What Innovations in Polymers Are Shaping Wearable Biosensors

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Biosensor Technology Background and Objectives

Polymer-based wearable biosensors represent a revolutionary intersection of materials science, biomedical engineering, and electronics. The evolution of this technology can be traced back to the early 2000s when researchers began exploring conductive polymers as alternatives to traditional rigid electronic components. Over the past two decades, significant advancements in polymer chemistry, nanomaterials, and flexible electronics have accelerated the development of wearable biosensing platforms that can continuously monitor physiological parameters with minimal invasiveness.

The technological trajectory has shifted from simple polymer-based electrodes to sophisticated multi-functional sensing matrices capable of detecting multiple biomarkers simultaneously. Early polymer biosensors primarily focused on basic vital sign monitoring, while current innovations enable molecular-level detection of metabolites, proteins, and electrolytes through the skin. This progression reflects broader trends in healthcare toward personalized, preventative, and remote monitoring solutions.

Key technological milestones include the development of intrinsically conductive polymers like polypyrrole and PEDOT:PSS, the integration of polymer nanocomposites with enhanced sensitivity, and the recent emergence of self-healing and biodegradable polymer systems. These advances have collectively addressed critical challenges in wearable biosensing, including biocompatibility, long-term stability, and signal fidelity under mechanical deformation.

The primary objective of current polymer biosensor research is to develop platforms that combine high sensitivity, specificity, and reliability with comfort, durability, and ease of use. Researchers aim to create sensing systems that can operate continuously for extended periods without performance degradation while maintaining seamless integration with the human body. This includes developing polymers with tunable mechanical properties that match human tissue characteristics while maintaining excellent electrical conductivity.

Additional technical goals include enhancing signal-to-noise ratios in polymer sensing elements, improving power efficiency through novel polymer-based energy harvesting systems, and developing biocompatible polymer interfaces that minimize foreign body responses. There is also significant focus on creating polymer formulations that enable multi-modal sensing capabilities within a single platform.

The field is moving toward closed-loop systems where polymer biosensors not only detect physiological changes but also respond therapeutically. This includes the development of stimuli-responsive polymers that can release drugs or adjust their properties based on detected biomarkers. The ultimate vision encompasses fully integrated polymer-based wearable health monitoring systems that provide comprehensive, real-time physiological data while maintaining user comfort and compliance.

The technological trajectory has shifted from simple polymer-based electrodes to sophisticated multi-functional sensing matrices capable of detecting multiple biomarkers simultaneously. Early polymer biosensors primarily focused on basic vital sign monitoring, while current innovations enable molecular-level detection of metabolites, proteins, and electrolytes through the skin. This progression reflects broader trends in healthcare toward personalized, preventative, and remote monitoring solutions.

Key technological milestones include the development of intrinsically conductive polymers like polypyrrole and PEDOT:PSS, the integration of polymer nanocomposites with enhanced sensitivity, and the recent emergence of self-healing and biodegradable polymer systems. These advances have collectively addressed critical challenges in wearable biosensing, including biocompatibility, long-term stability, and signal fidelity under mechanical deformation.

The primary objective of current polymer biosensor research is to develop platforms that combine high sensitivity, specificity, and reliability with comfort, durability, and ease of use. Researchers aim to create sensing systems that can operate continuously for extended periods without performance degradation while maintaining seamless integration with the human body. This includes developing polymers with tunable mechanical properties that match human tissue characteristics while maintaining excellent electrical conductivity.

Additional technical goals include enhancing signal-to-noise ratios in polymer sensing elements, improving power efficiency through novel polymer-based energy harvesting systems, and developing biocompatible polymer interfaces that minimize foreign body responses. There is also significant focus on creating polymer formulations that enable multi-modal sensing capabilities within a single platform.

The field is moving toward closed-loop systems where polymer biosensors not only detect physiological changes but also respond therapeutically. This includes the development of stimuli-responsive polymers that can release drugs or adjust their properties based on detected biomarkers. The ultimate vision encompasses fully integrated polymer-based wearable health monitoring systems that provide comprehensive, real-time physiological data while maintaining user comfort and compliance.

Market Analysis for Wearable Polymer Biosensors

The wearable biosensor market is experiencing unprecedented growth, driven by increasing health consciousness and the rising prevalence of chronic diseases requiring continuous monitoring. The global wearable biosensor market was valued at approximately $13.2 billion in 2022 and is projected to reach $38.7 billion by 2028, representing a compound annual growth rate (CAGR) of 19.6% during the forecast period.

Polymer-based wearable biosensors are emerging as a particularly promising segment within this market. These devices leverage innovative polymer materials to create flexible, lightweight, and skin-compatible sensors that can continuously monitor various physiological parameters. The polymer biosensor segment is expected to grow at a faster rate than the overall wearable biosensor market, with projections indicating a CAGR of 23.8% through 2028.

Healthcare applications currently dominate the market, accounting for approximately 65% of revenue. This includes continuous glucose monitoring systems, cardiac monitoring devices, and temperature sensors. The fitness and sports segment represents about 20% of the market, while industrial and environmental monitoring applications comprise the remaining 15%.

Geographically, North America leads the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and the presence of major manufacturing hubs in countries like China, Japan, and South Korea.

Key market drivers include the aging global population, increasing prevalence of chronic diseases, growing consumer interest in health monitoring, and technological advancements in polymer science. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of remote patient monitoring and telehealth solutions.

Challenges facing the market include concerns about data privacy and security, regulatory hurdles, and the need for improved battery technology to support continuous monitoring. Additionally, there is significant price sensitivity in consumer markets, which may limit adoption in developing regions.

The competitive landscape features both established medical device manufacturers and innovative startups. Major players include Abbott Laboratories, Medtronic, Dexcom, and Philips Healthcare, alongside polymer specialists like BASF, Covestro, and emerging companies such as MC10, Epicore Biosystems, and Sano Intelligence. Strategic partnerships between polymer manufacturers, sensor developers, and healthcare providers are becoming increasingly common as companies seek to leverage complementary expertise.

Polymer-based wearable biosensors are emerging as a particularly promising segment within this market. These devices leverage innovative polymer materials to create flexible, lightweight, and skin-compatible sensors that can continuously monitor various physiological parameters. The polymer biosensor segment is expected to grow at a faster rate than the overall wearable biosensor market, with projections indicating a CAGR of 23.8% through 2028.

Healthcare applications currently dominate the market, accounting for approximately 65% of revenue. This includes continuous glucose monitoring systems, cardiac monitoring devices, and temperature sensors. The fitness and sports segment represents about 20% of the market, while industrial and environmental monitoring applications comprise the remaining 15%.

Geographically, North America leads the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and the presence of major manufacturing hubs in countries like China, Japan, and South Korea.

Key market drivers include the aging global population, increasing prevalence of chronic diseases, growing consumer interest in health monitoring, and technological advancements in polymer science. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of remote patient monitoring and telehealth solutions.

Challenges facing the market include concerns about data privacy and security, regulatory hurdles, and the need for improved battery technology to support continuous monitoring. Additionally, there is significant price sensitivity in consumer markets, which may limit adoption in developing regions.

The competitive landscape features both established medical device manufacturers and innovative startups. Major players include Abbott Laboratories, Medtronic, Dexcom, and Philips Healthcare, alongside polymer specialists like BASF, Covestro, and emerging companies such as MC10, Epicore Biosystems, and Sano Intelligence. Strategic partnerships between polymer manufacturers, sensor developers, and healthcare providers are becoming increasingly common as companies seek to leverage complementary expertise.

Current Polymer Technology Challenges in Biosensing

Despite significant advancements in wearable biosensor technology, polymer materials used in these applications face several critical challenges that limit their widespread adoption and effectiveness. The foremost challenge is achieving optimal biocompatibility while maintaining functionality. Polymers must interface with biological tissues without causing irritation, inflammation, or immune responses, yet many current materials compromise either comfort or sensing accuracy when optimized for the other parameter.

Mechanical flexibility presents another significant hurdle. Wearable biosensors require materials that can withstand repeated deformation while maintaining structural integrity and sensing capabilities. Current polymer systems often experience performance degradation after extended cycles of bending, stretching, or compression, leading to shortened device lifespans and unreliable measurements in real-world applications.

Stability in diverse environments poses a complex challenge for polymer-based biosensors. These devices must function reliably across varying humidity levels, temperature fluctuations, and exposure to bodily fluids. Many existing polymers suffer from hydrolytic degradation, dimensional instability, or altered electrical properties when subjected to these environmental stressors, compromising data consistency and sensor longevity.

Signal transduction efficiency remains suboptimal in many polymer systems. The interface between biological analytes and electronic components often experiences signal attenuation or interference, particularly in non-invasive sensing applications. Current materials struggle to maintain high signal-to-noise ratios when detecting low-concentration biomarkers through skin or other biological barriers.

Manufacturing scalability presents significant barriers to commercialization. Many innovative polymer formulations that demonstrate excellent performance in laboratory settings prove difficult to mass-produce with consistent quality. Complex synthesis procedures, stringent purification requirements, and specialized processing conditions limit industrial viability and increase production costs.

Biodegradability and sustainability concerns are increasingly prominent as environmental regulations tighten globally. Many high-performance polymers used in biosensors contain non-biodegradable components or require environmentally harmful processing methods. The industry faces growing pressure to develop green alternatives without sacrificing performance metrics.

Integration challenges persist between polymer substrates and electronic components. Adhesion issues, thermal expansion mismatches, and chemical incompatibilities between polymers and metallic or semiconductor elements often lead to device failure. Current interface solutions frequently compromise either the electronic performance or the mechanical properties of the final device.

Power management remains problematic, as many polymer-based sensing systems lack efficient energy storage capabilities or require frequent recharging, limiting their practical application in continuous monitoring scenarios.

Mechanical flexibility presents another significant hurdle. Wearable biosensors require materials that can withstand repeated deformation while maintaining structural integrity and sensing capabilities. Current polymer systems often experience performance degradation after extended cycles of bending, stretching, or compression, leading to shortened device lifespans and unreliable measurements in real-world applications.

Stability in diverse environments poses a complex challenge for polymer-based biosensors. These devices must function reliably across varying humidity levels, temperature fluctuations, and exposure to bodily fluids. Many existing polymers suffer from hydrolytic degradation, dimensional instability, or altered electrical properties when subjected to these environmental stressors, compromising data consistency and sensor longevity.

Signal transduction efficiency remains suboptimal in many polymer systems. The interface between biological analytes and electronic components often experiences signal attenuation or interference, particularly in non-invasive sensing applications. Current materials struggle to maintain high signal-to-noise ratios when detecting low-concentration biomarkers through skin or other biological barriers.

Manufacturing scalability presents significant barriers to commercialization. Many innovative polymer formulations that demonstrate excellent performance in laboratory settings prove difficult to mass-produce with consistent quality. Complex synthesis procedures, stringent purification requirements, and specialized processing conditions limit industrial viability and increase production costs.

Biodegradability and sustainability concerns are increasingly prominent as environmental regulations tighten globally. Many high-performance polymers used in biosensors contain non-biodegradable components or require environmentally harmful processing methods. The industry faces growing pressure to develop green alternatives without sacrificing performance metrics.

Integration challenges persist between polymer substrates and electronic components. Adhesion issues, thermal expansion mismatches, and chemical incompatibilities between polymers and metallic or semiconductor elements often lead to device failure. Current interface solutions frequently compromise either the electronic performance or the mechanical properties of the final device.

Power management remains problematic, as many polymer-based sensing systems lack efficient energy storage capabilities or require frequent recharging, limiting their practical application in continuous monitoring scenarios.

Current Polymer Solutions for Wearable Biosensors

01 Polymer synthesis and polymerization methods

Various methods for synthesizing polymers and controlling polymerization processes are described. These include techniques for creating polymers with specific properties, controlling molecular weight distribution, and developing novel polymerization catalysts. The methods cover both addition and condensation polymerization approaches, with emphasis on reaction conditions that influence the final polymer characteristics.- Polymer synthesis and polymerization methods: Various methods for synthesizing polymers and controlling polymerization processes. These include techniques for creating specific polymer structures, controlling molecular weight, and developing novel polymerization catalysts. The methods cover different types of polymerization such as addition polymerization, condensation polymerization, and controlled radical polymerization to achieve desired polymer properties.

- Modified polymer compositions with enhanced properties: Polymer compositions that have been modified to enhance specific properties such as thermal stability, mechanical strength, or chemical resistance. These modifications may involve blending different polymers, incorporating additives, or chemically altering the polymer structure. The resulting materials exhibit improved performance characteristics for specialized applications in various industries.

- Biodegradable and sustainable polymers: Development of environmentally friendly polymers that are biodegradable or derived from renewable resources. These polymers are designed to reduce environmental impact while maintaining performance comparable to conventional petroleum-based polymers. The formulations include bio-based monomers, naturally occurring polymers with modifications, and synthetic polymers with enhanced biodegradability.

- Polymer processing technologies: Technologies and methods for processing polymers into usable forms, including extrusion, molding, and other fabrication techniques. These processes focus on optimizing the conversion of raw polymer materials into finished products with specific shapes, dimensions, and surface characteristics. The technologies address challenges in processing different polymer types and achieving consistent quality in the final products.

- Specialty polymers for industrial applications: Specialized polymer formulations designed for specific industrial applications such as coatings, adhesives, electronics, and medical devices. These polymers possess unique properties tailored to meet the requirements of particular industries, including electrical conductivity, optical clarity, biocompatibility, or chemical resistance. The formulations often involve complex polymer architectures or functional group modifications to achieve the desired performance characteristics.

02 Modified polymer compositions with enhanced properties

Polymer compositions that have been modified to enhance specific properties such as thermal stability, mechanical strength, or chemical resistance. These modifications include the incorporation of additives, crosslinking agents, or functional groups to improve performance characteristics. The resulting polymers exhibit superior properties compared to their unmodified counterparts, making them suitable for specialized applications.Expand Specific Solutions03 Biodegradable and sustainable polymer materials

Development of environmentally friendly polymer materials that are biodegradable or derived from renewable resources. These polymers are designed to reduce environmental impact while maintaining performance requirements. The approaches include using bio-based feedstocks, designing degradable polymer structures, and creating composite materials that combine sustainability with functional properties.Expand Specific Solutions04 Polymer processing techniques and applications

Methods for processing polymers into useful forms and applications across various industries. These techniques include extrusion, molding, film formation, and specialized processing methods that influence the final product properties. The applications span multiple sectors including packaging, construction, electronics, and medical devices, with specific processing parameters optimized for each use case.Expand Specific Solutions05 Polymer blends and composite materials

Development of polymer blends and composite materials that combine multiple polymers or incorporate non-polymeric materials to achieve enhanced performance characteristics. These materials leverage the synergistic effects of their components to deliver properties that cannot be achieved with single polymers. The blending techniques and compatibility factors are critical to ensuring uniform dispersion and optimal property enhancement.Expand Specific Solutions

Leading Companies in Polymer Biosensor Development

The wearable biosensor market is experiencing rapid growth, currently in its expansion phase with an estimated market size of $15-20 billion and projected CAGR of 25-30% through 2028. Technical maturity varies across polymer innovations, with established players like Medtronic, The Regents of the University of California, and Agency for Science, Technology & Research leading commercial applications. Academic institutions (Tsinghua University, National University of Singapore, University of Southern California) are driving fundamental research in flexible substrates and biocompatible materials. Companies like Osang Healthcare and Ascensia Diabetes Care are advancing polymer-based glucose monitoring technologies, while research organizations such as CNRS and Academia Sinica focus on next-generation biodegradable and self-healing polymers, positioning this field at the intersection of mature applications and emerging innovations.

The Regents of the University of California

Technical Solution: The University of California has pioneered stretchable polymer composites for wearable biosensors that can monitor multiple physiological parameters simultaneously. Their approach involves developing intrinsically stretchable polymer semiconductors with high charge mobility (>1 cm²/Vs) that maintain electrical performance even when stretched to 100% strain[1]. These materials incorporate novel molecular design strategies including the use of conjugated polymers with dynamic non-covalent crosslinking networks. The university's researchers have also developed self-healing polymers that can recover from mechanical damage, critical for long-term wearable applications. Their recent innovation includes skin-inspired electronic materials that combine elasticity with high electrical performance, enabling conformal contact with human skin for accurate biosensing[3]. These materials are processed using solution-based techniques compatible with large-area manufacturing methods.

Strengths: Superior mechanical properties with electrical stability under extreme deformation; self-healing capabilities extend device lifespan; biocompatibility enables direct skin contact for accurate measurements. Weaknesses: Higher production costs compared to conventional rigid electronics; challenges in scaling up manufacturing processes; potential long-term stability issues in varied environmental conditions.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed advanced polymer-based platforms for wearable biosensors focusing on multifunctional capabilities. Their proprietary technology utilizes conducting polymer nanocomposites with engineered interfaces that enhance both electrical conductivity and mechanical flexibility. A*STAR's approach incorporates poly(3,4-ethylenedioxythiophene) (PEDOT) derivatives modified with biocompatible side chains, achieving conductivity exceeding 3000 S/cm while maintaining flexibility[2]. Their innovation extends to creating breathable, microstructured polymer substrates that reduce skin irritation during prolonged wear. A*STAR has also pioneered printed electronics techniques for these materials, enabling low-cost, large-area fabrication of sensor arrays. Their recent developments include polymer-encapsulated enzymatic sensors with enhanced stability in biofluids, extending functional lifetimes to over 30 days in continuous operation conditions[4].

Strengths: Exceptional balance between electrical performance and mechanical properties; advanced manufacturing techniques enable cost-effective production; superior biofluid stability extends practical applications. Weaknesses: Complex synthesis procedures may limit scalability; some formulations require specialized handling and storage conditions; potential regulatory hurdles for novel material compositions.

Key Polymer Innovations and Patent Landscape

Polymer composites, methods of fabrication and uses thereof

PatentWO2021076054A1

Innovation

- A polymer composite comprising poly(ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS), waterborne polyurethane (WPU), and D-sorbitol is developed, which forms a self-adhesive and stretchable dry electrode with low skin-contact impedance, enabling high-quality ECG, EMG, and EEG signal acquisition on both dry and wet skin during body movement.

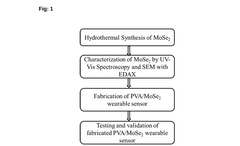

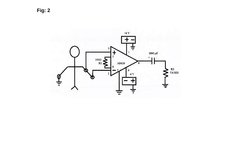

Preparation of polymer incorporated mose2 based wearable sensor and application thereof

PatentPendingIN202441050090A

Innovation

- A polymer-incorporated molybdenum diselenide (MoSe2) composite sensor with a nanoflower structure is developed using a casting method, leveraging MoSe2's water-resistant and biocompatible properties, along with polyvinyl alcohol (PVA), to create a flexible and safe wearable sensor for biosignal acquisition.

Biocompatibility and Safety Considerations

The integration of polymers in wearable biosensors necessitates rigorous evaluation of biocompatibility and safety profiles. Direct contact with human skin for extended periods requires materials that do not trigger adverse biological responses. Current polymer innovations focus on minimizing skin irritation, inflammation, and allergic reactions through advanced formulations and surface modifications.

Biocompatibility testing protocols for polymer-based wearable biosensors have evolved significantly, now encompassing cytotoxicity assessments, sensitization studies, and irritation evaluations in accordance with ISO 10993 standards. These comprehensive testing frameworks ensure that novel polymer materials meet stringent safety requirements before deployment in commercial wearable health monitoring devices.

Hypoallergenic polymers represent a critical advancement in this field, with materials such as medical-grade silicones, polyurethanes with modified surface properties, and biocompatible hydrogels demonstrating superior performance in minimizing adverse skin reactions. These materials maintain functionality while reducing the risk of dermatitis and other skin conditions associated with prolonged device wear.

Leaching of potentially harmful compounds presents another significant safety consideration. Recent polymer innovations incorporate stabilizers and cross-linking agents specifically designed to minimize migration of additives into the skin. Advanced encapsulation techniques further prevent direct contact between electronic components and biological tissues, reducing potential toxicity risks.

Biodegradation characteristics must be carefully controlled in polymer-based biosensors. While some applications benefit from intentionally biodegradable polymers, most wearable biosensors require materials with predictable stability profiles to ensure consistent performance throughout their intended use period. Recent developments in polymer chemistry have yielded materials with precisely engineered degradation rates tailored to specific application requirements.

Antimicrobial properties have emerged as an essential feature for polymers in wearable biosensors. Extended skin contact creates environments conducive to microbial growth, potentially leading to infections or device deterioration. Innovations include polymers with inherent antimicrobial properties and those incorporating controlled-release antimicrobial agents that maintain effectiveness throughout the device lifespan without causing skin irritation.

Regulatory frameworks governing polymer safety in wearable biosensors continue to evolve alongside technological advancements. The FDA, EMA, and other global regulatory bodies have established specific guidelines for evaluating the safety of materials in skin-contact applications. Manufacturers must navigate these complex regulatory landscapes while balancing innovation with compliance requirements, often necessitating extensive documentation of biocompatibility testing results and risk management strategies.

Biocompatibility testing protocols for polymer-based wearable biosensors have evolved significantly, now encompassing cytotoxicity assessments, sensitization studies, and irritation evaluations in accordance with ISO 10993 standards. These comprehensive testing frameworks ensure that novel polymer materials meet stringent safety requirements before deployment in commercial wearable health monitoring devices.

Hypoallergenic polymers represent a critical advancement in this field, with materials such as medical-grade silicones, polyurethanes with modified surface properties, and biocompatible hydrogels demonstrating superior performance in minimizing adverse skin reactions. These materials maintain functionality while reducing the risk of dermatitis and other skin conditions associated with prolonged device wear.

Leaching of potentially harmful compounds presents another significant safety consideration. Recent polymer innovations incorporate stabilizers and cross-linking agents specifically designed to minimize migration of additives into the skin. Advanced encapsulation techniques further prevent direct contact between electronic components and biological tissues, reducing potential toxicity risks.

Biodegradation characteristics must be carefully controlled in polymer-based biosensors. While some applications benefit from intentionally biodegradable polymers, most wearable biosensors require materials with predictable stability profiles to ensure consistent performance throughout their intended use period. Recent developments in polymer chemistry have yielded materials with precisely engineered degradation rates tailored to specific application requirements.

Antimicrobial properties have emerged as an essential feature for polymers in wearable biosensors. Extended skin contact creates environments conducive to microbial growth, potentially leading to infections or device deterioration. Innovations include polymers with inherent antimicrobial properties and those incorporating controlled-release antimicrobial agents that maintain effectiveness throughout the device lifespan without causing skin irritation.

Regulatory frameworks governing polymer safety in wearable biosensors continue to evolve alongside technological advancements. The FDA, EMA, and other global regulatory bodies have established specific guidelines for evaluating the safety of materials in skin-contact applications. Manufacturers must navigate these complex regulatory landscapes while balancing innovation with compliance requirements, often necessitating extensive documentation of biocompatibility testing results and risk management strategies.

Manufacturing Scalability of Advanced Polymer Biosensors

The manufacturing scalability of advanced polymer biosensors represents a critical challenge in transitioning innovative wearable health monitoring technologies from laboratory prototypes to mass-market consumer products. Current manufacturing processes face significant bottlenecks when attempting to scale production while maintaining the precision and functionality required for reliable biosensing applications.

Traditional manufacturing techniques such as screen printing and inkjet printing offer moderate throughput but often struggle with the complex multi-layer structures and precise deposition requirements of advanced polymer biosensors. Roll-to-roll (R2R) processing has emerged as a promising high-volume manufacturing approach, enabling continuous production of flexible polymer substrates with integrated sensing elements at significantly reduced unit costs. However, R2R processes still require substantial optimization to achieve the necessary resolution and registration accuracy for next-generation biosensors.

Material compatibility presents another manufacturing challenge, as many innovative sensing polymers require specific processing conditions that may not align with established high-volume production methods. The integration of multiple functional materials—conductive polymers, biorecognition elements, and protective layers—demands precise control over curing temperatures, solvent compatibility, and interface properties throughout the manufacturing process.

Quality control and consistency represent significant hurdles in scaled production. Minute variations in polymer composition, thickness, or surface properties can dramatically affect sensor performance, necessitating advanced in-line monitoring systems. Current inspection technologies often cannot detect subtle defects that may compromise biosensor functionality, creating yield challenges that impact economic viability.

Cost considerations further complicate manufacturing scale-up. While polymer-based sensors offer inherent cost advantages over traditional rigid electronics, the specialized materials and precision equipment required for advanced biosensor production remain expensive. Economic viability demands optimization of material utilization, process efficiency, and production yields to achieve competitive price points for consumer wearable devices.

Recent innovations addressing these challenges include the development of additive manufacturing techniques specifically tailored for multi-material polymer biosensors, allowing digital fabrication with reduced material waste. Advances in automated precision dispensing systems have improved the deposition accuracy of functional sensing materials, while new rapid-curing polymer formulations compatible with high-speed manufacturing have reduced production cycle times.

Industry-academic collaborations are increasingly focusing on manufacturing process innovation, with several pilot production lines demonstrating promising approaches to scaled fabrication of polymer biosensors. These efforts suggest that with continued investment in manufacturing technology development, the production scalability of advanced polymer biosensors will significantly improve within the next 3-5 years, potentially enabling widespread adoption in consumer health monitoring applications.

Traditional manufacturing techniques such as screen printing and inkjet printing offer moderate throughput but often struggle with the complex multi-layer structures and precise deposition requirements of advanced polymer biosensors. Roll-to-roll (R2R) processing has emerged as a promising high-volume manufacturing approach, enabling continuous production of flexible polymer substrates with integrated sensing elements at significantly reduced unit costs. However, R2R processes still require substantial optimization to achieve the necessary resolution and registration accuracy for next-generation biosensors.

Material compatibility presents another manufacturing challenge, as many innovative sensing polymers require specific processing conditions that may not align with established high-volume production methods. The integration of multiple functional materials—conductive polymers, biorecognition elements, and protective layers—demands precise control over curing temperatures, solvent compatibility, and interface properties throughout the manufacturing process.

Quality control and consistency represent significant hurdles in scaled production. Minute variations in polymer composition, thickness, or surface properties can dramatically affect sensor performance, necessitating advanced in-line monitoring systems. Current inspection technologies often cannot detect subtle defects that may compromise biosensor functionality, creating yield challenges that impact economic viability.

Cost considerations further complicate manufacturing scale-up. While polymer-based sensors offer inherent cost advantages over traditional rigid electronics, the specialized materials and precision equipment required for advanced biosensor production remain expensive. Economic viability demands optimization of material utilization, process efficiency, and production yields to achieve competitive price points for consumer wearable devices.

Recent innovations addressing these challenges include the development of additive manufacturing techniques specifically tailored for multi-material polymer biosensors, allowing digital fabrication with reduced material waste. Advances in automated precision dispensing systems have improved the deposition accuracy of functional sensing materials, while new rapid-curing polymer formulations compatible with high-speed manufacturing have reduced production cycle times.

Industry-academic collaborations are increasingly focusing on manufacturing process innovation, with several pilot production lines demonstrating promising approaches to scaled fabrication of polymer biosensors. These efforts suggest that with continued investment in manufacturing technology development, the production scalability of advanced polymer biosensors will significantly improve within the next 3-5 years, potentially enabling widespread adoption in consumer health monitoring applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!