Analysis of Wearable Biosensors in Industrial Applications

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Industrial Biosensor Technology Background and Objectives

Wearable biosensors represent a significant technological advancement in the industrial sector, evolving from basic monitoring devices to sophisticated systems capable of real-time health and safety surveillance. The integration of these technologies into industrial environments has progressed substantially over the past decade, driven by miniaturization of electronic components, improvements in sensor technology, and advancements in wireless communication protocols.

The historical trajectory of industrial biosensors began with simple environmental monitoring tools in hazardous workplaces during the 1990s. By the early 2000s, the first generation of wearable vital sign monitors emerged, primarily focusing on basic physiological parameters. The 2010s witnessed a paradigm shift with the introduction of smart wearables featuring multiple integrated sensors and wireless connectivity, enabling continuous data collection and analysis.

Current industrial biosensor technology encompasses a diverse range of applications, including fatigue monitoring, exposure assessment for hazardous substances, ergonomic analysis, and predictive health maintenance. These technologies are increasingly being deployed across manufacturing, construction, mining, and chemical processing industries where worker safety and operational efficiency are paramount concerns.

The primary objective of industrial biosensor technology development is to create robust, non-invasive monitoring systems that can operate reliably in harsh industrial environments while providing actionable insights to prevent workplace injuries and illnesses. Secondary objectives include enhancing productivity through optimized worker performance and reducing healthcare costs associated with occupational diseases and injuries.

Technical challenges driving innovation in this field include the need for improved sensor durability in extreme conditions, extended battery life for continuous operation during long shifts, enhanced data security protocols, and more sophisticated algorithms for interpreting complex physiological signals in noisy industrial settings.

The convergence of biosensor technology with artificial intelligence and edge computing represents the frontier of development, with the goal of creating predictive systems capable of identifying potential health risks before they manifest as symptoms. This proactive approach aligns with the industry-wide shift toward preventative safety measures rather than reactive responses to incidents.

Global research initiatives are increasingly focused on developing industry-specific biosensor solutions that address the unique challenges of different sectors, from heat stress monitoring in foundries to chemical exposure tracking in pharmaceutical manufacturing. These targeted applications demonstrate the growing specialization within the industrial biosensor market.

The historical trajectory of industrial biosensors began with simple environmental monitoring tools in hazardous workplaces during the 1990s. By the early 2000s, the first generation of wearable vital sign monitors emerged, primarily focusing on basic physiological parameters. The 2010s witnessed a paradigm shift with the introduction of smart wearables featuring multiple integrated sensors and wireless connectivity, enabling continuous data collection and analysis.

Current industrial biosensor technology encompasses a diverse range of applications, including fatigue monitoring, exposure assessment for hazardous substances, ergonomic analysis, and predictive health maintenance. These technologies are increasingly being deployed across manufacturing, construction, mining, and chemical processing industries where worker safety and operational efficiency are paramount concerns.

The primary objective of industrial biosensor technology development is to create robust, non-invasive monitoring systems that can operate reliably in harsh industrial environments while providing actionable insights to prevent workplace injuries and illnesses. Secondary objectives include enhancing productivity through optimized worker performance and reducing healthcare costs associated with occupational diseases and injuries.

Technical challenges driving innovation in this field include the need for improved sensor durability in extreme conditions, extended battery life for continuous operation during long shifts, enhanced data security protocols, and more sophisticated algorithms for interpreting complex physiological signals in noisy industrial settings.

The convergence of biosensor technology with artificial intelligence and edge computing represents the frontier of development, with the goal of creating predictive systems capable of identifying potential health risks before they manifest as symptoms. This proactive approach aligns with the industry-wide shift toward preventative safety measures rather than reactive responses to incidents.

Global research initiatives are increasingly focused on developing industry-specific biosensor solutions that address the unique challenges of different sectors, from heat stress monitoring in foundries to chemical exposure tracking in pharmaceutical manufacturing. These targeted applications demonstrate the growing specialization within the industrial biosensor market.

Market Demand Analysis for Wearable Biosensors

The wearable biosensor market in industrial applications is experiencing significant growth, driven by increasing awareness of workplace safety and health monitoring needs. Current market research indicates that the global industrial wearable biosensor market reached approximately $2.1 billion in 2022 and is projected to grow at a compound annual growth rate of 19.7% through 2028. This rapid expansion reflects the industrial sector's growing recognition of the value these devices bring to workforce management and operational efficiency.

Primary demand drivers include regulatory compliance requirements for workplace safety, particularly in high-risk industries such as manufacturing, construction, mining, and chemical processing. Organizations are increasingly seeking solutions that can provide real-time monitoring of workers' physiological parameters to prevent accidents, injuries, and occupational illnesses. The COVID-19 pandemic has further accelerated this trend, with heightened awareness of health monitoring and contact tracing capabilities.

Industrial wearable biosensors are particularly sought after for their ability to monitor vital signs such as heart rate, body temperature, blood oxygen levels, and stress indicators in challenging work environments. The demand for fatigue detection systems has grown substantially, with industries operating heavy machinery or involving shift work showing particular interest in technologies that can alert supervisors to potentially dangerous levels of worker fatigue.

Market segmentation reveals varying adoption rates across industries. Manufacturing leads adoption at 32% of the industrial wearable biosensor market, followed by construction (24%), oil and gas (18%), mining (14%), and other sectors (12%). Geographically, North America currently dominates the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%).

End-user feedback indicates strong demand for specific features including extended battery life, rugged design for harsh environments, seamless integration with existing industrial IoT systems, and advanced data analytics capabilities. Privacy concerns remain a significant consideration, with 67% of potential industrial adopters citing data security and worker privacy as major factors in purchasing decisions.

Cost considerations continue to influence market penetration, with medium and small enterprises showing price sensitivity. However, the demonstrable return on investment through reduced workplace incidents, lower insurance premiums, and improved productivity is gradually overcoming initial cost barriers. Industry analysts project that as unit costs decrease through economies of scale, adoption rates will accelerate significantly in the mid-market segment.

Emerging demand trends include integration with predictive analytics platforms, customization for industry-specific applications, and development of non-invasive continuous monitoring capabilities for chronic conditions relevant to aging workforce populations. The convergence of wearable biosensors with other industrial technologies such as augmented reality and artificial intelligence represents a particularly promising growth avenue for solution providers in this space.

Primary demand drivers include regulatory compliance requirements for workplace safety, particularly in high-risk industries such as manufacturing, construction, mining, and chemical processing. Organizations are increasingly seeking solutions that can provide real-time monitoring of workers' physiological parameters to prevent accidents, injuries, and occupational illnesses. The COVID-19 pandemic has further accelerated this trend, with heightened awareness of health monitoring and contact tracing capabilities.

Industrial wearable biosensors are particularly sought after for their ability to monitor vital signs such as heart rate, body temperature, blood oxygen levels, and stress indicators in challenging work environments. The demand for fatigue detection systems has grown substantially, with industries operating heavy machinery or involving shift work showing particular interest in technologies that can alert supervisors to potentially dangerous levels of worker fatigue.

Market segmentation reveals varying adoption rates across industries. Manufacturing leads adoption at 32% of the industrial wearable biosensor market, followed by construction (24%), oil and gas (18%), mining (14%), and other sectors (12%). Geographically, North America currently dominates the market with 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%).

End-user feedback indicates strong demand for specific features including extended battery life, rugged design for harsh environments, seamless integration with existing industrial IoT systems, and advanced data analytics capabilities. Privacy concerns remain a significant consideration, with 67% of potential industrial adopters citing data security and worker privacy as major factors in purchasing decisions.

Cost considerations continue to influence market penetration, with medium and small enterprises showing price sensitivity. However, the demonstrable return on investment through reduced workplace incidents, lower insurance premiums, and improved productivity is gradually overcoming initial cost barriers. Industry analysts project that as unit costs decrease through economies of scale, adoption rates will accelerate significantly in the mid-market segment.

Emerging demand trends include integration with predictive analytics platforms, customization for industry-specific applications, and development of non-invasive continuous monitoring capabilities for chronic conditions relevant to aging workforce populations. The convergence of wearable biosensors with other industrial technologies such as augmented reality and artificial intelligence represents a particularly promising growth avenue for solution providers in this space.

Current State and Challenges in Industrial Biosensing

The global industrial biosensing landscape has undergone significant transformation in recent years, with wearable biosensors emerging as a pivotal technology. Current industrial applications primarily focus on worker safety monitoring, productivity enhancement, and preventive health management. These devices have evolved from simple activity trackers to sophisticated multi-parameter monitoring systems capable of detecting physiological signals, environmental hazards, and biomechanical metrics simultaneously.

Market research indicates that approximately 60% of large manufacturing enterprises have implemented some form of wearable biosensing technology, though comprehensive integration remains limited. The most widely adopted applications include fatigue detection systems in transportation and mining, heat stress monitors in construction and foundry operations, and exposure assessment devices in chemical processing facilities. Recent technological advancements have enabled real-time data transmission and analytics, allowing for immediate intervention when abnormal conditions are detected.

Despite these advancements, industrial biosensing faces several significant challenges. Power management remains a critical limitation, with most current-generation sensors requiring frequent recharging or battery replacement, disrupting continuous monitoring capabilities. This is particularly problematic in extended shift operations or remote industrial environments where charging infrastructure is limited.

Data accuracy and reliability present another substantial hurdle, especially in harsh industrial environments characterized by extreme temperatures, humidity, vibration, and electromagnetic interference. False positives and negatives can undermine trust in these systems and potentially create dangerous situations if workers or supervisors become complacent or dismissive of alerts.

Interoperability issues persist across different sensor platforms and enterprise management systems. The lack of standardized protocols for data formatting, transmission, and integration creates significant barriers to implementing comprehensive monitoring solutions, particularly in facilities utilizing equipment from multiple vendors or those attempting to retrofit existing infrastructure.

Privacy and ethical considerations represent increasingly complex challenges as biosensing capabilities advance. The continuous monitoring of physiological parameters raises questions about data ownership, consent boundaries, and potential discrimination based on health metrics. Several recent legal cases have highlighted the tension between workplace safety objectives and individual privacy rights.

Regulatory frameworks governing industrial biosensors remain fragmented globally, with significant variations in approval processes, performance standards, and data protection requirements across different regions. This regulatory inconsistency creates compliance challenges for multinational corporations and impedes technology transfer between markets.

Cost-benefit justification continues to be problematic for many organizations, particularly small and medium enterprises. While the potential long-term benefits of improved safety and productivity are substantial, the initial investment and ongoing maintenance costs remain prohibitive for widespread adoption across all industrial sectors.

Market research indicates that approximately 60% of large manufacturing enterprises have implemented some form of wearable biosensing technology, though comprehensive integration remains limited. The most widely adopted applications include fatigue detection systems in transportation and mining, heat stress monitors in construction and foundry operations, and exposure assessment devices in chemical processing facilities. Recent technological advancements have enabled real-time data transmission and analytics, allowing for immediate intervention when abnormal conditions are detected.

Despite these advancements, industrial biosensing faces several significant challenges. Power management remains a critical limitation, with most current-generation sensors requiring frequent recharging or battery replacement, disrupting continuous monitoring capabilities. This is particularly problematic in extended shift operations or remote industrial environments where charging infrastructure is limited.

Data accuracy and reliability present another substantial hurdle, especially in harsh industrial environments characterized by extreme temperatures, humidity, vibration, and electromagnetic interference. False positives and negatives can undermine trust in these systems and potentially create dangerous situations if workers or supervisors become complacent or dismissive of alerts.

Interoperability issues persist across different sensor platforms and enterprise management systems. The lack of standardized protocols for data formatting, transmission, and integration creates significant barriers to implementing comprehensive monitoring solutions, particularly in facilities utilizing equipment from multiple vendors or those attempting to retrofit existing infrastructure.

Privacy and ethical considerations represent increasingly complex challenges as biosensing capabilities advance. The continuous monitoring of physiological parameters raises questions about data ownership, consent boundaries, and potential discrimination based on health metrics. Several recent legal cases have highlighted the tension between workplace safety objectives and individual privacy rights.

Regulatory frameworks governing industrial biosensors remain fragmented globally, with significant variations in approval processes, performance standards, and data protection requirements across different regions. This regulatory inconsistency creates compliance challenges for multinational corporations and impedes technology transfer between markets.

Cost-benefit justification continues to be problematic for many organizations, particularly small and medium enterprises. While the potential long-term benefits of improved safety and productivity are substantial, the initial investment and ongoing maintenance costs remain prohibitive for widespread adoption across all industrial sectors.

Current Technical Solutions for Industrial Biosensors

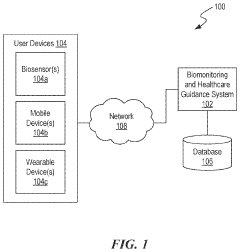

01 Wearable biosensors for health monitoring

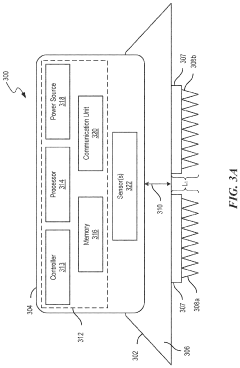

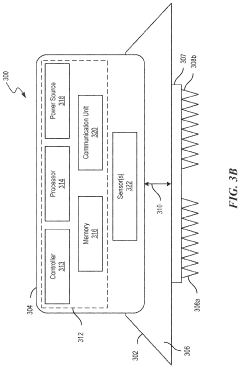

Wearable biosensors designed for continuous health monitoring can track various physiological parameters such as heart rate, blood pressure, body temperature, and glucose levels. These devices enable real-time health tracking and early detection of abnormalities, allowing for timely medical intervention. The sensors are typically integrated into comfortable wearable formats like patches, wristbands, or clothing to facilitate long-term use while maintaining accuracy in data collection.- Wearable biosensors for health monitoring: Wearable biosensors designed for continuous health monitoring can track various physiological parameters such as heart rate, blood pressure, body temperature, and glucose levels. These devices enable real-time health tracking and early detection of abnormalities, allowing for timely medical intervention. The sensors are typically integrated into comfortable wearable formats like patches, wristbands, or clothing to facilitate long-term use while maintaining accuracy in data collection.

- Sweat-based biosensing technologies: Sweat-based biosensors analyze biomarkers present in perspiration to provide non-invasive monitoring of various health indicators. These sensors can detect electrolytes, metabolites, hormones, and other biomolecules in sweat, offering insights into hydration status, stress levels, and potential disease markers. The technology typically employs electrochemical, optical, or colorimetric detection methods integrated into flexible, skin-adherent platforms that can withstand moisture and physical activity.

- Implantable and minimally invasive biosensors: Implantable and minimally invasive biosensors are designed to be placed within or just beneath the skin for continuous monitoring of biomarkers in interstitial fluid or blood. These sensors often utilize advanced biocompatible materials to minimize foreign body response and extend operational lifespan. Applications include continuous glucose monitoring, detection of cardiac biomarkers, and therapeutic drug monitoring, with data typically transmitted wirelessly to external devices for analysis and alert generation.

- Flexible and stretchable biosensor materials: Advanced materials that combine flexibility, stretchability, and biocompatibility are crucial for wearable biosensors that conform to body contours and movement. These materials include conductive polymers, nanocomposites, and specially engineered substrates that maintain electrical and sensing properties under mechanical deformation. The development focuses on creating sensors that provide reliable measurements while being comfortable enough for continuous wear, with minimal skin irritation or movement constraints.

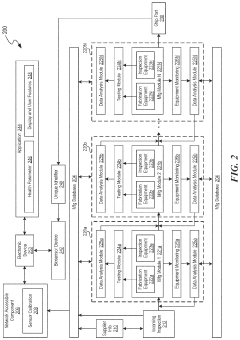

- Data processing and connectivity for biosensors: Wearable biosensors incorporate sophisticated data processing algorithms and connectivity solutions to transform raw sensor data into actionable health insights. These systems often employ edge computing for initial data processing, followed by secure transmission to smartphones or cloud platforms for comprehensive analysis. Machine learning algorithms help identify patterns, detect anomalies, and provide personalized health recommendations, while ensuring data privacy and security through encryption and authentication protocols.

02 Sweat-based biosensing technologies

Sweat-based biosensors analyze biomarkers present in perspiration to provide non-invasive monitoring of various health indicators. These sensors can detect electrolytes, metabolites, hormones, and other biomolecules in sweat, offering insights into hydration status, stress levels, and potential disease markers. The technology typically employs electrochemical, optical, or colorimetric detection methods integrated into flexible, skin-adherent platforms that can collect and analyze sweat in real-time during daily activities or exercise.Expand Specific Solutions03 Implantable and minimally invasive biosensors

Implantable and minimally invasive biosensors are designed to be placed within or just beneath the skin to monitor internal physiological parameters with high accuracy. These sensors can continuously track biomarkers in interstitial fluid or blood, providing precise measurements for conditions requiring constant monitoring such as diabetes or cardiac issues. Advanced materials and biocompatible coatings are employed to reduce foreign body response and extend the functional lifespan of these sensors while maintaining connectivity with external data collection systems.Expand Specific Solutions04 Flexible and stretchable biosensor platforms

Flexible and stretchable biosensor platforms utilize advanced materials and fabrication techniques to create conformable sensing devices that can adapt to body movements and contours. These platforms incorporate conductive polymers, nanomaterials, or thin-film electronics on substrates that can bend, stretch, and twist without compromising sensor functionality. The resulting devices offer improved comfort, better skin contact, and more reliable measurements during physical activity, while enabling novel form factors such as electronic tattoos or smart textiles for health monitoring.Expand Specific Solutions05 Data processing and connectivity solutions for biosensors

Advanced data processing and connectivity solutions enhance the functionality of wearable biosensors by enabling efficient data collection, analysis, and transmission. These systems incorporate low-power microprocessors, machine learning algorithms for signal processing, and wireless communication protocols to transmit health data securely to smartphones or cloud platforms. The integration of edge computing capabilities allows for real-time data analysis directly on the device, reducing power consumption and enabling immediate feedback while maintaining privacy and data security standards.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The wearable biosensors market in industrial applications is currently in a growth phase, with an expanding market size driven by increasing demand for real-time health monitoring and workplace safety solutions. The technology maturity varies across applications, with leading academic institutions like MIT, University of California, and Caltech pioneering fundamental research, while commercial players demonstrate different levels of implementation readiness. Companies like Google, Samsung, and Honeywell are leveraging their technological capabilities to develop advanced sensor platforms, while specialized firms such as EnLiSense, Polar Electro, and Affectiva focus on niche applications with proprietary technologies. Medical technology companies like Medtronic are extending their expertise into industrial wearables, creating a competitive landscape that balances innovation from research institutions with practical implementation from established manufacturers.

Honeywell Safety Products USA, Inc.

Technical Solution: Honeywell has developed advanced wearable biosensor systems specifically designed for industrial environments. Their Connected Worker platform integrates physiological monitoring sensors into personal protective equipment (PPE) to track vital signs such as heart rate, respiration, body temperature, and movement patterns in real-time. The system employs a multi-sensor fusion approach where data from various biosensors is processed through proprietary algorithms to detect early signs of heat stress, fatigue, and other physiological conditions that could compromise worker safety. Their industrial biosensors feature ruggedized designs capable of withstanding harsh environments including extreme temperatures, dust, moisture, and chemical exposure. The platform includes wireless connectivity options (BLE, Wi-Fi, LTE) for continuous data transmission to centralized monitoring systems, with edge computing capabilities for situations with limited connectivity. Honeywell's biosensors also incorporate advanced power management techniques to extend battery life throughout entire work shifts.

Strengths: Exceptional durability in harsh industrial environments; seamless integration with existing safety equipment; comprehensive safety monitoring ecosystem. Weaknesses: Higher implementation costs compared to consumer-grade alternatives; requires significant IT infrastructure investment; potential privacy concerns with continuous worker monitoring.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive industrial wearable biosensor ecosystem centered around their ARTIK IoT platform. Their approach integrates multiple sensing modalities into compact, energy-efficient wearable devices designed specifically for industrial applications. Samsung's industrial biosensors utilize advanced microelectromechanical systems (MEMS) technology to create miniaturized sensors capable of detecting various physiological parameters including heart rate variability, galvanic skin response, blood oxygen levels, and body temperature. These sensors are incorporated into wristbands, smart clothing, and safety equipment that workers can wear comfortably throughout their shifts. The collected biometric data is processed through Samsung's proprietary algorithms that can identify patterns indicating fatigue, stress, dehydration, or exposure to environmental hazards. Their system features real-time wireless data transmission to KNOX-secured cloud platforms, where advanced analytics provide supervisors with actionable insights while maintaining worker privacy through sophisticated data anonymization techniques. Samsung has also developed specialized sensors for detecting environmental hazards such as toxic gas exposure, radiation, and extreme temperatures.

Strengths: Comprehensive integration with existing Samsung enterprise ecosystem; strong security protocols for sensitive biometric data; extensive battery optimization for full-shift operation. Weaknesses: Potential vendor lock-in with proprietary systems; higher initial investment compared to standalone solutions; requires significant technical expertise for full implementation.

Core Patents and Technical Literature Analysis

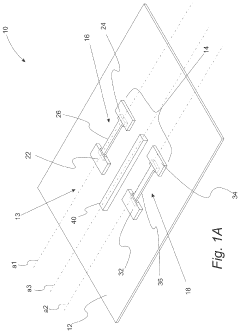

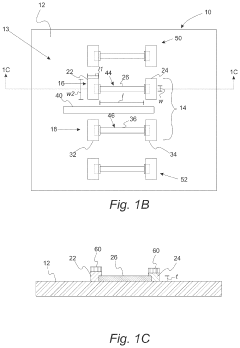

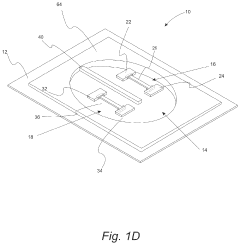

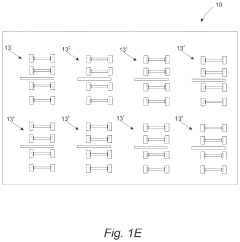

Wearable biosensors and applications thereof

PatentActiveUS11813057B2

Innovation

- Development of highly sensitive In2O3 nanoribbon transistor biosensors with integrated on-chip gold gate electrodes, deposited on flexible polyethylene terephthalate substrates, functionalized with glucose oxidase, chitosan, and single-walled carbon nanotubes, capable of detecting glucose concentrations between 10 nM to 1 mM in external body fluids without breaking the skin.

Wearable electronic biosensors and manufacturing methods

PatentPendingUS20230255527A1

Innovation

- The development of wearable biosensors with advanced manufacturing methods that include data-driven calibration adjustments and production data extrapolation, allowing for precise calibration and performance prediction, and dynamic manufacturing adjustments to enhance accuracy and reliability.

Safety Standards and Regulatory Compliance

The implementation of wearable biosensors in industrial environments necessitates strict adherence to comprehensive safety standards and regulatory frameworks. In the United States, the Occupational Safety and Health Administration (OSHA) has established guidelines for electronic devices used in workplace monitoring, requiring that such devices maintain data privacy and not interfere with existing safety equipment. Similarly, the European Union's General Data Protection Regulation (GDPR) imposes stringent requirements on the collection and processing of biometric data, mandating explicit consent and robust data security measures.

For industrial applications, wearable biosensors must comply with industry-specific certifications such as IEC 60601-1 for medical electrical equipment safety and ISO 13485 for quality management systems. These standards ensure that devices operate reliably in harsh industrial environments without posing electrical, mechanical, or thermal hazards to workers. Additionally, devices deployed in potentially explosive atmospheres must meet ATEX Directive requirements in Europe or equivalent standards in other regions.

Electromagnetic compatibility (EMC) standards, including IEC 61000-4-2 for electrostatic discharge immunity and IEC 61000-4-3 for radiated electromagnetic field immunity, are particularly critical for wearable biosensors. These standards ensure that devices neither cause interference with other industrial equipment nor experience performance degradation due to electromagnetic disturbances common in manufacturing environments.

Data security and privacy regulations present significant compliance challenges for industrial wearable biosensors. Beyond GDPR in Europe, various regional regulations such as the California Consumer Privacy Act (CCPA) and industry-specific requirements like HIPAA for health-related data impose additional obligations on manufacturers and deploying organizations. These regulations typically require implementation of encryption, access controls, and data minimization principles.

Certification processes for industrial wearable biosensors often involve rigorous testing by notified bodies or accredited laboratories. This includes environmental testing (temperature extremes, humidity, vibration), electrical safety testing, and biocompatibility assessment for devices with prolonged skin contact. The International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) provide frameworks for these certification processes.

Emerging regulatory considerations include the development of specific standards for AI-enabled wearable devices, as many modern biosensors incorporate machine learning algorithms for data interpretation. The FDA in the United States and the European Medicines Agency are developing frameworks to address the unique challenges posed by continuously evolving AI systems in health monitoring applications, which will likely influence industrial applications as the technology matures.

For industrial applications, wearable biosensors must comply with industry-specific certifications such as IEC 60601-1 for medical electrical equipment safety and ISO 13485 for quality management systems. These standards ensure that devices operate reliably in harsh industrial environments without posing electrical, mechanical, or thermal hazards to workers. Additionally, devices deployed in potentially explosive atmospheres must meet ATEX Directive requirements in Europe or equivalent standards in other regions.

Electromagnetic compatibility (EMC) standards, including IEC 61000-4-2 for electrostatic discharge immunity and IEC 61000-4-3 for radiated electromagnetic field immunity, are particularly critical for wearable biosensors. These standards ensure that devices neither cause interference with other industrial equipment nor experience performance degradation due to electromagnetic disturbances common in manufacturing environments.

Data security and privacy regulations present significant compliance challenges for industrial wearable biosensors. Beyond GDPR in Europe, various regional regulations such as the California Consumer Privacy Act (CCPA) and industry-specific requirements like HIPAA for health-related data impose additional obligations on manufacturers and deploying organizations. These regulations typically require implementation of encryption, access controls, and data minimization principles.

Certification processes for industrial wearable biosensors often involve rigorous testing by notified bodies or accredited laboratories. This includes environmental testing (temperature extremes, humidity, vibration), electrical safety testing, and biocompatibility assessment for devices with prolonged skin contact. The International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) provide frameworks for these certification processes.

Emerging regulatory considerations include the development of specific standards for AI-enabled wearable devices, as many modern biosensors incorporate machine learning algorithms for data interpretation. The FDA in the United States and the European Medicines Agency are developing frameworks to address the unique challenges posed by continuously evolving AI systems in health monitoring applications, which will likely influence industrial applications as the technology matures.

ROI and Implementation Strategies

Implementing wearable biosensors in industrial environments requires careful financial planning and strategic deployment to maximize return on investment. Companies can expect ROI from multiple avenues, including reduced workplace injuries, decreased insurance premiums, and improved productivity. Quantitative analysis shows that organizations implementing wearable biosensor programs can achieve 15-30% reduction in workplace accidents within the first year, translating to significant cost savings. For a mid-sized manufacturing facility, this could represent $200,000-500,000 in annual savings from reduced workers' compensation claims alone.

Beyond direct cost savings, wearable biosensors contribute to operational efficiency through decreased absenteeism and improved workforce management. Companies implementing these technologies report 8-12% reduction in unplanned downtime and 5-7% improvement in overall equipment effectiveness (OEE), further enhancing the financial case for adoption.

Successful implementation strategies begin with pilot programs in high-risk departments where immediate benefits can be demonstrated. This phased approach allows organizations to refine deployment methodologies and build internal support before full-scale implementation. Critical to success is establishing clear baseline metrics before deployment, including accident rates, near-miss incidents, productivity indicators, and employee health parameters.

Employee engagement represents a cornerstone of effective implementation. Organizations must address privacy concerns transparently and emphasize the personal benefits of the technology. Training programs should focus not only on proper device usage but also on interpreting the data to make meaningful behavioral changes. Companies that establish clear protocols for data handling and demonstrate tangible benefits to workers experience 60% higher adoption rates than those focusing solely on organizational benefits.

Integration with existing safety management systems and IT infrastructure presents another implementation challenge. Successful organizations designate cross-functional teams including representatives from operations, IT, occupational health, and human resources to ensure seamless integration. Cloud-based platforms with robust API capabilities facilitate data integration across enterprise systems, enabling comprehensive analytics and reporting.

Long-term sustainability requires ongoing evaluation and refinement of the biosensor program. Organizations should establish quarterly review cycles to assess technology performance, user adoption, and financial returns. As the technology landscape evolves rapidly, implementation strategies must include provisions for hardware upgrades and software updates to maintain system effectiveness and security compliance.

Beyond direct cost savings, wearable biosensors contribute to operational efficiency through decreased absenteeism and improved workforce management. Companies implementing these technologies report 8-12% reduction in unplanned downtime and 5-7% improvement in overall equipment effectiveness (OEE), further enhancing the financial case for adoption.

Successful implementation strategies begin with pilot programs in high-risk departments where immediate benefits can be demonstrated. This phased approach allows organizations to refine deployment methodologies and build internal support before full-scale implementation. Critical to success is establishing clear baseline metrics before deployment, including accident rates, near-miss incidents, productivity indicators, and employee health parameters.

Employee engagement represents a cornerstone of effective implementation. Organizations must address privacy concerns transparently and emphasize the personal benefits of the technology. Training programs should focus not only on proper device usage but also on interpreting the data to make meaningful behavioral changes. Companies that establish clear protocols for data handling and demonstrate tangible benefits to workers experience 60% higher adoption rates than those focusing solely on organizational benefits.

Integration with existing safety management systems and IT infrastructure presents another implementation challenge. Successful organizations designate cross-functional teams including representatives from operations, IT, occupational health, and human resources to ensure seamless integration. Cloud-based platforms with robust API capabilities facilitate data integration across enterprise systems, enabling comprehensive analytics and reporting.

Long-term sustainability requires ongoing evaluation and refinement of the biosensor program. Organizations should establish quarterly review cycles to assess technology performance, user adoption, and financial returns. As the technology landscape evolves rapidly, implementation strategies must include provisions for hardware upgrades and software updates to maintain system effectiveness and security compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!