How Do Coatings Enhance Wearable Biosensor Functionality

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biosensor Coating Technology Background and Objectives

Wearable biosensor technology has evolved significantly over the past two decades, transitioning from bulky laboratory equipment to miniaturized, flexible devices capable of continuous health monitoring. The integration of specialized coatings represents a critical advancement in this evolution, addressing fundamental challenges of biocompatibility, signal stability, and sensor longevity. Initially developed for clinical applications, wearable biosensors have expanded into consumer health, athletic performance monitoring, and preventive healthcare domains, driven by increasing demand for personalized health data.

The technological trajectory of biosensor coatings has been shaped by interdisciplinary convergence of materials science, biomedical engineering, and nanotechnology. Early generations of wearable biosensors suffered from signal drift, biofouling, and limited durability when exposed to biological fluids. These limitations prompted focused research on functional coatings that could simultaneously protect sensor components while facilitating selective analyte detection.

Current coating technologies encompass a diverse range of materials including hydrogels, conducting polymers, self-assembled monolayers, and nanocomposites. Each coating type addresses specific functional requirements, from preventing protein adsorption to enhancing electron transfer kinetics or providing antimicrobial properties. The field has witnessed accelerated innovation particularly since 2015, with the emergence of stimuli-responsive "smart" coatings capable of adapting to physiological changes.

The primary technical objectives for biosensor coating development center on achieving multifunctionality while maintaining nanoscale precision. These objectives include: enhancing biocompatibility to minimize foreign body responses; improving selectivity for target analytes while rejecting interferents; extending operational lifetime under physiological conditions; and maintaining sensor performance during mechanical deformation and environmental fluctuations.

Looking forward, the field is moving toward biomimetic and bioinspired coating designs that emulate natural biological interfaces. Integration of self-healing capabilities, controlled degradation profiles, and real-time reconfigurability represent frontier research directions. Additionally, there is growing emphasis on developing environmentally sustainable coating materials and processes that reduce reliance on rare earth elements and toxic compounds.

The convergence of coating technology with advances in flexible electronics and wireless power transfer is expected to enable the next generation of imperceptible, "wear-and-forget" biosensors. This evolution aligns with broader healthcare trends toward decentralized monitoring, preventive medicine, and patient empowerment through continuous health data access. The ultimate goal remains developing coating technologies that can transform wearable biosensors from periodic monitoring tools to seamlessly integrated components of personalized healthcare ecosystems.

The technological trajectory of biosensor coatings has been shaped by interdisciplinary convergence of materials science, biomedical engineering, and nanotechnology. Early generations of wearable biosensors suffered from signal drift, biofouling, and limited durability when exposed to biological fluids. These limitations prompted focused research on functional coatings that could simultaneously protect sensor components while facilitating selective analyte detection.

Current coating technologies encompass a diverse range of materials including hydrogels, conducting polymers, self-assembled monolayers, and nanocomposites. Each coating type addresses specific functional requirements, from preventing protein adsorption to enhancing electron transfer kinetics or providing antimicrobial properties. The field has witnessed accelerated innovation particularly since 2015, with the emergence of stimuli-responsive "smart" coatings capable of adapting to physiological changes.

The primary technical objectives for biosensor coating development center on achieving multifunctionality while maintaining nanoscale precision. These objectives include: enhancing biocompatibility to minimize foreign body responses; improving selectivity for target analytes while rejecting interferents; extending operational lifetime under physiological conditions; and maintaining sensor performance during mechanical deformation and environmental fluctuations.

Looking forward, the field is moving toward biomimetic and bioinspired coating designs that emulate natural biological interfaces. Integration of self-healing capabilities, controlled degradation profiles, and real-time reconfigurability represent frontier research directions. Additionally, there is growing emphasis on developing environmentally sustainable coating materials and processes that reduce reliance on rare earth elements and toxic compounds.

The convergence of coating technology with advances in flexible electronics and wireless power transfer is expected to enable the next generation of imperceptible, "wear-and-forget" biosensors. This evolution aligns with broader healthcare trends toward decentralized monitoring, preventive medicine, and patient empowerment through continuous health data access. The ultimate goal remains developing coating technologies that can transform wearable biosensors from periodic monitoring tools to seamlessly integrated components of personalized healthcare ecosystems.

Market Analysis for Coated Wearable Biosensors

The global market for coated wearable biosensors is experiencing robust growth, driven by increasing health consciousness, rising prevalence of chronic diseases, and technological advancements in sensor materials. Current market valuations indicate that the wearable biosensor market reached approximately 13 billion USD in 2022 and is projected to grow at a compound annual growth rate of 18% through 2030, with coated biosensors representing a significant growth segment.

Consumer demand for wearable health monitoring devices has surged post-pandemic, with particular emphasis on continuous glucose monitoring, heart rate tracking, and blood oxygen level measurement. The fitness and wellness sector remains the largest application segment, accounting for nearly 40% of market share, followed by healthcare monitoring at 35% and performance tracking at 25%.

Geographically, North America dominates the market with approximately 45% share due to advanced healthcare infrastructure and high consumer adoption rates. However, Asia-Pacific represents the fastest-growing region with anticipated growth exceeding 20% annually, driven by increasing healthcare expenditure in countries like China and India, and expanding manufacturing capabilities for sensor components.

The consumer segment shows distinct preferences for coated biosensors that offer enhanced durability, improved signal quality, and biocompatibility. Market research indicates that 78% of consumers prioritize device longevity and accuracy over other features, directly correlating with coating quality. Additionally, there is growing demand for waterproof and sweat-resistant coatings, with 65% of consumers citing these as essential features.

Healthcare providers are increasingly adopting coated wearable biosensors for remote patient monitoring, creating a substantial B2B market segment expected to grow at 22% annually. This trend is accelerated by insurance companies beginning to cover wearable monitoring devices for certain conditions, expanding the addressable market.

Key market restraints include concerns about data privacy, regulatory hurdles for medical-grade devices, and cost barriers for advanced coating technologies. The premium segment of coated biosensors commands price points 30-40% higher than standard versions, limiting mass-market penetration in developing economies.

Future market expansion will likely be driven by innovations in coating materials that enable new sensing modalities, such as non-invasive glucose monitoring and continuous blood pressure tracking. The integration of artificial intelligence with coated biosensor data is creating new market opportunities in predictive healthcare analytics, potentially adding 5 billion USD to the market by 2028.

Consumer demand for wearable health monitoring devices has surged post-pandemic, with particular emphasis on continuous glucose monitoring, heart rate tracking, and blood oxygen level measurement. The fitness and wellness sector remains the largest application segment, accounting for nearly 40% of market share, followed by healthcare monitoring at 35% and performance tracking at 25%.

Geographically, North America dominates the market with approximately 45% share due to advanced healthcare infrastructure and high consumer adoption rates. However, Asia-Pacific represents the fastest-growing region with anticipated growth exceeding 20% annually, driven by increasing healthcare expenditure in countries like China and India, and expanding manufacturing capabilities for sensor components.

The consumer segment shows distinct preferences for coated biosensors that offer enhanced durability, improved signal quality, and biocompatibility. Market research indicates that 78% of consumers prioritize device longevity and accuracy over other features, directly correlating with coating quality. Additionally, there is growing demand for waterproof and sweat-resistant coatings, with 65% of consumers citing these as essential features.

Healthcare providers are increasingly adopting coated wearable biosensors for remote patient monitoring, creating a substantial B2B market segment expected to grow at 22% annually. This trend is accelerated by insurance companies beginning to cover wearable monitoring devices for certain conditions, expanding the addressable market.

Key market restraints include concerns about data privacy, regulatory hurdles for medical-grade devices, and cost barriers for advanced coating technologies. The premium segment of coated biosensors commands price points 30-40% higher than standard versions, limiting mass-market penetration in developing economies.

Future market expansion will likely be driven by innovations in coating materials that enable new sensing modalities, such as non-invasive glucose monitoring and continuous blood pressure tracking. The integration of artificial intelligence with coated biosensor data is creating new market opportunities in predictive healthcare analytics, potentially adding 5 billion USD to the market by 2028.

Current Coating Technologies and Technical Barriers

The wearable biosensor market currently employs several advanced coating technologies that significantly enhance device functionality. Polymeric coatings, including polyurethane, polyimide, and parylene C, dominate the field due to their excellent biocompatibility and flexibility. These materials create effective barriers against moisture and biological fluids while maintaining sensor sensitivity. Particularly, parylene C has gained prominence for its conformal coating capabilities, providing uniform protection even on complex geometries.

Hydrogel-based coatings represent another critical category, offering superior water retention properties that mimic biological tissues. These coatings enhance the sensor-skin interface, reducing motion artifacts and improving signal quality during physical activity. Recent innovations in this space include stimuli-responsive hydrogels that can adapt to environmental changes, such as pH or temperature fluctuations, enabling more accurate biosensing in variable conditions.

Nanocomposite coatings have emerged as a promising frontier, incorporating nanomaterials like graphene, carbon nanotubes, and metal nanoparticles into polymer matrices. These composites offer enhanced electrical conductivity, mechanical strength, and antimicrobial properties. For instance, silver nanoparticle-infused coatings provide both electrical conductivity and antimicrobial protection, addressing multiple functional requirements simultaneously.

Despite these advancements, significant technical barriers persist. Adhesion failure between coating layers and substrate materials remains a primary challenge, particularly under repeated mechanical stress from body movement. This often results in delamination and subsequent sensor failure, limiting long-term reliability. Current adhesion promotion techniques often involve chemical treatments that may compromise biocompatibility or introduce additional manufacturing complexity.

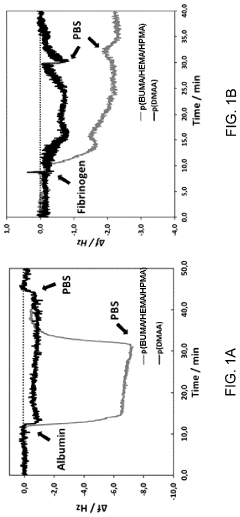

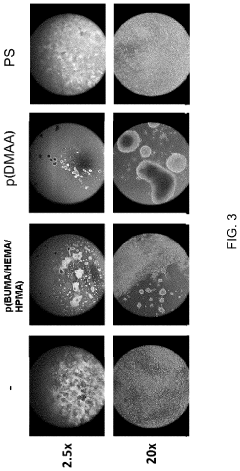

Biofouling presents another substantial obstacle, as protein adsorption and cellular attachment on sensor surfaces can progressively degrade signal quality. While hydrophobic and zwitterionic coatings show promise in reducing biofouling, complete prevention remains elusive, especially for continuous long-term monitoring applications exceeding several days.

Manufacturing scalability poses additional challenges, particularly for multi-layer coating systems requiring precise thickness control. Current deposition methods like dip-coating and spin-coating often struggle with reproducibility at scale, while more advanced techniques such as chemical vapor deposition require specialized equipment and significant capital investment.

Balancing conflicting requirements represents perhaps the most fundamental barrier. Coatings must simultaneously provide barrier properties against environmental factors while allowing selective permeability to target analytes. This paradoxical requirement becomes especially challenging for electrochemical sensors that must maintain electrical conductivity while remaining protected from interfering substances in biological fluids.

Hydrogel-based coatings represent another critical category, offering superior water retention properties that mimic biological tissues. These coatings enhance the sensor-skin interface, reducing motion artifacts and improving signal quality during physical activity. Recent innovations in this space include stimuli-responsive hydrogels that can adapt to environmental changes, such as pH or temperature fluctuations, enabling more accurate biosensing in variable conditions.

Nanocomposite coatings have emerged as a promising frontier, incorporating nanomaterials like graphene, carbon nanotubes, and metal nanoparticles into polymer matrices. These composites offer enhanced electrical conductivity, mechanical strength, and antimicrobial properties. For instance, silver nanoparticle-infused coatings provide both electrical conductivity and antimicrobial protection, addressing multiple functional requirements simultaneously.

Despite these advancements, significant technical barriers persist. Adhesion failure between coating layers and substrate materials remains a primary challenge, particularly under repeated mechanical stress from body movement. This often results in delamination and subsequent sensor failure, limiting long-term reliability. Current adhesion promotion techniques often involve chemical treatments that may compromise biocompatibility or introduce additional manufacturing complexity.

Biofouling presents another substantial obstacle, as protein adsorption and cellular attachment on sensor surfaces can progressively degrade signal quality. While hydrophobic and zwitterionic coatings show promise in reducing biofouling, complete prevention remains elusive, especially for continuous long-term monitoring applications exceeding several days.

Manufacturing scalability poses additional challenges, particularly for multi-layer coating systems requiring precise thickness control. Current deposition methods like dip-coating and spin-coating often struggle with reproducibility at scale, while more advanced techniques such as chemical vapor deposition require specialized equipment and significant capital investment.

Balancing conflicting requirements represents perhaps the most fundamental barrier. Coatings must simultaneously provide barrier properties against environmental factors while allowing selective permeability to target analytes. This paradoxical requirement becomes especially challenging for electrochemical sensors that must maintain electrical conductivity while remaining protected from interfering substances in biological fluids.

Mainstream Coating Solutions for Biosensor Enhancement

01 Biocompatible coatings for wearable biosensors

Biocompatible coatings are essential for wearable biosensors to ensure compatibility with human skin and tissues. These coatings prevent adverse reactions while maintaining sensor functionality. Materials such as hydrogels and polymers with specific biocompatible properties are used to create a barrier between the electronic components and the body, reducing irritation and improving user comfort during extended wear periods. These coatings also help in maintaining stable sensor-skin interface for accurate measurements.- Biocompatible coatings for wearable biosensors: Biocompatible coatings are essential for wearable biosensors to ensure compatibility with the human body and reduce adverse reactions. These coatings typically consist of materials that are non-toxic, non-irritating, and capable of maintaining functionality while in contact with skin or bodily fluids. Biocompatible polymers and hydrogels are commonly used as they provide a barrier between the electronic components and the body while allowing for the transmission of biological signals. These coatings also help in improving user comfort during prolonged wear.

- Moisture-resistant and waterproof coatings: Moisture-resistant and waterproof coatings are crucial for protecting the electronic components of wearable biosensors from sweat, water, and other liquids. These coatings typically consist of hydrophobic materials that repel water while maintaining the functionality of the sensor. Silicone-based polymers, fluoropolymers, and specialized epoxy resins are commonly used for this purpose. The coatings must be thin enough to not interfere with sensor performance while providing adequate protection against moisture ingress, which could otherwise lead to short circuits and device failure.

- Flexible and stretchable protective coatings: Flexible and stretchable coatings are designed to accommodate the natural movement of the body while maintaining sensor functionality. These coatings typically utilize elastomeric materials that can bend, twist, and stretch without cracking or delaminating from the sensor surface. Polyurethane, silicone elastomers, and specialized composite materials are commonly employed to achieve the desired flexibility. These coatings must maintain their protective properties while undergoing repeated deformation, ensuring the longevity and reliability of wearable biosensors during daily activities and exercise.

- Anti-fouling and self-cleaning coatings: Anti-fouling and self-cleaning coatings prevent the accumulation of biological materials, such as proteins, cells, and bacteria, on the surface of wearable biosensors. These coatings typically incorporate materials with low surface energy or active antimicrobial agents that repel or destroy contaminants. Zwitterionic polymers, PEG-based materials, and nanostructured surfaces are commonly used to achieve anti-fouling properties. By minimizing biofouling, these coatings help maintain sensor accuracy and extend the operational lifetime of wearable biosensors without requiring frequent cleaning or replacement.

- Conductive and signal-enhancing coatings: Conductive and signal-enhancing coatings improve the electrical performance of wearable biosensors by facilitating better signal transmission between the sensor and the biological environment. These coatings typically incorporate conductive polymers, carbon nanomaterials, or metallic nanoparticles that enhance electrical conductivity while maintaining biocompatibility. The coatings can also include materials that selectively interact with target analytes, thereby improving sensor sensitivity and specificity. By optimizing the interface between the electronic components and biological systems, these coatings contribute to more accurate and reliable biosensor readings.

02 Protective coatings for environmental resistance

Protective coatings for wearable biosensors shield sensitive electronic components from environmental factors such as moisture, sweat, and physical damage. These coatings typically consist of water-resistant polymers or composite materials that maintain sensor functionality while providing durability. The coatings are designed to withstand daily wear and tear, extending the lifespan of the biosensor while ensuring consistent performance in various conditions including high humidity, temperature fluctuations, and exposure to bodily fluids.Expand Specific Solutions03 Conductive and functional coatings for signal enhancement

Specialized conductive coatings enhance signal transmission and detection capabilities in wearable biosensors. These coatings incorporate materials such as carbon nanotubes, metallic nanoparticles, or conductive polymers that improve electrical conductivity while maintaining flexibility. The functional layers facilitate better sensor-skin contact and signal acquisition, reducing noise and improving measurement accuracy. These coatings can be engineered to target specific biomarkers or physiological parameters, enhancing the overall sensitivity and specificity of the biosensor.Expand Specific Solutions04 Flexible and stretchable coating technologies

Advanced flexible and stretchable coatings enable wearable biosensors to conform to body contours and movement. These coatings utilize elastomeric materials, specialized polymers, or composite structures that maintain functionality during bending, stretching, and compression. The mechanical properties of these coatings allow for comfortable wear while preserving the integrity of embedded electronic components and sensing elements. This flexibility is crucial for continuous monitoring applications where the sensor must adapt to body movements without detachment or performance degradation.Expand Specific Solutions05 Smart and responsive coating systems

Smart coating systems for wearable biosensors incorporate responsive materials that can adapt to changing conditions or provide additional functionality. These coatings may include stimuli-responsive polymers that change properties based on environmental factors, self-healing materials that repair minor damage, or coatings with controlled drug release capabilities. Some advanced coatings also integrate antimicrobial properties to prevent bacterial growth during extended wear periods, enhancing both safety and comfort for users while maintaining sensor performance.Expand Specific Solutions

Leading Companies in Wearable Biosensor Coatings

The wearable biosensor market is experiencing rapid growth, currently in its expansion phase with an estimated market size exceeding $15 billion and projected to grow at a CAGR of 25-30% through 2028. Coatings technology represents a critical competitive advantage in this evolving landscape. Leading players like Abbott Laboratories, Medtronic MiniMed, and Roche Diabetes Care are advancing biocompatible and functional coating technologies to enhance sensor longevity, accuracy, and user comfort. Tech giants including Apple and Samsung are leveraging their consumer electronics expertise to integrate sophisticated coating technologies for improved durability and signal quality. Academic-industry partnerships with institutions like California Institute of Technology and University of Southern California are accelerating innovation in nanomaterial coatings and biointerface engineering, pushing the boundaries of sensor functionality and biocompatibility.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced coating technologies for their wearable biosensors that focus on enhancing durability, accuracy, and user comfort. Their BioActive Sensor platform utilizes a multi-layered coating approach that protects optical and electrical sensors while optimizing signal acquisition. Samsung's proprietary coating includes a hydrophobic outer layer that repels moisture and sweat while maintaining close skin contact, essential for accurate heart rate and blood oxygen measurements. The company has implemented specialized anti-reflective coatings on their optical sensor arrays that reduce light scattering and improve signal-to-noise ratio, particularly important for darker skin tones where optical sensing traditionally faces challenges. Their electrode coatings incorporate conductive polymers with self-cleaning properties that maintain electrical conductivity despite prolonged skin contact. Samsung has also developed temperature-resistant coatings that maintain sensor performance across varying environmental conditions, addressing a common limitation in wearable biosensors. Their latest coating technology incorporates antimicrobial properties that reduce bacterial growth on sensor surfaces, addressing hygiene concerns associated with continuous wear devices.

Strengths: Comprehensive approach addressing multiple aspects of sensor performance including optical clarity, electrical conductivity, and biocompatibility. Coatings specifically optimized for diverse skin types and environmental conditions. Weaknesses: The complex multi-layer coating system may contribute to increased thickness of sensor modules, potentially affecting overall device comfort during extended wear.

F. Hoffmann-La Roche Ltd.

Technical Solution: Roche has developed advanced biocompatible coatings for continuous glucose monitoring biosensors that significantly enhance sensor longevity and accuracy. Their proprietary enzyme-stabilizing membrane technology incorporates specialized polymers that protect glucose oxidase enzymes from degradation while allowing selective glucose diffusion. This multi-layer coating approach includes an inner selective membrane that filters out interfering substances, a middle enzyme-containing layer with stabilizing compounds, and an outer biocompatible layer that reduces foreign body response. The coating technology employs hydrophilic polymers modified with specific functional groups to maintain enzyme activity in the subcutaneous environment for up to 14 days, representing a significant improvement over earlier generations that lasted only 3-5 days. Roche's coatings also incorporate anti-inflammatory agents that reduce tissue inflammation at the insertion site, improving measurement consistency.

Strengths: Superior enzyme stabilization technology extends sensor lifetime significantly beyond industry standards. The multi-layer approach effectively filters interferents while maintaining glucose sensitivity. Weaknesses: The complex manufacturing process for these specialized coatings may increase production costs and limit scalability for mass production.

Key Patents and Innovations in Biosensor Coating Materials

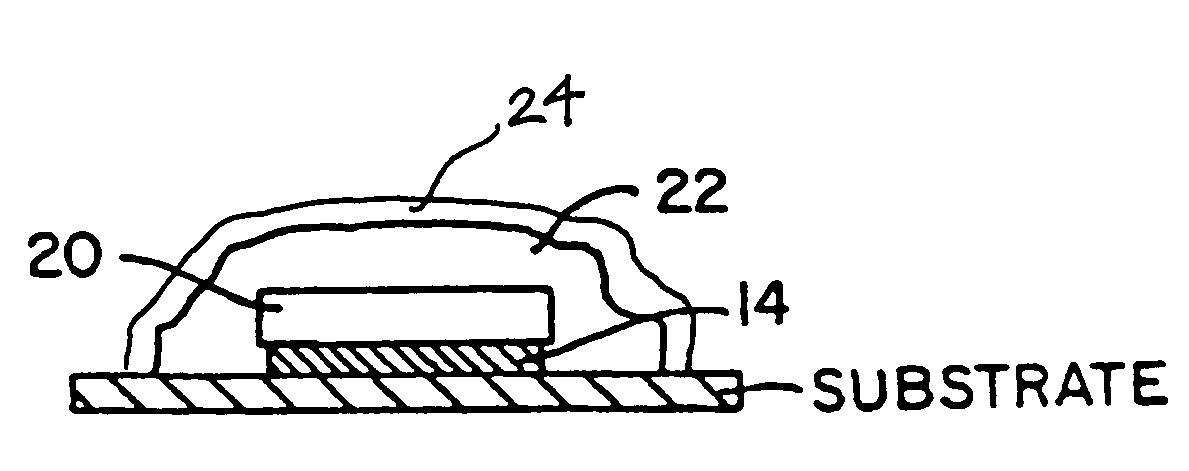

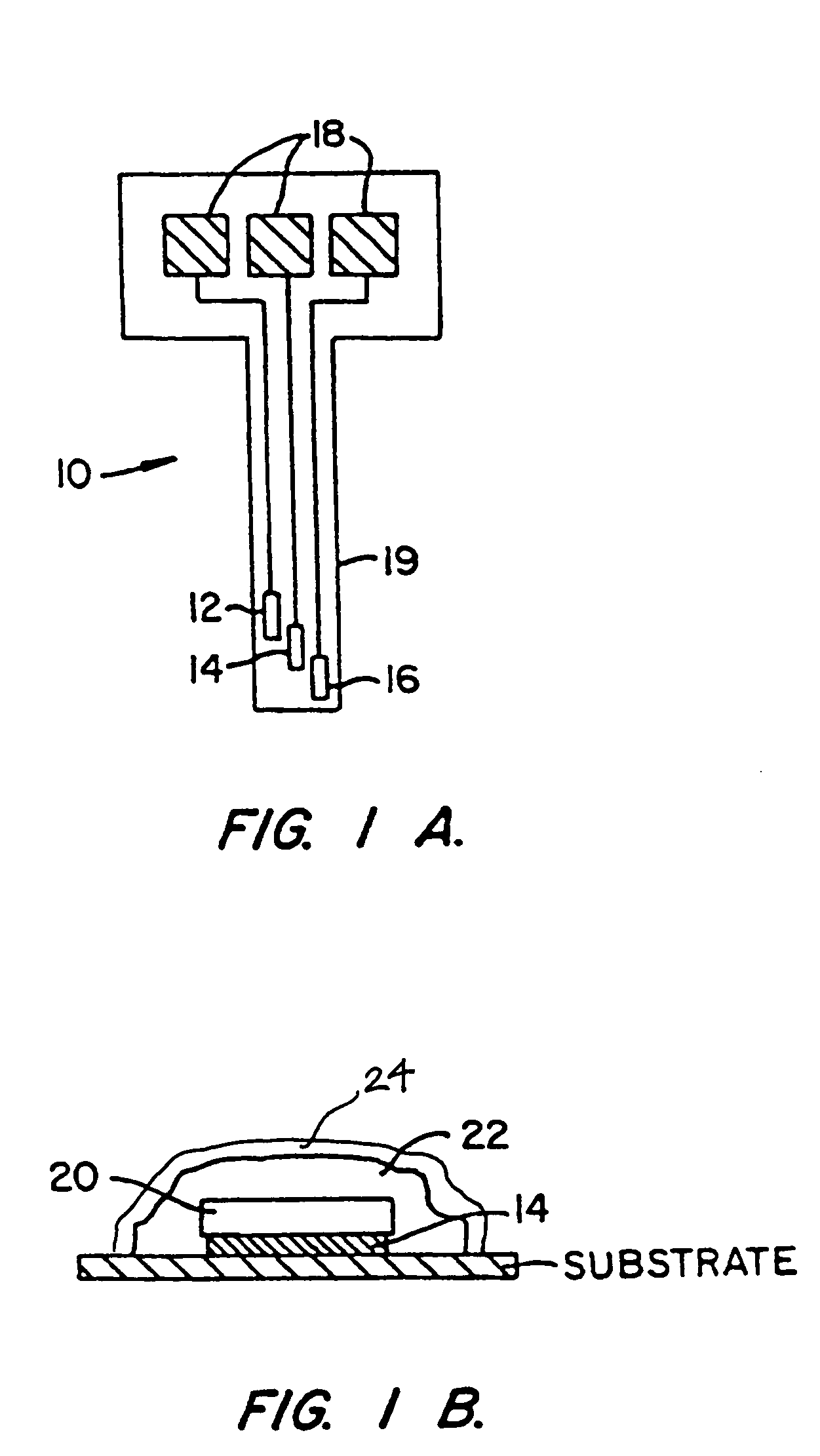

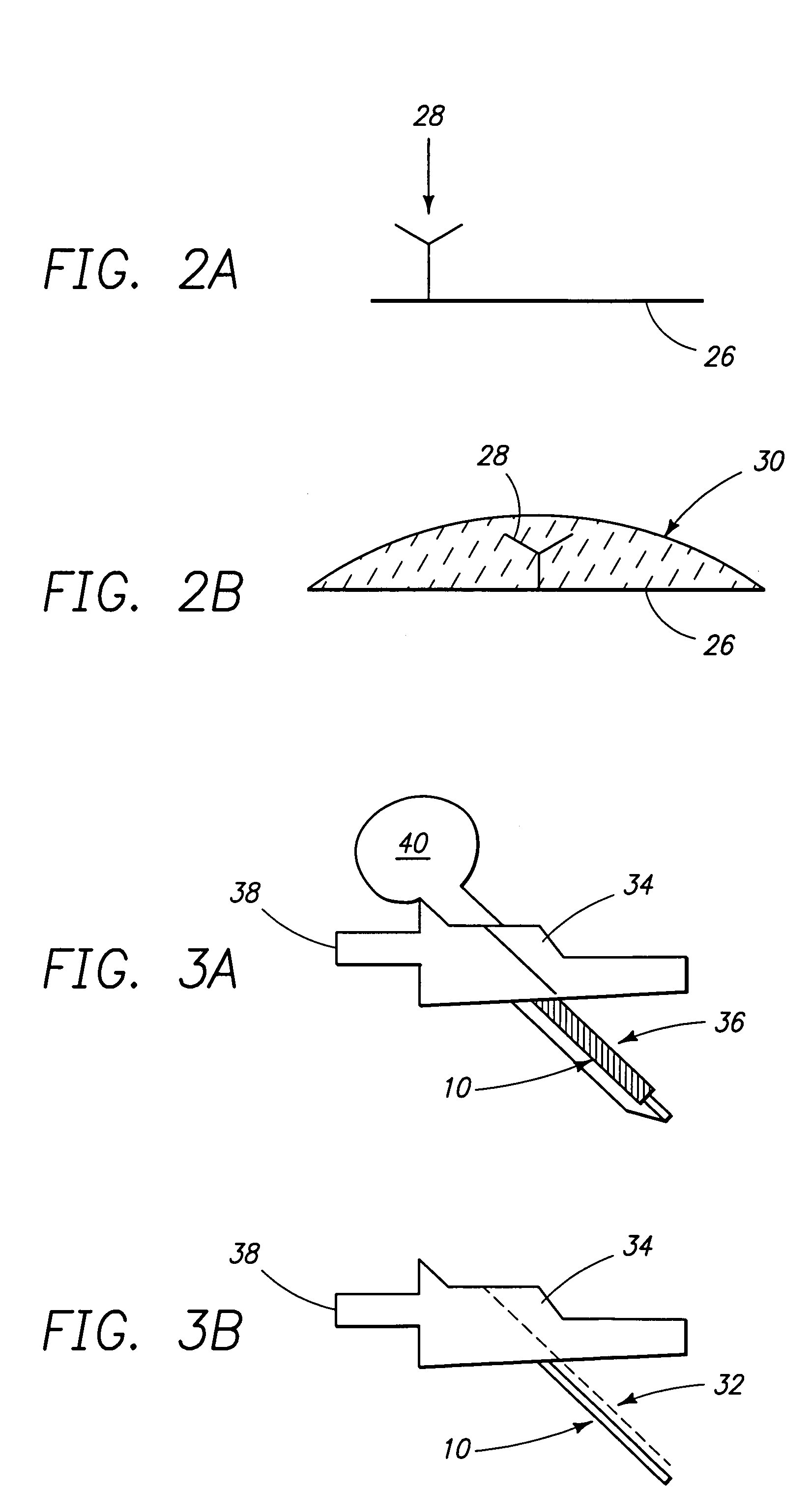

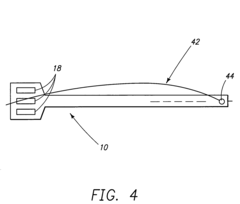

Anti-inflammatory biosensor for reduced biofouling and enhanced sensor performance

PatentInactiveUS7153265B2

Innovation

- A biosensor with an external surface coated with a hydrophilic polymer, such as PEO-containing polyurethane, and optionally a fiber modified to deliver an anti-inflammatory agent like dexamethasone, to minimize biofouling and inflammation, enhancing biocompatibility and sensor performance.

Biocompatibility coating for continuous analyte measurement

PatentActiveUS11925460B2

Innovation

- A biosensor with a biocompatibility coating comprising a polymer with —CO—NR1R2 side groups, where R1 and R2 are independently selected from —H and C1 to C6 alkyl, which reduces fouling and encapsulation, thereby enhancing the durability and accuracy of analyte measurement.

Biocompatibility and Safety Considerations

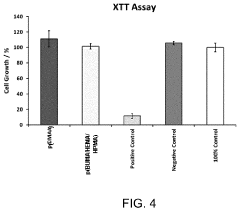

Biocompatibility represents a critical consideration in the development of coated wearable biosensors, as these devices maintain prolonged contact with human skin or other biological tissues. The interface between sensor materials and human physiology demands careful evaluation to prevent adverse reactions such as inflammation, irritation, or allergic responses. Coating materials must undergo rigorous biocompatibility testing according to ISO 10993 standards to ensure they do not release toxic compounds or trigger immune responses when in contact with biological systems.

Material selection for biosensor coatings requires balancing functionality with safety profiles. Commonly employed biocompatible coating materials include medical-grade silicones, polyurethanes, parylene variants, and certain hydrogels. These materials have demonstrated favorable tissue compatibility while maintaining the necessary protective and functional properties. Recent advances in biomimetic coatings that incorporate natural polymers like chitosan and alginate show promising biocompatibility profiles while enhancing sensor performance.

Long-term safety considerations extend beyond initial biocompatibility to include degradation behaviors of coating materials. Environmental factors such as moisture, temperature fluctuations, and mechanical stress can accelerate coating breakdown, potentially releasing particles or leachables that may cause delayed biological responses. Comprehensive stability testing under simulated use conditions has become standard practice to predict coating integrity throughout the intended product lifecycle.

Regulatory frameworks governing wearable biosensors have evolved to address the unique safety challenges of these devices. The FDA and European Medical Device Regulation have established specific guidelines for biocompatibility assessment of skin-contacting devices, with particular attention to cytotoxicity, sensitization, and irritation potential. Manufacturers must generate substantial safety data packages demonstrating both short and long-term biocompatibility before market approval.

Emerging research focuses on developing "stealth" coatings that minimize biological recognition and response while maintaining sensor functionality. These advanced coatings incorporate anti-fouling properties to prevent protein adsorption and subsequent inflammatory cascades. Zwitterionic polymers and PEG-based coatings represent promising approaches that reduce biofouling while preserving sensor performance and extending device longevity without compromising safety.

The integration of antimicrobial properties into biosensor coatings addresses another critical safety dimension. Prolonged skin contact creates favorable conditions for microbial colonization, potentially leading to infections or biofilm formation. Silver nanoparticles, quaternary ammonium compounds, and certain metal oxide coatings provide antimicrobial protection without compromising sensor function or introducing systemic toxicity risks.

Material selection for biosensor coatings requires balancing functionality with safety profiles. Commonly employed biocompatible coating materials include medical-grade silicones, polyurethanes, parylene variants, and certain hydrogels. These materials have demonstrated favorable tissue compatibility while maintaining the necessary protective and functional properties. Recent advances in biomimetic coatings that incorporate natural polymers like chitosan and alginate show promising biocompatibility profiles while enhancing sensor performance.

Long-term safety considerations extend beyond initial biocompatibility to include degradation behaviors of coating materials. Environmental factors such as moisture, temperature fluctuations, and mechanical stress can accelerate coating breakdown, potentially releasing particles or leachables that may cause delayed biological responses. Comprehensive stability testing under simulated use conditions has become standard practice to predict coating integrity throughout the intended product lifecycle.

Regulatory frameworks governing wearable biosensors have evolved to address the unique safety challenges of these devices. The FDA and European Medical Device Regulation have established specific guidelines for biocompatibility assessment of skin-contacting devices, with particular attention to cytotoxicity, sensitization, and irritation potential. Manufacturers must generate substantial safety data packages demonstrating both short and long-term biocompatibility before market approval.

Emerging research focuses on developing "stealth" coatings that minimize biological recognition and response while maintaining sensor functionality. These advanced coatings incorporate anti-fouling properties to prevent protein adsorption and subsequent inflammatory cascades. Zwitterionic polymers and PEG-based coatings represent promising approaches that reduce biofouling while preserving sensor performance and extending device longevity without compromising safety.

The integration of antimicrobial properties into biosensor coatings addresses another critical safety dimension. Prolonged skin contact creates favorable conditions for microbial colonization, potentially leading to infections or biofilm formation. Silver nanoparticles, quaternary ammonium compounds, and certain metal oxide coatings provide antimicrobial protection without compromising sensor function or introducing systemic toxicity risks.

Environmental Impact and Sustainability of Coating Materials

The environmental impact of coating materials used in wearable biosensors represents a critical consideration in the sustainable development of healthcare technology. Traditional coating materials often contain harmful chemicals such as phthalates, bisphenols, and certain heavy metals that can leach into the environment during manufacturing, use, or disposal phases. These substances may contaminate water systems, contribute to soil degradation, and potentially harm wildlife and ecosystems when biosensors reach end-of-life.

Recent advancements have focused on developing biodegradable and biocompatible coating alternatives that maintain sensor functionality while reducing environmental footprint. Materials such as cellulose derivatives, chitosan, alginate, and other naturally derived polymers show promising results as environmentally friendly coating options. These materials can degrade safely in natural environments without releasing toxic byproducts, addressing concerns about electronic waste accumulation from discarded wearable devices.

Life cycle assessment (LCA) studies of coating materials reveal significant variations in environmental impact across different formulations. Factors including raw material sourcing, energy requirements for synthesis, manufacturing waste generation, and end-of-life degradability all contribute to the overall sustainability profile. Research indicates that bio-based coatings typically demonstrate 30-60% lower carbon footprints compared to petroleum-derived alternatives, though performance characteristics may differ.

Water consumption represents another critical environmental consideration in coating production. Conventional coating processes may require substantial water volumes for synthesis, application, and cleaning stages. Innovative approaches such as solvent-free deposition techniques and water-based formulations have emerged to address this challenge, reducing water usage by up to 80% in some manufacturing scenarios.

Regulatory frameworks increasingly influence coating material selection for wearable biosensors. The European Union's Restriction of Hazardous Substances (RoHS) directive, Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, and similar policies worldwide have accelerated the transition toward more sustainable coating options. These regulations restrict the use of certain toxic substances and encourage manufacturers to develop environmentally responsible alternatives.

Circular economy principles are gradually being applied to wearable biosensor design, with coating materials playing a crucial role in enabling component recovery and recycling. Advanced coating technologies that facilitate easy separation of electronic components from substrates can improve material recovery rates. Some innovative approaches include thermally reversible adhesives and stimuli-responsive coatings that can be triggered to release components at end-of-life, enabling more efficient recycling processes.

Recent advancements have focused on developing biodegradable and biocompatible coating alternatives that maintain sensor functionality while reducing environmental footprint. Materials such as cellulose derivatives, chitosan, alginate, and other naturally derived polymers show promising results as environmentally friendly coating options. These materials can degrade safely in natural environments without releasing toxic byproducts, addressing concerns about electronic waste accumulation from discarded wearable devices.

Life cycle assessment (LCA) studies of coating materials reveal significant variations in environmental impact across different formulations. Factors including raw material sourcing, energy requirements for synthesis, manufacturing waste generation, and end-of-life degradability all contribute to the overall sustainability profile. Research indicates that bio-based coatings typically demonstrate 30-60% lower carbon footprints compared to petroleum-derived alternatives, though performance characteristics may differ.

Water consumption represents another critical environmental consideration in coating production. Conventional coating processes may require substantial water volumes for synthesis, application, and cleaning stages. Innovative approaches such as solvent-free deposition techniques and water-based formulations have emerged to address this challenge, reducing water usage by up to 80% in some manufacturing scenarios.

Regulatory frameworks increasingly influence coating material selection for wearable biosensors. The European Union's Restriction of Hazardous Substances (RoHS) directive, Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, and similar policies worldwide have accelerated the transition toward more sustainable coating options. These regulations restrict the use of certain toxic substances and encourage manufacturers to develop environmentally responsible alternatives.

Circular economy principles are gradually being applied to wearable biosensor design, with coating materials playing a crucial role in enabling component recovery and recycling. Advanced coating technologies that facilitate easy separation of electronic components from substrates can improve material recovery rates. Some innovative approaches include thermally reversible adhesives and stimuli-responsive coatings that can be triggered to release components at end-of-life, enabling more efficient recycling processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!