due to their compact design and higher efficiency. Research from the International Journal of Heat and Mass Transfer demonstrates that microchannel designs can achieve the same cooling performance while using 30-45% less aluminum or copper than traditional fin-based heat sinks, contributing to resource conservation.

Energy efficiency remains perhaps the most significant sustainability advantage of microchannel cooling. By reducing thermal resistance more effectively, these systems can decrease the overall energy consumption of electronic devices and industrial processes. Quantitative analyses show that implementing microchannel cooling in data centers can reduce cooling energy requirements by 25-40%, translating to substantial carbon footprint reductions and operational cost savings.

Manufacturing processes for microchannel cooling systems present environmental challenges that require attention. Precision fabrication techniques often involve energy-intensive processes and potentially hazardous chemicals for etching microchannels. Recent advances in additive manufacturing offer promising alternatives, potentially reducing the environmental footprint of production by eliminating chemical etching and minimizing material waste.

End-of-life considerations must also factor into sustainability assessments. The multi-material nature of some microchannel cooling systems can complicate recycling efforts. However, designs utilizing mono-materials or easily separable components are emerging to address this challenge. Several manufacturers have implemented design-for-disassembly principles, improving recyclability rates by up to 85% compared to conventional cooling systems.

Water consumption represents a growing concern, particularly in water-stressed regions. While microchannel systems often use less coolant volume than conventional systems, they may require higher water quality to prevent clogging. Closed-loop designs and water treatment technologies are being integrated to minimize consumption and enable the use of reclaimed water, reducing freshwater demands by up to 90% in some applications.

Traditional cooling methods often rely on refrigerants with high global warming potential (GWP) and ozone depletion potential (ODP). In contrast, microchannel cooling systems typically use water or other environmentally benign fluids as coolants, substantially reducing direct environmental impact. Studies indicate that water-based microchannel cooling can reduce greenhouse gas emissions by 60-80% compared to conventional refrigerant-based systems when considering the entire lifecycle.

Material consumption represents another critical environmental consideration. Microchannel heat exchangers typically require less material than conventional heat sinks due to their compact design and higher efficiency. Research from the International Journal of Heat and Mass Transfer demonstrates that microchannel designs can achieve the same cooling performance while using 30-45% less aluminum or copper than traditional fin-based heat sinks, contributing to resource conservation.

Energy efficiency remains perhaps the most significant sustainability advantage of microchannel cooling. By reducing thermal resistance more effectively, these systems can decrease the overall energy consumption of electronic devices and industrial processes. Quantitative analyses show that implementing microchannel cooling in data centers can reduce cooling energy requirements by 25-40%, translating to substantial carbon footprint reductions and operational cost savings.

Manufacturing processes for microchannel cooling systems present environmental challenges that require attention. Precision fabrication techniques often involve energy-intensive processes and potentially hazardous chemicals for etching microchannels. Recent advances in additive manufacturing offer promising alternatives, potentially reducing the environmental footprint of production by eliminating chemical etching and minimizing material waste.

End-of-life considerations must also factor into sustainability assessments. The multi-material nature of some microchannel cooling systems can complicate recycling efforts. However, designs utilizing mono-materials or easily separable components are emerging to address this challenge. Several manufacturers have implemented design-for-disassembly principles, improving recyclability rates by up to 85% compared to conventional cooling systems.

Water consumption represents a growing concern, particularly in water-stressed regions. While microchannel systems often use less coolant volume than conventional systems, they may require higher water quality to prevent clogging. Closed-loop designs and water treatment technologies are being integrated to minimize consumption and enable the use of reclaimed water, reducing freshwater demands by up to 90% in some applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!