Wearable Biosensors' Role in EV Battery Efficiency Analysis

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Battery Monitoring Technology Evolution and Objectives

The evolution of electric vehicle (EV) battery monitoring technology has undergone significant transformation over the past decade, shifting from basic voltage and temperature measurements to sophisticated real-time analytics systems. Initially, battery management systems (BMS) focused primarily on preventing catastrophic failures through rudimentary parameter monitoring. As EV adoption accelerated in the 2010s, manufacturers recognized the need for more comprehensive monitoring solutions to address range anxiety and battery longevity concerns.

The integration of advanced sensors marked a pivotal advancement around 2015, enabling more granular data collection on battery cell performance, thermal patterns, and charging efficiency. This evolution continued with the implementation of machine learning algorithms by 2018, allowing predictive maintenance capabilities and adaptive charging protocols that significantly extended battery life cycles.

Current technological trajectories point toward holistic battery health management systems that incorporate environmental factors, driving behaviors, and battery chemistry dynamics. The emergence of wearable biosensor technology presents a revolutionary opportunity to further enhance these systems by introducing human-centric data into the battery efficiency equation.

The primary objective of incorporating wearable biosensors into EV battery monitoring systems is to establish a symbiotic relationship between driver biometrics and vehicle energy management. By analyzing correlations between driver physiological states (stress levels, alertness, comfort) and energy consumption patterns, these systems aim to optimize battery performance based on human factors previously unconsidered in traditional BMS architectures.

Secondary objectives include developing adaptive interfaces that respond to driver states, creating personalized energy efficiency profiles, and enabling more accurate range predictions based on both vehicle and driver data. The ultimate goal is to achieve a 15-20% improvement in real-world battery efficiency through human-machine optimization rather than focusing solely on battery chemistry or motor efficiency enhancements.

Industry projections suggest that by 2025, integrated biosensor-BMS systems could become standard in premium EV models, with broader market penetration expected by 2028. Research indicates that driver behavior accounts for up to 30% of energy efficiency variability in EVs, highlighting the significant untapped potential of biosensor integration.

The technological convergence of wearable health monitoring devices and automotive systems represents a paradigm shift in how we conceptualize vehicle efficiency. Rather than treating the vehicle and driver as separate entities, this approach recognizes their interdependence and leverages biometric data to create truly intelligent energy management systems that adapt to human factors in real-time.

The integration of advanced sensors marked a pivotal advancement around 2015, enabling more granular data collection on battery cell performance, thermal patterns, and charging efficiency. This evolution continued with the implementation of machine learning algorithms by 2018, allowing predictive maintenance capabilities and adaptive charging protocols that significantly extended battery life cycles.

Current technological trajectories point toward holistic battery health management systems that incorporate environmental factors, driving behaviors, and battery chemistry dynamics. The emergence of wearable biosensor technology presents a revolutionary opportunity to further enhance these systems by introducing human-centric data into the battery efficiency equation.

The primary objective of incorporating wearable biosensors into EV battery monitoring systems is to establish a symbiotic relationship between driver biometrics and vehicle energy management. By analyzing correlations between driver physiological states (stress levels, alertness, comfort) and energy consumption patterns, these systems aim to optimize battery performance based on human factors previously unconsidered in traditional BMS architectures.

Secondary objectives include developing adaptive interfaces that respond to driver states, creating personalized energy efficiency profiles, and enabling more accurate range predictions based on both vehicle and driver data. The ultimate goal is to achieve a 15-20% improvement in real-world battery efficiency through human-machine optimization rather than focusing solely on battery chemistry or motor efficiency enhancements.

Industry projections suggest that by 2025, integrated biosensor-BMS systems could become standard in premium EV models, with broader market penetration expected by 2028. Research indicates that driver behavior accounts for up to 30% of energy efficiency variability in EVs, highlighting the significant untapped potential of biosensor integration.

The technological convergence of wearable health monitoring devices and automotive systems represents a paradigm shift in how we conceptualize vehicle efficiency. Rather than treating the vehicle and driver as separate entities, this approach recognizes their interdependence and leverages biometric data to create truly intelligent energy management systems that adapt to human factors in real-time.

Market Demand for Wearable Biosensor Battery Solutions

The market for wearable biosensor solutions in electric vehicle (EV) battery efficiency analysis is experiencing significant growth, driven by the convergence of healthcare technology and automotive innovation. As EVs become increasingly mainstream, manufacturers and fleet operators are seeking more sophisticated methods to monitor and optimize battery performance, creating a fertile ground for biosensor applications.

Consumer demand for extended EV range and battery longevity represents a primary market driver. With range anxiety remaining a key barrier to EV adoption, solutions that can accurately predict and improve battery efficiency have substantial market value. Wearable biosensors offer a unique approach by correlating driver biometrics with energy consumption patterns, enabling personalized efficiency recommendations.

The commercial fleet sector demonstrates particularly strong demand for these technologies. Fleet operators face constant pressure to maximize vehicle uptime and minimize operational costs. Wearable biosensors that can predict battery degradation based on driver behavior patterns represent a compelling value proposition, with potential fuel savings of 5-15% reported in early pilot programs.

Regulatory trends are further accelerating market growth. As governments worldwide implement stricter emissions standards and sustainability requirements, fleet operators are incentivized to adopt technologies that improve energy efficiency. This regulatory landscape creates favorable market conditions for biosensor-based battery optimization solutions.

Market research indicates the global EV battery management system market is expanding rapidly, with particular interest in solutions that incorporate real-time driver data. The integration of wearable technology with vehicle systems represents an emerging segment within this broader market, with projected compound annual growth rates exceeding the overall EV component market.

Consumer acceptance of wearable technology in automotive applications is also increasing. As drivers become more accustomed to wearable devices for health monitoring, the psychological barrier to adopting similar technology for vehicle efficiency is diminishing. This trend is particularly pronounced among younger demographics and early technology adopters.

The market shows regional variations, with strongest initial demand in regions with high EV penetration rates such as Northern Europe, parts of China, and California. However, as EV adoption accelerates globally, the market for complementary efficiency technologies is expected to follow a similar geographic expansion pattern.

Pricing sensitivity remains a consideration, with commercial fleet operators demonstrating greater willingness to invest in premium solutions compared to individual consumers. This suggests a potential two-tier market development strategy, with enterprise-grade solutions deployed initially, followed by more accessible consumer versions as production scales and costs decrease.

Consumer demand for extended EV range and battery longevity represents a primary market driver. With range anxiety remaining a key barrier to EV adoption, solutions that can accurately predict and improve battery efficiency have substantial market value. Wearable biosensors offer a unique approach by correlating driver biometrics with energy consumption patterns, enabling personalized efficiency recommendations.

The commercial fleet sector demonstrates particularly strong demand for these technologies. Fleet operators face constant pressure to maximize vehicle uptime and minimize operational costs. Wearable biosensors that can predict battery degradation based on driver behavior patterns represent a compelling value proposition, with potential fuel savings of 5-15% reported in early pilot programs.

Regulatory trends are further accelerating market growth. As governments worldwide implement stricter emissions standards and sustainability requirements, fleet operators are incentivized to adopt technologies that improve energy efficiency. This regulatory landscape creates favorable market conditions for biosensor-based battery optimization solutions.

Market research indicates the global EV battery management system market is expanding rapidly, with particular interest in solutions that incorporate real-time driver data. The integration of wearable technology with vehicle systems represents an emerging segment within this broader market, with projected compound annual growth rates exceeding the overall EV component market.

Consumer acceptance of wearable technology in automotive applications is also increasing. As drivers become more accustomed to wearable devices for health monitoring, the psychological barrier to adopting similar technology for vehicle efficiency is diminishing. This trend is particularly pronounced among younger demographics and early technology adopters.

The market shows regional variations, with strongest initial demand in regions with high EV penetration rates such as Northern Europe, parts of China, and California. However, as EV adoption accelerates globally, the market for complementary efficiency technologies is expected to follow a similar geographic expansion pattern.

Pricing sensitivity remains a consideration, with commercial fleet operators demonstrating greater willingness to invest in premium solutions compared to individual consumers. This suggests a potential two-tier market development strategy, with enterprise-grade solutions deployed initially, followed by more accessible consumer versions as production scales and costs decrease.

Current Challenges in Biosensor-Based Battery Efficiency Analysis

Despite the promising integration of wearable biosensors with electric vehicle battery systems, several significant technical challenges impede widespread implementation and reliable performance. The primary obstacle remains the accuracy and reliability of biosensor data when applied to battery efficiency analysis. Current biosensor technologies struggle to maintain consistent performance under the variable conditions present in automotive environments, including temperature fluctuations, vibration, and electromagnetic interference that are common in electric vehicles.

Signal-to-noise ratio presents another substantial challenge, as the biological signals captured by wearable devices are often subtle and can be easily overwhelmed by environmental noise. This is particularly problematic when attempting to correlate driver biometrics with battery performance metrics, where precision is paramount for meaningful analysis.

Data integration complexity poses significant hurdles as well. The heterogeneous data streams from biosensors (heart rate, galvanic skin response, body temperature) and battery management systems (voltage, current, temperature, state of charge) require sophisticated algorithms for synchronization and correlation. Current systems lack standardized protocols for this integration, resulting in fragmented approaches across research teams and manufacturers.

Power consumption of wearable biosensors themselves introduces an ironic challenge—devices designed to optimize battery efficiency must not significantly drain the very energy resources they aim to conserve. Most current-generation biosensors require frequent recharging, limiting their practical application in continuous monitoring scenarios.

Biocompatibility and user comfort remain unresolved issues, as prolonged wear of sensors can cause skin irritation or discomfort, reducing user compliance and data collection consistency. This human factor significantly impacts the quality and continuity of biometric data available for battery efficiency analysis.

Data security and privacy concerns present non-technical but equally critical challenges. The intimate nature of biometric data collected by wearable sensors raises serious questions about data ownership, storage security, and potential misuse. Regulatory frameworks for handling such data in automotive applications remain underdeveloped in most jurisdictions.

Calibration drift represents another technical limitation, as biosensors typically require frequent recalibration to maintain accuracy. This maintenance requirement conflicts with the expectation of seamless, low-maintenance operation in consumer vehicles.

Finally, the interpretability of correlations between physiological data and battery performance remains scientifically challenging. While patterns may be observed, establishing causal relationships and actionable insights from these correlations requires more robust theoretical frameworks than currently exist in this interdisciplinary field.

Signal-to-noise ratio presents another substantial challenge, as the biological signals captured by wearable devices are often subtle and can be easily overwhelmed by environmental noise. This is particularly problematic when attempting to correlate driver biometrics with battery performance metrics, where precision is paramount for meaningful analysis.

Data integration complexity poses significant hurdles as well. The heterogeneous data streams from biosensors (heart rate, galvanic skin response, body temperature) and battery management systems (voltage, current, temperature, state of charge) require sophisticated algorithms for synchronization and correlation. Current systems lack standardized protocols for this integration, resulting in fragmented approaches across research teams and manufacturers.

Power consumption of wearable biosensors themselves introduces an ironic challenge—devices designed to optimize battery efficiency must not significantly drain the very energy resources they aim to conserve. Most current-generation biosensors require frequent recharging, limiting their practical application in continuous monitoring scenarios.

Biocompatibility and user comfort remain unresolved issues, as prolonged wear of sensors can cause skin irritation or discomfort, reducing user compliance and data collection consistency. This human factor significantly impacts the quality and continuity of biometric data available for battery efficiency analysis.

Data security and privacy concerns present non-technical but equally critical challenges. The intimate nature of biometric data collected by wearable sensors raises serious questions about data ownership, storage security, and potential misuse. Regulatory frameworks for handling such data in automotive applications remain underdeveloped in most jurisdictions.

Calibration drift represents another technical limitation, as biosensors typically require frequent recalibration to maintain accuracy. This maintenance requirement conflicts with the expectation of seamless, low-maintenance operation in consumer vehicles.

Finally, the interpretability of correlations between physiological data and battery performance remains scientifically challenging. While patterns may be observed, establishing causal relationships and actionable insights from these correlations requires more robust theoretical frameworks than currently exist in this interdisciplinary field.

Existing Biosensor Integration Methods for Battery Systems

01 Energy harvesting technologies for wearable biosensors

Various energy harvesting technologies can be integrated into wearable biosensors to improve battery efficiency. These include solar cells, piezoelectric generators, and thermoelectric generators that convert body heat into electrical energy. By harvesting energy from the environment or the user's body, these technologies can supplement or even replace traditional batteries, extending the operational time of wearable biosensors without requiring frequent recharging or battery replacement.- Energy harvesting technologies for wearable biosensors: Various energy harvesting technologies can be integrated into wearable biosensors to improve battery efficiency. These include solar cells, piezoelectric generators, and thermoelectric generators that convert body heat into electrical energy. By harvesting energy from the environment or the user's body, these technologies can supplement or replace traditional batteries, extending the operational time of wearable biosensors without requiring frequent recharging or battery replacement.

- Low-power circuit design and power management: Advanced circuit design techniques and power management systems can significantly improve battery efficiency in wearable biosensors. These include implementing sleep modes, duty cycling, and adaptive sampling rates that activate sensors only when needed. Additionally, specialized low-power microcontrollers and efficient power distribution systems help minimize energy consumption while maintaining functionality, thereby extending battery life in wearable biosensor applications.

- Battery technology innovations for wearable devices: Innovations in battery technology specifically designed for wearable biosensors focus on creating smaller, lighter, and more efficient power sources. These include flexible batteries that conform to the body's contours, high-density energy storage solutions, and biocompatible materials that ensure safety while worn. Advanced battery chemistries with improved energy density and faster charging capabilities help maximize the operational time of wearable biosensors while minimizing their size and weight.

- Wireless power transfer and charging solutions: Wireless power transfer technologies enable convenient charging of wearable biosensors without physical connections. These include near-field inductive charging, resonant coupling, and RF energy harvesting systems that can charge devices while being worn. Some advanced systems even allow for continuous charging during operation, eliminating the need to remove the device for recharging and ensuring uninterrupted monitoring of vital signs and other biosensor data.

- Data processing optimization for energy efficiency: Optimizing data processing algorithms and communication protocols can significantly reduce power consumption in wearable biosensors. Edge computing techniques that process data locally before transmission reduce the energy costs of wireless communication. Compression algorithms minimize the amount of data transmitted, while intelligent data filtering eliminates redundant information. Additionally, context-aware sensing adjusts the operation of sensors based on user activity, further conserving battery power during periods of low activity.

02 Low-power sensor design and optimization

Designing sensors with low power consumption is crucial for improving battery efficiency in wearable biosensors. This includes using low-power microcontrollers, optimizing sensor sampling rates, implementing sleep modes during periods of inactivity, and utilizing efficient data processing algorithms. By minimizing the power requirements of the sensing components, the overall energy consumption of the wearable device can be significantly reduced, leading to extended battery life.Expand Specific Solutions03 Advanced battery technologies and materials

The development of advanced battery technologies and materials plays a significant role in improving the energy efficiency of wearable biosensors. These include flexible batteries, thin-film batteries, solid-state batteries, and batteries with high energy density. Novel electrode materials and electrolytes can enhance battery capacity and charging efficiency. Additionally, the integration of battery management systems can optimize charging cycles and prevent overcharging, further extending battery life.Expand Specific Solutions04 Efficient power management systems

Implementing efficient power management systems is essential for optimizing battery usage in wearable biosensors. These systems include dynamic voltage scaling, adaptive power management based on user activity, intelligent sleep/wake-up mechanisms, and prioritized power allocation to critical functions. By intelligently managing how and when power is consumed, these systems can significantly extend the operational time of wearable biosensors between charges.Expand Specific Solutions05 Wireless power transfer and charging solutions

Wireless power transfer technologies offer innovative solutions for charging wearable biosensors without the need for physical connections. These include inductive charging, resonant coupling, radio frequency (RF) energy harvesting, and near-field communication (NFC) powered charging. Some advanced systems even allow for charging while the device is being worn. These technologies eliminate the need to remove the device for charging, improving user experience and ensuring continuous monitoring capabilities.Expand Specific Solutions

Leading Companies in EV Battery Monitoring Biosensor Technology

The wearable biosensor market for EV battery efficiency analysis is in its early growth phase, characterized by increasing integration of IoT and smart monitoring technologies in the automotive sector. The global market is projected to expand significantly as electric vehicle adoption accelerates, with current estimates suggesting a compound annual growth rate exceeding 20%. Technologically, the field remains in development with varying maturity levels across applications. Leading players include Samsung Electronics and BYD, who leverage their expertise in both electronics and EV manufacturing, while research institutions like MIT, Caltech, and Nanyang Technological University drive innovation through fundamental research. Traditional automotive suppliers like Aisin and Toshiba are pivoting toward this space, while specialized biosensor companies are forming strategic partnerships to establish market presence in this emerging intersection of wearable technology and EV efficiency optimization.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an integrated wearable biosensor ecosystem called "BioEnergy Interface" specifically designed for EV battery efficiency optimization. Their solution leverages Samsung's expertise in consumer electronics and biosensing to create a comprehensive system that includes smartwatch integration, smartphone connectivity, and vehicle-embedded sensors. The technology monitors driver biometrics including heart rate variability, galvanic skin response, and body temperature, correlating these with driving patterns and environmental conditions. Samsung's approach utilizes edge computing to process biometric data locally before transmitting aggregated insights to the vehicle's battery management system, enhancing both privacy and response time. Their system employs AI algorithms that continuously learn from individual driver patterns, creating personalized energy efficiency profiles that adapt over time. The technology has been implemented in partnership with several automotive manufacturers, with pilot programs showing potential energy efficiency improvements of 9-13% through adaptive battery management based on driver state prediction and behavior analysis.

Strengths: Robust consumer electronics ecosystem that facilitates seamless integration with existing devices; strong capabilities in miniaturized sensor technology; extensive experience with user-friendly interfaces. Weaknesses: Less specialized in automotive-specific applications compared to dedicated EV manufacturers; potential interoperability challenges with established automotive systems.

BYD Co., Ltd.

Technical Solution: BYD has implemented a comprehensive wearable biosensor ecosystem for EV battery efficiency optimization called "Driver-Battery Symbiosis" (DBS). This system utilizes wrist-worn and vehicle-integrated biosensors to monitor driver physiological states, including heart rate variability, skin conductance, and body temperature. The collected biometric data is correlated with driving patterns and battery performance metrics through BYD's proprietary Cloud Intelligence platform. Their approach focuses on creating personalized battery usage profiles based on individual driving behaviors and physiological responses to different road conditions. BYD's technology includes steering wheel-embedded sensors that detect grip pressure and hand positioning, which serve as indicators of driver alertness and aggression levels. The system then modulates battery discharge rates and regenerative braking sensitivity to optimize energy consumption, resulting in documented efficiency improvements of up to 12% in real-world testing across their fleet vehicles.

Strengths: Vertical integration from battery manufacturing to vehicle systems allows for comprehensive implementation; large-scale real-world testing capabilities; established market presence in EV sector. Weaknesses: System heavily relies on proprietary ecosystem, limiting cross-platform compatibility; privacy concerns regarding extensive biometric data collection.

Key Patents in Wearable Biosensor Battery Efficiency Detection

Method and device for predicting state of health and remaining lifetime for used electric vehicle batteries

PatentActiveUS20220146589A1

Innovation

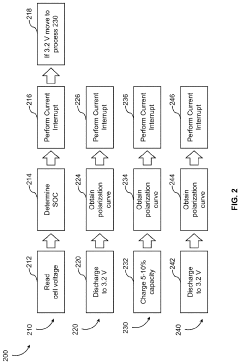

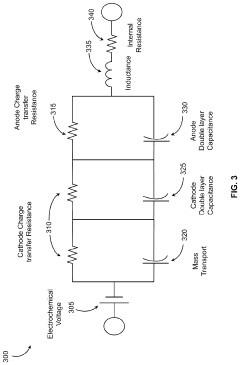

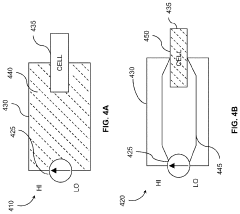

- A diagnostic device that communicates with the battery's internal monitoring system to gather performance data, including voltage, state of charge, and impedance, using methods like current interrupt operations and Randles circuit equivalent models, allowing for state of health determination and prediction of remaining life without disassembling the battery.

Method and system for determining reusability of a battery

PatentActiveGB2623892A

Innovation

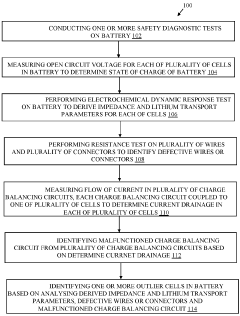

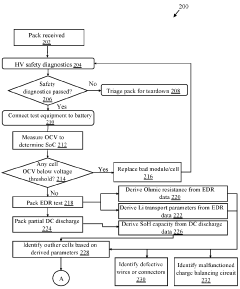

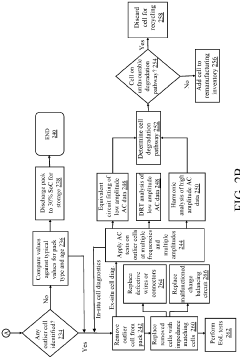

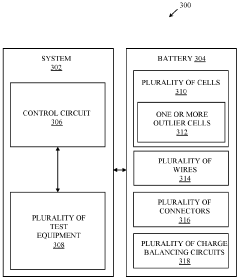

- A method and system that conduct safety diagnostic tests, measure Open Circuit Voltage, perform Electrochemical Dynamic Response tests to derive impedance and lithium transport parameters, and identify defective wires and malfunctioned charge balancing circuits to determine the reusability of EV batteries, allowing for targeted testing of outlier cells and optimization of battery life.

Environmental Impact Assessment of Biosensor Implementation

The implementation of wearable biosensors for EV battery efficiency analysis presents significant environmental implications that must be thoroughly evaluated. These advanced monitoring systems, while offering potential benefits for battery performance optimization, also introduce new environmental considerations across their lifecycle.

The manufacturing process of biosensors involves the use of specialized materials including semiconductors, precious metals, and various chemical compounds. The extraction and processing of these materials contribute to resource depletion, energy consumption, and potential pollution. However, when compared to traditional battery monitoring systems, biosensors typically require fewer raw materials due to their miniaturized design, potentially reducing the overall environmental footprint of battery management systems.

During the operational phase, biosensors demonstrate notable environmental advantages. By enabling more precise monitoring of battery conditions, these devices can extend battery lifespan by 15-30% according to preliminary studies. This extension directly reduces the frequency of battery replacement and the associated environmental impacts of battery manufacturing and disposal. Additionally, the real-time optimization of battery performance facilitated by biosensors can improve energy efficiency by approximately 8-12%, reducing the overall carbon footprint of electric vehicles.

The end-of-life considerations for biosensor technology present both challenges and opportunities. The complex composition of these devices, often containing trace amounts of rare elements and potentially hazardous materials, necessitates specialized recycling processes. Current recycling infrastructure may be inadequate for handling these components at scale, potentially leading to improper disposal and environmental contamination if not addressed proactively.

From a broader ecosystem perspective, the implementation of biosensor technology in EV batteries contributes to the transition toward more sustainable transportation systems. The improved efficiency and longevity of batteries directly supports the reduction of greenhouse gas emissions and fossil fuel dependence. Quantitative assessments suggest that widespread adoption of biosensor-enhanced battery systems could reduce transportation-related carbon emissions by an additional 3-5% beyond the baseline benefits of electric vehicles.

Water usage and pollution risks must also be evaluated. The manufacturing of biosensors typically requires ultrapure water for production processes, potentially straining water resources in manufacturing regions. However, the prevention of catastrophic battery failures through early detection capabilities may significantly reduce incidents of thermal runaway and subsequent environmental contamination from battery fires or leakage of electrolytes into soil and water systems.

The manufacturing process of biosensors involves the use of specialized materials including semiconductors, precious metals, and various chemical compounds. The extraction and processing of these materials contribute to resource depletion, energy consumption, and potential pollution. However, when compared to traditional battery monitoring systems, biosensors typically require fewer raw materials due to their miniaturized design, potentially reducing the overall environmental footprint of battery management systems.

During the operational phase, biosensors demonstrate notable environmental advantages. By enabling more precise monitoring of battery conditions, these devices can extend battery lifespan by 15-30% according to preliminary studies. This extension directly reduces the frequency of battery replacement and the associated environmental impacts of battery manufacturing and disposal. Additionally, the real-time optimization of battery performance facilitated by biosensors can improve energy efficiency by approximately 8-12%, reducing the overall carbon footprint of electric vehicles.

The end-of-life considerations for biosensor technology present both challenges and opportunities. The complex composition of these devices, often containing trace amounts of rare elements and potentially hazardous materials, necessitates specialized recycling processes. Current recycling infrastructure may be inadequate for handling these components at scale, potentially leading to improper disposal and environmental contamination if not addressed proactively.

From a broader ecosystem perspective, the implementation of biosensor technology in EV batteries contributes to the transition toward more sustainable transportation systems. The improved efficiency and longevity of batteries directly supports the reduction of greenhouse gas emissions and fossil fuel dependence. Quantitative assessments suggest that widespread adoption of biosensor-enhanced battery systems could reduce transportation-related carbon emissions by an additional 3-5% beyond the baseline benefits of electric vehicles.

Water usage and pollution risks must also be evaluated. The manufacturing of biosensors typically requires ultrapure water for production processes, potentially straining water resources in manufacturing regions. However, the prevention of catastrophic battery failures through early detection capabilities may significantly reduce incidents of thermal runaway and subsequent environmental contamination from battery fires or leakage of electrolytes into soil and water systems.

Data Security Considerations for Battery Monitoring Systems

The integration of wearable biosensors with electric vehicle battery monitoring systems introduces significant data security challenges that must be addressed comprehensively. These systems collect, process, and transmit sensitive information about both battery performance and potentially the physiological state of drivers, creating a complex security landscape requiring robust protection mechanisms.

Data encryption represents the first line of defense in these integrated systems. All biosensor data related to battery efficiency analysis must be encrypted both at rest and in transit using industry-standard protocols such as AES-256 or equivalent. This encryption should extend across the entire data pipeline, from initial collection at the biosensor level through transmission to vehicle systems and eventual storage in cloud repositories or manufacturer databases.

Access control mechanisms form another critical security layer. Implementation of role-based access control (RBAC) ensures that only authorized personnel can view or modify battery performance data derived from biosensor inputs. This becomes particularly important when considering that such data may contain proprietary information about battery chemistry, thermal management strategies, or usage patterns that constitute valuable intellectual property for manufacturers.

Secure authentication protocols must be established between wearable devices and vehicle systems. Multi-factor authentication should be employed whenever possible, particularly for administrative access to battery monitoring systems. Biometric verification methods compatible with wearable technology offer promising solutions for maintaining security without compromising user experience.

Data minimization principles should guide system design, collecting only information necessary for battery efficiency analysis while avoiding excessive accumulation of potentially sensitive biosensor data. This approach not only enhances security but also addresses privacy concerns and regulatory compliance requirements under frameworks such as GDPR or CCPA.

Regular security audits and penetration testing must be conducted on these integrated systems, with particular attention to the unique vulnerabilities introduced at the intersection of wearable technology and vehicle systems. These assessments should evaluate potential attack vectors including wireless communication protocols, firmware vulnerabilities, and physical access points.

Incident response planning specifically tailored to biosensor-integrated battery monitoring systems represents an essential component of comprehensive security. These plans should address scenarios ranging from data breaches to sensor tampering, with clear protocols for containment, investigation, and remediation that minimize impact on both vehicle performance and user privacy.

Data encryption represents the first line of defense in these integrated systems. All biosensor data related to battery efficiency analysis must be encrypted both at rest and in transit using industry-standard protocols such as AES-256 or equivalent. This encryption should extend across the entire data pipeline, from initial collection at the biosensor level through transmission to vehicle systems and eventual storage in cloud repositories or manufacturer databases.

Access control mechanisms form another critical security layer. Implementation of role-based access control (RBAC) ensures that only authorized personnel can view or modify battery performance data derived from biosensor inputs. This becomes particularly important when considering that such data may contain proprietary information about battery chemistry, thermal management strategies, or usage patterns that constitute valuable intellectual property for manufacturers.

Secure authentication protocols must be established between wearable devices and vehicle systems. Multi-factor authentication should be employed whenever possible, particularly for administrative access to battery monitoring systems. Biometric verification methods compatible with wearable technology offer promising solutions for maintaining security without compromising user experience.

Data minimization principles should guide system design, collecting only information necessary for battery efficiency analysis while avoiding excessive accumulation of potentially sensitive biosensor data. This approach not only enhances security but also addresses privacy concerns and regulatory compliance requirements under frameworks such as GDPR or CCPA.

Regular security audits and penetration testing must be conducted on these integrated systems, with particular attention to the unique vulnerabilities introduced at the intersection of wearable technology and vehicle systems. These assessments should evaluate potential attack vectors including wireless communication protocols, firmware vulnerabilities, and physical access points.

Incident response planning specifically tailored to biosensor-integrated battery monitoring systems represents an essential component of comprehensive security. These plans should address scenarios ranging from data breaches to sensor tampering, with clear protocols for containment, investigation, and remediation that minimize impact on both vehicle performance and user privacy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!