Evaluating Microchannel Cooling's Role in Grid-Tied Energy Systems

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Evolution and Objectives

Microchannel cooling technology has evolved significantly over the past three decades, transitioning from theoretical concepts to practical applications across multiple industries. Initially developed in the 1980s for microelectronics cooling, the technology has undergone substantial refinement in channel design, material selection, and manufacturing processes. Early implementations featured relatively simple channel geometries with widths of 100-1000 micrometers, while modern designs incorporate complex three-dimensional structures with channel dimensions below 50 micrometers, dramatically enhancing heat transfer efficiency.

The evolution of microchannel cooling has been driven by increasing thermal management demands across various sectors. In computing and electronics, the continuous miniaturization of components coupled with rising power densities has necessitated more effective cooling solutions. Similarly, in power electronics for grid applications, the push toward higher power densities and switching frequencies has created thermal challenges that conventional cooling methods struggle to address.

A significant technological milestone occurred in the early 2000s with the development of advanced manufacturing techniques, including precision etching, laser machining, and additive manufacturing, which enabled more complex and efficient microchannel designs. This manufacturing evolution coincided with breakthroughs in computational fluid dynamics modeling, allowing engineers to optimize channel geometries for specific applications with unprecedented precision.

In the context of grid-tied energy systems, microchannel cooling technology has emerged as a critical enabler for high-density power conversion equipment. The integration of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) in grid-tied inverters and converters has pushed operating temperatures and power densities to new heights, creating an urgent need for advanced thermal management solutions.

The primary objective of microchannel cooling in grid-tied energy systems is to enable higher power densities while maintaining component temperatures within safe operating limits. This translates to smaller, more efficient power conversion equipment with reduced material requirements and installation footprints. Secondary objectives include enhancing system reliability through more uniform temperature distribution, extending component lifespans, and enabling operation in harsh environmental conditions.

Looking forward, the technology trajectory aims to achieve several ambitious goals: reducing thermal resistance below 0.1°C/W for high-power applications, developing integrated cooling solutions that combine microchannels with phase-change materials for enhanced thermal buffering, and creating self-regulating cooling systems that dynamically adjust to varying thermal loads. These advancements would significantly impact the deployment of distributed energy resources, grid-scale storage systems, and high-power electric vehicle charging infrastructure.

The evolution of microchannel cooling has been driven by increasing thermal management demands across various sectors. In computing and electronics, the continuous miniaturization of components coupled with rising power densities has necessitated more effective cooling solutions. Similarly, in power electronics for grid applications, the push toward higher power densities and switching frequencies has created thermal challenges that conventional cooling methods struggle to address.

A significant technological milestone occurred in the early 2000s with the development of advanced manufacturing techniques, including precision etching, laser machining, and additive manufacturing, which enabled more complex and efficient microchannel designs. This manufacturing evolution coincided with breakthroughs in computational fluid dynamics modeling, allowing engineers to optimize channel geometries for specific applications with unprecedented precision.

In the context of grid-tied energy systems, microchannel cooling technology has emerged as a critical enabler for high-density power conversion equipment. The integration of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) in grid-tied inverters and converters has pushed operating temperatures and power densities to new heights, creating an urgent need for advanced thermal management solutions.

The primary objective of microchannel cooling in grid-tied energy systems is to enable higher power densities while maintaining component temperatures within safe operating limits. This translates to smaller, more efficient power conversion equipment with reduced material requirements and installation footprints. Secondary objectives include enhancing system reliability through more uniform temperature distribution, extending component lifespans, and enabling operation in harsh environmental conditions.

Looking forward, the technology trajectory aims to achieve several ambitious goals: reducing thermal resistance below 0.1°C/W for high-power applications, developing integrated cooling solutions that combine microchannels with phase-change materials for enhanced thermal buffering, and creating self-regulating cooling systems that dynamically adjust to varying thermal loads. These advancements would significantly impact the deployment of distributed energy resources, grid-scale storage systems, and high-power electric vehicle charging infrastructure.

Grid-Tied Energy Systems Market Demand Analysis

The global grid-tied energy systems market is experiencing significant growth driven by increasing energy demands, sustainability concerns, and the transition toward renewable energy sources. Current market analysis indicates that the integration of efficient thermal management solutions, particularly microchannel cooling technologies, is becoming increasingly critical as power densities in grid infrastructure continue to rise.

Market research shows that the grid-tied energy storage systems market is projected to grow at a compound annual growth rate of 16% through 2030, with thermal management solutions representing a substantial segment within this expansion. This growth is primarily fueled by the increasing deployment of high-density power electronics in grid infrastructure, including inverters, converters, and energy storage systems.

The demand for microchannel cooling solutions in grid-tied systems is particularly pronounced in regions experiencing rapid renewable energy adoption. North America, Europe, and parts of Asia-Pacific currently lead this market segment, with emerging economies showing accelerated growth trajectories as they modernize their grid infrastructure.

Key market drivers include the increasing integration of distributed energy resources (DERs), which require efficient cooling solutions to maintain optimal performance and longevity. The proliferation of solar photovoltaic installations, wind farms, and battery energy storage systems has created substantial demand for advanced thermal management technologies that can handle the high heat fluxes generated by power conversion equipment.

Industry surveys indicate that grid operators and energy system manufacturers are prioritizing cooling solutions that offer improved energy efficiency, reduced footprint, and enhanced reliability. Microchannel cooling systems, with their superior heat transfer capabilities and compact design, are increasingly viewed as a strategic technology to address these requirements.

The market demand is further segmented by application areas, with utility-scale installations representing approximately 45% of the current market, commercial applications at 30%, and residential systems accounting for 25%. However, the residential segment is showing the fastest growth rate as distributed generation becomes more mainstream.

Customer requirements analysis reveals that the market increasingly values cooling solutions that can demonstrate tangible improvements in overall system efficiency, with potential energy savings of 3-7% being a significant decision factor. Additionally, solutions that can extend the operational lifespan of grid-tied electronics by preventing thermal degradation are commanding premium positioning in the market.

Regulatory factors are also shaping market demand, with increasingly stringent efficiency standards for grid-connected equipment driving the adoption of advanced cooling technologies. Several major markets have introduced or are planning to introduce regulations that will effectively require more efficient thermal management solutions than traditional air cooling can provide.

Market research shows that the grid-tied energy storage systems market is projected to grow at a compound annual growth rate of 16% through 2030, with thermal management solutions representing a substantial segment within this expansion. This growth is primarily fueled by the increasing deployment of high-density power electronics in grid infrastructure, including inverters, converters, and energy storage systems.

The demand for microchannel cooling solutions in grid-tied systems is particularly pronounced in regions experiencing rapid renewable energy adoption. North America, Europe, and parts of Asia-Pacific currently lead this market segment, with emerging economies showing accelerated growth trajectories as they modernize their grid infrastructure.

Key market drivers include the increasing integration of distributed energy resources (DERs), which require efficient cooling solutions to maintain optimal performance and longevity. The proliferation of solar photovoltaic installations, wind farms, and battery energy storage systems has created substantial demand for advanced thermal management technologies that can handle the high heat fluxes generated by power conversion equipment.

Industry surveys indicate that grid operators and energy system manufacturers are prioritizing cooling solutions that offer improved energy efficiency, reduced footprint, and enhanced reliability. Microchannel cooling systems, with their superior heat transfer capabilities and compact design, are increasingly viewed as a strategic technology to address these requirements.

The market demand is further segmented by application areas, with utility-scale installations representing approximately 45% of the current market, commercial applications at 30%, and residential systems accounting for 25%. However, the residential segment is showing the fastest growth rate as distributed generation becomes more mainstream.

Customer requirements analysis reveals that the market increasingly values cooling solutions that can demonstrate tangible improvements in overall system efficiency, with potential energy savings of 3-7% being a significant decision factor. Additionally, solutions that can extend the operational lifespan of grid-tied electronics by preventing thermal degradation are commanding premium positioning in the market.

Regulatory factors are also shaping market demand, with increasingly stringent efficiency standards for grid-connected equipment driving the adoption of advanced cooling technologies. Several major markets have introduced or are planning to introduce regulations that will effectively require more efficient thermal management solutions than traditional air cooling can provide.

Current Microchannel Cooling Challenges in Energy Systems

Microchannel cooling technology faces several significant challenges in grid-tied energy systems despite its promising thermal management capabilities. The primary obstacle remains the high manufacturing complexity and associated costs. Current fabrication processes require precision engineering at microscale dimensions, often involving specialized equipment and clean room environments. These requirements substantially increase production expenses, limiting widespread adoption in cost-sensitive energy applications.

Pressure drop issues present another critical challenge. As fluid flows through microchannels, significant pressure drops occur due to viscous effects and flow constriction, necessitating higher pumping power. This increased energy consumption partially offsets the efficiency gains achieved through improved thermal management, creating a performance trade-off that must be carefully balanced in grid-connected systems.

Fouling and clogging represent persistent operational concerns. Microchannels are particularly susceptible to blockage from particulates, mineral deposits, and biological growth due to their small dimensions. In grid-tied applications where continuous operation is essential, maintenance requirements and system reliability become significant considerations. Current filtration solutions add complexity and additional pressure drops to the system.

Material compatibility challenges also emerge when integrating microchannel cooling with existing grid infrastructure. The need for corrosion-resistant materials that simultaneously offer high thermal conductivity creates design constraints. Additionally, thermal expansion mismatches between microchannel structures and surrounding components can lead to mechanical stress and potential failure points during thermal cycling.

Scaling challenges persist when attempting to implement microchannel cooling in large-scale energy systems. While the technology demonstrates excellent performance in laboratory settings and smaller applications, maintaining uniform flow distribution and thermal performance across larger arrays remains problematic. This non-uniformity can create hotspots and reduce overall system efficiency.

Control system integration presents further complications. The rapid thermal response of microchannel systems requires sophisticated control algorithms to maintain stable operation under varying load conditions typical in grid-tied applications. Current control systems often struggle to optimize performance across the wide operating range demanded by energy systems.

Finally, long-term reliability data remains limited. With most microchannel cooling systems in energy applications being relatively recent implementations, comprehensive understanding of degradation mechanisms, maintenance requirements, and expected service life is still developing. This uncertainty creates hesitation among system designers and operators considering adoption of this technology in critical grid infrastructure.

Pressure drop issues present another critical challenge. As fluid flows through microchannels, significant pressure drops occur due to viscous effects and flow constriction, necessitating higher pumping power. This increased energy consumption partially offsets the efficiency gains achieved through improved thermal management, creating a performance trade-off that must be carefully balanced in grid-connected systems.

Fouling and clogging represent persistent operational concerns. Microchannels are particularly susceptible to blockage from particulates, mineral deposits, and biological growth due to their small dimensions. In grid-tied applications where continuous operation is essential, maintenance requirements and system reliability become significant considerations. Current filtration solutions add complexity and additional pressure drops to the system.

Material compatibility challenges also emerge when integrating microchannel cooling with existing grid infrastructure. The need for corrosion-resistant materials that simultaneously offer high thermal conductivity creates design constraints. Additionally, thermal expansion mismatches between microchannel structures and surrounding components can lead to mechanical stress and potential failure points during thermal cycling.

Scaling challenges persist when attempting to implement microchannel cooling in large-scale energy systems. While the technology demonstrates excellent performance in laboratory settings and smaller applications, maintaining uniform flow distribution and thermal performance across larger arrays remains problematic. This non-uniformity can create hotspots and reduce overall system efficiency.

Control system integration presents further complications. The rapid thermal response of microchannel systems requires sophisticated control algorithms to maintain stable operation under varying load conditions typical in grid-tied applications. Current control systems often struggle to optimize performance across the wide operating range demanded by energy systems.

Finally, long-term reliability data remains limited. With most microchannel cooling systems in energy applications being relatively recent implementations, comprehensive understanding of degradation mechanisms, maintenance requirements, and expected service life is still developing. This uncertainty creates hesitation among system designers and operators considering adoption of this technology in critical grid infrastructure.

Existing Microchannel Integration Approaches

01 Microchannel design optimization for cooling efficiency

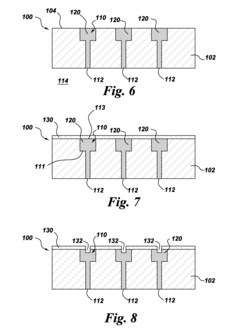

The design of microchannels significantly impacts cooling efficiency. Optimized geometries, including channel width, depth, and spacing, can enhance heat transfer rates. Various cross-sectional shapes and flow path configurations are employed to reduce pressure drop while maximizing thermal performance. Advanced designs incorporate variable channel dimensions and custom flow patterns to address hotspots and ensure uniform cooling across the entire system.- Microchannel design optimization for cooling efficiency: The design of microchannels significantly impacts cooling efficiency. Optimized geometries, including channel width, depth, and spacing, can enhance heat transfer rates. Advanced designs incorporate variable cross-sections, curved channels, and engineered surface structures to reduce flow resistance while maximizing thermal exchange. These optimizations help to prevent hotspots and ensure uniform cooling across the entire system.

- Coolant flow management in microchannel systems: Effective management of coolant flow is crucial for microchannel cooling efficiency. This includes controlling flow rates, pressure distribution, and flow patterns to optimize heat removal. Advanced systems incorporate flow regulators, manifolds, and distributors to ensure uniform coolant distribution across parallel microchannels. Techniques such as pulsed flow, counter-flow arrangements, and turbulence generators can significantly enhance heat transfer coefficients while minimizing pumping power requirements.

- Advanced materials for microchannel cooling systems: Material selection plays a critical role in microchannel cooling efficiency. High thermal conductivity materials like copper, aluminum alloys, and silicon carbide enhance heat transfer from hot surfaces to coolants. Specialized coatings and surface treatments can prevent corrosion, reduce fouling, and modify surface wettability to improve cooling performance. Composite materials and engineered structures with tailored thermal properties are being developed to optimize heat dissipation while maintaining structural integrity under thermal cycling.

- Two-phase cooling in microchannels: Two-phase cooling leverages the latent heat of vaporization to significantly increase cooling efficiency in microchannel systems. By allowing the coolant to undergo phase change from liquid to vapor within the microchannels, much higher heat transfer rates can be achieved compared to single-phase cooling. This approach requires careful management of bubble formation, flow boiling instabilities, and vapor extraction to prevent dry-out conditions. Advanced designs incorporate nucleation sites, flow stabilizers, and vapor extraction mechanisms to optimize two-phase cooling performance.

- Monitoring and control systems for microchannel cooling: Intelligent monitoring and control systems enhance microchannel cooling efficiency by dynamically adjusting cooling parameters based on real-time thermal conditions. These systems incorporate temperature sensors, flow meters, and pressure transducers to collect operational data. Advanced algorithms process this information to optimize coolant flow rates, pressure, and distribution according to changing thermal loads. Predictive models can anticipate cooling needs based on system usage patterns, allowing for proactive thermal management that maximizes efficiency while minimizing energy consumption.

02 Advanced materials for microchannel cooling systems

Material selection plays a crucial role in microchannel cooling efficiency. High thermal conductivity materials like copper and aluminum alloys improve heat dissipation. Novel materials including specialized polymers, ceramics, and composite materials offer benefits such as corrosion resistance, reduced weight, and enhanced thermal properties. Surface treatments and coatings can further improve wettability and heat transfer characteristics of microchannel walls.Expand Specific Solutions03 Two-phase flow and phase change cooling techniques

Two-phase cooling leverages the latent heat of vaporization to achieve superior cooling efficiency in microchannels. By utilizing working fluids that undergo phase change, these systems can handle significantly higher heat fluxes compared to single-phase cooling. Techniques include flow boiling, condensation, and evaporation within microchannels. Specialized designs address challenges such as flow instabilities, dry-out conditions, and vapor management to maximize cooling performance.Expand Specific Solutions04 Integration of microchannel cooling with electronic devices

Direct integration of microchannel cooling with electronic components enables more efficient thermal management. These integrated cooling solutions can be incorporated into semiconductor packages, processors, power electronics, and other high-heat-generating devices. Techniques include embedding microchannels directly into silicon substrates, 3D integration of cooling layers, and close-coupled cooling designs that minimize thermal resistance between heat sources and cooling channels.Expand Specific Solutions05 Monitoring and control systems for microchannel cooling

Advanced monitoring and control systems enhance microchannel cooling efficiency through real-time adjustment of cooling parameters. These systems utilize temperature sensors, flow meters, and pressure transducers to collect operational data. Intelligent control algorithms dynamically adjust flow rates, pressure, and coolant distribution based on thermal load requirements. Predictive models and machine learning techniques optimize cooling performance while minimizing energy consumption and preventing system failures.Expand Specific Solutions

Leading Companies and Competitive Landscape

Microchannel cooling technology in grid-tied energy systems is currently in a growth phase, with the market expanding as thermal management becomes critical for power electronics efficiency. The global market is projected to reach significant scale as data centers, renewable energy systems, and electric vehicles drive demand. Technologically, the field shows varying maturity levels across applications, with companies like Intel, GLOBALFOUNDRIES, and Fujitsu leading semiconductor cooling innovations, while Fraunhofer-Gesellschaft, GE, and Volkswagen advance power electronics applications. Research institutions including Karlsruhe Institute of Technology and Shandong University are developing next-generation solutions, while Carrier and Lam Research focus on commercial implementation. The ecosystem demonstrates strong collaboration between academic research and industrial applications, with increasing integration into renewable energy infrastructure.

Intel Corp.

Technical Solution: Intel has developed advanced microchannel cooling solutions specifically designed for high-performance computing systems and data centers that interface with grid-tied energy systems. Their technology utilizes microchannels etched directly into silicon substrates with dimensions ranging from 50-500 micrometers, allowing coolant to flow in close proximity to heat-generating components. Intel's two-phase cooling approach employs dielectric fluids that undergo phase change within the microchannels, absorbing significant thermal energy through latent heat of vaporization. This system is integrated with intelligent control systems that optimize coolant flow rates based on real-time thermal loads and grid energy availability, enabling dynamic response to both computing demands and grid conditions. Intel has demonstrated up to 1000 W/cm² heat flux removal capability in laboratory settings, significantly outperforming traditional air cooling methods while reducing overall energy consumption of cooling infrastructure by approximately 30-40% compared to conventional approaches.

Strengths: Superior thermal performance allowing for higher power density computing; reduced energy consumption for cooling; ability to integrate with dynamic grid response systems. Weaknesses: Higher implementation costs; requires specialized manufacturing processes; potential for coolant leakage concerns in production environments.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has pioneered an innovative microchannel cooling system specifically designed for grid-tied energy applications. Their approach utilizes a network of precisely engineered microchannels (typically 50-200μm in width) fabricated using advanced MEMS technology. The system incorporates a novel working fluid with enhanced thermal properties that enables efficient heat transfer while maintaining electrical isolation properties critical for grid applications. HRL's solution features embedded sensors throughout the microchannel network that provide real-time temperature and flow data, enabling dynamic adjustment of cooling parameters based on grid load conditions. This adaptive control system optimizes energy usage by modulating cooling intensity according to actual thermal demands and grid energy availability. The technology has demonstrated cooling capacities exceeding 500 W/cm² in laboratory testing, with the ability to handle the transient thermal loads characteristic of grid-tied power electronics. HRL has integrated this cooling technology with their power conversion systems, achieving a 25% reduction in overall system size while improving conversion efficiency by approximately 3-5% compared to conventional cooling approaches.

Strengths: Exceptional thermal management capability for high-power density applications; intelligent adaptive control system that responds to grid conditions; reduced system footprint enabling more compact power electronics. Weaknesses: Higher initial manufacturing complexity and cost; requires specialized maintenance protocols; potential challenges with long-term reliability in field deployment conditions.

Critical Patents and Technical Innovations

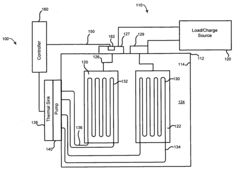

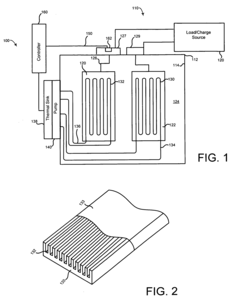

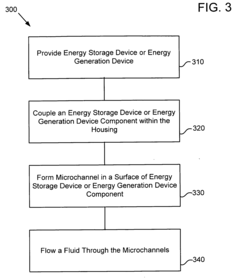

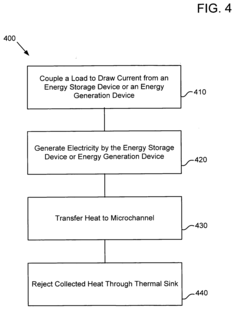

System for operating an electrical energy storage device or an electrochemical energy generation device using microchannels based on mobile device states and vehicle states

PatentInactiveUS20100304250A1

Innovation

- A microchannel thermal control system integrated with high thermal conductivity materials and a fluid control system, controlled by a controller with a sophisticated algorithm, to manage heat generated during charging and discharging processes, utilizing sensors to monitor electrical and vehicle characteristics for optimized cooling.

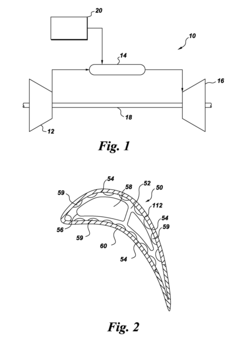

Cooling channel systems for high-temperature components covered by coatings, and related processes

PatentActiveUS20120163984A1

Innovation

- A method involving the formation of microchannels and coolant passage holes, followed by filling with a sacrificial material, applying a metallic structural coating, creating passive cooling holes or slots, and removing the filler material, with additional coating layers to enhance coolant flow and protect against TBC failure.

Energy Efficiency and Sustainability Impact

Microchannel cooling technology demonstrates significant potential for enhancing energy efficiency across grid-tied energy systems. When properly implemented, these systems can reduce cooling energy consumption by 15-30% compared to conventional cooling methods, directly contributing to lower operational costs and reduced carbon footprints for data centers, power electronics, and renewable energy installations.

The sustainability impact of microchannel cooling extends beyond direct energy savings. By enabling more efficient thermal management, these systems allow for higher power densities in electronic components without corresponding increases in cooling requirements. This efficiency translates to smaller physical footprints for energy infrastructure, reducing material usage and associated environmental impacts throughout the supply chain.

From a lifecycle perspective, microchannel cooling systems typically demonstrate favorable sustainability metrics. Although manufacturing processes for precision microchannels require specialized equipment and potentially energy-intensive fabrication methods, the operational efficiency gains over the system lifetime generally offset initial production impacts. Recent lifecycle assessments indicate that the embodied carbon of microchannel systems can be recovered through operational savings within 1-3 years of deployment in high-utilization scenarios.

Water consumption represents an important consideration in evaluating sustainability impacts. While liquid-cooled microchannel systems require water resources, their closed-loop design minimizes consumption compared to traditional cooling towers. Additionally, the higher efficiency of heat transfer enables reduced overall water requirements per unit of cooling capacity. In regions facing water scarcity, this attribute provides significant environmental advantages.

Grid resilience benefits emerge as another sustainability dimension of microchannel cooling technology. By enabling more efficient operation of power electronics and conversion equipment, these systems can help stabilize grid operations during peak demand periods. The improved thermal management allows power systems to operate closer to their theoretical limits without risking thermal damage, effectively increasing the functional capacity of existing grid infrastructure without requiring extensive new construction.

When integrated with renewable energy systems, microchannel cooling can address intermittency challenges by improving the efficiency of energy storage components. Battery systems and power conversion equipment operate more efficiently at controlled temperatures, extending their operational lifespans and improving round-trip efficiency. This synergy between thermal management and renewable integration represents a critical pathway toward sustainable energy transition.

The sustainability impact of microchannel cooling extends beyond direct energy savings. By enabling more efficient thermal management, these systems allow for higher power densities in electronic components without corresponding increases in cooling requirements. This efficiency translates to smaller physical footprints for energy infrastructure, reducing material usage and associated environmental impacts throughout the supply chain.

From a lifecycle perspective, microchannel cooling systems typically demonstrate favorable sustainability metrics. Although manufacturing processes for precision microchannels require specialized equipment and potentially energy-intensive fabrication methods, the operational efficiency gains over the system lifetime generally offset initial production impacts. Recent lifecycle assessments indicate that the embodied carbon of microchannel systems can be recovered through operational savings within 1-3 years of deployment in high-utilization scenarios.

Water consumption represents an important consideration in evaluating sustainability impacts. While liquid-cooled microchannel systems require water resources, their closed-loop design minimizes consumption compared to traditional cooling towers. Additionally, the higher efficiency of heat transfer enables reduced overall water requirements per unit of cooling capacity. In regions facing water scarcity, this attribute provides significant environmental advantages.

Grid resilience benefits emerge as another sustainability dimension of microchannel cooling technology. By enabling more efficient operation of power electronics and conversion equipment, these systems can help stabilize grid operations during peak demand periods. The improved thermal management allows power systems to operate closer to their theoretical limits without risking thermal damage, effectively increasing the functional capacity of existing grid infrastructure without requiring extensive new construction.

When integrated with renewable energy systems, microchannel cooling can address intermittency challenges by improving the efficiency of energy storage components. Battery systems and power conversion equipment operate more efficiently at controlled temperatures, extending their operational lifespans and improving round-trip efficiency. This synergy between thermal management and renewable integration represents a critical pathway toward sustainable energy transition.

Regulatory Framework for Grid-Connected Cooling Technologies

The regulatory landscape governing grid-connected cooling technologies, particularly microchannel cooling systems, presents a complex framework that varies significantly across jurisdictions. In the United States, the Federal Energy Regulatory Commission (FERC) oversees grid interconnection standards, while state-level public utility commissions implement specific requirements for distributed energy resources. These regulations typically address safety protocols, grid stability measures, and technical specifications for energy systems connected to the public grid.

The European Union has established the Network Code on Requirements for Grid Connection, which provides harmonized rules for connecting new power-generating modules, including cooling systems that interact with the grid. This framework emphasizes frequency stability, voltage control, and fault ride-through capabilities to ensure grid resilience when integrating new technologies like microchannel cooling systems.

Energy efficiency standards represent another critical regulatory component. The International Electrotechnical Commission (IEC) has developed standards specifically addressing the performance metrics and safety requirements for thermal management systems in grid-connected applications. These standards establish minimum efficiency thresholds and testing protocols that manufacturers must meet before market entry.

Grid-connected cooling technologies must also comply with environmental regulations. The Montreal Protocol and subsequent amendments restrict the use of refrigerants with high global warming potential, directly impacting the design and operation of advanced cooling systems. The Kigali Amendment specifically mandates the phase-down of hydrofluorocarbons (HFCs), pushing manufacturers toward natural refrigerants or low-GWP alternatives in microchannel applications.

Incentive structures and market mechanisms form an essential part of the regulatory framework. Many jurisdictions have implemented demand response programs, capacity markets, and ancillary service markets that can provide revenue streams for grid-interactive cooling technologies. These market structures reward systems that can modulate their operation to support grid stability, creating economic incentives for the deployment of advanced cooling technologies with grid-responsive capabilities.

Building codes and energy standards increasingly incorporate provisions for grid-interactive building systems. ASHRAE Standard 189.1 and the International Green Construction Code include requirements for building systems to communicate with and respond to grid signals, creating a regulatory pathway for the integration of advanced cooling technologies like microchannel systems into smart building infrastructure.

Cybersecurity regulations have emerged as a critical consideration for grid-connected technologies. The North American Electric Reliability Corporation (NERC) Critical Infrastructure Protection (CIP) standards establish requirements for the security of cyber assets essential to the reliable operation of the electric grid, which increasingly includes advanced cooling systems integrated into grid operations.

The European Union has established the Network Code on Requirements for Grid Connection, which provides harmonized rules for connecting new power-generating modules, including cooling systems that interact with the grid. This framework emphasizes frequency stability, voltage control, and fault ride-through capabilities to ensure grid resilience when integrating new technologies like microchannel cooling systems.

Energy efficiency standards represent another critical regulatory component. The International Electrotechnical Commission (IEC) has developed standards specifically addressing the performance metrics and safety requirements for thermal management systems in grid-connected applications. These standards establish minimum efficiency thresholds and testing protocols that manufacturers must meet before market entry.

Grid-connected cooling technologies must also comply with environmental regulations. The Montreal Protocol and subsequent amendments restrict the use of refrigerants with high global warming potential, directly impacting the design and operation of advanced cooling systems. The Kigali Amendment specifically mandates the phase-down of hydrofluorocarbons (HFCs), pushing manufacturers toward natural refrigerants or low-GWP alternatives in microchannel applications.

Incentive structures and market mechanisms form an essential part of the regulatory framework. Many jurisdictions have implemented demand response programs, capacity markets, and ancillary service markets that can provide revenue streams for grid-interactive cooling technologies. These market structures reward systems that can modulate their operation to support grid stability, creating economic incentives for the deployment of advanced cooling technologies with grid-responsive capabilities.

Building codes and energy standards increasingly incorporate provisions for grid-interactive building systems. ASHRAE Standard 189.1 and the International Green Construction Code include requirements for building systems to communicate with and respond to grid signals, creating a regulatory pathway for the integration of advanced cooling technologies like microchannel systems into smart building infrastructure.

Cybersecurity regulations have emerged as a critical consideration for grid-connected technologies. The North American Electric Reliability Corporation (NERC) Critical Infrastructure Protection (CIP) standards establish requirements for the security of cyber assets essential to the reliable operation of the electric grid, which increasingly includes advanced cooling systems integrated into grid operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!