Microchannel Cooling Applications in Biochemical Sensor Devices

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Evolution and Objectives

Microchannel cooling technology emerged in the late 1980s as a revolutionary approach to thermal management, initially developed for high-performance computing applications. The fundamental concept involves the use of microscale channels (typically 10-500 micrometers in width) to facilitate enhanced heat transfer through increased surface area-to-volume ratios. This technology has evolved significantly over the past three decades, transitioning from theoretical concepts to practical implementations across various industries.

The evolution of microchannel cooling in biochemical sensor devices represents a fascinating convergence of thermal engineering and analytical chemistry. Early biochemical sensors faced significant challenges related to temperature control, as many biological reactions and sensing mechanisms are highly temperature-dependent. Traditional cooling methods proved inadequate for maintaining precise thermal conditions in miniaturized sensing platforms, creating a technological gap that microchannel cooling has progressively addressed.

By the early 2000s, researchers began exploring microchannel integration specifically for lab-on-a-chip devices, marking a critical turning point in the technology's application trajectory. The miniaturization trend in analytical chemistry created unique thermal management challenges that conventional cooling approaches could not effectively solve. This period saw the development of fundamental design principles for microfluidic cooling systems tailored to biochemical sensing applications.

The past decade has witnessed accelerated advancement in fabrication techniques, enabling more sophisticated microchannel geometries and multi-material integration. Innovations in microfabrication, including improved photolithography processes, laser ablation techniques, and 3D printing capabilities, have dramatically expanded design possibilities. These manufacturing breakthroughs have facilitated the creation of increasingly complex cooling architectures optimized for specific biochemical sensing modalities.

Current technological objectives focus on several key areas: enhancing cooling efficiency while further reducing system footprint, improving temperature uniformity across sensing arrays, developing adaptive cooling capabilities for dynamic thermal management, and integrating cooling systems with other microfluidic functions. Additionally, there is growing emphasis on energy efficiency and sustainability in cooling system design, particularly for portable and field-deployable biochemical sensing platforms.

Looking forward, the field aims to achieve seamless integration of cooling functionality within next-generation biochemical sensors, enabling unprecedented thermal precision at the microscale. Research objectives include developing intelligent thermal management systems capable of responding to changing analytical conditions, creating standardized design frameworks to accelerate implementation, and establishing comprehensive modeling tools to optimize microchannel configurations for specific biochemical applications.

The evolution of microchannel cooling in biochemical sensor devices represents a fascinating convergence of thermal engineering and analytical chemistry. Early biochemical sensors faced significant challenges related to temperature control, as many biological reactions and sensing mechanisms are highly temperature-dependent. Traditional cooling methods proved inadequate for maintaining precise thermal conditions in miniaturized sensing platforms, creating a technological gap that microchannel cooling has progressively addressed.

By the early 2000s, researchers began exploring microchannel integration specifically for lab-on-a-chip devices, marking a critical turning point in the technology's application trajectory. The miniaturization trend in analytical chemistry created unique thermal management challenges that conventional cooling approaches could not effectively solve. This period saw the development of fundamental design principles for microfluidic cooling systems tailored to biochemical sensing applications.

The past decade has witnessed accelerated advancement in fabrication techniques, enabling more sophisticated microchannel geometries and multi-material integration. Innovations in microfabrication, including improved photolithography processes, laser ablation techniques, and 3D printing capabilities, have dramatically expanded design possibilities. These manufacturing breakthroughs have facilitated the creation of increasingly complex cooling architectures optimized for specific biochemical sensing modalities.

Current technological objectives focus on several key areas: enhancing cooling efficiency while further reducing system footprint, improving temperature uniformity across sensing arrays, developing adaptive cooling capabilities for dynamic thermal management, and integrating cooling systems with other microfluidic functions. Additionally, there is growing emphasis on energy efficiency and sustainability in cooling system design, particularly for portable and field-deployable biochemical sensing platforms.

Looking forward, the field aims to achieve seamless integration of cooling functionality within next-generation biochemical sensors, enabling unprecedented thermal precision at the microscale. Research objectives include developing intelligent thermal management systems capable of responding to changing analytical conditions, creating standardized design frameworks to accelerate implementation, and establishing comprehensive modeling tools to optimize microchannel configurations for specific biochemical applications.

Market Analysis for Thermally-Optimized Biochemical Sensors

The global market for thermally-optimized biochemical sensors is experiencing robust growth, driven by increasing demand in healthcare diagnostics, environmental monitoring, and pharmaceutical research. Current market valuations indicate that the biochemical sensor market reached approximately $22 billion in 2022, with thermal management solutions comprising a significant segment of this market. Industry forecasts project a compound annual growth rate (CAGR) of 7.8% through 2028, with microchannel cooling technologies expected to outpace the broader market at 9.3% CAGR.

Healthcare applications represent the largest market segment, accounting for nearly 42% of demand. The integration of microchannel cooling in point-of-care diagnostic devices has enabled faster processing times and improved accuracy, particularly in polymerase chain reaction (PCR) and immunoassay platforms. This segment is projected to maintain dominance due to increasing prevalence of chronic diseases and the shift toward personalized medicine.

Environmental monitoring applications constitute the fastest-growing segment, with 11.2% annual growth. This acceleration stems from stricter regulatory requirements for water quality assessment, air pollution monitoring, and industrial emissions control. Thermally-optimized sensors with microchannel cooling provide enhanced stability in variable environmental conditions, making them particularly valuable for continuous monitoring systems.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the highest growth trajectory, fueled by expanding healthcare infrastructure, industrial development, and increasing environmental concerns in countries like China, India, and South Korea.

Key market drivers include miniaturization trends in sensor technology, increasing demand for real-time monitoring capabilities, and the growing adoption of Internet of Things (IoT) platforms that integrate multiple sensor types. The push toward portable, field-deployable instruments has particularly accelerated demand for efficient thermal management solutions that maintain precise temperature control while minimizing power consumption.

Market challenges include high initial development costs, complex manufacturing processes for microchannel structures, and integration difficulties with existing sensor platforms. Additionally, standardization issues across different application domains have slowed adoption in some sectors.

Customer segmentation reveals distinct needs across different user groups. Research institutions prioritize precision and customization capabilities, while industrial users emphasize reliability and operational longevity. Healthcare providers focus on ease of use, rapid results, and regulatory compliance. This diversity in requirements has led to market fragmentation, with specialized solutions emerging for specific application niches rather than one-size-fits-all approaches.

Healthcare applications represent the largest market segment, accounting for nearly 42% of demand. The integration of microchannel cooling in point-of-care diagnostic devices has enabled faster processing times and improved accuracy, particularly in polymerase chain reaction (PCR) and immunoassay platforms. This segment is projected to maintain dominance due to increasing prevalence of chronic diseases and the shift toward personalized medicine.

Environmental monitoring applications constitute the fastest-growing segment, with 11.2% annual growth. This acceleration stems from stricter regulatory requirements for water quality assessment, air pollution monitoring, and industrial emissions control. Thermally-optimized sensors with microchannel cooling provide enhanced stability in variable environmental conditions, making them particularly valuable for continuous monitoring systems.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the highest growth trajectory, fueled by expanding healthcare infrastructure, industrial development, and increasing environmental concerns in countries like China, India, and South Korea.

Key market drivers include miniaturization trends in sensor technology, increasing demand for real-time monitoring capabilities, and the growing adoption of Internet of Things (IoT) platforms that integrate multiple sensor types. The push toward portable, field-deployable instruments has particularly accelerated demand for efficient thermal management solutions that maintain precise temperature control while minimizing power consumption.

Market challenges include high initial development costs, complex manufacturing processes for microchannel structures, and integration difficulties with existing sensor platforms. Additionally, standardization issues across different application domains have slowed adoption in some sectors.

Customer segmentation reveals distinct needs across different user groups. Research institutions prioritize precision and customization capabilities, while industrial users emphasize reliability and operational longevity. Healthcare providers focus on ease of use, rapid results, and regulatory compliance. This diversity in requirements has led to market fragmentation, with specialized solutions emerging for specific application niches rather than one-size-fits-all approaches.

Current Challenges in Microchannel Cooling Integration

Despite significant advancements in microchannel cooling technology for biochemical sensor devices, several critical challenges continue to impede widespread integration and optimal performance. The miniaturization of cooling systems presents fundamental physical constraints, as the reduction in channel dimensions to micro and nano scales introduces complex fluid dynamics that do not conform to conventional macroscale models. Surface tension, viscous forces, and boundary layer effects become dominant at these scales, complicating flow prediction and thermal management.

Material compatibility represents another significant hurdle, particularly in biochemical applications where sensors must maintain biocompatibility while simultaneously providing efficient heat transfer. The materials must resist corrosion from biological samples and reagents while maintaining structural integrity under thermal cycling conditions. Additionally, these materials must not interfere with sensing mechanisms or introduce contamination that could compromise analytical results.

Fabrication precision poses substantial technical difficulties, as microchannel geometries require extremely tight tolerances. Current manufacturing techniques struggle to consistently produce channels with uniform cross-sections and smooth surfaces at scale. Surface roughness, even at nanometer scales, can significantly disrupt flow patterns and reduce cooling efficiency, while manufacturing inconsistencies lead to unpredictable thermal performance across devices.

Power consumption remains a critical constraint, especially for portable or implantable biochemical sensing applications. The pumping mechanisms required to maintain adequate flow rates through microchannels often consume disproportionate energy relative to the cooling benefit they provide. This energy-efficiency gap limits the deployment of microchannel cooling in battery-operated or energy-harvesting sensor systems.

Integration complexity presents multidisciplinary challenges that span microfluidics, electronics, materials science, and biochemistry. The proximity of cooling channels to sensitive detection elements creates potential for electromagnetic interference, while thermal gradients can affect sensor calibration and measurement accuracy. Moreover, the interconnection between cooling systems and sample handling pathways introduces potential points of failure and contamination.

Fouling and clogging represent persistent operational challenges, particularly in biochemical applications where proteins, cells, or other biological materials can adhere to channel walls or form aggregates that restrict flow. These issues are exacerbated in long-term deployments where regular maintenance may be impractical, such as in implantable sensors or remote environmental monitoring systems.

Cost-effectiveness remains a significant barrier to commercial adoption, as the precision manufacturing techniques required for microchannel fabrication often involve expensive equipment and processes that do not readily scale to high-volume production. This economic constraint limits the application of microchannel cooling to high-value biochemical sensing applications where performance justifies the increased cost.

Material compatibility represents another significant hurdle, particularly in biochemical applications where sensors must maintain biocompatibility while simultaneously providing efficient heat transfer. The materials must resist corrosion from biological samples and reagents while maintaining structural integrity under thermal cycling conditions. Additionally, these materials must not interfere with sensing mechanisms or introduce contamination that could compromise analytical results.

Fabrication precision poses substantial technical difficulties, as microchannel geometries require extremely tight tolerances. Current manufacturing techniques struggle to consistently produce channels with uniform cross-sections and smooth surfaces at scale. Surface roughness, even at nanometer scales, can significantly disrupt flow patterns and reduce cooling efficiency, while manufacturing inconsistencies lead to unpredictable thermal performance across devices.

Power consumption remains a critical constraint, especially for portable or implantable biochemical sensing applications. The pumping mechanisms required to maintain adequate flow rates through microchannels often consume disproportionate energy relative to the cooling benefit they provide. This energy-efficiency gap limits the deployment of microchannel cooling in battery-operated or energy-harvesting sensor systems.

Integration complexity presents multidisciplinary challenges that span microfluidics, electronics, materials science, and biochemistry. The proximity of cooling channels to sensitive detection elements creates potential for electromagnetic interference, while thermal gradients can affect sensor calibration and measurement accuracy. Moreover, the interconnection between cooling systems and sample handling pathways introduces potential points of failure and contamination.

Fouling and clogging represent persistent operational challenges, particularly in biochemical applications where proteins, cells, or other biological materials can adhere to channel walls or form aggregates that restrict flow. These issues are exacerbated in long-term deployments where regular maintenance may be impractical, such as in implantable sensors or remote environmental monitoring systems.

Cost-effectiveness remains a significant barrier to commercial adoption, as the precision manufacturing techniques required for microchannel fabrication often involve expensive equipment and processes that do not readily scale to high-volume production. This economic constraint limits the application of microchannel cooling to high-value biochemical sensing applications where performance justifies the increased cost.

Existing Microchannel Cooling Implementations

01 Microchannel heat sink designs for electronic cooling

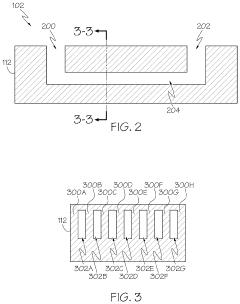

Microchannel heat sinks provide efficient cooling for electronic components by allowing coolant to flow through small channels, maximizing heat transfer surface area. These designs incorporate optimized channel geometries, flow patterns, and materials to enhance thermal performance. The compact nature of microchannels makes them ideal for high-power density applications like processors and power electronics, where traditional cooling methods are insufficient.- Microchannel heat sink designs for electronic cooling: Microchannel heat sinks are designed specifically for cooling electronic components by efficiently transferring heat away from high-power density devices. These designs typically feature small channels etched or machined into a substrate, allowing coolant to flow through and absorb heat. The geometry of these channels, including width, depth, and spacing, is optimized to maximize heat transfer while minimizing pressure drop. These heat sinks are particularly effective for cooling CPUs, GPUs, and other high-performance computing components.

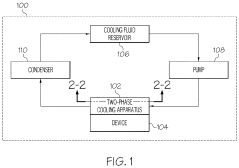

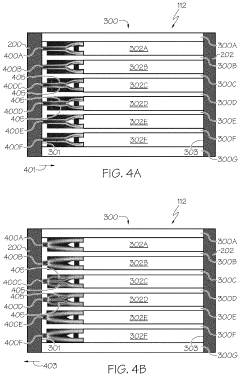

- Two-phase cooling systems in microchannels: Two-phase cooling systems utilize the phase change of the coolant (typically from liquid to vapor) within microchannels to enhance heat transfer efficiency. As the coolant absorbs heat and evaporates, it takes advantage of the latent heat of vaporization, which provides significantly higher cooling capacity compared to single-phase systems. These systems can maintain more uniform temperatures across the cooled surface and operate with lower flow rates. The design includes considerations for vapor management, pressure control, and condensation to ensure optimal cooling performance.

- Microchannel cooling for power electronics and batteries: Specialized microchannel cooling solutions are developed for power electronics and battery systems, addressing their unique thermal management requirements. These systems feature customized channel geometries and coolant distribution networks designed to handle the high heat fluxes generated by power semiconductors or the uniform cooling needs of battery packs. The cooling systems help maintain optimal operating temperatures, prevent thermal runaway in batteries, and extend the lifespan of power electronic components while enabling higher power densities.

- Advanced materials and manufacturing for microchannel coolers: Innovative materials and manufacturing techniques are employed to enhance the performance and reliability of microchannel cooling systems. These include the use of high thermal conductivity materials like copper, aluminum, and silicon, as well as advanced fabrication methods such as additive manufacturing, chemical etching, and micro-machining. Surface treatments and coatings are applied to improve wettability, reduce corrosion, and enhance heat transfer. These advancements allow for more complex channel geometries, better thermal performance, and increased durability of cooling systems.

- Integrated cooling solutions with microchannels: Integrated cooling solutions combine microchannel technology with other cooling methods to create comprehensive thermal management systems. These hybrid approaches may incorporate jet impingement, thermoelectric cooling, or heat pipes alongside microchannels to address complex cooling challenges. The integration can be at various levels, from chip-level to system-level cooling, and often includes intelligent control systems to optimize cooling performance based on thermal loads. These solutions are particularly valuable in data centers, telecommunications equipment, and high-performance computing applications where space is limited and cooling demands are high.

02 Two-phase cooling systems with microchannels

Two-phase cooling systems utilize the phase change of coolants (liquid to vapor) within microchannels to achieve superior heat dissipation. This approach leverages the latent heat of vaporization, significantly increasing cooling capacity compared to single-phase systems. These systems incorporate specialized flow management, pressure control mechanisms, and channel designs to handle vapor formation while maintaining efficient heat transfer across the entire cooling surface.Expand Specific Solutions03 Microchannel cooling for data centers and servers

Microchannel cooling solutions specifically designed for data centers and server environments provide efficient thermal management for high-density computing infrastructure. These systems integrate directly with server racks or individual components, using liquid coolants through microchannels to remove heat more effectively than air cooling. The designs focus on reliability, serviceability, and compatibility with existing data center infrastructure while significantly reducing energy consumption for cooling operations.Expand Specific Solutions04 Microchannel manufacturing techniques and materials

Advanced manufacturing techniques and material selections are crucial for creating effective microchannel cooling systems. These include precision etching, additive manufacturing, micro-machining, and bonding processes that enable the creation of complex channel geometries at microscale dimensions. Material innovations focus on high thermal conductivity, corrosion resistance, and compatibility with coolants, while manufacturing processes are optimized for cost-effectiveness and scalability in production.Expand Specific Solutions05 Integrated microchannel cooling for specialized applications

Specialized microchannel cooling solutions are designed for specific applications with unique thermal management requirements. These include cooling for high-power electronics, automotive systems, aerospace components, medical devices, and renewable energy systems. The designs integrate directly with the target components, featuring customized channel configurations, coolant selection, and flow control mechanisms tailored to the specific thermal loads, space constraints, and operational environments of each application.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Microchannel cooling technology in biochemical sensor devices is currently in a growth phase, with the market expanding due to increasing demand for miniaturized, efficient sensing platforms. The global market is projected to grow significantly as applications in point-of-care diagnostics and lab-on-chip systems gain traction. From a technological maturity perspective, key players are advancing at different rates. Intel and Texas Instruments lead in semiconductor-based cooling solutions, while Zhejiang University and Nanjing University of Science & Technology contribute significant academic research. Companies like OMRON and STMicroelectronics are developing specialized sensor applications, with IBM and Fujitsu focusing on integration with advanced computing systems. Analogic and Philips are pioneering medical implementations, creating a competitive landscape where cross-industry collaboration is becoming increasingly important for innovation.

Intel Corp.

Technical Solution: 英特尔开发了先进的微通道冷却技术,专为高性能生化传感器阵列设计。其技术方案基于硅-玻璃键合工艺制造的微通道热交换器,通道尺寸精确控制在15-80微米范围。该系统采用分层流体分配网络,确保均匀冷却效果,温度梯度控制在±0.3°C以内。英特尔的技术整合了微电子制造工艺与微流体技术,实现了大规模传感器阵列的精确温度管理。系统采用创新的双流体设计,分离电子冷却回路与生化样本处理回路,避免交叉污染。微通道结构经过计算流体动力学优化,减少了50%的流体阻力,同时提高热传递效率。该技术还集成了微型固态泵和阀门系统,实现了完全电子控制的流体管理,无需外部机械部件。英特尔的系统特别适用于高通量生化分析和DNA测序等应用场景。

优势:系统集成度高,温度均匀性出色,适合大规模传感器阵列;双流体设计提高了生物安全性;制造工艺与半导体产业兼容,便于规模化生产。劣势:系统复杂度高,初始成本大;对工作环境要求严格;功耗相对较高,便携应用受限。

International Business Machines Corp.

Technical Solution: IBM开发了先进的微通道冷却系统,专为生化传感器设备设计。其技术方案采用硅基微加工技术制造的高密度微通道阵列,通道宽度可达10-100微米,能够实现精确的温度控制(±0.1°C)。IBM的系统整合了微流控芯片与传感元件,形成完整的实验室芯片(Lab-on-a-Chip)解决方案。该技术利用液冷方式,热传递效率比传统空气冷却高出约40倍,使得高灵敏度生化检测成为可能。IBM还开发了专用的微泵系统,流量可精确控制在5-500μL/min范围内,满足不同生化反应的需求。系统采用模块化设计,可根据不同应用场景进行定制化配置。

优势:热传递效率极高,温度控制精度出色,系统集成度高,可实现复杂生化分析功能。微通道设计优化减少了流体阻力,降低了能耗。缺点:制造成本较高,微通道容易发生堵塞,需要定期维护,系统复杂度高导致可靠性挑战。

Key Patents and Innovations in Thermal Management

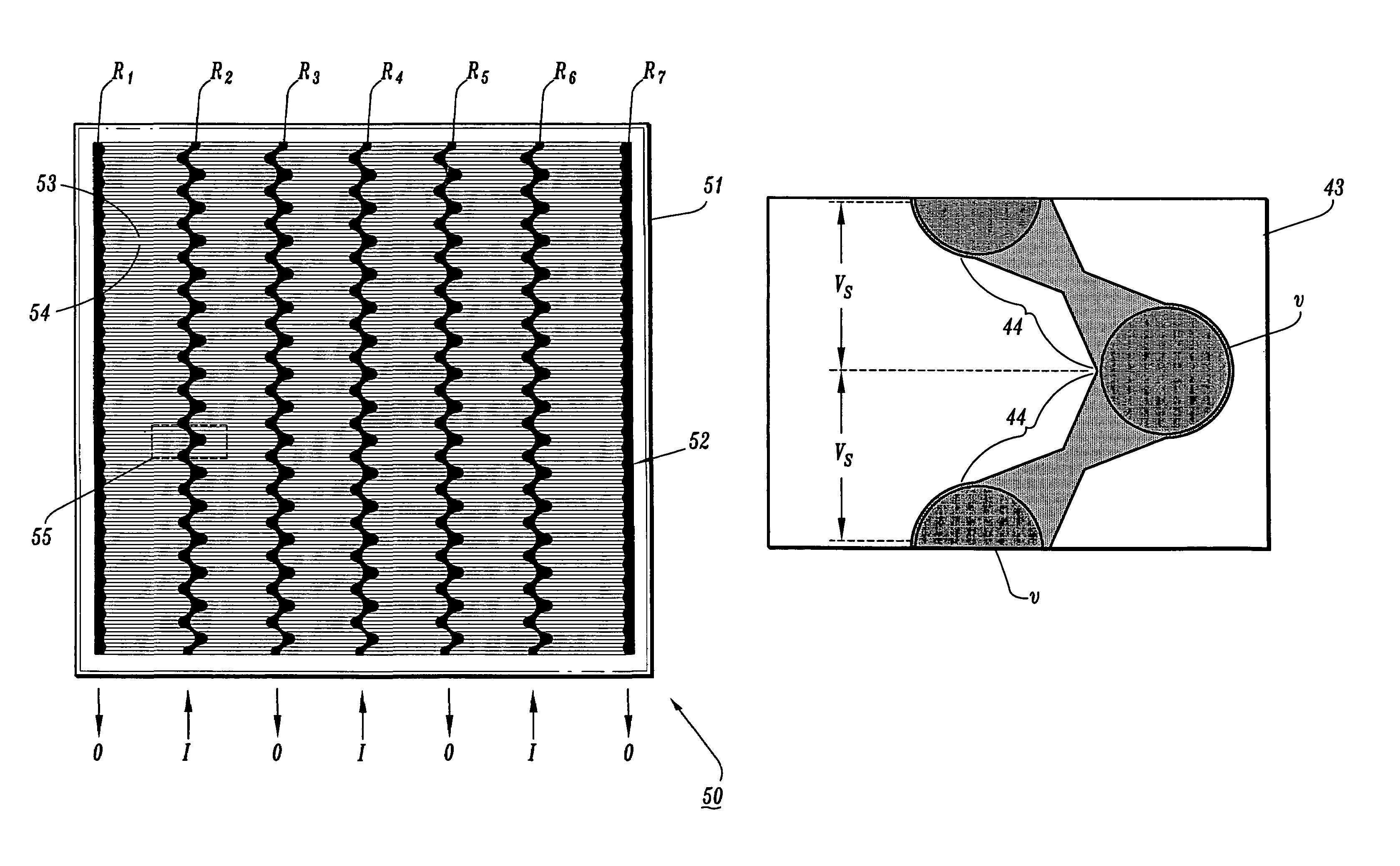

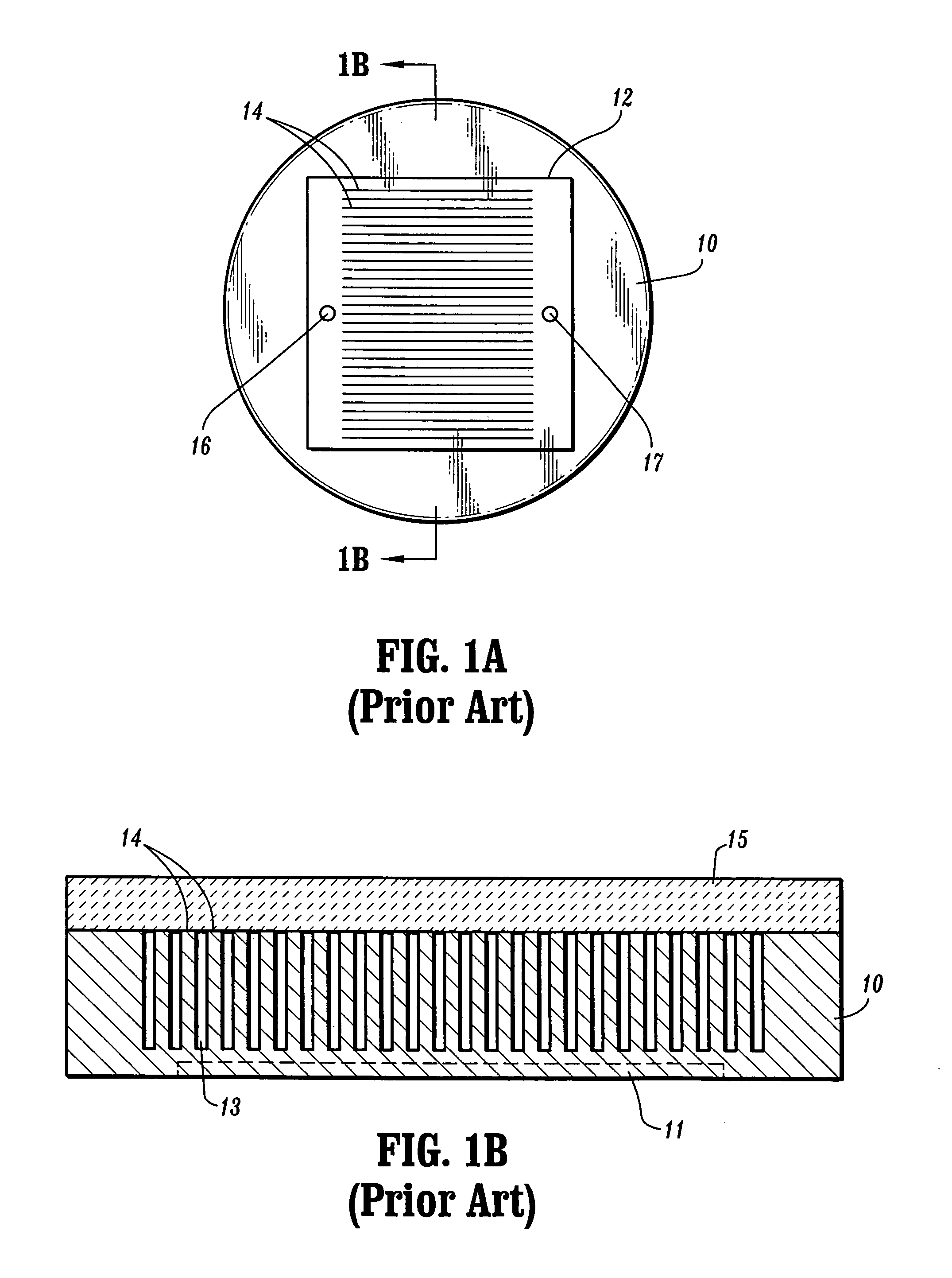

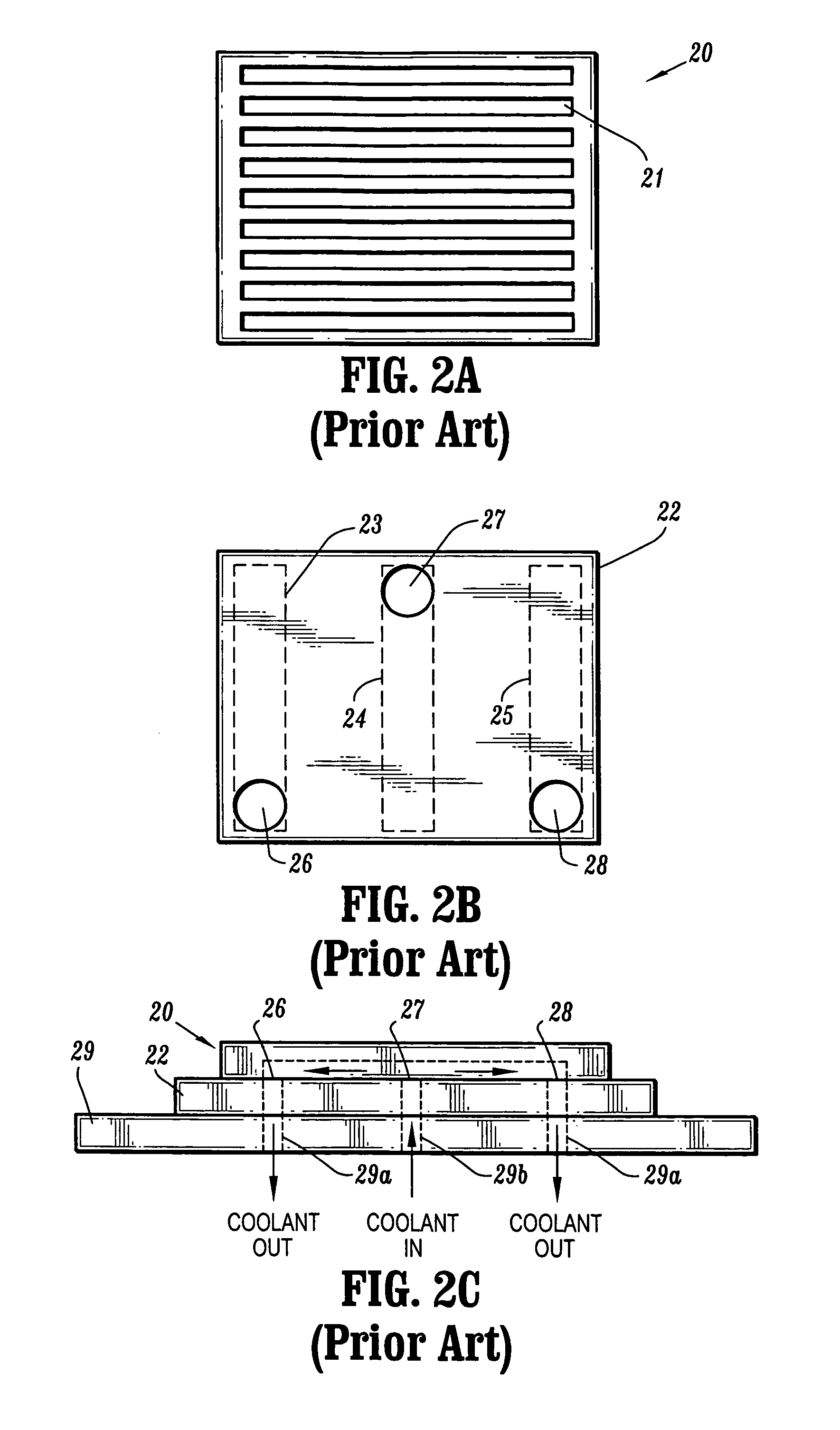

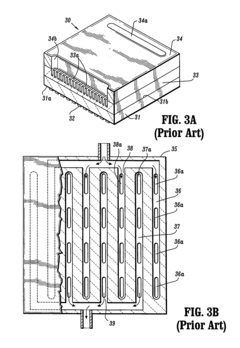

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

PatentInactiveUS7190580B2

Innovation

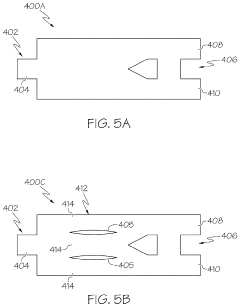

- The development of an integrated microchannel cooler device with a manifold plate and microchannel plate thermally bonded together, featuring alternating input and output manifolds with zig-zag patterns and varying cross-sectional areas, along with microfins that define microchannels, to ensure uniform coolant flow and minimize pressure drops.

Cooling systems comprising fluid diodes with variable diodicity for two-phase flow control

PatentActiveUS10945354B1

Innovation

- Incorporating a fluid diode array with varying diodicities at the channel inlets of heat sink fluid channels to preferentially direct the cooling fluid flow forward and prevent backflow, with higher diodicity fluid diodes positioned near the center of the cooling manifold where boiling instabilities are most pronounced.

Materials Science Advancements for Microchannel Fabrication

The evolution of materials science has been pivotal in advancing microchannel fabrication techniques for biochemical sensor devices. Traditional materials such as silicon and glass have dominated early microchannel development due to their established fabrication protocols and compatibility with semiconductor manufacturing processes. However, these materials present limitations in terms of cost, flexibility, and biocompatibility for certain biochemical sensing applications.

Recent advancements have introduced polymer-based materials including polydimethylsiloxane (PDMS), polymethyl methacrylate (PMMA), and cyclic olefin copolymer (COC) as viable alternatives. These polymers offer advantages in rapid prototyping, reduced manufacturing costs, and enhanced optical properties crucial for biochemical detection systems. PDMS, in particular, has gained prominence due to its oxygen permeability, which supports cell culture applications within microfluidic devices.

Ceramic materials represent another frontier in microchannel fabrication, offering superior thermal conductivity and chemical resistance compared to polymers. Aluminum nitride (AlN) and aluminum oxide (Al₂O₃) ceramics enable efficient heat dissipation in high-power biochemical sensing applications where temperature control is critical for reaction kinetics and sensor performance.

Nanocomposite materials combining polymers with nanoparticles have emerged as a promising direction for enhancing specific properties of microchannels. For instance, incorporating silver nanoparticles into polymer matrices provides antimicrobial properties, while carbon nanotubes or graphene enhance thermal conductivity and mechanical strength without compromising flexibility.

Surface modification techniques have also advanced significantly, allowing precise control over the chemical and physical properties of microchannel surfaces. Plasma treatment, chemical vapor deposition, and layer-by-layer assembly enable tailoring of surface energy, hydrophobicity, and functional group density, which directly impact fluid flow behavior and biomolecule interactions within the channels.

3D printing technologies have revolutionized microchannel fabrication by enabling complex geometries previously unattainable through conventional methods. Multi-material 3D printing allows integration of different functional materials within a single device, creating gradient properties or discrete functional zones optimized for specific sensing mechanisms.

Biodegradable and environmentally friendly materials such as polylactic acid (PLA) and cellulose derivatives are gaining attention for disposable biochemical sensing applications. These materials address growing concerns about electronic waste while maintaining the performance requirements for short-term diagnostic applications.

Recent advancements have introduced polymer-based materials including polydimethylsiloxane (PDMS), polymethyl methacrylate (PMMA), and cyclic olefin copolymer (COC) as viable alternatives. These polymers offer advantages in rapid prototyping, reduced manufacturing costs, and enhanced optical properties crucial for biochemical detection systems. PDMS, in particular, has gained prominence due to its oxygen permeability, which supports cell culture applications within microfluidic devices.

Ceramic materials represent another frontier in microchannel fabrication, offering superior thermal conductivity and chemical resistance compared to polymers. Aluminum nitride (AlN) and aluminum oxide (Al₂O₃) ceramics enable efficient heat dissipation in high-power biochemical sensing applications where temperature control is critical for reaction kinetics and sensor performance.

Nanocomposite materials combining polymers with nanoparticles have emerged as a promising direction for enhancing specific properties of microchannels. For instance, incorporating silver nanoparticles into polymer matrices provides antimicrobial properties, while carbon nanotubes or graphene enhance thermal conductivity and mechanical strength without compromising flexibility.

Surface modification techniques have also advanced significantly, allowing precise control over the chemical and physical properties of microchannel surfaces. Plasma treatment, chemical vapor deposition, and layer-by-layer assembly enable tailoring of surface energy, hydrophobicity, and functional group density, which directly impact fluid flow behavior and biomolecule interactions within the channels.

3D printing technologies have revolutionized microchannel fabrication by enabling complex geometries previously unattainable through conventional methods. Multi-material 3D printing allows integration of different functional materials within a single device, creating gradient properties or discrete functional zones optimized for specific sensing mechanisms.

Biodegradable and environmentally friendly materials such as polylactic acid (PLA) and cellulose derivatives are gaining attention for disposable biochemical sensing applications. These materials address growing concerns about electronic waste while maintaining the performance requirements for short-term diagnostic applications.

Biocompatibility and Safety Considerations

The integration of microchannel cooling systems in biochemical sensor devices necessitates rigorous consideration of biocompatibility and safety factors. Materials used in these microfluidic systems must be carefully selected to prevent adverse biological reactions when in contact with biological samples, reagents, or living tissues. Common biocompatible materials include medical-grade polymers such as polydimethylsiloxane (PDMS), polymethyl methacrylate (PMMA), and certain grades of stainless steel, titanium, and ceramics that demonstrate minimal cytotoxicity and protein adsorption.

Surface modification techniques play a crucial role in enhancing biocompatibility. Treatments such as plasma oxidation, chemical functionalization, and coating with hydrophilic polymers can significantly reduce non-specific binding of biomolecules and cellular components to channel surfaces. These modifications help maintain sample integrity and prevent fouling that could compromise cooling efficiency or sensor performance.

Leachable compounds present a significant safety concern in microchannel systems. Plasticizers, catalysts, and unreacted monomers from polymer-based microchannels may leach into biological samples, potentially affecting analytical results or introducing toxicity. Comprehensive extraction studies and thorough washing protocols must be established to minimize these risks, particularly for applications involving sensitive biological assays or in-vivo diagnostics.

Sterilization compatibility represents another critical consideration, as biochemical sensor devices often require sterile conditions to prevent contamination and ensure accurate measurements. Materials used in microchannel cooling systems must withstand common sterilization methods such as autoclaving, ethylene oxide treatment, or gamma irradiation without degradation of physical properties or generation of toxic byproducts.

The potential for microbial growth within microchannels poses both safety and performance challenges. Biofilm formation can obstruct channels, reducing cooling efficiency and potentially contaminating samples. Design considerations should include smooth channel surfaces, appropriate flow rates to prevent stagnation, and potentially the incorporation of antimicrobial materials or coatings in non-sensing regions.

Regulatory compliance frameworks vary globally but generally require demonstration of biocompatibility through standardized testing protocols such as ISO 10993 for medical devices. Documentation of material composition, manufacturing processes, and quality control measures is essential for devices intended for clinical applications. Early consideration of these regulatory requirements can significantly streamline the development and approval process for microchannel-cooled biochemical sensors.

Surface modification techniques play a crucial role in enhancing biocompatibility. Treatments such as plasma oxidation, chemical functionalization, and coating with hydrophilic polymers can significantly reduce non-specific binding of biomolecules and cellular components to channel surfaces. These modifications help maintain sample integrity and prevent fouling that could compromise cooling efficiency or sensor performance.

Leachable compounds present a significant safety concern in microchannel systems. Plasticizers, catalysts, and unreacted monomers from polymer-based microchannels may leach into biological samples, potentially affecting analytical results or introducing toxicity. Comprehensive extraction studies and thorough washing protocols must be established to minimize these risks, particularly for applications involving sensitive biological assays or in-vivo diagnostics.

Sterilization compatibility represents another critical consideration, as biochemical sensor devices often require sterile conditions to prevent contamination and ensure accurate measurements. Materials used in microchannel cooling systems must withstand common sterilization methods such as autoclaving, ethylene oxide treatment, or gamma irradiation without degradation of physical properties or generation of toxic byproducts.

The potential for microbial growth within microchannels poses both safety and performance challenges. Biofilm formation can obstruct channels, reducing cooling efficiency and potentially contaminating samples. Design considerations should include smooth channel surfaces, appropriate flow rates to prevent stagnation, and potentially the incorporation of antimicrobial materials or coatings in non-sensing regions.

Regulatory compliance frameworks vary globally but generally require demonstration of biocompatibility through standardized testing protocols such as ISO 10993 for medical devices. Documentation of material composition, manufacturing processes, and quality control measures is essential for devices intended for clinical applications. Early consideration of these regulatory requirements can significantly streamline the development and approval process for microchannel-cooled biochemical sensors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!