How Microchannel Cooling Maximizes Performance in Turbomachinery

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Evolution and Objectives

Microchannel cooling technology has evolved significantly over the past four decades since its initial conceptualization in the early 1980s. Originally developed for electronic cooling applications, this technology has undergone substantial transformation to address the increasing thermal management challenges in high-performance systems. The evolution began with simple straight channel designs and has progressed to complex three-dimensional architectures that optimize fluid flow and heat transfer characteristics.

In the turbomachinery sector, microchannel cooling represents a revolutionary approach to thermal management. Traditional cooling methods such as film cooling and conventional internal cooling passages have reached their performance limits as operating temperatures continue to rise in pursuit of higher efficiency. The transition toward microchannel technology marks a paradigm shift in how engineers approach cooling design in turbine blades, combustion liners, and other critical components.

The fundamental principle behind microchannel cooling involves the creation of small passages (typically 10-200 micrometers in hydraulic diameter) that maximize the surface area-to-volume ratio, thereby enhancing heat transfer coefficients by 2-5 times compared to conventional cooling techniques. This characteristic becomes increasingly valuable as turbomachinery systems push toward higher operating temperatures and power densities.

A significant milestone in this evolution was the development of advanced manufacturing techniques, particularly additive manufacturing, which has enabled the production of previously impossible geometries. This manufacturing revolution, beginning around 2010, has accelerated the implementation of microchannel cooling in turbomachinery by overcoming traditional fabrication limitations that restricted channel dimensions and configurations.

The primary objectives of microchannel cooling in turbomachinery applications are multifaceted. First, to increase the thermal efficiency of gas turbines by enabling higher turbine inlet temperatures without compromising component lifespan. Second, to reduce cooling air requirements, thereby improving overall cycle efficiency. Third, to achieve more uniform temperature distributions across critical components, minimizing thermal stress and extending service intervals.

Looking forward, the technology aims to enable next-generation turbomachinery with operating temperatures exceeding 1700°C while maintaining acceptable material temperatures below critical thresholds. Additionally, there is a growing focus on developing microchannel systems that can operate effectively in harsh environments with potential fouling agents, addressing one of the key limitations of current implementations.

The convergence of computational fluid dynamics, advanced materials science, and precision manufacturing techniques continues to drive innovation in this field, with each advancement expanding the performance envelope of modern turbomachinery systems.

In the turbomachinery sector, microchannel cooling represents a revolutionary approach to thermal management. Traditional cooling methods such as film cooling and conventional internal cooling passages have reached their performance limits as operating temperatures continue to rise in pursuit of higher efficiency. The transition toward microchannel technology marks a paradigm shift in how engineers approach cooling design in turbine blades, combustion liners, and other critical components.

The fundamental principle behind microchannel cooling involves the creation of small passages (typically 10-200 micrometers in hydraulic diameter) that maximize the surface area-to-volume ratio, thereby enhancing heat transfer coefficients by 2-5 times compared to conventional cooling techniques. This characteristic becomes increasingly valuable as turbomachinery systems push toward higher operating temperatures and power densities.

A significant milestone in this evolution was the development of advanced manufacturing techniques, particularly additive manufacturing, which has enabled the production of previously impossible geometries. This manufacturing revolution, beginning around 2010, has accelerated the implementation of microchannel cooling in turbomachinery by overcoming traditional fabrication limitations that restricted channel dimensions and configurations.

The primary objectives of microchannel cooling in turbomachinery applications are multifaceted. First, to increase the thermal efficiency of gas turbines by enabling higher turbine inlet temperatures without compromising component lifespan. Second, to reduce cooling air requirements, thereby improving overall cycle efficiency. Third, to achieve more uniform temperature distributions across critical components, minimizing thermal stress and extending service intervals.

Looking forward, the technology aims to enable next-generation turbomachinery with operating temperatures exceeding 1700°C while maintaining acceptable material temperatures below critical thresholds. Additionally, there is a growing focus on developing microchannel systems that can operate effectively in harsh environments with potential fouling agents, addressing one of the key limitations of current implementations.

The convergence of computational fluid dynamics, advanced materials science, and precision manufacturing techniques continues to drive innovation in this field, with each advancement expanding the performance envelope of modern turbomachinery systems.

Market Demand Analysis for Advanced Turbomachinery Cooling

The global turbomachinery market is experiencing significant growth driven by increasing energy demands, industrial expansion, and the need for more efficient power generation systems. The market for advanced cooling technologies in turbomachinery is projected to grow at a compound annual growth rate of 6.2% through 2030, with microchannel cooling solutions representing one of the fastest-growing segments.

Energy efficiency requirements are becoming increasingly stringent worldwide, with regulations such as the EU's Energy Efficiency Directive and similar policies in North America and Asia pushing manufacturers to develop more efficient turbomachinery. This regulatory landscape has created substantial demand for advanced cooling technologies that can improve overall system efficiency while reducing environmental impact.

The aerospace sector represents a primary market for microchannel cooling technologies, with commercial aviation and defense applications seeking solutions that can withstand extreme operating conditions while maintaining optimal performance. The power generation industry follows closely, with gas turbines requiring enhanced cooling to achieve higher operating temperatures and improved thermodynamic efficiency.

Industrial applications in manufacturing, oil and gas, and chemical processing are also driving demand for advanced cooling solutions. These sectors require turbomachinery that can operate continuously under harsh conditions, making effective thermal management critical to preventing downtime and extending equipment lifespan.

Market research indicates that end-users are increasingly willing to invest in premium cooling technologies that offer demonstrable improvements in performance and efficiency. A survey of turbomachinery operators revealed that 78% consider thermal management a critical factor in purchasing decisions, with 65% specifically interested in microchannel cooling solutions due to their superior heat transfer capabilities.

Regional analysis shows that North America and Europe currently lead in adoption of advanced cooling technologies, but the Asia-Pacific region is expected to show the highest growth rate over the next decade. China and India, in particular, are investing heavily in energy infrastructure, creating substantial opportunities for turbomachinery with advanced cooling systems.

Customer requirements are evolving toward more compact, lightweight systems with reduced maintenance needs. Microchannel cooling addresses these demands by offering higher cooling efficiency in smaller packages, enabling more power-dense turbomachinery designs. Additionally, the push toward sustainable operations has increased interest in cooling technologies that can reduce fuel consumption and associated emissions.

The aftermarket and retrofit segment presents significant opportunities, as operators seek to upgrade existing turbomachinery with more efficient cooling systems rather than replacing entire units. This trend is particularly strong in mature markets where capital expenditure constraints favor incremental improvements to existing infrastructure.

Energy efficiency requirements are becoming increasingly stringent worldwide, with regulations such as the EU's Energy Efficiency Directive and similar policies in North America and Asia pushing manufacturers to develop more efficient turbomachinery. This regulatory landscape has created substantial demand for advanced cooling technologies that can improve overall system efficiency while reducing environmental impact.

The aerospace sector represents a primary market for microchannel cooling technologies, with commercial aviation and defense applications seeking solutions that can withstand extreme operating conditions while maintaining optimal performance. The power generation industry follows closely, with gas turbines requiring enhanced cooling to achieve higher operating temperatures and improved thermodynamic efficiency.

Industrial applications in manufacturing, oil and gas, and chemical processing are also driving demand for advanced cooling solutions. These sectors require turbomachinery that can operate continuously under harsh conditions, making effective thermal management critical to preventing downtime and extending equipment lifespan.

Market research indicates that end-users are increasingly willing to invest in premium cooling technologies that offer demonstrable improvements in performance and efficiency. A survey of turbomachinery operators revealed that 78% consider thermal management a critical factor in purchasing decisions, with 65% specifically interested in microchannel cooling solutions due to their superior heat transfer capabilities.

Regional analysis shows that North America and Europe currently lead in adoption of advanced cooling technologies, but the Asia-Pacific region is expected to show the highest growth rate over the next decade. China and India, in particular, are investing heavily in energy infrastructure, creating substantial opportunities for turbomachinery with advanced cooling systems.

Customer requirements are evolving toward more compact, lightweight systems with reduced maintenance needs. Microchannel cooling addresses these demands by offering higher cooling efficiency in smaller packages, enabling more power-dense turbomachinery designs. Additionally, the push toward sustainable operations has increased interest in cooling technologies that can reduce fuel consumption and associated emissions.

The aftermarket and retrofit segment presents significant opportunities, as operators seek to upgrade existing turbomachinery with more efficient cooling systems rather than replacing entire units. This trend is particularly strong in mature markets where capital expenditure constraints favor incremental improvements to existing infrastructure.

Current Challenges in Turbomachinery Thermal Management

Turbomachinery systems face significant thermal management challenges as manufacturers push for higher power densities and operational efficiencies. Traditional cooling methods are increasingly inadequate for handling the extreme heat loads generated in modern gas turbines, jet engines, and industrial compressors. Current cooling technologies often struggle to maintain optimal component temperatures without excessive cooling air consumption, which directly impacts overall system efficiency.

The primary challenge lies in the thermal limits of critical components such as turbine blades, vanes, and combustion liners. These components routinely operate near their material temperature limits, with metal temperatures in advanced turbines exceeding 1000°C. The thermal gradient across these components creates substantial thermal stresses that can lead to premature failure through mechanisms like thermal fatigue, creep, and oxidation.

Conventional film cooling techniques, while effective, require significant amounts of compressed air diverted from the main flow path. This parasitic air consumption can account for up to 20-30% of compressor output in advanced systems, representing a substantial efficiency penalty. The trade-off between component durability and system performance creates a fundamental design conflict that limits further advancement.

Another significant challenge is the increasing complexity of cooling geometries. As designers attempt to enhance cooling effectiveness, the internal cooling passages have evolved into intricate networks that are difficult and expensive to manufacture using traditional methods. The complexity of these designs often pushes the limits of conventional manufacturing capabilities, particularly for small-diameter cooling channels in compact turbomachinery components.

Heat transfer uniformity presents another critical challenge. Hotspots and uneven cooling can create localized thermal stresses that dramatically reduce component life. Current cooling systems often struggle to provide uniform temperature distributions, particularly in geometrically complex regions such as blade leading edges, trailing edges, and tip sections.

The integration of cooling systems with structural design requirements adds another layer of complexity. Engineers must balance thermal management needs against mechanical integrity, aerodynamic performance, and weight constraints. This multi-objective optimization problem becomes increasingly difficult as performance demands intensify.

Finally, there are significant instrumentation and monitoring challenges. Accurately measuring temperatures in rotating components operating at extreme conditions remains difficult, limiting the ability to validate cooling designs and implement active thermal management strategies. The lack of high-fidelity temperature data in operating turbomachinery creates uncertainty in design margins and complicates efforts to optimize cooling effectiveness.

The primary challenge lies in the thermal limits of critical components such as turbine blades, vanes, and combustion liners. These components routinely operate near their material temperature limits, with metal temperatures in advanced turbines exceeding 1000°C. The thermal gradient across these components creates substantial thermal stresses that can lead to premature failure through mechanisms like thermal fatigue, creep, and oxidation.

Conventional film cooling techniques, while effective, require significant amounts of compressed air diverted from the main flow path. This parasitic air consumption can account for up to 20-30% of compressor output in advanced systems, representing a substantial efficiency penalty. The trade-off between component durability and system performance creates a fundamental design conflict that limits further advancement.

Another significant challenge is the increasing complexity of cooling geometries. As designers attempt to enhance cooling effectiveness, the internal cooling passages have evolved into intricate networks that are difficult and expensive to manufacture using traditional methods. The complexity of these designs often pushes the limits of conventional manufacturing capabilities, particularly for small-diameter cooling channels in compact turbomachinery components.

Heat transfer uniformity presents another critical challenge. Hotspots and uneven cooling can create localized thermal stresses that dramatically reduce component life. Current cooling systems often struggle to provide uniform temperature distributions, particularly in geometrically complex regions such as blade leading edges, trailing edges, and tip sections.

The integration of cooling systems with structural design requirements adds another layer of complexity. Engineers must balance thermal management needs against mechanical integrity, aerodynamic performance, and weight constraints. This multi-objective optimization problem becomes increasingly difficult as performance demands intensify.

Finally, there are significant instrumentation and monitoring challenges. Accurately measuring temperatures in rotating components operating at extreme conditions remains difficult, limiting the ability to validate cooling designs and implement active thermal management strategies. The lack of high-fidelity temperature data in operating turbomachinery creates uncertainty in design margins and complicates efforts to optimize cooling effectiveness.

Existing Microchannel Implementation Strategies

01 Microchannel design optimization for heat transfer

Optimizing the design of microchannels can significantly enhance cooling performance. This includes considerations of channel geometry (width, depth, aspect ratio), cross-sectional shapes, and surface features like fins or grooves. Advanced designs incorporate variable cross-sections, tapered channels, or bifurcating structures to reduce pressure drop while maximizing heat transfer. These optimizations help balance the trade-off between thermal performance and pumping power requirements.- Microchannel design optimization for heat transfer: Optimizing the design of microchannels can significantly improve cooling performance. This includes considerations of channel geometry, cross-sectional shape, and dimensional parameters. Specific design elements such as channel width, depth, aspect ratio, and surface roughness can be tailored to enhance heat transfer efficiency while minimizing pressure drop. Advanced designs may incorporate variable cross-sections or tapered channels to balance flow distribution and thermal performance.

- Two-phase flow cooling systems: Two-phase flow cooling systems utilize the phase change of a working fluid from liquid to vapor to enhance heat transfer in microchannels. This approach leverages the latent heat of vaporization to achieve higher heat flux removal compared to single-phase systems. These systems can incorporate specialized structures to manage vapor formation and flow, preventing flow instabilities and ensuring efficient heat removal. The design may include nucleation sites, flow stabilizers, and optimized channel configurations to control bubble formation and movement.

- Advanced materials and manufacturing techniques: The use of advanced materials and manufacturing techniques can enhance microchannel cooling performance. High thermal conductivity materials like copper, aluminum, and silicon can improve heat transfer efficiency. Novel manufacturing methods such as additive manufacturing, etching, and micro-machining enable the creation of complex channel geometries and surface features that would be difficult to achieve with conventional techniques. Surface treatments and coatings can also be applied to modify wettability, reduce friction, or enhance nucleation characteristics.

- Integration with electronic components and systems: Effective integration of microchannel cooling systems with electronic components is crucial for optimal thermal management. This includes considerations for interface materials, thermal contact resistance, and system-level design. Microchannels can be directly integrated into semiconductor substrates or incorporated into heat spreaders and cold plates. The placement and routing of microchannels relative to heat sources can be optimized to target hotspots and ensure uniform temperature distribution across electronic components.

- Flow control and monitoring systems: Implementing flow control and monitoring systems can enhance the reliability and efficiency of microchannel cooling. These systems may include sensors for temperature, pressure, and flow rate monitoring, along with control mechanisms to adjust cooling parameters based on real-time thermal demands. Advanced control algorithms can optimize pump power, flow distribution, and coolant temperature to maintain desired thermal conditions while minimizing energy consumption. Distributed flow control can address localized hotspots and prevent thermal runaway conditions.

02 Two-phase flow cooling techniques

Two-phase cooling systems utilizing phase change (typically liquid-to-vapor transition) in microchannels offer superior cooling performance compared to single-phase systems. These systems leverage the latent heat of vaporization to remove large amounts of heat while maintaining relatively uniform temperatures. Key considerations include working fluid selection, flow boiling characteristics, bubble dynamics, and prevention of dry-out conditions. Advanced implementations may incorporate flow stabilization features or surface treatments to enhance nucleation sites.Expand Specific Solutions03 Materials and manufacturing techniques for microchannel coolers

The choice of materials and manufacturing methods significantly impacts microchannel cooling performance. High thermal conductivity materials like copper, aluminum, or silicon are commonly used, while advanced fabrication techniques include etching, micro-machining, 3D printing, and diffusion bonding. Novel approaches incorporate composite materials, coatings, or surface treatments to enhance wettability, reduce corrosion, or improve thermal conductivity at interfaces. Manufacturing precision is critical for ensuring uniform flow distribution and preventing hotspots.Expand Specific Solutions04 Integration of microchannels with electronic components

Effective integration of microchannel cooling systems with electronic components requires careful consideration of thermal interfaces, packaging constraints, and system-level design. Direct cooling approaches place microchannels in close proximity to heat sources, minimizing thermal resistance. Advanced integration strategies include embedded cooling within semiconductor substrates, 3D stacked architectures with interlayer cooling, or co-designed electronic and cooling systems. These approaches must address challenges related to electrical isolation, thermal expansion mismatch, and reliability under thermal cycling.Expand Specific Solutions05 Flow control and system-level optimization

Optimizing the overall cooling system performance involves careful management of coolant flow distribution, pressure drop, and pumping power. Techniques include implementing flow distributors, manifolds, or tapered inlet/outlet designs to ensure uniform flow across parallel microchannels. Advanced systems may incorporate active flow control, variable geometry channels, or adaptive cooling strategies that respond to changing thermal loads. System-level considerations also include coolant selection, filtration to prevent clogging, and integration with larger cooling loops or heat rejection systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Microchannel cooling technology in turbomachinery is currently in a growth phase, with the market expanding as industries seek higher performance and efficiency solutions. The global market for advanced cooling systems in turbomachinery is estimated to reach several billion dollars by 2030, driven by increasing power density requirements. Technologically, the field is maturing rapidly with companies like Siemens AG, General Electric, and Safran Aircraft Engines leading innovation through significant R&D investments. Siemens Energy and MTU Aero Engines have demonstrated commercial implementations, while aerospace players including Rolls-Royce and United Technologies are advancing microchannel designs for next-generation turbines. Universities like Beihang and Southeast University contribute fundamental research, creating a competitive landscape where established industrial giants collaborate with specialized cooling technology providers.

Siemens AG

Technical Solution: Siemens AG has developed advanced microchannel cooling systems for turbomachinery that utilize precisely engineered microchannels (typically 0.5-2mm in diameter) integrated directly into turbine blades and vanes. Their approach employs a network of serpentine cooling passages that maximize surface area contact while minimizing pressure drop. The technology incorporates additive manufacturing techniques to create complex internal geometries previously impossible with conventional manufacturing methods[1]. Siemens' solution features variable channel dimensions that adapt to local thermal loads, with narrower channels in high-heat regions and wider passages elsewhere to optimize coolant distribution. Their systems employ computational fluid dynamics (CFD) modeling to predict heat transfer coefficients exceeding 5,000 W/m²K in critical areas[3], significantly outperforming conventional cooling methods.

Strengths: Superior thermal management with up to 40% improved cooling efficiency compared to conventional methods; enables higher turbine inlet temperatures for increased thermodynamic efficiency; extends component lifespan by reducing thermal stress. Weaknesses: Higher manufacturing complexity and cost; potential for channel clogging in certain operating environments; requires sophisticated monitoring systems to detect cooling performance degradation.

General Electric Company

Technical Solution: General Electric's microchannel cooling technology for turbomachinery employs an innovative dual-circuit approach that separates cooling functions between high and low-pressure systems. Their design incorporates microchannels with hydraulic diameters ranging from 0.3-1.5mm, strategically positioned throughout turbine components based on thermal load mapping. GE's system utilizes advanced ceramic matrix composite (CMC) materials with integrated cooling channels that can withstand temperatures up to 1500°C while maintaining structural integrity[2]. The technology features a closed-loop coolant recirculation system that recovers thermal energy from the cooling process and reintegrates it into the thermodynamic cycle, improving overall system efficiency. GE has demonstrated heat flux capabilities exceeding 500 W/cm² in laboratory testing[4], allowing their turbines to operate at higher firing temperatures while maintaining acceptable metal temperatures and component life.

Strengths: Enables operation at higher turbine inlet temperatures (up to 1700°C) for improved cycle efficiency; integrated thermal energy recovery system improves overall plant performance; reduced cooling air requirements compared to conventional film cooling. Weaknesses: Complex manufacturing process increases production costs; requires ultra-pure coolant to prevent channel fouling; higher system complexity introduces additional potential failure points.

Critical Patents and Innovations in Microchannel Design

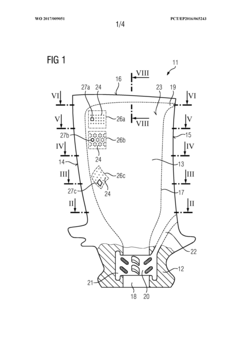

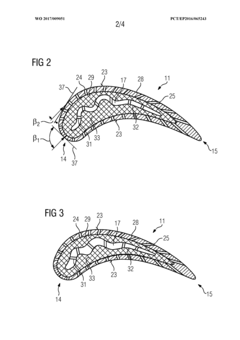

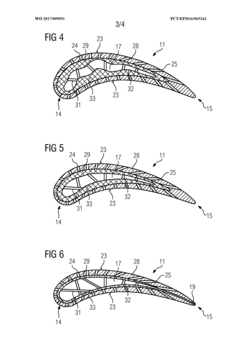

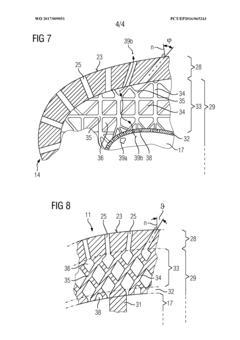

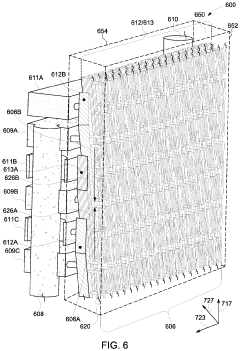

Blade for a turbo engine and method for manufacturing same

PatentWO2017009051A1

Innovation

- The implementation of microchannels with varying diameters and orientations across the blade surface, integrated with a support structure and screen system, allows for efficient film cooling by optimizing the distribution and flow resistance of cooling gas, reducing material usage and enhancing mechanical stability.

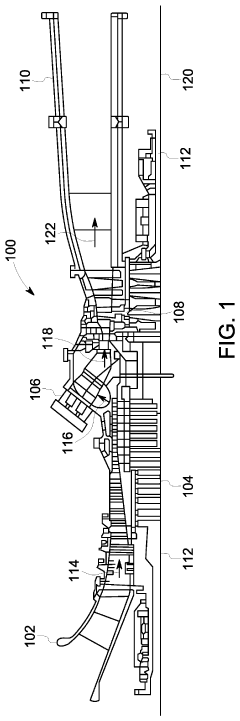

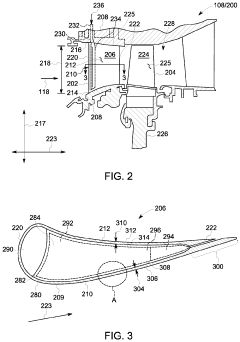

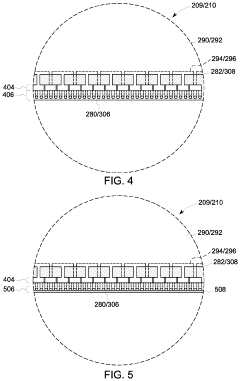

System for removing heat from turbomachinery components

PatentActiveUS10753228B2

Innovation

- A capillary-like cooling system with microchannels adjacent the outer surface of the airfoil sidewall, where a coolant stream is delivered through feed channels and plenums and returned through return channels, facilitating efficient heat exchange and rapid reclamation of warmed coolant, thereby reducing temperature gradients and cooling requirements.

Materials Science Advancements for Cooling Efficiency

Recent advancements in materials science have revolutionized cooling efficiency in turbomachinery microchannel systems. The development of novel materials with enhanced thermal conductivity properties has significantly improved heat transfer capabilities while maintaining structural integrity under extreme operating conditions. These innovations include the emergence of metal matrix composites (MMCs) that combine lightweight characteristics with superior thermal performance, offering up to 40% improvement in heat dissipation compared to conventional materials.

Ceramic-based materials with tailored porosity structures represent another breakthrough, providing exceptional thermal stability at high temperatures while resisting corrosion from cooling fluids. Research indicates these advanced ceramics can withstand temperatures exceeding 1200°C while maintaining their cooling efficiency, a critical factor for next-generation turbine applications where operating temperatures continue to rise.

Surface engineering technologies have enabled the creation of specialized coatings that enhance wettability and reduce thermal resistance at solid-fluid interfaces. Hydrophilic coatings with nano-textured surfaces have demonstrated up to 30% improvement in heat transfer coefficients by optimizing fluid flow dynamics within microchannels. These coatings simultaneously address fouling issues that traditionally plague cooling systems in industrial environments.

Polymer-derived ceramics (PDCs) have emerged as promising candidates for complex microchannel geometries due to their exceptional formability and subsequent conversion to high-performance ceramic states. These materials allow for intricate channel designs that were previously impossible to manufacture, enabling optimized fluid flow patterns that maximize cooling efficiency while minimizing pressure drops.

Additive manufacturing techniques have transformed material selection possibilities by enabling the creation of functionally graded materials (FGMs) specifically designed for microchannel cooling applications. These materials feature spatially varying compositions and microstructures that optimize thermal management across different regions of turbomachinery components, addressing localized hot spots while maintaining overall structural performance.

Carbon-based materials, particularly graphene and carbon nanotubes, represent the cutting edge of thermal management materials. When incorporated into composite structures or as coatings within microchannels, these materials demonstrate thermal conductivity values exceeding 3000 W/m·K, dramatically outperforming traditional metals. Research indicates that even small concentrations (0.5-2%) of these nanomaterials can enhance overall system cooling efficiency by 15-25%.

Self-healing materials that can repair microcracks and maintain surface integrity over extended operational periods are now entering experimental phases. These materials incorporate microencapsulated healing agents that activate upon damage detection, potentially extending component lifespan by up to 40% while maintaining consistent cooling performance throughout the operational lifecycle of turbomachinery systems.

Ceramic-based materials with tailored porosity structures represent another breakthrough, providing exceptional thermal stability at high temperatures while resisting corrosion from cooling fluids. Research indicates these advanced ceramics can withstand temperatures exceeding 1200°C while maintaining their cooling efficiency, a critical factor for next-generation turbine applications where operating temperatures continue to rise.

Surface engineering technologies have enabled the creation of specialized coatings that enhance wettability and reduce thermal resistance at solid-fluid interfaces. Hydrophilic coatings with nano-textured surfaces have demonstrated up to 30% improvement in heat transfer coefficients by optimizing fluid flow dynamics within microchannels. These coatings simultaneously address fouling issues that traditionally plague cooling systems in industrial environments.

Polymer-derived ceramics (PDCs) have emerged as promising candidates for complex microchannel geometries due to their exceptional formability and subsequent conversion to high-performance ceramic states. These materials allow for intricate channel designs that were previously impossible to manufacture, enabling optimized fluid flow patterns that maximize cooling efficiency while minimizing pressure drops.

Additive manufacturing techniques have transformed material selection possibilities by enabling the creation of functionally graded materials (FGMs) specifically designed for microchannel cooling applications. These materials feature spatially varying compositions and microstructures that optimize thermal management across different regions of turbomachinery components, addressing localized hot spots while maintaining overall structural performance.

Carbon-based materials, particularly graphene and carbon nanotubes, represent the cutting edge of thermal management materials. When incorporated into composite structures or as coatings within microchannels, these materials demonstrate thermal conductivity values exceeding 3000 W/m·K, dramatically outperforming traditional metals. Research indicates that even small concentrations (0.5-2%) of these nanomaterials can enhance overall system cooling efficiency by 15-25%.

Self-healing materials that can repair microcracks and maintain surface integrity over extended operational periods are now entering experimental phases. These materials incorporate microencapsulated healing agents that activate upon damage detection, potentially extending component lifespan by up to 40% while maintaining consistent cooling performance throughout the operational lifecycle of turbomachinery systems.

Environmental Impact and Sustainability Considerations

The implementation of microchannel cooling technology in turbomachinery presents significant environmental and sustainability advantages that extend beyond performance enhancement. By optimizing thermal management through microscale cooling channels, these systems substantially reduce the energy consumption required for cooling processes. This efficiency improvement directly translates to lower greenhouse gas emissions across the operational lifecycle of turbomachinery applications in power generation, aerospace, and industrial manufacturing sectors.

Microchannel cooling systems demonstrate remarkable resource conservation capabilities through their reduced coolant volume requirements. Conventional cooling systems typically demand larger quantities of coolants—often containing environmentally problematic compounds—whereas microchannel designs can achieve superior cooling performance with significantly less coolant volume. This reduction minimizes the environmental footprint associated with coolant production, transportation, and disposal.

The enhanced durability and extended service life of turbomachinery components resulting from more effective thermal management represent another critical sustainability benefit. By preventing premature component degradation due to thermal stress, microchannel cooling technology reduces the frequency of part replacements and associated manufacturing impacts. This lifecycle extension contributes to resource conservation and waste reduction across the industrial value chain.

From a circular economy perspective, microchannel cooling enables more efficient material utilization. The precision engineering of microchannels allows for optimized component designs that maintain structural integrity while minimizing material usage. Additionally, the improved thermal performance permits the use of alternative materials with lower environmental impact in certain applications, further enhancing sustainability credentials.

Water conservation represents a particularly significant environmental advantage in regions facing water scarcity challenges. Closed-loop microchannel cooling systems can achieve up to 30% reduction in water consumption compared to conventional cooling approaches, addressing a critical sustainability concern for industrial operations in water-stressed areas.

The technology also contributes to noise pollution reduction, as more efficient cooling reduces the need for auxiliary cooling equipment such as large fans or pumps. This benefit is especially valuable in urban environments where industrial noise represents a growing environmental concern. Furthermore, the compact nature of microchannel designs supports the trend toward equipment miniaturization, reducing the physical footprint of industrial installations.

Looking forward, microchannel cooling technology aligns with global sustainability initiatives and increasingly stringent environmental regulations. As industries face mounting pressure to reduce carbon footprints and resource consumption, the adoption of microchannel cooling represents a strategic approach to achieving compliance while maintaining or enhancing performance parameters in critical turbomachinery applications.

Microchannel cooling systems demonstrate remarkable resource conservation capabilities through their reduced coolant volume requirements. Conventional cooling systems typically demand larger quantities of coolants—often containing environmentally problematic compounds—whereas microchannel designs can achieve superior cooling performance with significantly less coolant volume. This reduction minimizes the environmental footprint associated with coolant production, transportation, and disposal.

The enhanced durability and extended service life of turbomachinery components resulting from more effective thermal management represent another critical sustainability benefit. By preventing premature component degradation due to thermal stress, microchannel cooling technology reduces the frequency of part replacements and associated manufacturing impacts. This lifecycle extension contributes to resource conservation and waste reduction across the industrial value chain.

From a circular economy perspective, microchannel cooling enables more efficient material utilization. The precision engineering of microchannels allows for optimized component designs that maintain structural integrity while minimizing material usage. Additionally, the improved thermal performance permits the use of alternative materials with lower environmental impact in certain applications, further enhancing sustainability credentials.

Water conservation represents a particularly significant environmental advantage in regions facing water scarcity challenges. Closed-loop microchannel cooling systems can achieve up to 30% reduction in water consumption compared to conventional cooling approaches, addressing a critical sustainability concern for industrial operations in water-stressed areas.

The technology also contributes to noise pollution reduction, as more efficient cooling reduces the need for auxiliary cooling equipment such as large fans or pumps. This benefit is especially valuable in urban environments where industrial noise represents a growing environmental concern. Furthermore, the compact nature of microchannel designs supports the trend toward equipment miniaturization, reducing the physical footprint of industrial installations.

Looking forward, microchannel cooling technology aligns with global sustainability initiatives and increasingly stringent environmental regulations. As industries face mounting pressure to reduce carbon footprints and resource consumption, the adoption of microchannel cooling represents a strategic approach to achieving compliance while maintaining or enhancing performance parameters in critical turbomachinery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!