Wearable Biosensors and Their Integration with Smart Textiles

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wearable Biosensor Evolution and Objectives

Wearable biosensors have undergone significant evolution since their inception in the late 20th century. Initially, these devices were bulky, limited in functionality, and primarily used in controlled clinical settings. The first generation of wearable biosensors focused on basic physiological measurements such as heart rate and body temperature, utilizing rigid electronic components that restricted comfort and continuous use.

The early 2000s marked a pivotal shift with the miniaturization of electronic components and advancements in material science, enabling the development of more flexible and less intrusive biosensing technologies. This period saw the emergence of consumer-oriented wearable devices like fitness trackers and smartwatches, which incorporated basic biosensing capabilities while prioritizing user comfort and extended battery life.

By the 2010s, wearable biosensor technology had progressed to include more sophisticated sensing modalities, including electrochemical sensors for sweat analysis, optical sensors for blood oxygen monitoring, and advanced motion sensors for detailed activity tracking. The integration of these sensors with wireless communication technologies facilitated real-time data transmission and analysis, expanding their utility beyond simple monitoring to predictive health applications.

The current technological landscape is characterized by a convergence of wearable biosensors with smart textile technologies. This integration represents a paradigm shift from "devices worn on the body" to "technology embedded within everyday clothing." Advanced materials such as conductive yarns, piezoelectric fibers, and textile-based electrodes have enabled the development of garments that can seamlessly monitor multiple physiological parameters without compromising comfort or mobility.

Looking forward, the primary objectives for wearable biosensor development include enhancing sensor accuracy and reliability under various environmental conditions, improving energy efficiency to enable longer operational periods, and developing more sophisticated algorithms for data interpretation. There is also a growing focus on creating biosensors capable of detecting and monitoring specific biomarkers related to chronic diseases, stress levels, and nutritional status.

Another critical objective is the standardization of data collection and interpretation protocols to ensure interoperability between different wearable systems and healthcare platforms. This standardization will be essential for the broader adoption of wearable biosensors in clinical settings and for their integration into comprehensive healthcare management systems.

The ultimate goal of this technological evolution is to create unobtrusive, reliable, and highly functional biosensing systems that can be seamlessly integrated into daily life, providing continuous health monitoring without user intervention. Such systems hold the potential to revolutionize preventive healthcare by enabling early detection of health issues and facilitating personalized interventions based on individual physiological data.

The early 2000s marked a pivotal shift with the miniaturization of electronic components and advancements in material science, enabling the development of more flexible and less intrusive biosensing technologies. This period saw the emergence of consumer-oriented wearable devices like fitness trackers and smartwatches, which incorporated basic biosensing capabilities while prioritizing user comfort and extended battery life.

By the 2010s, wearable biosensor technology had progressed to include more sophisticated sensing modalities, including electrochemical sensors for sweat analysis, optical sensors for blood oxygen monitoring, and advanced motion sensors for detailed activity tracking. The integration of these sensors with wireless communication technologies facilitated real-time data transmission and analysis, expanding their utility beyond simple monitoring to predictive health applications.

The current technological landscape is characterized by a convergence of wearable biosensors with smart textile technologies. This integration represents a paradigm shift from "devices worn on the body" to "technology embedded within everyday clothing." Advanced materials such as conductive yarns, piezoelectric fibers, and textile-based electrodes have enabled the development of garments that can seamlessly monitor multiple physiological parameters without compromising comfort or mobility.

Looking forward, the primary objectives for wearable biosensor development include enhancing sensor accuracy and reliability under various environmental conditions, improving energy efficiency to enable longer operational periods, and developing more sophisticated algorithms for data interpretation. There is also a growing focus on creating biosensors capable of detecting and monitoring specific biomarkers related to chronic diseases, stress levels, and nutritional status.

Another critical objective is the standardization of data collection and interpretation protocols to ensure interoperability between different wearable systems and healthcare platforms. This standardization will be essential for the broader adoption of wearable biosensors in clinical settings and for their integration into comprehensive healthcare management systems.

The ultimate goal of this technological evolution is to create unobtrusive, reliable, and highly functional biosensing systems that can be seamlessly integrated into daily life, providing continuous health monitoring without user intervention. Such systems hold the potential to revolutionize preventive healthcare by enabling early detection of health issues and facilitating personalized interventions based on individual physiological data.

Smart Textile Market Demand Analysis

The global smart textile market is experiencing significant growth driven by increasing consumer demand for wearable technology that seamlessly integrates into daily life. Current market analysis indicates that the smart textile sector is expanding at a compound annual growth rate of approximately 25%, with particular acceleration in healthcare, sports, and military applications. This growth trajectory is expected to continue as technological advancements make smart textiles more accessible and functional.

Healthcare represents the largest market segment for smart textiles integrated with biosensors, accounting for nearly 40% of the total market share. The aging population in developed countries has created substantial demand for remote health monitoring solutions that can track vital signs, medication adherence, and mobility patterns without disrupting patients' daily activities. Healthcare providers are increasingly recognizing the value of continuous monitoring through smart textiles for chronic disease management, preventive care, and reducing hospital readmissions.

The sports and fitness industry constitutes the second-largest market segment, with professional athletes and fitness enthusiasts seeking performance optimization through real-time biometric feedback. Consumer surveys indicate that 65% of regular exercisers express interest in smart textiles that can monitor muscle activity, hydration levels, and recovery metrics. Major sportswear brands have responded by investing heavily in research and development of smart textile products, creating strategic partnerships with technology companies to enhance their offerings.

Military and defense applications represent a smaller but rapidly growing segment with high-value contracts. These applications require robust biosensors integrated into uniforms that can monitor soldier health status, detect environmental hazards, and enhance battlefield awareness. The stringent requirements for durability, reliability, and security in military applications are driving innovation that eventually benefits consumer markets.

Regional analysis reveals that North America currently leads the smart textile market, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the fastest growth rate due to increasing disposable income, rapid urbanization, and expanding manufacturing capabilities. Countries like China, Japan, and South Korea are emerging as both significant consumers and producers of smart textiles with integrated biosensors.

Consumer preference studies highlight that comfort, washability, and battery life remain the primary concerns for potential buyers of smart textiles. The price sensitivity varies significantly across different market segments, with healthcare applications commanding premium prices due to their critical nature and regulatory compliance requirements. For mass-market adoption, industry analysts suggest that smart textiles with integrated biosensors need to reach price points comparable to mid-range conventional garments while offering clear value propositions to consumers.

Healthcare represents the largest market segment for smart textiles integrated with biosensors, accounting for nearly 40% of the total market share. The aging population in developed countries has created substantial demand for remote health monitoring solutions that can track vital signs, medication adherence, and mobility patterns without disrupting patients' daily activities. Healthcare providers are increasingly recognizing the value of continuous monitoring through smart textiles for chronic disease management, preventive care, and reducing hospital readmissions.

The sports and fitness industry constitutes the second-largest market segment, with professional athletes and fitness enthusiasts seeking performance optimization through real-time biometric feedback. Consumer surveys indicate that 65% of regular exercisers express interest in smart textiles that can monitor muscle activity, hydration levels, and recovery metrics. Major sportswear brands have responded by investing heavily in research and development of smart textile products, creating strategic partnerships with technology companies to enhance their offerings.

Military and defense applications represent a smaller but rapidly growing segment with high-value contracts. These applications require robust biosensors integrated into uniforms that can monitor soldier health status, detect environmental hazards, and enhance battlefield awareness. The stringent requirements for durability, reliability, and security in military applications are driving innovation that eventually benefits consumer markets.

Regional analysis reveals that North America currently leads the smart textile market, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the fastest growth rate due to increasing disposable income, rapid urbanization, and expanding manufacturing capabilities. Countries like China, Japan, and South Korea are emerging as both significant consumers and producers of smart textiles with integrated biosensors.

Consumer preference studies highlight that comfort, washability, and battery life remain the primary concerns for potential buyers of smart textiles. The price sensitivity varies significantly across different market segments, with healthcare applications commanding premium prices due to their critical nature and regulatory compliance requirements. For mass-market adoption, industry analysts suggest that smart textiles with integrated biosensors need to reach price points comparable to mid-range conventional garments while offering clear value propositions to consumers.

Biosensor-Textile Integration Challenges

The integration of biosensors with textiles presents significant technical challenges that must be addressed to achieve reliable, comfortable, and effective wearable health monitoring systems. One primary challenge is maintaining sensor functionality during textile manufacturing processes, which often involve high temperatures, mechanical stress, and chemical treatments that can damage sensitive electronic components. Traditional textile production methods were not designed with electronics integration in mind, necessitating substantial modifications to accommodate biosensing elements.

Material compatibility represents another critical hurdle. Biosensors typically utilize rigid materials like silicon and metals that contrast sharply with the flexible, breathable nature of textiles. This fundamental mismatch creates mechanical stress at interface points, potentially leading to delamination, cracking, or complete sensor failure during normal wear. Additionally, the hydrophilic properties of many textiles conflict with the moisture-sensitive nature of electronic components, requiring effective encapsulation solutions.

Power management presents persistent difficulties in biosensor-textile integration. Conventional batteries are bulky, rigid, and potentially hazardous if damaged, making them poorly suited for wearable applications. Alternative power sources such as flexible batteries, energy harvesting systems (kinetic, thermal, or solar), or wireless power transfer technologies are being explored but each comes with its own set of limitations regarding power density, reliability, and form factor.

Washability remains a significant barrier to widespread adoption. Consumers expect textiles to withstand regular cleaning, but most electronic components are highly vulnerable to water exposure, detergents, and mechanical agitation during washing cycles. Developing waterproof encapsulation that maintains breathability while protecting sensitive components presents a complex engineering challenge.

Signal quality and consistency pose additional challenges. Body movement, changing skin-sensor contact pressure, and environmental factors like temperature and humidity can significantly affect sensor readings. Maintaining reliable signal acquisition under these variable conditions requires sophisticated signal processing algorithms and robust sensor designs that can compensate for these fluctuations.

Manufacturing scalability represents a substantial obstacle to commercialization. Current integration methods often rely on labor-intensive processes that are difficult to scale for mass production. The lack of standardized manufacturing protocols for smart textiles further complicates industrial adoption, as does the absence of quality control standards specific to textile-integrated biosensors.

Biocompatibility and user comfort cannot be overlooked. Extended contact between sensors and skin can cause irritation, allergic reactions, or pressure sores if not properly designed. The added weight and reduced flexibility of sensor-integrated regions can also compromise the natural drape and feel of the textile, potentially reducing user compliance.

Material compatibility represents another critical hurdle. Biosensors typically utilize rigid materials like silicon and metals that contrast sharply with the flexible, breathable nature of textiles. This fundamental mismatch creates mechanical stress at interface points, potentially leading to delamination, cracking, or complete sensor failure during normal wear. Additionally, the hydrophilic properties of many textiles conflict with the moisture-sensitive nature of electronic components, requiring effective encapsulation solutions.

Power management presents persistent difficulties in biosensor-textile integration. Conventional batteries are bulky, rigid, and potentially hazardous if damaged, making them poorly suited for wearable applications. Alternative power sources such as flexible batteries, energy harvesting systems (kinetic, thermal, or solar), or wireless power transfer technologies are being explored but each comes with its own set of limitations regarding power density, reliability, and form factor.

Washability remains a significant barrier to widespread adoption. Consumers expect textiles to withstand regular cleaning, but most electronic components are highly vulnerable to water exposure, detergents, and mechanical agitation during washing cycles. Developing waterproof encapsulation that maintains breathability while protecting sensitive components presents a complex engineering challenge.

Signal quality and consistency pose additional challenges. Body movement, changing skin-sensor contact pressure, and environmental factors like temperature and humidity can significantly affect sensor readings. Maintaining reliable signal acquisition under these variable conditions requires sophisticated signal processing algorithms and robust sensor designs that can compensate for these fluctuations.

Manufacturing scalability represents a substantial obstacle to commercialization. Current integration methods often rely on labor-intensive processes that are difficult to scale for mass production. The lack of standardized manufacturing protocols for smart textiles further complicates industrial adoption, as does the absence of quality control standards specific to textile-integrated biosensors.

Biocompatibility and user comfort cannot be overlooked. Extended contact between sensors and skin can cause irritation, allergic reactions, or pressure sores if not properly designed. The added weight and reduced flexibility of sensor-integrated regions can also compromise the natural drape and feel of the textile, potentially reducing user compliance.

Current Biosensor-Textile Integration Methods

01 Health monitoring biosensors in textiles

Wearable biosensors integrated into textiles can continuously monitor various health parameters such as heart rate, body temperature, and respiratory rate. These smart textiles use embedded sensors that collect physiological data in real-time, allowing for non-invasive health monitoring. The technology enables early detection of health issues and provides valuable data for preventive healthcare, making it particularly useful for patients with chronic conditions or athletes monitoring performance.- Health monitoring biosensors in textiles: Wearable biosensors integrated into textiles can continuously monitor various health parameters such as heart rate, body temperature, and respiratory rate. These smart textiles use embedded sensors that collect physiological data in real-time, allowing for non-invasive health monitoring. The technology enables early detection of health issues and provides valuable data for preventive healthcare, making it particularly useful for patients with chronic conditions, athletes, and elderly individuals.

- Energy harvesting and power management in smart textiles: Smart textiles incorporate energy harvesting technologies to power integrated biosensors and electronic components. These textiles can generate electricity from body movement, temperature differentials, or ambient light, reducing the need for traditional batteries. Advanced power management systems optimize energy consumption, extending the operational life of wearable devices. This self-powering capability makes smart textiles more practical for everyday use and eliminates the inconvenience of frequent charging.

- Data communication and connectivity solutions: Wearable biosensors and smart textiles feature integrated communication systems that enable data transmission to smartphones, cloud platforms, or healthcare providers. These textiles utilize wireless technologies such as Bluetooth, Wi-Fi, or NFC to establish connectivity with external devices. The communication infrastructure allows for real-time data analysis, remote monitoring, and immediate alerts in case of abnormal readings, enhancing the practical application of these technologies in healthcare and fitness contexts.

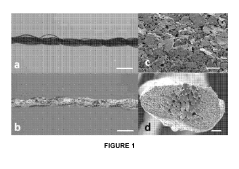

- Flexible and stretchable sensor technologies: Advanced flexible and stretchable sensor technologies are incorporated into textiles to ensure comfort and durability while maintaining accurate sensing capabilities. These sensors are designed to withstand washing, bending, and stretching without compromising functionality. Materials such as conductive polymers, metallic nanofibers, and graphene are used to create sensors that conform to body movements. This flexibility allows for seamless integration into everyday clothing while providing reliable biometric data collection.

- Environmental and activity monitoring systems: Smart textiles equipped with environmental and activity monitoring sensors can detect external conditions and track user movements. These textiles incorporate sensors for measuring UV exposure, air quality, temperature, and humidity, as well as accelerometers and gyroscopes for motion tracking. The collected data helps users make informed decisions about their environment and activities, supporting applications in sports performance analysis, workplace safety, and outdoor recreation.

02 Energy harvesting and power management in smart textiles

Smart textiles incorporate energy harvesting technologies to power embedded biosensors and electronic components. These textiles can generate electricity through various methods including movement, body heat, or solar energy, eliminating the need for bulky batteries. Advanced power management systems optimize energy consumption, extending the operational life of the wearable devices while maintaining comfort and flexibility of the fabric.Expand Specific Solutions03 Communication and data transmission systems for smart textiles

Smart textiles feature integrated communication systems that enable data transmission from biosensors to external devices such as smartphones or cloud platforms. These systems utilize wireless technologies like Bluetooth, NFC, or IoT protocols to transmit collected biometric data securely. The communication infrastructure allows for real-time monitoring, data analysis, and immediate alerts in case of detected anomalies, making these textiles valuable for healthcare and fitness applications.Expand Specific Solutions04 Advanced materials and manufacturing techniques for biosensor integration

Innovative materials and manufacturing processes enable seamless integration of biosensors into textiles while maintaining comfort and durability. These include conductive fibers, flexible electronics, and specialized coating technologies that protect electronic components from moisture and wear. Novel fabrication methods such as 3D printing, screen printing, and laser patterning allow for precise placement of sensors within the textile structure, ensuring accuracy in data collection while preserving the fabric's flexibility and breathability.Expand Specific Solutions05 Environmental and activity monitoring smart textiles

Smart textiles equipped with specialized sensors can monitor environmental conditions and physical activities. These textiles incorporate sensors that detect environmental factors such as UV exposure, air quality, and temperature, as well as motion sensors that track body movements and posture. The collected data helps users make informed decisions about their surroundings and activities, with applications ranging from sports performance optimization to occupational safety in hazardous environments.Expand Specific Solutions

Leading Companies in Smart Textile Biosensors

The wearable biosensors and smart textiles market is currently in a growth phase, characterized by increasing integration of technology into clothing for health monitoring and performance enhancement. The market is projected to expand significantly, driven by rising health consciousness and demand for continuous monitoring solutions. Technologically, the field is advancing rapidly with companies at different maturity levels. Leading players include MIT and ETH Zurich conducting pioneering research, while commercial entities like Samsung Electronics, Honeywell Safety Products, and Flex Ltd. are developing market-ready applications. Specialized startups such as Fibra Inc. and Prevayl Innovations are introducing innovative textile-integrated biosensing solutions, while academic institutions like Donghua University and North Carolina State University are advancing textile engineering capabilities essential for future development.

Prevayl Innovations Ltd.

Technical Solution: Prevayl has developed a proprietary smart textile platform that seamlessly integrates biosensing capabilities into everyday clothing. Their technology centers around knitted textile sensors that can monitor ECG, respiratory rate, body temperature, and movement without compromising comfort or aesthetics. Prevayl's innovation lies in their specialized conductive yarn technology that maintains sensing capabilities through washing cycles and regular wear. Their manufacturing process involves precision knitting machines that integrate these conductive yarns with standard textile fibers, creating zones of sensing capability within garments. The company has developed a modular approach where a small, detachable electronic module connects to these textile sensors, processing and transmitting data to mobile applications. This architecture allows the expensive electronics to be removed while the textile component can be washed normally. Prevayl has focused particularly on consumer applications, developing algorithms that translate raw biosensor data into actionable health and fitness insights.

Strengths: Consumer-focused design with emphasis on wearability and aesthetics; modular approach separating electronics from textiles; strong data analytics capabilities. Weaknesses: Limited to specific garment types; relatively new market entrant with less established distribution channels; challenges in scaling production while maintaining quality control.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered significant advancements in wearable biosensors integrated with smart textiles through their research at the Media Lab and Department of Materials Science. Their approach focuses on developing electronic textiles (e-textiles) that seamlessly incorporate sensing capabilities while maintaining textile-like properties. MIT researchers have created fiber-based sensors that can be woven directly into fabrics, enabling continuous monitoring of physiological parameters such as heart rate, respiration, temperature, and movement. Their proprietary technology involves specialized conductive fibers with integrated microelectronics that maintain flexibility and washability. MIT has also developed novel manufacturing techniques for mass-producing these smart textiles, including digital fabrication methods that allow precise placement of sensing elements within the textile structure. Their recent innovations include self-powered textile sensors that harvest energy from body movement and temperature differentials, eliminating the need for external power sources.

Strengths: Cutting-edge research capabilities, interdisciplinary approach combining materials science, electronics, and textile engineering; strong intellectual property portfolio. Weaknesses: Technologies often remain at research prototype stage with challenges in scaling to commercial production; higher costs associated with specialized materials and manufacturing processes.

Key Patents in Wearable Biosensor Technology

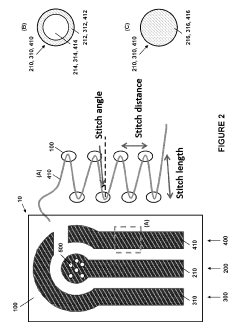

Embroidered electrochemical biosensors and related methods

PatentActiveUS20190137436A1

Innovation

- Development of self-powered textile biosensors using a bio-micro-electromechanical system (bioMEMS) platform with embroidered electrochemical sensors integrated into flexible substrates, featuring working, counter, and reference electrodes made from conductive fibers, which can detect target analytes through enzyme or capture probes, enabling continuous health monitoring and point-of-care diagnostics.

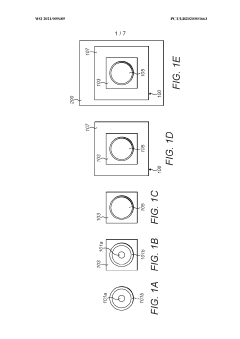

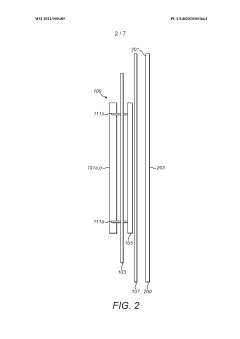

Biosensing textile and method of making the same

PatentWO2021009489A1

Innovation

- A method of manufacturing a biosensing textile that involves attaching a biosensing unit and a controller to a textile patch, which is then integrated into a textile panel using conductive connections or wireless communication, allowing for a releasable and flexible attachment that maintains the biosensing unit in close proximity to the body surface without visible external components.

Biocompatibility and User Comfort Considerations

Biocompatibility and user comfort represent critical considerations in the development and adoption of wearable biosensors integrated with smart textiles. The direct and prolonged contact between these devices and human skin necessitates careful material selection and design approaches that minimize adverse biological reactions while maximizing wearability.

Materials used in wearable biosensors must meet stringent biocompatibility standards to prevent skin irritation, allergic reactions, or cytotoxicity. Current research focuses on hypoallergenic polymers, medical-grade silicones, and naturally derived materials such as cellulose and chitosan that demonstrate minimal immunological response. These materials must maintain their biocompatibility properties even after repeated washing cycles and prolonged exposure to bodily fluids like sweat.

The mechanical properties of biosensor-integrated textiles significantly impact user comfort. Flexibility and stretchability are paramount to accommodate natural body movements without restriction. Recent advancements have yielded ultra-thin, conformal electronic components that can withstand mechanical deformation while maintaining functionality. Breathability represents another crucial factor, as impermeable materials can trap heat and moisture, leading to discomfort and potentially compromising sensor readings.

Weight distribution across the garment emerges as an often-overlooked comfort consideration. Uneven distribution of sensor components can create pressure points and disrupt the natural drape of the textile. Innovative approaches include distributing electronic components throughout the garment and utilizing lightweight materials to minimize the perception of wearing technology.

The form factor of integrated sensors must balance visibility with functionality. While some users prefer discreet integration that maintains the aesthetic appeal of conventional clothing, others may accept more visible components if they deliver superior performance. This balance varies significantly across application contexts, from medical monitoring to fitness tracking to occupational safety.

Thermal management presents unique challenges, as electronic components generate heat during operation. Effective heat dissipation strategies are essential to prevent user discomfort and potential skin irritation. Advanced thermal management solutions include phase-change materials that absorb excess heat and thermally conductive pathways that direct heat away from skin contact points.

User-centered design methodologies have proven invaluable in addressing biocompatibility and comfort challenges. Iterative testing with diverse user groups helps identify potential issues before commercial deployment. Quantitative measures such as pressure mapping and moisture vapor transmission rates are increasingly complemented by qualitative user feedback to create holistic comfort profiles for wearable biosensor systems.

Materials used in wearable biosensors must meet stringent biocompatibility standards to prevent skin irritation, allergic reactions, or cytotoxicity. Current research focuses on hypoallergenic polymers, medical-grade silicones, and naturally derived materials such as cellulose and chitosan that demonstrate minimal immunological response. These materials must maintain their biocompatibility properties even after repeated washing cycles and prolonged exposure to bodily fluids like sweat.

The mechanical properties of biosensor-integrated textiles significantly impact user comfort. Flexibility and stretchability are paramount to accommodate natural body movements without restriction. Recent advancements have yielded ultra-thin, conformal electronic components that can withstand mechanical deformation while maintaining functionality. Breathability represents another crucial factor, as impermeable materials can trap heat and moisture, leading to discomfort and potentially compromising sensor readings.

Weight distribution across the garment emerges as an often-overlooked comfort consideration. Uneven distribution of sensor components can create pressure points and disrupt the natural drape of the textile. Innovative approaches include distributing electronic components throughout the garment and utilizing lightweight materials to minimize the perception of wearing technology.

The form factor of integrated sensors must balance visibility with functionality. While some users prefer discreet integration that maintains the aesthetic appeal of conventional clothing, others may accept more visible components if they deliver superior performance. This balance varies significantly across application contexts, from medical monitoring to fitness tracking to occupational safety.

Thermal management presents unique challenges, as electronic components generate heat during operation. Effective heat dissipation strategies are essential to prevent user discomfort and potential skin irritation. Advanced thermal management solutions include phase-change materials that absorb excess heat and thermally conductive pathways that direct heat away from skin contact points.

User-centered design methodologies have proven invaluable in addressing biocompatibility and comfort challenges. Iterative testing with diverse user groups helps identify potential issues before commercial deployment. Quantitative measures such as pressure mapping and moisture vapor transmission rates are increasingly complemented by qualitative user feedback to create holistic comfort profiles for wearable biosensor systems.

Data Privacy and Security Framework

The integration of wearable biosensors with smart textiles introduces significant data privacy and security challenges that must be addressed through a comprehensive framework. As these devices continuously collect sensitive biometric data, including heart rate, body temperature, and even biochemical markers, they create an unprecedented volume of personal health information requiring robust protection. The primary security concerns include unauthorized data access, data breaches during transmission, and potential exploitation of collected information by third parties.

A multi-layered security approach is essential for these integrated systems. At the hardware level, secure elements and trusted execution environments can protect data at its source. Encryption must be implemented both for data at rest within the device storage and during transmission to smartphones or cloud platforms. Given the resource constraints of wearable devices, lightweight cryptographic protocols specifically designed for IoT applications represent the optimal solution for balancing security requirements with power consumption limitations.

Authentication mechanisms require particular attention in wearable biosensor systems. Biometric authentication leveraging the very data these devices collect offers a promising approach, enabling continuous authentication without user intervention. Multi-factor authentication combining physiological parameters with traditional methods provides enhanced security while maintaining usability in daily wear scenarios.

Regulatory compliance forms another critical component of the security framework. Developers must navigate complex requirements including GDPR in Europe, HIPAA in the United States for health-related applications, and emerging regulations specific to wearable technology. Privacy-by-design principles should be incorporated from the earliest development stages, ensuring data minimization, purpose limitation, and user consent mechanisms are built into the system architecture.

User control and transparency deserve special consideration. Wearable biosensor systems should provide intuitive interfaces allowing users to understand what data is being collected, how it's being used, and options to control data sharing. Granular permission settings enable users to selectively share different types of biometric data with various applications or healthcare providers according to their comfort level and specific needs.

Security testing methodologies for these integrated systems must address both the textile and electronic components. Penetration testing should evaluate vulnerabilities in the entire ecosystem, including the sensors, embedded processors, wireless communication protocols, and associated mobile applications. Regular security updates must be delivered seamlessly, considering the unique challenges of updating firmware in garments that undergo regular washing and physical stress.

A multi-layered security approach is essential for these integrated systems. At the hardware level, secure elements and trusted execution environments can protect data at its source. Encryption must be implemented both for data at rest within the device storage and during transmission to smartphones or cloud platforms. Given the resource constraints of wearable devices, lightweight cryptographic protocols specifically designed for IoT applications represent the optimal solution for balancing security requirements with power consumption limitations.

Authentication mechanisms require particular attention in wearable biosensor systems. Biometric authentication leveraging the very data these devices collect offers a promising approach, enabling continuous authentication without user intervention. Multi-factor authentication combining physiological parameters with traditional methods provides enhanced security while maintaining usability in daily wear scenarios.

Regulatory compliance forms another critical component of the security framework. Developers must navigate complex requirements including GDPR in Europe, HIPAA in the United States for health-related applications, and emerging regulations specific to wearable technology. Privacy-by-design principles should be incorporated from the earliest development stages, ensuring data minimization, purpose limitation, and user consent mechanisms are built into the system architecture.

User control and transparency deserve special consideration. Wearable biosensor systems should provide intuitive interfaces allowing users to understand what data is being collected, how it's being used, and options to control data sharing. Granular permission settings enable users to selectively share different types of biometric data with various applications or healthcare providers according to their comfort level and specific needs.

Security testing methodologies for these integrated systems must address both the textile and electronic components. Penetration testing should evaluate vulnerabilities in the entire ecosystem, including the sensors, embedded processors, wireless communication protocols, and associated mobile applications. Regular security updates must be delivered seamlessly, considering the unique challenges of updating firmware in garments that undergo regular washing and physical stress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!