How Microchannel Cooling Enhances Electronics Thermal Management

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Evolution and Objectives

Microchannel cooling technology emerged in the early 1980s when researchers at Tuskegee Institute first demonstrated the concept of using microscale channels for heat dissipation. This pioneering work laid the foundation for what would become a revolutionary approach to thermal management in electronics. The technology gained significant momentum in the 1990s when semiconductor manufacturers began exploring more efficient cooling solutions to address the increasing power densities in integrated circuits.

The evolution of microchannel cooling has been closely tied to the advancement of semiconductor manufacturing techniques. As transistor sizes shrunk following Moore's Law, the heat flux generated by electronic components increased exponentially, creating an urgent need for more effective thermal management solutions. Traditional air cooling methods quickly reached their physical limitations, prompting the exploration of liquid cooling alternatives, with microchannels emerging as a particularly promising approach.

By the early 2000s, research institutions and industry leaders began developing practical implementations of microchannel cooling systems. The technology's fundamental principle involves creating small channels (typically 10-500 micrometers in width) directly in or attached to the heat-generating substrate, allowing coolant to flow through these channels and efficiently remove heat via forced convection. This approach offers significantly higher heat transfer coefficients compared to conventional cooling methods.

The primary objective of microchannel cooling technology is to enable the continued advancement of electronic systems by effectively managing the thermal challenges associated with increasing power densities. Specific goals include achieving heat flux dissipation capabilities exceeding 500 W/cm², maintaining junction temperatures below critical thresholds, minimizing thermal gradients across chips, and enabling three-dimensional integration of electronic components.

Another crucial objective is the miniaturization of cooling systems to accommodate the ongoing trend toward smaller and more compact electronic devices. Microchannel cooling aims to provide thermal management solutions that maintain or reduce the overall form factor of electronic systems while handling increasingly concentrated heat loads. This is particularly important for applications in mobile devices, aerospace systems, and medical implants.

Looking forward, the technology trajectory is focused on developing more sophisticated microchannel designs, exploring advanced manufacturing techniques for channel fabrication, and investigating novel coolants including nanofluids and phase-change materials. The ultimate goal is to create integrated cooling solutions that can be seamlessly incorporated into electronic packages during the manufacturing process, providing efficient thermal management without compromising system reliability or performance.

The evolution of microchannel cooling has been closely tied to the advancement of semiconductor manufacturing techniques. As transistor sizes shrunk following Moore's Law, the heat flux generated by electronic components increased exponentially, creating an urgent need for more effective thermal management solutions. Traditional air cooling methods quickly reached their physical limitations, prompting the exploration of liquid cooling alternatives, with microchannels emerging as a particularly promising approach.

By the early 2000s, research institutions and industry leaders began developing practical implementations of microchannel cooling systems. The technology's fundamental principle involves creating small channels (typically 10-500 micrometers in width) directly in or attached to the heat-generating substrate, allowing coolant to flow through these channels and efficiently remove heat via forced convection. This approach offers significantly higher heat transfer coefficients compared to conventional cooling methods.

The primary objective of microchannel cooling technology is to enable the continued advancement of electronic systems by effectively managing the thermal challenges associated with increasing power densities. Specific goals include achieving heat flux dissipation capabilities exceeding 500 W/cm², maintaining junction temperatures below critical thresholds, minimizing thermal gradients across chips, and enabling three-dimensional integration of electronic components.

Another crucial objective is the miniaturization of cooling systems to accommodate the ongoing trend toward smaller and more compact electronic devices. Microchannel cooling aims to provide thermal management solutions that maintain or reduce the overall form factor of electronic systems while handling increasingly concentrated heat loads. This is particularly important for applications in mobile devices, aerospace systems, and medical implants.

Looking forward, the technology trajectory is focused on developing more sophisticated microchannel designs, exploring advanced manufacturing techniques for channel fabrication, and investigating novel coolants including nanofluids and phase-change materials. The ultimate goal is to create integrated cooling solutions that can be seamlessly incorporated into electronic packages during the manufacturing process, providing efficient thermal management without compromising system reliability or performance.

Market Demand Analysis for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid evolution of high-performance computing systems, data centers, and power electronics. Current market valuations indicate that the thermal management sector is projected to reach approximately 20 billion USD by 2026, with microchannel cooling technologies representing one of the fastest-growing segments at a compound annual growth rate exceeding 9%.

This surge in demand stems from several converging factors. First, the continuous miniaturization of electronic components has resulted in significantly higher power densities, with some high-performance computing chips now exceeding 500 W/cm². Conventional cooling methods such as air cooling and traditional liquid cooling are increasingly inadequate for managing such thermal loads, creating an urgent need for more efficient solutions like microchannel cooling.

The data center industry represents a particularly strong market driver, with cooling costs accounting for up to 40% of total operational expenses in many facilities. As global data center capacity continues to expand at approximately 14% annually to support cloud computing, AI applications, and big data analytics, the demand for energy-efficient cooling solutions has become critical for both operational sustainability and cost management.

Consumer electronics manufacturers are also seeking advanced thermal management solutions as devices become thinner while processing capabilities increase. The gaming industry specifically has created a substantial market segment for enhanced cooling technologies, with premium gaming laptops and desktops requiring effective thermal management to maintain performance during extended usage periods.

Electric vehicle manufacturers represent another significant market, as battery thermal management directly impacts vehicle range, charging speeds, and battery longevity. Industry analysts note that effective thermal management can improve EV battery life by up to 30%, representing substantial value for manufacturers and consumers alike.

Geographically, North America currently leads the market for advanced thermal management solutions, followed closely by Asia-Pacific, where rapid industrialization and technology adoption are driving significant growth. The European market shows strong demand particularly in automotive and renewable energy sectors, where thermal management plays a crucial role in system efficiency.

Market research indicates that customers are increasingly willing to pay premium prices for thermal solutions that offer demonstrable improvements in energy efficiency, reliability, and system performance. This trend suggests that microchannel cooling technologies, despite potentially higher initial costs, have significant market potential if they can deliver measurable advantages in thermal performance and energy efficiency.

This surge in demand stems from several converging factors. First, the continuous miniaturization of electronic components has resulted in significantly higher power densities, with some high-performance computing chips now exceeding 500 W/cm². Conventional cooling methods such as air cooling and traditional liquid cooling are increasingly inadequate for managing such thermal loads, creating an urgent need for more efficient solutions like microchannel cooling.

The data center industry represents a particularly strong market driver, with cooling costs accounting for up to 40% of total operational expenses in many facilities. As global data center capacity continues to expand at approximately 14% annually to support cloud computing, AI applications, and big data analytics, the demand for energy-efficient cooling solutions has become critical for both operational sustainability and cost management.

Consumer electronics manufacturers are also seeking advanced thermal management solutions as devices become thinner while processing capabilities increase. The gaming industry specifically has created a substantial market segment for enhanced cooling technologies, with premium gaming laptops and desktops requiring effective thermal management to maintain performance during extended usage periods.

Electric vehicle manufacturers represent another significant market, as battery thermal management directly impacts vehicle range, charging speeds, and battery longevity. Industry analysts note that effective thermal management can improve EV battery life by up to 30%, representing substantial value for manufacturers and consumers alike.

Geographically, North America currently leads the market for advanced thermal management solutions, followed closely by Asia-Pacific, where rapid industrialization and technology adoption are driving significant growth. The European market shows strong demand particularly in automotive and renewable energy sectors, where thermal management plays a crucial role in system efficiency.

Market research indicates that customers are increasingly willing to pay premium prices for thermal solutions that offer demonstrable improvements in energy efficiency, reliability, and system performance. This trend suggests that microchannel cooling technologies, despite potentially higher initial costs, have significant market potential if they can deliver measurable advantages in thermal performance and energy efficiency.

Current Microchannel Cooling Implementations and Barriers

Microchannel cooling technology has been implemented across various industries, with significant adoption in high-performance computing, data centers, and power electronics. Current implementations typically feature microchannels with hydraulic diameters ranging from 10 to 500 micrometers, etched or fabricated directly into silicon substrates or integrated into metal heat sinks. These channels facilitate the flow of coolants—commonly water, dielectric fluids, or phase-change materials—in close proximity to heat-generating components.

In data center applications, companies like Google and Microsoft have deployed microchannel cold plates in their server racks, achieving cooling capacities exceeding 500 W/cm² in some cases. The automotive industry has also embraced this technology for electric vehicle battery thermal management, with manufacturers implementing microchannel cooling plates between battery cells to maintain optimal operating temperatures and extend battery life.

Despite these successful implementations, several significant barriers impede widespread adoption. Manufacturing complexity represents a primary challenge, as fabricating uniform microchannels with precise dimensions requires specialized equipment and processes. Current manufacturing methods often struggle with scaling production while maintaining consistent channel geometry and surface quality, leading to performance variations across identical systems.

Cost remains another substantial barrier. The specialized manufacturing processes, materials, and integration requirements result in significantly higher implementation costs compared to traditional cooling solutions. This cost differential has largely confined microchannel cooling to high-value applications where thermal performance justifies the premium.

Reliability concerns also persist in practical implementations. Clogging of microchannels due to particulate contamination or biological fouling can severely degrade performance over time. Additionally, corrosion issues may arise from the interaction between coolants and channel materials, particularly in mixed-metal systems. These reliability challenges necessitate regular maintenance and potentially costly system downtime.

Integration complexity presents another obstacle, as microchannel cooling systems must interface with existing electronic packaging architectures. The need for fluid connections, sealing mechanisms, and pumping systems adds complexity to product design and assembly processes. Furthermore, concerns about potential coolant leakage near sensitive electronic components have slowed adoption in consumer electronics and other applications where reliability is paramount.

Thermal interface resistance between the heat source and microchannel structure remains a performance-limiting factor in many implementations. Even with advanced thermal interface materials, this resistance can significantly reduce the overall cooling efficiency of microchannel systems.

In data center applications, companies like Google and Microsoft have deployed microchannel cold plates in their server racks, achieving cooling capacities exceeding 500 W/cm² in some cases. The automotive industry has also embraced this technology for electric vehicle battery thermal management, with manufacturers implementing microchannel cooling plates between battery cells to maintain optimal operating temperatures and extend battery life.

Despite these successful implementations, several significant barriers impede widespread adoption. Manufacturing complexity represents a primary challenge, as fabricating uniform microchannels with precise dimensions requires specialized equipment and processes. Current manufacturing methods often struggle with scaling production while maintaining consistent channel geometry and surface quality, leading to performance variations across identical systems.

Cost remains another substantial barrier. The specialized manufacturing processes, materials, and integration requirements result in significantly higher implementation costs compared to traditional cooling solutions. This cost differential has largely confined microchannel cooling to high-value applications where thermal performance justifies the premium.

Reliability concerns also persist in practical implementations. Clogging of microchannels due to particulate contamination or biological fouling can severely degrade performance over time. Additionally, corrosion issues may arise from the interaction between coolants and channel materials, particularly in mixed-metal systems. These reliability challenges necessitate regular maintenance and potentially costly system downtime.

Integration complexity presents another obstacle, as microchannel cooling systems must interface with existing electronic packaging architectures. The need for fluid connections, sealing mechanisms, and pumping systems adds complexity to product design and assembly processes. Furthermore, concerns about potential coolant leakage near sensitive electronic components have slowed adoption in consumer electronics and other applications where reliability is paramount.

Thermal interface resistance between the heat source and microchannel structure remains a performance-limiting factor in many implementations. Even with advanced thermal interface materials, this resistance can significantly reduce the overall cooling efficiency of microchannel systems.

Contemporary Microchannel Design and Implementation Approaches

01 Microchannel design optimization for electronic cooling

Optimized microchannel designs can significantly enhance thermal management in electronic devices. These designs focus on channel geometry, including width, depth, and spacing to maximize heat transfer efficiency while minimizing pressure drop. Advanced configurations such as tapered channels, bifurcating structures, and variable cross-sections help distribute coolant flow more effectively across hot spots. These optimizations enable higher heat flux dissipation in compact electronic components like processors and power modules.- Microchannel design optimization for electronic cooling: Optimized microchannel designs can significantly enhance thermal management in electronic devices. These designs focus on channel geometry, dimensions, and layout patterns to maximize heat transfer efficiency while minimizing pressure drop. Advanced configurations include variable width channels, tapered designs, and optimized aspect ratios that improve coolant flow distribution and thermal performance. These innovations enable more effective cooling of high-power density components in compact electronic systems.

- Advanced cooling fluids and flow management: The selection and management of cooling fluids play a crucial role in microchannel thermal management systems. Innovations include the use of nanofluids, phase-change materials, and dielectric coolants that offer enhanced thermal conductivity and heat capacity. Advanced flow management techniques such as pulsating flows, jet impingement, and multi-phase cooling can significantly improve heat transfer coefficients. These approaches enable more efficient heat removal from high-power electronic components while maintaining safe operating temperatures.

- Integrated manufacturing techniques for microchannel systems: Advanced manufacturing methods enable the production of complex microchannel cooling systems with enhanced performance. Techniques include additive manufacturing, micro-machining, chemical etching, and diffusion bonding that allow for precise fabrication of intricate channel geometries and multi-layer structures. These manufacturing innovations enable the integration of cooling systems directly into electronic components, reducing thermal resistance and improving overall system efficiency while minimizing size and weight constraints.

- Microchannel cooling for high-power electronics and batteries: Specialized microchannel cooling solutions have been developed for high-power electronics and battery thermal management. These systems feature customized channel configurations, strategic coolant routing, and integrated temperature monitoring to address the unique cooling requirements of power electronics, batteries, and electric vehicle components. The designs focus on uniform temperature distribution, prevention of hotspots, and rapid heat dissipation to enhance performance, reliability, and safety of high-power systems under various operating conditions.

- Smart and adaptive microchannel cooling systems: Intelligent microchannel cooling systems incorporate sensors, controllers, and variable flow mechanisms to dynamically adjust cooling performance based on real-time thermal demands. These adaptive systems can modify coolant flow rates, flow patterns, or activate additional cooling channels in response to changing heat loads or environmental conditions. The integration of smart control algorithms and predictive thermal management enables optimized energy efficiency while maintaining ideal operating temperatures for sensitive electronic components.

02 Advanced coolant systems for microchannel heat exchangers

Innovative coolant formulations and delivery systems enhance the performance of microchannel cooling solutions. These include two-phase cooling systems utilizing phase change materials, dielectric fluids for direct electronic cooling, and nanofluids with improved thermal conductivity. Precision pumping mechanisms ensure optimal flow rates through microchannels, while advanced manifold designs distribute coolant evenly across parallel channels. These technologies significantly increase heat transfer coefficients and cooling capacity in high-power density applications.Expand Specific Solutions03 Integrated microchannel fabrication techniques

Novel manufacturing methods enable the production of high-performance microchannel cooling systems integrated directly into electronic components. These techniques include advanced etching processes, additive manufacturing for complex 3D channel networks, and direct bonding of cooling structures to semiconductor dies. Micro-electromechanical systems (MEMS) fabrication approaches allow for precise control of channel dimensions at the microscale. These integrated solutions minimize thermal resistance between heat sources and cooling structures, significantly improving thermal management efficiency.Expand Specific Solutions04 Smart thermal management systems with microchannels

Intelligent thermal management systems incorporate sensors, controllers, and variable flow mechanisms to dynamically adjust cooling performance based on real-time thermal demands. These systems monitor temperature distributions across critical components and modulate coolant flow rates or pathways to address localized hotspots. Machine learning algorithms optimize cooling efficiency by predicting thermal loads and preemptively adjusting cooling parameters. This approach minimizes energy consumption while maintaining optimal operating temperatures for electronic systems under varying workloads.Expand Specific Solutions05 Application-specific microchannel cooling solutions

Specialized microchannel cooling designs address the unique thermal challenges of specific applications such as high-performance computing, power electronics, and telecommunications infrastructure. These solutions consider factors like space constraints, reliability requirements, and environmental conditions. For data centers, microchannel cold plates enable direct liquid cooling of server components, while automotive applications feature robust designs for power electronics in electric vehicles. Aerospace implementations emphasize lightweight materials and redundant cooling paths for critical systems, demonstrating the versatility of microchannel technology across diverse thermal management scenarios.Expand Specific Solutions

Leading Companies and Research Institutions in Microchannel Cooling

Microchannel cooling technology is currently in a growth phase within the electronics thermal management market, with an estimated global market size exceeding $2 billion and projected to grow at 8-10% annually. The competitive landscape features established semiconductor giants like Intel, IBM, and Micron Technology leading commercial implementation, while research institutions such as North China Electric Power University and Huazhong University of Science & Technology drive fundamental innovation. Companies including GlobalFoundries and Advanced Liquid Cooling Technologies are developing specialized solutions for high-performance computing applications. The technology has reached moderate maturity in certain applications but remains in development for broader implementation, with Intel and IBM demonstrating the most advanced commercial deployments through their integrated microchannel solutions for high-power density chips.

Intel Corp.

Technical Solution: Intel has developed advanced microchannel cooling solutions for high-performance computing and data center applications. Their technology integrates microchannels directly into the silicon interposer or substrate, allowing coolant to flow in close proximity to heat-generating components. Intel's two-phase cooling system utilizes microchannels with hydraulic diameters of 50-200 micrometers, enabling heat flux dissipation exceeding 1000 W/cm² in some applications [1]. The company has implemented manifold microchannel (MMC) designs that reduce pressure drop while maintaining high heat transfer coefficients. Their latest implementations incorporate machine learning algorithms to optimize coolant flow rates based on real-time thermal demands, significantly improving energy efficiency in data centers [3]. Intel has also pioneered the integration of microchannel cooling with their high-performance processors, demonstrating up to 30% improvement in thermal performance compared to traditional cooling methods.

Strengths: Superior thermal performance with ability to handle extremely high heat fluxes; direct integration with silicon manufacturing processes; reduced system-level energy consumption. Weaknesses: Higher manufacturing complexity and cost; requires sophisticated fluid delivery systems; potential reliability concerns with liquid cooling in electronic environments.

International Business Machines Corp.

Technical Solution: IBM has pioneered microchannel cooling technology through their "Aquasar" and subsequent "SuperMUC" systems, which utilize microscale water-cooling channels integrated directly with electronic components. Their approach features hierarchical cooling networks with channel dimensions ranging from 50-500 micrometers that can be embedded within multi-chip modules or attached directly to processor dies [2]. IBM's technology employs a closed-loop system with specialized coolants that maximize heat transfer while remaining electrically non-conductive. Their most advanced implementations achieve cooling capacities exceeding 350 W/cm², allowing for significant processor overclocking without thermal throttling [4]. IBM has further enhanced their microchannel designs with 3D-printed structures that optimize fluid distribution and incorporate turbulence-inducing features to break up boundary layers. This technology has demonstrated energy savings of up to 40% in data center cooling costs while enabling higher computational density through improved thermal management [5].

Strengths: Proven implementation in large-scale systems; significant energy efficiency improvements; enables higher computational density through superior cooling. Weaknesses: Complex system integration requirements; higher initial implementation costs; requires specialized maintenance protocols for liquid cooling systems.

Critical Patents and Research in Microchannel Heat Transfer

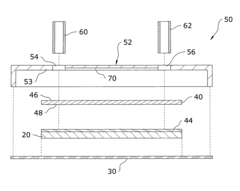

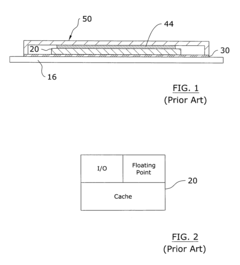

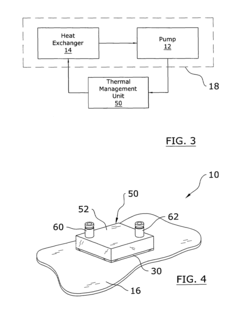

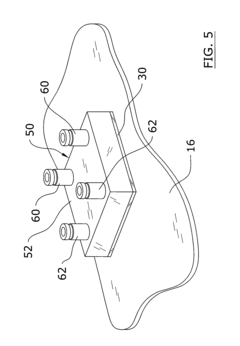

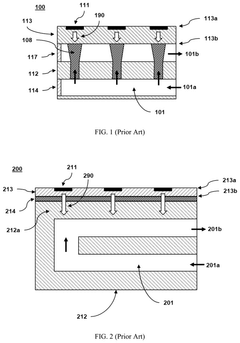

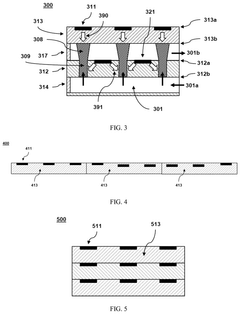

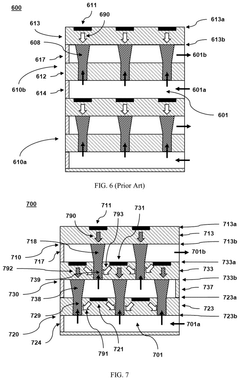

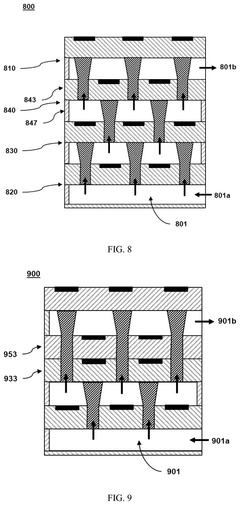

Microchannel thermal management system

PatentInactiveUS7265976B1

Innovation

- A microchannel thermal management system comprising a housing with an interior surface, a cap having microchannels attached to the housing, and inlet and outlet ports for coolant flow, which can be thermally attached to a heat-producing device using a thermal interface layer, optimizing heat transfer by directing microchannels to hot zones and allowing for various configurations and coolant management systems.

Thermal management of electronics using co-located microjet nozzles and electronic elements

PatentActiveUS12100643B2

Innovation

- Integrating microjet nozzles with electronic elements on the same substrate layer to provide both microjet nozzle cooling for lower power-density components and microjet impingement cooling for higher power components, reducing the need for separate thermal management layers and enhancing heat transfer efficiency.

Materials Science Advancements for Enhanced Microchannel Performance

The evolution of microchannel cooling technology has been significantly influenced by advancements in materials science. Traditional microchannel heat sinks predominantly utilized copper and aluminum due to their excellent thermal conductivity. However, these materials present limitations in terms of weight, corrosion resistance, and manufacturing complexity for intricate microchannel geometries.

Recent breakthroughs in material development have introduced silicon carbide (SiC) and diamond-based composites that offer thermal conductivity values exceeding 1000 W/m·K, substantially outperforming conventional metals. These advanced materials enable the creation of thinner channel walls while maintaining structural integrity, thereby increasing the surface area available for heat transfer without compromising mechanical stability.

Polymer-metal composites represent another promising direction, combining the lightweight and corrosion-resistant properties of polymers with the thermal conductivity of metallic particles. Research indicates that these composites can achieve thermal conductivity values of 20-50 W/m·K while reducing weight by up to 60% compared to all-metal alternatives, making them particularly suitable for portable electronics applications.

Surface engineering techniques have also transformed microchannel performance through the development of hydrophilic and hydrophobic coatings. Hydrophilic coatings enhance wetting characteristics, improving liquid distribution across channel surfaces, while hydrophobic coatings strategically placed can reduce flow resistance. Studies demonstrate that these surface modifications can enhance heat transfer coefficients by 15-30% without altering the underlying channel geometry.

Nanomaterial integration represents perhaps the most revolutionary advancement in microchannel technology. Carbon nanotubes and graphene additives dispersed in cooling fluids have demonstrated thermal conductivity enhancements of up to 40% at relatively low concentrations (0.1-0.5% by volume). These nanofluids not only improve heat transfer rates but also exhibit self-healing properties for microchannel surfaces, potentially extending operational lifespans.

Additive manufacturing techniques have enabled the production of previously impossible microchannel geometries using novel materials. Selective laser melting now allows for the creation of titanium alloy microchannels with wall thicknesses below 100 μm, featuring integrated turbulators and variable cross-sections that optimize flow dynamics and heat transfer simultaneously.

The convergence of these material advancements has created a new generation of microchannel cooling solutions capable of managing heat fluxes exceeding 500 W/cm², positioning this technology as a viable solution for thermal management challenges in next-generation electronics, particularly in high-performance computing, electric vehicle power systems, and aerospace applications.

Recent breakthroughs in material development have introduced silicon carbide (SiC) and diamond-based composites that offer thermal conductivity values exceeding 1000 W/m·K, substantially outperforming conventional metals. These advanced materials enable the creation of thinner channel walls while maintaining structural integrity, thereby increasing the surface area available for heat transfer without compromising mechanical stability.

Polymer-metal composites represent another promising direction, combining the lightweight and corrosion-resistant properties of polymers with the thermal conductivity of metallic particles. Research indicates that these composites can achieve thermal conductivity values of 20-50 W/m·K while reducing weight by up to 60% compared to all-metal alternatives, making them particularly suitable for portable electronics applications.

Surface engineering techniques have also transformed microchannel performance through the development of hydrophilic and hydrophobic coatings. Hydrophilic coatings enhance wetting characteristics, improving liquid distribution across channel surfaces, while hydrophobic coatings strategically placed can reduce flow resistance. Studies demonstrate that these surface modifications can enhance heat transfer coefficients by 15-30% without altering the underlying channel geometry.

Nanomaterial integration represents perhaps the most revolutionary advancement in microchannel technology. Carbon nanotubes and graphene additives dispersed in cooling fluids have demonstrated thermal conductivity enhancements of up to 40% at relatively low concentrations (0.1-0.5% by volume). These nanofluids not only improve heat transfer rates but also exhibit self-healing properties for microchannel surfaces, potentially extending operational lifespans.

Additive manufacturing techniques have enabled the production of previously impossible microchannel geometries using novel materials. Selective laser melting now allows for the creation of titanium alloy microchannels with wall thicknesses below 100 μm, featuring integrated turbulators and variable cross-sections that optimize flow dynamics and heat transfer simultaneously.

The convergence of these material advancements has created a new generation of microchannel cooling solutions capable of managing heat fluxes exceeding 500 W/cm², positioning this technology as a viable solution for thermal management challenges in next-generation electronics, particularly in high-performance computing, electric vehicle power systems, and aerospace applications.

Energy Efficiency and Sustainability Aspects of Microchannel Cooling

Microchannel cooling technology represents a significant advancement in sustainable thermal management for electronics. The implementation of this technology has demonstrated substantial energy efficiency improvements compared to conventional cooling methods. Studies indicate that microchannel cooling systems can reduce energy consumption by 20-30% in high-performance computing environments, directly translating to lower operational costs and reduced carbon footprints for data centers and other computing facilities.

The sustainability benefits extend beyond mere energy savings. Microchannel cooling systems typically require less coolant volume than traditional methods, reducing the environmental impact associated with coolant production, transportation, and disposal. When designed with closed-loop systems, these solutions minimize water consumption—a critical consideration as water scarcity becomes an increasing global concern.

From a lifecycle perspective, microchannel cooling enhances the longevity of electronic components by maintaining more consistent operating temperatures and reducing thermal cycling. This extension of component lifespan contributes significantly to sustainability by reducing electronic waste generation and the associated environmental impacts of manufacturing replacement components.

Recent innovations in microchannel design have focused on utilizing environmentally friendly refrigerants and coolants with lower global warming potential. The transition from traditional refrigerants to natural alternatives or engineered fluids with minimal environmental impact represents an important advancement in the sustainability profile of these cooling systems.

The manufacturing processes for microchannel heat exchangers have also evolved toward more sustainable practices. Advanced fabrication techniques such as additive manufacturing reduce material waste compared to traditional subtractive manufacturing methods. Additionally, the compact nature of microchannel designs often results in smaller overall system footprints, requiring less raw material for construction.

Integration of microchannel cooling with renewable energy sources presents another promising sustainability avenue. The precise temperature control offered by microchannel systems enables more efficient heat recovery, creating opportunities for waste heat utilization in secondary applications such as building heating or hot water production, further improving overall energy efficiency.

As electronics continue to become more power-dense, the sustainability advantages of microchannel cooling will likely become increasingly significant. The technology's ability to manage higher heat fluxes while consuming less energy positions it as a key enabler for sustainable development in the electronics industry, supporting global efforts to reduce energy consumption and mitigate climate change impacts.

The sustainability benefits extend beyond mere energy savings. Microchannel cooling systems typically require less coolant volume than traditional methods, reducing the environmental impact associated with coolant production, transportation, and disposal. When designed with closed-loop systems, these solutions minimize water consumption—a critical consideration as water scarcity becomes an increasing global concern.

From a lifecycle perspective, microchannel cooling enhances the longevity of electronic components by maintaining more consistent operating temperatures and reducing thermal cycling. This extension of component lifespan contributes significantly to sustainability by reducing electronic waste generation and the associated environmental impacts of manufacturing replacement components.

Recent innovations in microchannel design have focused on utilizing environmentally friendly refrigerants and coolants with lower global warming potential. The transition from traditional refrigerants to natural alternatives or engineered fluids with minimal environmental impact represents an important advancement in the sustainability profile of these cooling systems.

The manufacturing processes for microchannel heat exchangers have also evolved toward more sustainable practices. Advanced fabrication techniques such as additive manufacturing reduce material waste compared to traditional subtractive manufacturing methods. Additionally, the compact nature of microchannel designs often results in smaller overall system footprints, requiring less raw material for construction.

Integration of microchannel cooling with renewable energy sources presents another promising sustainability avenue. The precise temperature control offered by microchannel systems enables more efficient heat recovery, creating opportunities for waste heat utilization in secondary applications such as building heating or hot water production, further improving overall energy efficiency.

As electronics continue to become more power-dense, the sustainability advantages of microchannel cooling will likely become increasingly significant. The technology's ability to manage higher heat fluxes while consuming less energy positions it as a key enabler for sustainable development in the electronics industry, supporting global efforts to reduce energy consumption and mitigate climate change impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!