Wearable Biosensors: Electrode Kinetics Across Applications

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wearable Biosensor Evolution and Objectives

Wearable biosensors have evolved significantly over the past few decades, transforming from bulky, limited-function devices to sophisticated, miniaturized systems capable of continuous health monitoring. The journey began in the 1960s with the development of the first wearable cardiac monitors, which, while revolutionary, were cumbersome and offered limited functionality. By the 1990s, advancements in microelectronics enabled more compact designs, though electrode technology remained relatively primitive.

The early 2000s marked a turning point with the introduction of flexible electronics and improved electrode materials, allowing for better skin contact and signal quality. This period saw the emergence of the first commercially viable continuous glucose monitors, representing a significant milestone in wearable biosensor technology. The electrode kinetics—the electrochemical reactions occurring at the electrode-analyte interface—became a focal point for research as scientists recognized its critical role in sensor performance.

From 2010 onwards, wearable biosensors experienced exponential growth, driven by miniaturization, wireless connectivity, and enhanced electrode designs. The development of nanomaterial-based electrodes significantly improved sensitivity and specificity, enabling detection of biomarkers at previously unattainable concentrations. Concurrently, advances in flexible substrates allowed sensors to conform to the body's contours, improving comfort and signal stability.

Today's wearable biosensors incorporate sophisticated electrode technologies that address previous limitations in selectivity, stability, and biocompatibility. Modern electrodes utilize nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles to enhance electron transfer kinetics and improve detection limits. Additionally, surface modification techniques have been developed to reduce biofouling and extend sensor lifetime in biological environments.

The primary objectives in current wearable biosensor research center on optimizing electrode kinetics across diverse applications. These include achieving faster response times, enhancing selectivity in complex biological matrices, improving long-term stability, and reducing power consumption. Researchers aim to develop electrodes capable of maintaining consistent performance despite variations in skin properties, environmental conditions, and physiological states.

Looking forward, the field is moving toward multimodal sensing platforms that integrate multiple electrode types to monitor various biomarkers simultaneously. There is also growing interest in self-calibrating electrodes that can adapt to changing physiological conditions without user intervention. The ultimate goal is to develop "invisible" biosensors with seamless integration into daily life, providing continuous, accurate health monitoring without user burden while maintaining optimal electrode kinetics across all applications.

The early 2000s marked a turning point with the introduction of flexible electronics and improved electrode materials, allowing for better skin contact and signal quality. This period saw the emergence of the first commercially viable continuous glucose monitors, representing a significant milestone in wearable biosensor technology. The electrode kinetics—the electrochemical reactions occurring at the electrode-analyte interface—became a focal point for research as scientists recognized its critical role in sensor performance.

From 2010 onwards, wearable biosensors experienced exponential growth, driven by miniaturization, wireless connectivity, and enhanced electrode designs. The development of nanomaterial-based electrodes significantly improved sensitivity and specificity, enabling detection of biomarkers at previously unattainable concentrations. Concurrently, advances in flexible substrates allowed sensors to conform to the body's contours, improving comfort and signal stability.

Today's wearable biosensors incorporate sophisticated electrode technologies that address previous limitations in selectivity, stability, and biocompatibility. Modern electrodes utilize nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles to enhance electron transfer kinetics and improve detection limits. Additionally, surface modification techniques have been developed to reduce biofouling and extend sensor lifetime in biological environments.

The primary objectives in current wearable biosensor research center on optimizing electrode kinetics across diverse applications. These include achieving faster response times, enhancing selectivity in complex biological matrices, improving long-term stability, and reducing power consumption. Researchers aim to develop electrodes capable of maintaining consistent performance despite variations in skin properties, environmental conditions, and physiological states.

Looking forward, the field is moving toward multimodal sensing platforms that integrate multiple electrode types to monitor various biomarkers simultaneously. There is also growing interest in self-calibrating electrodes that can adapt to changing physiological conditions without user intervention. The ultimate goal is to develop "invisible" biosensors with seamless integration into daily life, providing continuous, accurate health monitoring without user burden while maintaining optimal electrode kinetics across all applications.

Market Analysis for Wearable Biosensor Applications

The global wearable biosensor market is experiencing robust growth, driven by increasing health consciousness, rising prevalence of chronic diseases, and technological advancements in electrode kinetics. Current market valuations place the wearable biosensor sector at approximately 13.2 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 18.7% through 2030, potentially reaching 42.3 billion USD.

Consumer healthcare represents the largest application segment, accounting for nearly 40% of the market share. This dominance stems from growing adoption of fitness trackers and smartwatches incorporating advanced biosensing capabilities. The medical diagnostics segment follows closely, showing the fastest growth rate at 21.3% annually, fueled by increasing integration of biosensors in remote patient monitoring systems.

Regionally, North America leads the market with approximately 38% share, attributed to advanced healthcare infrastructure and high technology adoption rates. However, Asia-Pacific is emerging as the fastest-growing region with a 22.5% CAGR, driven by increasing healthcare expenditure in countries like China and India, alongside growing manufacturing capabilities for biosensor components.

Electrode kinetics technology specifically has created distinct market segments based on application requirements. Continuous glucose monitoring represents the largest single application, valued at 4.8 billion USD, with electrode kinetics innovations enabling longer sensor lifespans and improved accuracy. Cardiovascular monitoring follows at 3.7 billion USD, where advances in electrode materials have significantly enhanced signal quality and reduced motion artifacts.

Market demand is increasingly shifting toward multi-parameter biosensors, with 68% of industry stakeholders identifying this as a primary growth vector. Electrochemical sensors dominate with 45% market share, followed by optical sensors at 28%, though electrochemical solutions maintain advantages in cost-effectiveness and miniaturization potential.

Key market drivers include aging populations in developed economies, with over 20% of consumers aged 65+ adopting wearable health monitoring devices, representing a 15% year-over-year increase. Additionally, the COVID-19 pandemic accelerated market growth by 24% in 2020-2021 by heightening health monitoring awareness and normalizing remote healthcare solutions.

Challenges facing market expansion include regulatory hurdles, with approval timelines averaging 18 months for novel biosensor technologies, and consumer concerns regarding data privacy, with surveys indicating 72% of users express significant concerns about health data security.

Consumer healthcare represents the largest application segment, accounting for nearly 40% of the market share. This dominance stems from growing adoption of fitness trackers and smartwatches incorporating advanced biosensing capabilities. The medical diagnostics segment follows closely, showing the fastest growth rate at 21.3% annually, fueled by increasing integration of biosensors in remote patient monitoring systems.

Regionally, North America leads the market with approximately 38% share, attributed to advanced healthcare infrastructure and high technology adoption rates. However, Asia-Pacific is emerging as the fastest-growing region with a 22.5% CAGR, driven by increasing healthcare expenditure in countries like China and India, alongside growing manufacturing capabilities for biosensor components.

Electrode kinetics technology specifically has created distinct market segments based on application requirements. Continuous glucose monitoring represents the largest single application, valued at 4.8 billion USD, with electrode kinetics innovations enabling longer sensor lifespans and improved accuracy. Cardiovascular monitoring follows at 3.7 billion USD, where advances in electrode materials have significantly enhanced signal quality and reduced motion artifacts.

Market demand is increasingly shifting toward multi-parameter biosensors, with 68% of industry stakeholders identifying this as a primary growth vector. Electrochemical sensors dominate with 45% market share, followed by optical sensors at 28%, though electrochemical solutions maintain advantages in cost-effectiveness and miniaturization potential.

Key market drivers include aging populations in developed economies, with over 20% of consumers aged 65+ adopting wearable health monitoring devices, representing a 15% year-over-year increase. Additionally, the COVID-19 pandemic accelerated market growth by 24% in 2020-2021 by heightening health monitoring awareness and normalizing remote healthcare solutions.

Challenges facing market expansion include regulatory hurdles, with approval timelines averaging 18 months for novel biosensor technologies, and consumer concerns regarding data privacy, with surveys indicating 72% of users express significant concerns about health data security.

Electrode Kinetics Challenges in Wearable Biosensors

Electrode kinetics in wearable biosensors presents a complex set of challenges that significantly impact device performance, reliability, and user experience. The fundamental electrochemical processes occurring at the electrode-electrolyte interface are particularly problematic in wearable contexts due to the dynamic nature of the human body environment. These kinetic processes include electron transfer rates, adsorption/desorption phenomena, and diffusion limitations that collectively determine sensor response time and signal quality.

One primary challenge is maintaining stable electrode-skin contact under various physical activities. Movement artifacts create inconsistent electrode kinetics, resulting in signal noise and false readings. This is particularly evident in applications requiring continuous monitoring such as cardiac rhythm assessment or glucose monitoring, where even minor disruptions in electrode kinetics can lead to clinically significant measurement errors.

The biological interface presents additional complications for electrode kinetics. Skin perspiration, varying hydration levels, and the presence of oils and dead skin cells create a constantly changing electrochemical environment. These factors alter the effective electrode area, impedance characteristics, and charge transfer resistance, making consistent measurements difficult to achieve over extended periods.

Material degradation represents another significant hurdle. Electrodes in wearable biosensors are subject to mechanical stress, chemical interactions with bodily fluids, and environmental factors that progressively alter their surface properties. This degradation directly impacts electrode kinetics by changing catalytic activity, effective surface area, and charge transfer capabilities, ultimately leading to sensor drift and decreased sensitivity over time.

Miniaturization requirements further complicate electrode kinetics optimization. As wearable devices become increasingly compact and unobtrusive, electrode dimensions must decrease accordingly. This reduction in size fundamentally alters the electrochemical behavior due to increased influence of edge effects, higher current densities, and modified mass transport dynamics at the microscale.

Power constraints in wearable systems also affect electrode design and operation. Lower operating voltages can limit the driving force for electrochemical reactions, potentially pushing electrode processes into kinetically limited regimes rather than diffusion-limited ones. This shift fundamentally changes sensor behavior and requires careful consideration of electrode materials and surface modifications.

Biocompatibility requirements further restrict material selection for electrodes, often forcing compromises between optimal electrochemical performance and biological safety. Materials with excellent electron transfer kinetics may cause skin irritation or immune responses, necessitating protective coatings that can impede ideal electrode kinetics.

These multifaceted challenges in electrode kinetics represent a critical bottleneck in advancing wearable biosensor technology, requiring interdisciplinary approaches spanning electrochemistry, materials science, biomedical engineering, and human factors research to develop effective solutions.

One primary challenge is maintaining stable electrode-skin contact under various physical activities. Movement artifacts create inconsistent electrode kinetics, resulting in signal noise and false readings. This is particularly evident in applications requiring continuous monitoring such as cardiac rhythm assessment or glucose monitoring, where even minor disruptions in electrode kinetics can lead to clinically significant measurement errors.

The biological interface presents additional complications for electrode kinetics. Skin perspiration, varying hydration levels, and the presence of oils and dead skin cells create a constantly changing electrochemical environment. These factors alter the effective electrode area, impedance characteristics, and charge transfer resistance, making consistent measurements difficult to achieve over extended periods.

Material degradation represents another significant hurdle. Electrodes in wearable biosensors are subject to mechanical stress, chemical interactions with bodily fluids, and environmental factors that progressively alter their surface properties. This degradation directly impacts electrode kinetics by changing catalytic activity, effective surface area, and charge transfer capabilities, ultimately leading to sensor drift and decreased sensitivity over time.

Miniaturization requirements further complicate electrode kinetics optimization. As wearable devices become increasingly compact and unobtrusive, electrode dimensions must decrease accordingly. This reduction in size fundamentally alters the electrochemical behavior due to increased influence of edge effects, higher current densities, and modified mass transport dynamics at the microscale.

Power constraints in wearable systems also affect electrode design and operation. Lower operating voltages can limit the driving force for electrochemical reactions, potentially pushing electrode processes into kinetically limited regimes rather than diffusion-limited ones. This shift fundamentally changes sensor behavior and requires careful consideration of electrode materials and surface modifications.

Biocompatibility requirements further restrict material selection for electrodes, often forcing compromises between optimal electrochemical performance and biological safety. Materials with excellent electron transfer kinetics may cause skin irritation or immune responses, necessitating protective coatings that can impede ideal electrode kinetics.

These multifaceted challenges in electrode kinetics represent a critical bottleneck in advancing wearable biosensor technology, requiring interdisciplinary approaches spanning electrochemistry, materials science, biomedical engineering, and human factors research to develop effective solutions.

Current Electrode Kinetics Solutions for Wearable Applications

01 Electrode materials and surface modifications for wearable biosensors

Various electrode materials and surface modifications are employed in wearable biosensors to enhance electrode kinetics. These include nanomaterials, conductive polymers, and surface treatments that improve electron transfer rates and sensor sensitivity. Modifications can reduce electrode fouling, enhance biocompatibility, and maintain stable performance during continuous wear. These advancements enable more accurate and reliable detection of biomarkers in sweat, interstitial fluid, and other biological samples.- Electrode materials and surface modifications for enhanced kinetics: Various electrode materials and surface modifications are employed in wearable biosensors to enhance electrode kinetics. These include nanomaterials, conductive polymers, and surface treatments that increase the electroactive surface area and improve electron transfer rates. Such modifications can significantly enhance sensitivity, reduce response time, and improve the overall performance of electrochemical biosensors in wearable applications.

- Flexible and stretchable electrode designs for wearable applications: Specialized electrode designs that maintain electrical performance during body movement are crucial for wearable biosensors. These include serpentine patterns, mesh structures, and composite materials that combine conductivity with flexibility. Such designs ensure stable electrode-skin contact and consistent electrode kinetics despite mechanical deformation, making them suitable for continuous monitoring in dynamic environments.

- Signal processing and noise reduction techniques: Advanced signal processing algorithms and circuit designs are implemented to enhance electrode kinetic measurements in wearable biosensors. These techniques filter out motion artifacts, environmental interference, and biological noise, improving signal-to-noise ratios. Real-time data processing enables accurate interpretation of electrode kinetics even in challenging conditions, enhancing the reliability of wearable biosensor measurements.

- Sweat and interstitial fluid sensing electrode technologies: Specialized electrode technologies are developed for non-invasive biosensing through sweat and interstitial fluid. These electrodes are designed with specific materials and geometries to optimize kinetics for detecting biomarkers in these body fluids. Microfluidic channels, porous membranes, and selective coatings enhance sample collection and electrode-analyte interactions, improving the kinetic response and sensitivity of wearable biosensors.

- Miniaturized electrochemical systems for continuous monitoring: Miniaturized electrochemical systems integrate multiple electrode components into compact wearable formats. These systems incorporate reference, working, and counter electrodes with optimized kinetic properties for specific biomarkers. Advanced fabrication techniques enable the production of microscale electrode arrays that maintain excellent kinetic performance while reducing power consumption and size, making them ideal for long-term continuous monitoring applications.

02 Flexible and stretchable electrode designs for wearable applications

Innovative electrode designs focus on flexibility and stretchability to maintain consistent electrode kinetics during body movement. These designs incorporate serpentine patterns, mesh structures, and composite materials that can conform to skin contours while preserving electrical conductivity. Such electrodes minimize motion artifacts and maintain stable skin-electrode interfaces, which is crucial for accurate biosensing in dynamic environments. These advancements enable continuous monitoring during daily activities without compromising measurement accuracy.Expand Specific Solutions03 Real-time monitoring and analysis of electrode kinetic parameters

Advanced systems for real-time monitoring of electrode kinetic parameters enable continuous assessment of biosensor performance. These systems incorporate algorithms that analyze impedance, charge transfer resistance, and other electrochemical parameters to evaluate electrode condition and measurement reliability. Real-time analysis allows for automatic calibration, drift compensation, and early detection of electrode degradation, ensuring consistent measurement quality over extended periods of continuous wear.Expand Specific Solutions04 Miniaturized electrochemical systems for non-invasive biosensing

Miniaturized electrochemical systems integrate multiple electrode configurations into compact wearable devices for non-invasive biosensing. These systems optimize electrode kinetics through microfluidic sample handling, precise temperature control, and integrated reference electrodes. The miniaturization enables efficient collection and analysis of biological fluids like sweat or interstitial fluid while maintaining high sensitivity and specificity. These advancements make continuous health monitoring more practical and user-friendly for everyday use.Expand Specific Solutions05 Electrode stabilization techniques for long-term wearable monitoring

Specialized techniques for electrode stabilization extend the functional lifetime of wearable biosensors. These include protective coatings, anti-fouling strategies, and self-cleaning mechanisms that preserve electrode kinetics during prolonged wear. Advanced stabilization approaches incorporate redox mediators, enzyme immobilization techniques, and controlled-release systems that maintain consistent electrode performance over time. These innovations address challenges related to biofouling, pH variations, and electrode degradation in continuous monitoring applications.Expand Specific Solutions

Leading Companies and Research Institutions in Biosensor Development

The wearable biosensors market for electrode kinetics applications is in a growth phase, characterized by increasing adoption across healthcare, fitness, and consumer electronics sectors. The market size is expanding rapidly, projected to reach significant value due to rising health consciousness and remote monitoring needs. Technologically, the field shows varying maturity levels, with established players like Samsung Electronics, Apple, and Philips leading commercial applications, while research institutions such as MIT and University of California drive innovation in electrode materials and sensing mechanisms. Companies like Nitto Denko and Toray Industries contribute specialized materials expertise, while healthcare-focused firms including F. Hoffmann-La Roche and PHC Holdings develop clinical applications. The competitive landscape features both technology giants and specialized medical device manufacturers collaborating with academic institutions to overcome challenges in sensor accuracy, biocompatibility, and power efficiency.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an extensive wearable biosensor platform focusing on electrode kinetics optimization for their Galaxy Watch series and specialized health monitoring devices. Their technology employs biocompatible electrode materials with specialized surface treatments that enhance signal acquisition while minimizing skin irritation during prolonged wear. Samsung's approach incorporates multi-modal sensing electrodes that can simultaneously measure electrocardiogram (ECG), bioimpedance, and galvanic skin response through a single integrated sensor array. Their recent innovations include electrodes with microstructured surfaces that increase effective contact area while maintaining user comfort, significantly improving signal-to-noise ratios. Samsung has also developed proprietary algorithms that compensate for electrode polarization effects during continuous monitoring, maintaining measurement accuracy over extended periods. Additionally, their electrode designs incorporate environmental isolation features that maintain consistent performance across varying humidity and temperature conditions, addressing key challenges in real-world wearable applications.

Strengths: Extensive manufacturing capabilities enabling cost-effective mass production; strong vertical integration from materials to finished devices; robust consumer testing infrastructure; seamless integration with mobile ecosystem. Weaknesses: Less focus on clinical-grade applications compared to medical device specialists; consumer electronics development cycles sometimes prioritizing features over fundamental electrode performance; less published research compared to academic institutions.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered several breakthrough technologies in wearable biosensors focusing on electrode kinetics. Their research teams have developed conformable electrode arrays using nanomaterials that maintain consistent electrode-skin interfaces despite movement and environmental variations. MIT's approach incorporates graphene-based electrodes with engineered surface topographies that enhance signal transduction while minimizing contact impedance. Their recent innovations include "ionic-electronic" hybrid electrodes that leverage both electronic and ionic charge carriers to improve signal fidelity across the skin barrier. MIT researchers have also developed self-healing electrode materials that can recover from mechanical damage during extended wear, maintaining electrical performance over time. Additionally, they've created computational models that predict electrode behavior under various physiological conditions, enabling optimization of electrode geometries and materials for specific biosensing applications. Their work on "epidermal electronics" has produced ultra-thin, skin-like electrodes that conform perfectly to skin microstructures.

Strengths: Cutting-edge materials science expertise; strong interdisciplinary collaboration between engineering, biology, and computer science; access to advanced fabrication facilities; fundamental research approach that addresses core challenges. Weaknesses: Technologies often at early TRL levels requiring significant development for commercialization; focus on novel approaches sometimes at expense of practical implementation; less emphasis on mass manufacturing considerations.

Key Patents and Research in Electrode-Skin Interface Optimization

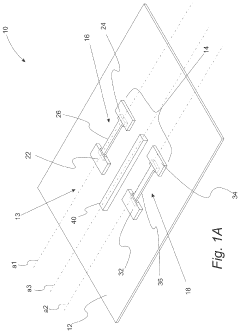

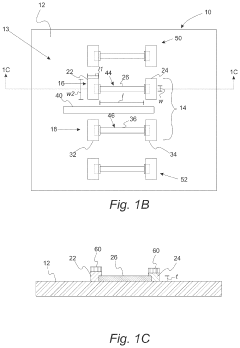

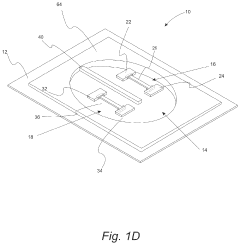

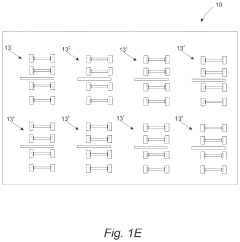

Wearable biosensors and applications thereof

PatentActiveUS11813057B2

Innovation

- Development of highly sensitive In2O3 nanoribbon transistor biosensors with integrated on-chip gold gate electrodes, deposited on flexible polyethylene terephthalate substrates, functionalized with glucose oxidase, chitosan, and single-walled carbon nanotubes, capable of detecting glucose concentrations between 10 nM to 1 mM in external body fluids without breaking the skin.

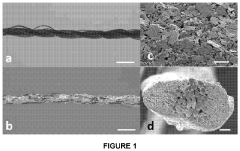

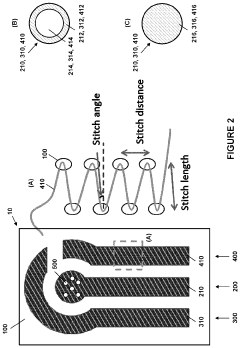

Embroidered electrochemical biosensors and related methods

PatentActiveUS11867655B2

Innovation

- Development of self-powered textile biosensors using a bio-micro-electromechanical system (bioMEMS) platform with embroidered electrochemical sensors integrated into flexible substrates, featuring working, counter, and reference electrodes made from conductive fibers, which can detect target analytes through enzyme or capture probes, enabling continuous health monitoring and point-of-care diagnostics.

Biocompatibility and Long-term Stability Considerations

Biocompatibility and long-term stability represent critical challenges in the development and deployment of wearable biosensors. The direct interface between electrode materials and human skin or tissue necessitates careful consideration of potential adverse reactions, including inflammation, allergic responses, and tissue damage. Current biocompatible materials employed in electrode fabrication include medical-grade silicone, polyimide, and various hydrogels that minimize immune responses while maintaining effective signal transduction.

The degradation of electrode performance over time presents significant obstacles to continuous monitoring applications. Studies indicate that most current-generation wearable biosensors experience a 15-30% reduction in signal quality after 72 hours of continuous wear, primarily due to biofouling processes where proteins and cellular debris accumulate on electrode surfaces. This degradation affects both the sensitivity and specificity of measurements, particularly in sweat-based glucose monitoring and electrocardiogram (ECG) applications.

Material innovations addressing these challenges include self-cleaning electrode surfaces incorporating antimicrobial nanoparticles and hydrophobic coatings that resist protein adsorption. Recent developments in "living electrodes" utilizing conducting polymers with integrated anti-fouling mechanisms show promise, with preliminary data suggesting stability improvements of up to 300% compared to conventional electrodes under identical conditions.

The mechanical interface between rigid electronic components and soft biological tissues introduces additional stability concerns. Repeated movement, perspiration, and environmental factors contribute to electrode displacement and subsequent signal degradation. Advanced approaches utilizing stretchable electronics and conformal designs have demonstrated improved adherence, with recent serpentine-patterned electrodes maintaining positional stability through over 10,000 flexion cycles in laboratory testing.

Regulatory considerations further complicate the biocompatibility landscape, with ISO 10993 standards requiring comprehensive cytotoxicity, sensitization, and irritation testing for materials in prolonged skin contact. The FDA has recently proposed additional guidelines specifically addressing wearable biosensor materials, emphasizing the need for long-term safety data beyond traditional acute toxicity assessments.

Future directions in this field include the development of biodegradable electrode materials that maintain performance while eliminating concerns about long-term implantation effects, and "smart" interfaces that can adapt to changing biological conditions to maintain optimal electrode kinetics despite tissue changes or inflammatory responses.

The degradation of electrode performance over time presents significant obstacles to continuous monitoring applications. Studies indicate that most current-generation wearable biosensors experience a 15-30% reduction in signal quality after 72 hours of continuous wear, primarily due to biofouling processes where proteins and cellular debris accumulate on electrode surfaces. This degradation affects both the sensitivity and specificity of measurements, particularly in sweat-based glucose monitoring and electrocardiogram (ECG) applications.

Material innovations addressing these challenges include self-cleaning electrode surfaces incorporating antimicrobial nanoparticles and hydrophobic coatings that resist protein adsorption. Recent developments in "living electrodes" utilizing conducting polymers with integrated anti-fouling mechanisms show promise, with preliminary data suggesting stability improvements of up to 300% compared to conventional electrodes under identical conditions.

The mechanical interface between rigid electronic components and soft biological tissues introduces additional stability concerns. Repeated movement, perspiration, and environmental factors contribute to electrode displacement and subsequent signal degradation. Advanced approaches utilizing stretchable electronics and conformal designs have demonstrated improved adherence, with recent serpentine-patterned electrodes maintaining positional stability through over 10,000 flexion cycles in laboratory testing.

Regulatory considerations further complicate the biocompatibility landscape, with ISO 10993 standards requiring comprehensive cytotoxicity, sensitization, and irritation testing for materials in prolonged skin contact. The FDA has recently proposed additional guidelines specifically addressing wearable biosensor materials, emphasizing the need for long-term safety data beyond traditional acute toxicity assessments.

Future directions in this field include the development of biodegradable electrode materials that maintain performance while eliminating concerns about long-term implantation effects, and "smart" interfaces that can adapt to changing biological conditions to maintain optimal electrode kinetics despite tissue changes or inflammatory responses.

Standardization and Testing Protocols for Electrode Performance

The standardization of electrode performance testing in wearable biosensors represents a critical challenge for the industry. Currently, there exists significant variability in how manufacturers evaluate and report electrode characteristics, making direct comparisons between different biosensor systems problematic. This inconsistency hampers both research advancement and clinical adoption of wearable biosensing technologies.

A comprehensive standardization framework must address multiple performance parameters. Electrode-skin interface impedance measurements should follow consistent protocols specifying frequency ranges (typically 0.1Hz to 100kHz), contact pressure conditions, and environmental parameters such as temperature and humidity. These standardized measurements would enable meaningful cross-platform comparisons of signal quality and noise characteristics.

Signal-to-noise ratio (SNR) evaluation protocols require particular attention, as they directly impact biosensor reliability in real-world applications. Standardized testing should include defined motion artifacts simulation procedures, environmental interference testing, and long-term stability assessments under controlled conditions. The IEEE P2650 working group has made progress in this direction, though broader industry adoption remains limited.

Electrode material characterization represents another critical area requiring standardization. Testing protocols should evaluate biocompatibility according to ISO 10993 standards, while also addressing electrochemical stability through accelerated aging tests. Standardized protocols for measuring charge transfer capacity and faradaic versus non-faradaic behavior would significantly advance electrode material science for wearable applications.

Mechanical testing standards must address adhesion strength, flexibility, and durability under various conditions. This includes standardized protocols for measuring electrode performance during stretching, bending, and after repeated application/removal cycles. Such mechanical testing is particularly important for long-term monitoring applications where electrode degradation can significantly impact data quality.

Calibration procedures represent perhaps the most urgent standardization need. Establishing reference standards for common biosignals (ECG, EMG, EEG) would enable cross-validation between different electrode systems. This should include standardized phantom models that simulate tissue electrical properties and physiological signal characteristics across diverse demographic groups.

Implementation of these standardized testing protocols would accelerate innovation by providing clear benchmarks for performance evaluation. Additionally, regulatory bodies increasingly require standardized performance metrics for approval processes, making this standardization effort not merely academic but essential for commercial viability in the expanding wearable biosensor market.

A comprehensive standardization framework must address multiple performance parameters. Electrode-skin interface impedance measurements should follow consistent protocols specifying frequency ranges (typically 0.1Hz to 100kHz), contact pressure conditions, and environmental parameters such as temperature and humidity. These standardized measurements would enable meaningful cross-platform comparisons of signal quality and noise characteristics.

Signal-to-noise ratio (SNR) evaluation protocols require particular attention, as they directly impact biosensor reliability in real-world applications. Standardized testing should include defined motion artifacts simulation procedures, environmental interference testing, and long-term stability assessments under controlled conditions. The IEEE P2650 working group has made progress in this direction, though broader industry adoption remains limited.

Electrode material characterization represents another critical area requiring standardization. Testing protocols should evaluate biocompatibility according to ISO 10993 standards, while also addressing electrochemical stability through accelerated aging tests. Standardized protocols for measuring charge transfer capacity and faradaic versus non-faradaic behavior would significantly advance electrode material science for wearable applications.

Mechanical testing standards must address adhesion strength, flexibility, and durability under various conditions. This includes standardized protocols for measuring electrode performance during stretching, bending, and after repeated application/removal cycles. Such mechanical testing is particularly important for long-term monitoring applications where electrode degradation can significantly impact data quality.

Calibration procedures represent perhaps the most urgent standardization need. Establishing reference standards for common biosignals (ECG, EMG, EEG) would enable cross-validation between different electrode systems. This should include standardized phantom models that simulate tissue electrical properties and physiological signal characteristics across diverse demographic groups.

Implementation of these standardized testing protocols would accelerate innovation by providing clear benchmarks for performance evaluation. Additionally, regulatory bodies increasingly require standardized performance metrics for approval processes, making this standardization effort not merely academic but essential for commercial viability in the expanding wearable biosensor market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!