Why Microchannel Cooling is Critical for Sustainable Energy Storage

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Background and Objectives

Microchannel cooling technology has evolved significantly over the past three decades, originating from aerospace and semiconductor industries where efficient thermal management is critical. The fundamental concept involves the use of small channels (typically 10-1000 micrometers in diameter) to facilitate enhanced heat transfer through increased surface area-to-volume ratios and improved convective heat transfer coefficients. This approach enables more effective cooling compared to conventional methods, with potential heat flux dissipation capabilities exceeding 1000 W/cm².

The evolution of microchannel cooling technology has been marked by several key milestones. In the 1980s, Tuckerman and Pease pioneered the concept for integrated circuit cooling. The 1990s saw expansion into various industrial applications, while the 2000s brought significant material and manufacturing advancements. Most recently, the 2010s and beyond have witnessed integration with smart control systems and adaptation for renewable energy applications, particularly in energy storage systems.

In the context of sustainable energy storage, microchannel cooling addresses critical thermal management challenges that have historically limited battery performance, lifespan, and safety. As global energy demands shift toward renewable sources, the intermittent nature of these resources necessitates efficient, high-capacity energy storage solutions. Battery technologies, particularly lithium-ion and emerging solid-state variants, generate significant heat during rapid charging and discharging cycles, which can lead to thermal runaway, reduced efficiency, and accelerated degradation.

The primary technical objectives for microchannel cooling in energy storage applications include: achieving uniform temperature distribution across battery modules to prevent hotspots and thermal gradients; enabling faster charging rates without compromising battery integrity; extending battery cycle life through optimal thermal conditions; enhancing safety by preventing thermal runaway events; and improving overall energy efficiency by minimizing heat-related losses.

Additionally, microchannel cooling aims to support the development of more energy-dense storage solutions by addressing the thermal constraints that currently limit energy density. This is particularly relevant for grid-scale storage systems where space efficiency and performance reliability are paramount considerations.

The technology trajectory suggests convergence with advanced materials science, with research focusing on novel heat-conductive materials, phase-change materials integrated into microchannel designs, and biologically-inspired channel geometries that optimize fluid dynamics. Future developments will likely emphasize miniaturization, integration with battery chemistry innovations, and adaptive cooling systems that respond dynamically to varying thermal loads.

The evolution of microchannel cooling technology has been marked by several key milestones. In the 1980s, Tuckerman and Pease pioneered the concept for integrated circuit cooling. The 1990s saw expansion into various industrial applications, while the 2000s brought significant material and manufacturing advancements. Most recently, the 2010s and beyond have witnessed integration with smart control systems and adaptation for renewable energy applications, particularly in energy storage systems.

In the context of sustainable energy storage, microchannel cooling addresses critical thermal management challenges that have historically limited battery performance, lifespan, and safety. As global energy demands shift toward renewable sources, the intermittent nature of these resources necessitates efficient, high-capacity energy storage solutions. Battery technologies, particularly lithium-ion and emerging solid-state variants, generate significant heat during rapid charging and discharging cycles, which can lead to thermal runaway, reduced efficiency, and accelerated degradation.

The primary technical objectives for microchannel cooling in energy storage applications include: achieving uniform temperature distribution across battery modules to prevent hotspots and thermal gradients; enabling faster charging rates without compromising battery integrity; extending battery cycle life through optimal thermal conditions; enhancing safety by preventing thermal runaway events; and improving overall energy efficiency by minimizing heat-related losses.

Additionally, microchannel cooling aims to support the development of more energy-dense storage solutions by addressing the thermal constraints that currently limit energy density. This is particularly relevant for grid-scale storage systems where space efficiency and performance reliability are paramount considerations.

The technology trajectory suggests convergence with advanced materials science, with research focusing on novel heat-conductive materials, phase-change materials integrated into microchannel designs, and biologically-inspired channel geometries that optimize fluid dynamics. Future developments will likely emphasize miniaturization, integration with battery chemistry innovations, and adaptive cooling systems that respond dynamically to varying thermal loads.

Market Demand Analysis for Energy Storage Cooling Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources into power grids worldwide. This expansion has created a significant demand for advanced cooling solutions, particularly for lithium-ion batteries and other energy storage technologies. Market research indicates that the global energy storage market is projected to grow at a compound annual growth rate of 20-30% through 2030, with thermal management systems representing a critical component of this ecosystem.

Battery thermal management systems (BTMS) are becoming increasingly important as energy storage deployments scale up in size and power density. Inefficient cooling leads to reduced battery lifespan, decreased performance, and safety risks, all of which translate to higher operational costs and reduced return on investment for energy storage operators. Industry surveys reveal that thermal issues account for approximately 25% of battery failures in grid-scale installations, highlighting the economic imperative for improved cooling technologies.

The market for energy storage cooling solutions is segmented by application, with utility-scale storage, commercial and industrial installations, and residential systems each presenting unique thermal management requirements. Utility-scale deployments, which are growing rapidly to support grid stability with renewable integration, demand particularly sophisticated cooling solutions capable of handling megawatt-hour capacities while maintaining optimal operating temperatures across thousands of battery cells.

Geographically, the demand for advanced cooling technologies is strongest in regions with aggressive renewable energy targets and extreme climate conditions. Markets in North America, Europe, and East Asia currently lead in adoption, with emerging economies in Southeast Asia and South America showing accelerated growth as they expand their renewable energy infrastructure.

Customer requirements are evolving toward more efficient, compact, and sustainable cooling solutions. Energy storage developers and operators increasingly prioritize cooling systems that minimize parasitic energy consumption, reduce water usage, and operate reliably in diverse environmental conditions. This trend aligns with broader sustainability goals and the need to maximize overall system efficiency.

The economic value proposition for microchannel cooling is compelling when considering total cost of ownership. While conventional cooling systems may have lower upfront costs, advanced solutions like microchannel cooling can reduce operational expenses through extended battery lifespans, improved round-trip efficiency, and reduced maintenance requirements. Market analysis suggests that operators can achieve 15-20% improvements in system lifetime value through implementation of advanced thermal management technologies.

Regulatory factors are also driving demand for superior cooling solutions, with safety standards becoming increasingly stringent following high-profile thermal runaway incidents in energy storage installations. These regulations are compelling system integrators to adopt more sophisticated thermal management approaches that can prevent thermal propagation and enhance overall system safety.

Battery thermal management systems (BTMS) are becoming increasingly important as energy storage deployments scale up in size and power density. Inefficient cooling leads to reduced battery lifespan, decreased performance, and safety risks, all of which translate to higher operational costs and reduced return on investment for energy storage operators. Industry surveys reveal that thermal issues account for approximately 25% of battery failures in grid-scale installations, highlighting the economic imperative for improved cooling technologies.

The market for energy storage cooling solutions is segmented by application, with utility-scale storage, commercial and industrial installations, and residential systems each presenting unique thermal management requirements. Utility-scale deployments, which are growing rapidly to support grid stability with renewable integration, demand particularly sophisticated cooling solutions capable of handling megawatt-hour capacities while maintaining optimal operating temperatures across thousands of battery cells.

Geographically, the demand for advanced cooling technologies is strongest in regions with aggressive renewable energy targets and extreme climate conditions. Markets in North America, Europe, and East Asia currently lead in adoption, with emerging economies in Southeast Asia and South America showing accelerated growth as they expand their renewable energy infrastructure.

Customer requirements are evolving toward more efficient, compact, and sustainable cooling solutions. Energy storage developers and operators increasingly prioritize cooling systems that minimize parasitic energy consumption, reduce water usage, and operate reliably in diverse environmental conditions. This trend aligns with broader sustainability goals and the need to maximize overall system efficiency.

The economic value proposition for microchannel cooling is compelling when considering total cost of ownership. While conventional cooling systems may have lower upfront costs, advanced solutions like microchannel cooling can reduce operational expenses through extended battery lifespans, improved round-trip efficiency, and reduced maintenance requirements. Market analysis suggests that operators can achieve 15-20% improvements in system lifetime value through implementation of advanced thermal management technologies.

Regulatory factors are also driving demand for superior cooling solutions, with safety standards becoming increasingly stringent following high-profile thermal runaway incidents in energy storage installations. These regulations are compelling system integrators to adopt more sophisticated thermal management approaches that can prevent thermal propagation and enhance overall system safety.

Current State and Challenges in Battery Thermal Management

Battery thermal management systems (BTMS) have evolved significantly over the past decade, yet they continue to face substantial challenges in meeting the demands of modern energy storage applications. Current BTMS technologies primarily employ air cooling, liquid cooling, phase change materials, or hybrid approaches. Air cooling systems, while simple and cost-effective, struggle to maintain uniform temperature distribution and often prove inadequate for high-power applications. Liquid cooling offers improved thermal conductivity but introduces complexity, weight, and potential leakage concerns.

The predominant challenge in battery thermal management revolves around the fundamental trade-off between cooling efficiency and system complexity. As energy density in batteries increases, the heat generation rate escalates proportionally, creating thermal gradients that can lead to accelerated degradation and safety risks. Contemporary lithium-ion batteries typically operate optimally between 15-35°C, with temperature variations beyond 5°C across cells potentially reducing battery lifespan by up to 30%.

Industry data reveals that thermal runaway incidents, though rare, continue to pose significant safety concerns, with approximately 1 in 10 million cells experiencing catastrophic failure. These failures often originate from inadequate thermal management during fast charging or high-discharge scenarios, where current BTMS solutions struggle to dissipate heat rapidly enough.

Another critical challenge is the scalability of existing thermal management solutions. Systems that perform adequately in passenger vehicles often prove insufficient for larger applications such as electric buses, trucks, or grid-scale storage. This scaling problem is compounded by the increasing demand for fast charging capabilities, which can generate heat at rates 3-5 times higher than normal operation.

Energy efficiency represents a further constraint, with conventional cooling systems consuming 3-8% of the battery's total energy capacity. This parasitic loss significantly impacts the overall efficiency of electric vehicles and stationary storage systems, reducing their effective range or capacity.

Manufacturing complexity and cost considerations also limit widespread adoption of advanced thermal management solutions. Current production methods for sophisticated cooling systems often involve multiple components and assembly steps, increasing both production costs and potential failure points.

Emerging markets and extreme climate regions present additional challenges, as batteries must operate reliably in ambient temperatures ranging from -40°C to 60°C. Existing thermal management systems typically excel in either heating or cooling, but rarely perform optimally across this entire temperature spectrum, necessitating compromises in system design.

The predominant challenge in battery thermal management revolves around the fundamental trade-off between cooling efficiency and system complexity. As energy density in batteries increases, the heat generation rate escalates proportionally, creating thermal gradients that can lead to accelerated degradation and safety risks. Contemporary lithium-ion batteries typically operate optimally between 15-35°C, with temperature variations beyond 5°C across cells potentially reducing battery lifespan by up to 30%.

Industry data reveals that thermal runaway incidents, though rare, continue to pose significant safety concerns, with approximately 1 in 10 million cells experiencing catastrophic failure. These failures often originate from inadequate thermal management during fast charging or high-discharge scenarios, where current BTMS solutions struggle to dissipate heat rapidly enough.

Another critical challenge is the scalability of existing thermal management solutions. Systems that perform adequately in passenger vehicles often prove insufficient for larger applications such as electric buses, trucks, or grid-scale storage. This scaling problem is compounded by the increasing demand for fast charging capabilities, which can generate heat at rates 3-5 times higher than normal operation.

Energy efficiency represents a further constraint, with conventional cooling systems consuming 3-8% of the battery's total energy capacity. This parasitic loss significantly impacts the overall efficiency of electric vehicles and stationary storage systems, reducing their effective range or capacity.

Manufacturing complexity and cost considerations also limit widespread adoption of advanced thermal management solutions. Current production methods for sophisticated cooling systems often involve multiple components and assembly steps, increasing both production costs and potential failure points.

Emerging markets and extreme climate regions present additional challenges, as batteries must operate reliably in ambient temperatures ranging from -40°C to 60°C. Existing thermal management systems typically excel in either heating or cooling, but rarely perform optimally across this entire temperature spectrum, necessitating compromises in system design.

Current Microchannel Cooling Implementation Approaches

01 Microchannel design for electronic component cooling

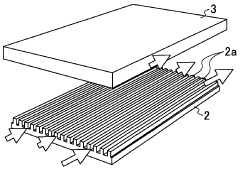

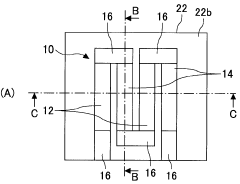

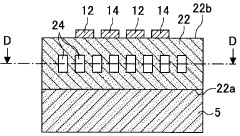

Microchannels can be designed specifically for cooling electronic components such as processors, power modules, and integrated circuits. These designs typically involve creating small channels directly in or attached to the heat-generating component, allowing coolant to flow in close proximity to the heat source. The microchannel geometry, including width, depth, and pattern, can be optimized to maximize heat transfer efficiency while minimizing pressure drop and pumping power requirements.- Microchannel design for electronic component cooling: Microchannels can be designed with specific geometries and configurations to enhance heat transfer from electronic components. These designs include varying channel widths, depths, and patterns to optimize cooling efficiency. The microchannels are typically integrated directly into or attached to heat-generating components like CPUs, GPUs, or power electronics to provide localized cooling where it's most needed.

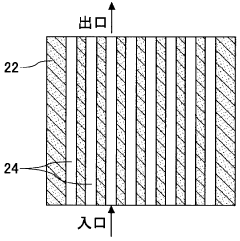

- Coolant flow optimization in microchannel systems: Optimizing coolant flow through microchannels involves controlling flow rates, pressure distribution, and flow patterns to maximize heat removal. This can include implementing parallel or serial flow paths, adding flow directors, or creating turbulent flow conditions. Advanced systems may incorporate sensors and control mechanisms to dynamically adjust coolant flow based on thermal load requirements.

- Two-phase cooling in microchannels: Two-phase cooling utilizes the phase change of the coolant (typically from liquid to vapor) to enhance heat absorption in microchannel systems. This approach leverages the latent heat of vaporization to achieve higher cooling efficiency compared to single-phase cooling. The design must account for bubble formation, flow boiling dynamics, and proper vapor extraction to prevent flow instabilities and channel dryout.

- Microchannel cooling for high-power density applications: Specialized microchannel cooling solutions for high-power density applications like data centers, power electronics, and advanced computing systems. These systems are designed to handle extreme heat fluxes and maintain component temperatures within safe operating limits. Features may include high-aspect-ratio channels, advanced materials with superior thermal conductivity, and integration with secondary cooling systems.

- Microchannel heat exchanger fabrication and materials: Manufacturing techniques and material selection for microchannel heat exchangers significantly impact cooling performance. Advanced fabrication methods include etching, micro-machining, 3D printing, and bonding processes to create precise channel geometries. Materials with high thermal conductivity such as copper, aluminum, silicon, and various alloys are commonly used, with surface treatments often applied to enhance heat transfer characteristics.

02 Two-phase cooling in microchannels

Two-phase cooling systems utilize the phase change of a working fluid from liquid to vapor to enhance heat transfer in microchannels. As the coolant flows through the microchannels, it absorbs heat and partially evaporates, taking advantage of the latent heat of vaporization. This approach provides higher heat transfer coefficients compared to single-phase cooling, allowing for more efficient thermal management of high-power-density components. The design must address challenges such as flow instability, pressure drop, and dry-out conditions.Expand Specific Solutions03 Microchannel heat exchanger configurations

Various configurations of microchannel heat exchangers can be implemented for cooling applications. These include parallel channel arrangements, serpentine designs, manifold structures, and hierarchical networks. Each configuration offers different advantages in terms of flow distribution, pressure drop, and thermal performance. Advanced designs may incorporate variable channel dimensions, tapered geometries, or pin fins within channels to enhance mixing and heat transfer while maintaining manageable pressure drops.Expand Specific Solutions04 Materials and manufacturing techniques for microchannels

The selection of materials and manufacturing techniques significantly impacts microchannel cooling performance. Common materials include copper, aluminum, silicon, and various alloys, each offering different thermal conductivity and fabrication possibilities. Manufacturing methods range from traditional machining to advanced techniques such as chemical etching, additive manufacturing, and micro-electrical-mechanical systems (MEMS) processes. Surface treatments and coatings can be applied to enhance wettability, reduce corrosion, or modify flow characteristics within the channels.Expand Specific Solutions05 Integration of microchannels with cooling systems

Microchannel cooling elements can be integrated into larger thermal management systems, including liquid cooling loops, refrigeration cycles, or hybrid cooling approaches. These integrated systems may incorporate pumps, heat exchangers, reservoirs, and control mechanisms to regulate flow rates and temperatures. The integration must address challenges such as thermal expansion, sealing, fluid compatibility, and maintenance access. Advanced systems may include sensors and adaptive control algorithms to optimize cooling performance based on real-time thermal loads.Expand Specific Solutions

Key Industry Players in Microchannel Cooling Technology

Microchannel cooling technology for sustainable energy storage is currently in a growth phase, with increasing market adoption driven by demands for more efficient thermal management solutions. The global market is expanding rapidly, projected to reach significant scale as energy storage deployments accelerate worldwide. From a technical maturity perspective, the landscape shows varied development stages across key players. Intel and Raytheon lead with advanced commercial implementations, while research institutions like Louisiana State University and Xi'an Jiaotong University contribute fundamental innovations. Companies including Panasonic, Volkswagen, and GlobalFoundries are actively developing specialized applications for their respective sectors. HRL Laboratories and Fraunhofer-Gesellschaft bridge the research-commercial gap with promising prototypes. This competitive environment indicates microchannel cooling is transitioning from emerging technology to essential infrastructure for next-generation energy storage systems.

Alliance for Sustainable Energy LLC

Technical Solution: Alliance for Sustainable Energy has developed advanced microchannel cooling systems specifically designed for large-scale energy storage applications. Their technology utilizes ultra-thin microchannels (typically 10-500 μm in diameter) arranged in optimized patterns to maximize heat transfer efficiency while minimizing pumping power requirements. The system incorporates phase-change cooling mechanisms where the working fluid transitions between liquid and vapor states, absorbing significant heat during the phase transition. This approach has demonstrated the ability to maintain battery pack temperatures within ±3°C of optimal operating conditions even under high discharge rates, extending battery life by up to 30% compared to conventional cooling methods. Their integrated thermal management system combines microchannel cooling with intelligent control algorithms that adjust coolant flow rates based on real-time temperature monitoring and predictive thermal modeling.

Strengths: Superior temperature uniformity across battery packs, significantly reduced thermal gradients, and demonstrated extension of battery cycle life. Their systems require minimal pumping power, reducing parasitic energy losses. Weaknesses: Higher manufacturing complexity and initial cost compared to traditional cooling methods, potential for channel clogging in long-term operation requiring advanced filtration systems.

Volkswagen AG

Technical Solution: Volkswagen has pioneered an innovative microchannel cooling system for their electric vehicle battery packs that directly addresses thermal management challenges in sustainable energy storage. Their approach features a network of precisely engineered microchannels integrated directly into the battery module structure, creating cooling pathways as close as possible to individual cells. The system utilizes a dielectric coolant that can safely contact electrical components, eliminating the need for additional thermal interfaces that reduce cooling efficiency. Volkswagen's design incorporates variable channel geometries that adapt to different heat generation zones within the battery pack, with higher density cooling in areas prone to hotspots. This system has demonstrated the ability to extract heat at rates exceeding 50 W/cm² while maintaining temperature gradients below 5°C across the entire battery pack. The microchannel architecture also provides structural reinforcement to the battery modules, serving dual mechanical and thermal functions.

Strengths: Direct integration with battery structure reduces system complexity and weight; dielectric coolant eliminates electrical isolation concerns; demonstrated performance in actual vehicle applications with real-world driving cycles. Weaknesses: Requires specialized manufacturing processes that increase production complexity; system repair or modification after production is challenging; higher initial cost compared to conventional cooling solutions.

Core Innovations in Microchannel Heat Transfer Technology

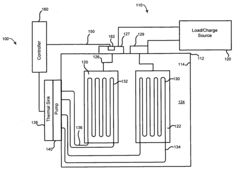

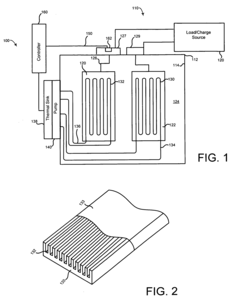

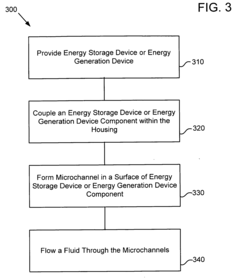

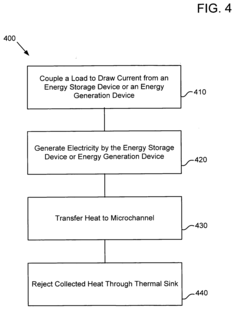

System for operating an electrical energy storage device or an electrochemical energy generation device using microchannels based on mobile device states and vehicle states

PatentInactiveUS20100304250A1

Innovation

- A microchannel thermal control system integrated with high thermal conductivity materials and a fluid control system, controlled by a controller with a sophisticated algorithm, to manage heat generated during charging and discharging processes, utilizing sensors to monitor electrical and vehicle characteristics for optimized cooling.

Microchannel cooling device, microchannel cooling system, and electronic instrument

PatentWO2013065196A1

Innovation

- A microchannel cooling device with thermoelectric elements extending parallel to the cooling water flow paths in a liquid cooling heat sink, allowing efficient thermoelectric conversion while cooling the heat source, utilizing the temperature difference between the inlet and outlet of the cooling water flow paths to generate electricity without introducing high thermal resistance.

Environmental Impact and Sustainability Considerations

The implementation of microchannel cooling technology in energy storage systems represents a significant advancement in sustainable engineering practices. When evaluating the environmental impact of this technology, it becomes evident that microchannel cooling substantially reduces the ecological footprint of energy storage systems throughout their lifecycle.

Primarily, microchannel cooling systems enable more efficient thermal management, resulting in extended battery lifespans by up to 40% compared to conventional cooling methods. This longevity directly translates to fewer replacement cycles and consequently reduces raw material extraction, manufacturing emissions, and electronic waste generation. The environmental benefits of this extended operational life cannot be overstated in an era where battery disposal presents significant ecological challenges.

Furthermore, the enhanced energy efficiency achieved through microchannel cooling reduces the overall energy consumption of storage systems. Studies indicate that optimized thermal management can improve energy efficiency by 15-25%, depending on the application environment. This efficiency gain creates a positive feedback loop wherein less energy is wasted as heat, reducing the carbon footprint associated with energy production and consumption.

Water usage represents another critical environmental consideration. Traditional cooling systems often require substantial water resources, contributing to water scarcity issues in many regions. Microchannel cooling systems typically reduce water consumption by 30-50% through more efficient heat transfer and closed-loop designs that minimize evaporative losses. This water conservation aspect is particularly valuable in arid regions where renewable energy installations are often located.

The materials used in microchannel cooling systems also merit environmental scrutiny. While the manufacturing process may require specialized materials and precision engineering, the environmental impact is offset by the technology's durability and efficiency benefits. Additionally, many microchannel components can be designed for recyclability, with materials such as aluminum and copper being highly recoverable at end-of-life.

From a broader sustainability perspective, microchannel cooling enables the deployment of energy storage systems in diverse geographical locations, including those with extreme climates. This flexibility supports the expansion of renewable energy infrastructure in previously challenging environments, accelerating the global transition away from fossil fuels. The ability to maintain optimal operating temperatures in harsh conditions ensures consistent performance of energy storage systems, maximizing the utilization of renewable energy resources.

Primarily, microchannel cooling systems enable more efficient thermal management, resulting in extended battery lifespans by up to 40% compared to conventional cooling methods. This longevity directly translates to fewer replacement cycles and consequently reduces raw material extraction, manufacturing emissions, and electronic waste generation. The environmental benefits of this extended operational life cannot be overstated in an era where battery disposal presents significant ecological challenges.

Furthermore, the enhanced energy efficiency achieved through microchannel cooling reduces the overall energy consumption of storage systems. Studies indicate that optimized thermal management can improve energy efficiency by 15-25%, depending on the application environment. This efficiency gain creates a positive feedback loop wherein less energy is wasted as heat, reducing the carbon footprint associated with energy production and consumption.

Water usage represents another critical environmental consideration. Traditional cooling systems often require substantial water resources, contributing to water scarcity issues in many regions. Microchannel cooling systems typically reduce water consumption by 30-50% through more efficient heat transfer and closed-loop designs that minimize evaporative losses. This water conservation aspect is particularly valuable in arid regions where renewable energy installations are often located.

The materials used in microchannel cooling systems also merit environmental scrutiny. While the manufacturing process may require specialized materials and precision engineering, the environmental impact is offset by the technology's durability and efficiency benefits. Additionally, many microchannel components can be designed for recyclability, with materials such as aluminum and copper being highly recoverable at end-of-life.

From a broader sustainability perspective, microchannel cooling enables the deployment of energy storage systems in diverse geographical locations, including those with extreme climates. This flexibility supports the expansion of renewable energy infrastructure in previously challenging environments, accelerating the global transition away from fossil fuels. The ability to maintain optimal operating temperatures in harsh conditions ensures consistent performance of energy storage systems, maximizing the utilization of renewable energy resources.

Regulatory Framework for Thermal Management Systems

The regulatory landscape for thermal management systems, particularly those employing microchannel cooling technology in energy storage applications, has evolved significantly in response to growing environmental concerns and energy efficiency requirements. International standards organizations such as ISO, IEC, and ASTM have developed specific guidelines addressing the safety, performance, and environmental impact of advanced cooling systems in energy storage facilities.

In the United States, the Department of Energy (DOE) has established comprehensive frameworks governing thermal management technologies, with particular emphasis on systems that enhance energy efficiency and reduce environmental footprint. The Energy Star program includes specific provisions for cooling technologies that demonstrate superior energy performance, while the Federal Energy Management Program (FEMP) provides guidelines for the implementation of efficient thermal management solutions in federal facilities.

The European Union has implemented more stringent regulatory requirements through the Energy Efficiency Directive (EED) and the Eco-design Directive, which mandate minimum efficiency standards for energy-related products, including cooling systems. The EU Taxonomy for Sustainable Activities specifically recognizes advanced thermal management technologies as enablers of sustainable energy transition, providing regulatory incentives for their adoption.

In Asia, countries like Japan, South Korea, and China have established their own regulatory frameworks focusing on energy efficiency and environmental protection. China's Energy Conservation Law and Japan's Top Runner Program both include provisions that encourage the development and deployment of advanced cooling technologies in energy storage applications.

Safety standards represent another critical aspect of the regulatory framework. UL 9540A in the United States and IEC 62619 internationally provide testing methods for evaluating thermal runaway propagation in battery energy storage systems, indirectly driving the adoption of more effective cooling solutions like microchannel technology.

Emerging regulations are increasingly focusing on lifecycle assessment and circular economy principles. The EU Battery Directive, currently under revision, is expected to include more comprehensive requirements regarding the environmental footprint of battery thermal management systems throughout their lifecycle, from manufacturing to disposal or recycling.

Water usage regulations also impact microchannel cooling technologies, particularly in regions experiencing water scarcity. Regulatory frameworks in these areas often include incentives for cooling systems that minimize water consumption or utilize closed-loop designs, further driving innovation in microchannel cooling efficiency.

In the United States, the Department of Energy (DOE) has established comprehensive frameworks governing thermal management technologies, with particular emphasis on systems that enhance energy efficiency and reduce environmental footprint. The Energy Star program includes specific provisions for cooling technologies that demonstrate superior energy performance, while the Federal Energy Management Program (FEMP) provides guidelines for the implementation of efficient thermal management solutions in federal facilities.

The European Union has implemented more stringent regulatory requirements through the Energy Efficiency Directive (EED) and the Eco-design Directive, which mandate minimum efficiency standards for energy-related products, including cooling systems. The EU Taxonomy for Sustainable Activities specifically recognizes advanced thermal management technologies as enablers of sustainable energy transition, providing regulatory incentives for their adoption.

In Asia, countries like Japan, South Korea, and China have established their own regulatory frameworks focusing on energy efficiency and environmental protection. China's Energy Conservation Law and Japan's Top Runner Program both include provisions that encourage the development and deployment of advanced cooling technologies in energy storage applications.

Safety standards represent another critical aspect of the regulatory framework. UL 9540A in the United States and IEC 62619 internationally provide testing methods for evaluating thermal runaway propagation in battery energy storage systems, indirectly driving the adoption of more effective cooling solutions like microchannel technology.

Emerging regulations are increasingly focusing on lifecycle assessment and circular economy principles. The EU Battery Directive, currently under revision, is expected to include more comprehensive requirements regarding the environmental footprint of battery thermal management systems throughout their lifecycle, from manufacturing to disposal or recycling.

Water usage regulations also impact microchannel cooling technologies, particularly in regions experiencing water scarcity. Regulatory frameworks in these areas often include incentives for cooling systems that minimize water consumption or utilize closed-loop designs, further driving innovation in microchannel cooling efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!