Exploring Polymer Innovations in Wearable Biosensor Design

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Biosensor Technology Background and Objectives

Polymer-based biosensors have evolved significantly over the past three decades, transforming from simple laboratory tools to sophisticated wearable health monitoring devices. The integration of polymers in biosensor technology began in the early 1990s with rudimentary applications in glucose monitoring systems. Since then, the field has witnessed exponential growth, particularly in the last decade, driven by advancements in material science, nanotechnology, and increasing demand for personalized healthcare solutions.

The technological trajectory of polymer biosensors has been characterized by continuous improvements in sensitivity, selectivity, flexibility, and biocompatibility. Early polymer biosensors suffered from limited detection capabilities and poor durability in biological environments. However, recent innovations in conductive polymers, hydrogels, and polymer nanocomposites have addressed these limitations, enabling real-time, continuous monitoring of various biomarkers with unprecedented precision.

Current research focuses on developing multifunctional polymer platforms that can simultaneously detect multiple analytes while maintaining comfort and reliability for extended wear. The convergence of polymer science with microelectronics and wireless communication technologies has further accelerated the development of integrated wearable biosensing systems that can transmit health data to smartphones and cloud-based platforms for analysis and interpretation.

The primary objective of polymer innovation in wearable biosensor design is to create next-generation devices that combine high analytical performance with user-centric features such as comfort, durability, and aesthetic appeal. Specifically, researchers aim to develop polymer materials that can withstand mechanical deformation, resist biofouling, and maintain stable sensor performance under various environmental conditions while remaining biocompatible and causing minimal skin irritation.

Another critical goal is to enhance the sustainability of wearable biosensors through the development of biodegradable and recyclable polymer materials that reduce environmental impact without compromising device performance. This aligns with growing consumer demand for eco-friendly healthcare solutions and regulatory pressures for sustainable medical devices.

From a manufacturing perspective, the industry seeks to establish scalable production methods for polymer-based biosensors that can reduce costs while maintaining quality and performance standards. This includes exploring advanced fabrication techniques such as 3D printing, roll-to-roll processing, and microfluidic patterning that enable mass production of customizable wearable devices.

The ultimate technological objective remains the seamless integration of polymer biosensors into everyday life, creating unobtrusive health monitoring systems that can provide continuous, accurate data while adapting to individual user needs and preferences. This vision drives current research efforts and shapes the future trajectory of polymer innovations in wearable biosensor design.

The technological trajectory of polymer biosensors has been characterized by continuous improvements in sensitivity, selectivity, flexibility, and biocompatibility. Early polymer biosensors suffered from limited detection capabilities and poor durability in biological environments. However, recent innovations in conductive polymers, hydrogels, and polymer nanocomposites have addressed these limitations, enabling real-time, continuous monitoring of various biomarkers with unprecedented precision.

Current research focuses on developing multifunctional polymer platforms that can simultaneously detect multiple analytes while maintaining comfort and reliability for extended wear. The convergence of polymer science with microelectronics and wireless communication technologies has further accelerated the development of integrated wearable biosensing systems that can transmit health data to smartphones and cloud-based platforms for analysis and interpretation.

The primary objective of polymer innovation in wearable biosensor design is to create next-generation devices that combine high analytical performance with user-centric features such as comfort, durability, and aesthetic appeal. Specifically, researchers aim to develop polymer materials that can withstand mechanical deformation, resist biofouling, and maintain stable sensor performance under various environmental conditions while remaining biocompatible and causing minimal skin irritation.

Another critical goal is to enhance the sustainability of wearable biosensors through the development of biodegradable and recyclable polymer materials that reduce environmental impact without compromising device performance. This aligns with growing consumer demand for eco-friendly healthcare solutions and regulatory pressures for sustainable medical devices.

From a manufacturing perspective, the industry seeks to establish scalable production methods for polymer-based biosensors that can reduce costs while maintaining quality and performance standards. This includes exploring advanced fabrication techniques such as 3D printing, roll-to-roll processing, and microfluidic patterning that enable mass production of customizable wearable devices.

The ultimate technological objective remains the seamless integration of polymer biosensors into everyday life, creating unobtrusive health monitoring systems that can provide continuous, accurate data while adapting to individual user needs and preferences. This vision drives current research efforts and shapes the future trajectory of polymer innovations in wearable biosensor design.

Market Analysis for Wearable Polymer Biosensors

The wearable biosensor market has experienced remarkable growth in recent years, driven by increasing health consciousness, technological advancements, and the rising prevalence of chronic diseases. The global wearable biosensor market was valued at approximately $13.2 billion in 2022 and is projected to reach $37.4 billion by 2028, growing at a CAGR of 19.2% during the forecast period.

Polymer-based biosensors represent a significant segment within this market due to their flexibility, biocompatibility, and cost-effectiveness. These attributes make them particularly suitable for continuous health monitoring applications. The polymer biosensor segment accounts for roughly 27% of the overall wearable biosensor market, with expectations to increase to 35% by 2027.

Consumer healthcare applications currently dominate the market, representing approximately 45% of total revenue. This includes fitness tracking, heart rate monitoring, and sleep analysis. However, medical applications are growing at a faster rate (23% CAGR) as regulatory barriers are gradually overcome and clinical validation improves.

Regionally, North America leads the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%). The Asia-Pacific region is expected to witness the highest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and the presence of major manufacturing hubs in countries like China and South Korea.

Key market drivers include the aging global population, increasing incidence of lifestyle diseases, growing demand for non-invasive monitoring solutions, and technological advancements in polymer science. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of remote health monitoring capabilities.

Challenges facing the market include concerns about data privacy and security, regulatory hurdles for medical-grade devices, and technical limitations such as sensor durability and power consumption. Additionally, market penetration in developing economies remains limited due to affordability issues and lack of awareness.

Consumer preferences are shifting toward multifunctional devices that can monitor multiple parameters simultaneously. There is also growing demand for real-time data analysis and actionable insights rather than just raw data collection. This trend is driving integration of advanced analytics and artificial intelligence into wearable biosensor systems.

The competitive landscape is characterized by both established medical device manufacturers and technology companies entering the space. Strategic partnerships between polymer manufacturers, sensor technology developers, and healthcare providers are becoming increasingly common to create comprehensive monitoring solutions.

Polymer-based biosensors represent a significant segment within this market due to their flexibility, biocompatibility, and cost-effectiveness. These attributes make them particularly suitable for continuous health monitoring applications. The polymer biosensor segment accounts for roughly 27% of the overall wearable biosensor market, with expectations to increase to 35% by 2027.

Consumer healthcare applications currently dominate the market, representing approximately 45% of total revenue. This includes fitness tracking, heart rate monitoring, and sleep analysis. However, medical applications are growing at a faster rate (23% CAGR) as regulatory barriers are gradually overcome and clinical validation improves.

Regionally, North America leads the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%). The Asia-Pacific region is expected to witness the highest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and the presence of major manufacturing hubs in countries like China and South Korea.

Key market drivers include the aging global population, increasing incidence of lifestyle diseases, growing demand for non-invasive monitoring solutions, and technological advancements in polymer science. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of remote health monitoring capabilities.

Challenges facing the market include concerns about data privacy and security, regulatory hurdles for medical-grade devices, and technical limitations such as sensor durability and power consumption. Additionally, market penetration in developing economies remains limited due to affordability issues and lack of awareness.

Consumer preferences are shifting toward multifunctional devices that can monitor multiple parameters simultaneously. There is also growing demand for real-time data analysis and actionable insights rather than just raw data collection. This trend is driving integration of advanced analytics and artificial intelligence into wearable biosensor systems.

The competitive landscape is characterized by both established medical device manufacturers and technology companies entering the space. Strategic partnerships between polymer manufacturers, sensor technology developers, and healthcare providers are becoming increasingly common to create comprehensive monitoring solutions.

Current Polymer Materials Challenges in Biosensing

Despite significant advancements in wearable biosensor technology, polymer materials continue to face substantial challenges that limit their widespread application and effectiveness. The primary obstacle remains achieving optimal biocompatibility while maintaining sensor functionality. Many polymers that offer excellent electrical properties may trigger inflammatory responses or protein fouling when in prolonged contact with biological tissues, compromising both sensor performance and user comfort.

Mechanical flexibility presents another critical challenge, as wearable biosensors must conform to complex body contours while withstanding repeated deformation during normal movement. Current polymer materials often exhibit performance degradation after extended flexing cycles, leading to reduced sensor lifespan and reliability. This trade-off between flexibility and durability continues to constrain design possibilities.

Stability in diverse physiological environments poses significant difficulties for polymer-based biosensors. Exposure to varying pH levels, ionic concentrations, and enzymatic activity can degrade polymer structures or alter their electrical properties. Additionally, temperature fluctuations and humidity variations encountered during normal wear conditions frequently compromise sensor accuracy and longevity.

Permeability control represents a sophisticated engineering challenge, as biosensors must selectively allow target analytes to reach sensing elements while excluding interfering substances. Current polymer membranes often lack sufficient selectivity, resulting in cross-sensitivity issues that diminish measurement accuracy. Furthermore, achieving consistent pore size distribution across manufacturing batches remains problematic.

Scalable manufacturing techniques for advanced polymer composites constitute another significant hurdle. Many promising laboratory-developed materials utilize complex synthesis procedures that prove difficult to scale for commercial production. Techniques like electrospinning, which create high-surface-area nanofiber structures ideal for sensing applications, face challenges in maintaining consistent fiber morphology during mass production.

Biodegradability concerns have emerged as environmental considerations gain prominence. Many high-performance polymers used in biosensors are not biodegradable, creating potential environmental hazards when devices reach end-of-life. Conversely, biodegradable polymers often lack the durability and stability required for long-term sensing applications, presenting a difficult engineering compromise.

Signal transduction efficiency remains suboptimal in many polymer-based sensing platforms. The interface between biological analytes and electronic components frequently suffers from signal attenuation or noise introduction. Enhancing the signal-to-noise ratio while maintaining other desirable polymer properties represents an ongoing materials science challenge that requires interdisciplinary approaches combining polymer chemistry, electronics, and bioengineering expertise.

Mechanical flexibility presents another critical challenge, as wearable biosensors must conform to complex body contours while withstanding repeated deformation during normal movement. Current polymer materials often exhibit performance degradation after extended flexing cycles, leading to reduced sensor lifespan and reliability. This trade-off between flexibility and durability continues to constrain design possibilities.

Stability in diverse physiological environments poses significant difficulties for polymer-based biosensors. Exposure to varying pH levels, ionic concentrations, and enzymatic activity can degrade polymer structures or alter their electrical properties. Additionally, temperature fluctuations and humidity variations encountered during normal wear conditions frequently compromise sensor accuracy and longevity.

Permeability control represents a sophisticated engineering challenge, as biosensors must selectively allow target analytes to reach sensing elements while excluding interfering substances. Current polymer membranes often lack sufficient selectivity, resulting in cross-sensitivity issues that diminish measurement accuracy. Furthermore, achieving consistent pore size distribution across manufacturing batches remains problematic.

Scalable manufacturing techniques for advanced polymer composites constitute another significant hurdle. Many promising laboratory-developed materials utilize complex synthesis procedures that prove difficult to scale for commercial production. Techniques like electrospinning, which create high-surface-area nanofiber structures ideal for sensing applications, face challenges in maintaining consistent fiber morphology during mass production.

Biodegradability concerns have emerged as environmental considerations gain prominence. Many high-performance polymers used in biosensors are not biodegradable, creating potential environmental hazards when devices reach end-of-life. Conversely, biodegradable polymers often lack the durability and stability required for long-term sensing applications, presenting a difficult engineering compromise.

Signal transduction efficiency remains suboptimal in many polymer-based sensing platforms. The interface between biological analytes and electronic components frequently suffers from signal attenuation or noise introduction. Enhancing the signal-to-noise ratio while maintaining other desirable polymer properties represents an ongoing materials science challenge that requires interdisciplinary approaches combining polymer chemistry, electronics, and bioengineering expertise.

Current Polymer Solutions for Wearable Biosensors

01 Polymer synthesis and polymerization methods

Various methods for synthesizing polymers including different polymerization techniques such as addition polymerization, condensation polymerization, and controlled radical polymerization. These methods allow for the creation of polymers with specific properties and structures tailored for different applications. The synthesis processes can be optimized to control molecular weight, distribution, and polymer architecture.- Polymer synthesis and polymerization methods: Various methods for synthesizing polymers including different polymerization techniques such as addition polymerization, condensation polymerization, and controlled radical polymerization. These methods allow for the creation of polymers with specific properties and characteristics by controlling the reaction conditions, catalysts, and monomers used in the process.

- Modified polymer compositions and copolymers: Development of modified polymer compositions and copolymers with enhanced properties. These include blends of different polymers, copolymers with specific monomer ratios, and polymers modified with functional groups to improve characteristics such as strength, flexibility, thermal stability, and chemical resistance for various industrial applications.

- Biodegradable and sustainable polymers: Innovations in biodegradable and environmentally friendly polymers derived from renewable resources. These polymers are designed to break down naturally in the environment, reducing waste and environmental impact. Research focuses on improving the mechanical properties and processability of these sustainable materials while maintaining their biodegradability.

- Polymer processing and manufacturing techniques: Advanced techniques for processing and manufacturing polymers into usable products. These include extrusion, injection molding, blow molding, and other methods to shape polymers into desired forms. Innovations in these processes focus on improving efficiency, reducing energy consumption, and enhancing the quality of the final polymer products.

- Specialty polymers for specific applications: Development of specialty polymers designed for specific industrial applications such as electronics, medicine, aerospace, and automotive industries. These polymers possess unique properties such as high temperature resistance, electrical conductivity, biocompatibility, or chemical resistance tailored to meet the demands of specialized applications.

02 Modified polymers with enhanced properties

Polymers can be modified through various techniques to enhance their properties such as thermal stability, mechanical strength, and chemical resistance. Modification methods include copolymerization, grafting, crosslinking, and the incorporation of functional groups. These modifications allow polymers to be tailored for specific applications where standard polymers would not meet performance requirements.Expand Specific Solutions03 Biodegradable and sustainable polymers

Development of biodegradable and environmentally friendly polymers derived from renewable resources. These polymers are designed to break down naturally in the environment, reducing waste and environmental impact. Research focuses on creating sustainable alternatives to petroleum-based polymers while maintaining comparable performance characteristics for various applications.Expand Specific Solutions04 Polymer blends and composites

Creation of polymer blends and composites by combining different polymers or incorporating fillers and reinforcing materials. These combinations can result in materials with superior properties compared to individual components, such as improved strength, durability, and thermal resistance. The synergistic effects of different components allow for customization of material properties for specific applications.Expand Specific Solutions05 Specialty polymers for industrial applications

Development of specialty polymers designed for specific industrial applications such as coatings, adhesives, electronics, and medical devices. These polymers possess unique properties such as conductivity, biocompatibility, or extreme temperature resistance. Research focuses on tailoring polymer structures at the molecular level to achieve desired performance characteristics for demanding applications.Expand Specific Solutions

Leading Companies in Polymer Biosensor Development

The wearable biosensor market is experiencing rapid growth in the polymer innovation sector, currently in an early expansion phase characterized by increasing research activity and commercial applications. The market size is projected to reach significant scale as healthcare monitoring trends accelerate, with polymer-based solutions offering advantages in flexibility and biocompatibility. Technical maturity varies across players, with academic institutions like MIT, University of South Florida, and Tsinghua University driving fundamental research, while companies including Nitto Denko, Opteev Technologies, and Ascensia Diabetes Care are advancing commercial applications. Research organizations such as CNRS and A*STAR are bridging the gap between academic innovation and industrial implementation, creating a competitive landscape where cross-sector collaboration is increasingly important for market advancement.

The Regents of the University of California

Technical Solution: The University of California has pioneered intrinsically stretchable polymer semiconductors for wearable biosensors that overcome the fundamental limitations of traditional rigid electronics. Their approach utilizes conjugated polymers with engineered molecular structures that maintain electrical performance even when stretched to twice their original length. The technology incorporates a unique nanoconfinement strategy where conducting polymers are embedded within elastomeric matrices, creating sensors that can withstand repeated mechanical deformation while maintaining stable electrical properties. UC researchers have developed a manufacturing process that enables direct printing of these polymer composites onto biodegradable substrates, addressing environmental concerns associated with electronic waste. Their recent innovations include self-healing polymer networks that can recover from mechanical damage, significantly extending sensor lifespan in real-world applications. The platform also features polymer-based microfluidic channels that can collect and analyze bodily fluids while maintaining a low profile and comfortable form factor. This integrated approach allows for continuous monitoring of multiple physiological parameters simultaneously.

Strengths: Exceptional mechanical properties with minimal performance degradation during stretching; environmentally friendly materials and manufacturing processes; self-healing capabilities extending operational lifespan; seamless integration of sensing and fluid handling components. Weaknesses: Higher initial research and development costs; challenges in scaling production to commercial levels; potential limitations in sensitivity compared to traditional rigid sensors; more complex calibration requirements due to dynamic mechanical environment.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed an innovative polymer-based wearable biosensor platform utilizing biodegradable polymers combined with nanomaterials. Their approach centers on polylactic acid (PLA) and polycaprolactone (PCL) blends modified with graphene oxide to create flexible, environmentally friendly sensors. A*STAR's technology incorporates a unique microstructured surface design that enhances skin contact while allowing breathability, significantly improving comfort during extended wear periods. The platform features a multilayer polymer architecture that separates sensing, transduction, and protection functions, optimizing performance while maintaining mechanical flexibility. Their sensors employ a proprietary encapsulation technique using UV-curable polymers that provides excellent barrier properties against environmental contaminants while remaining permeable to target analytes. Recent advancements include the integration of stimuli-responsive hydrogels that can modulate drug delivery based on detected biomarkers, creating a closed-loop monitoring and treatment system.

Strengths: Excellent biocompatibility and reduced environmental impact through biodegradable materials; superior moisture management properties; innovative manufacturing techniques allowing for complex sensor geometries; potential for integrated therapeutic capabilities. Weaknesses: Lower electrical conductivity compared to traditional materials requiring additional signal amplification; mechanical properties may degrade over time in biological environments; limited long-term stability data; higher initial production costs compared to conventional sensors.

Key Polymer Innovations and Patent Landscape

Polymer composites, methods of fabrication and uses thereof

PatentWO2021076054A1

Innovation

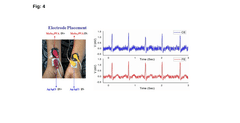

- A polymer composite comprising poly(ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS), waterborne polyurethane (WPU), and D-sorbitol is developed, which forms a self-adhesive and stretchable dry electrode with low skin-contact impedance, enabling high-quality ECG, EMG, and EEG signal acquisition on both dry and wet skin during body movement.

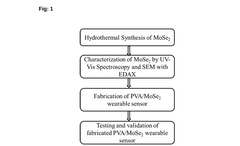

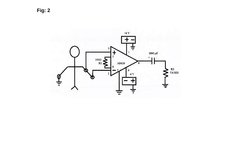

Preparation of polymer incorporated mose2 based wearable sensor and application thereof

PatentPendingIN202441050090A

Innovation

- A polymer-incorporated molybdenum diselenide (MoSe2) composite sensor with a nanoflower structure is developed using a casting method, leveraging MoSe2's water-resistant and biocompatible properties, along with polyvinyl alcohol (PVA), to create a flexible and safe wearable sensor for biosignal acquisition.

Biocompatibility and Safety Considerations

The integration of polymers in wearable biosensor design necessitates rigorous evaluation of biocompatibility and safety considerations. When materials interface directly with human skin or tissue for extended periods, they must not trigger adverse biological responses such as inflammation, irritation, or allergic reactions. Current polymer selection for biosensors prioritizes materials with established biocompatibility profiles, including medical-grade silicones, polyurethanes, and certain hydrogels that have demonstrated minimal immunogenic responses in clinical applications.

Regulatory frameworks worldwide impose stringent requirements on wearable biosensor materials. The FDA in the United States, the European Medicines Agency, and similar bodies in Asia have established comprehensive guidelines for biocompatibility testing according to ISO 10993 standards. These protocols typically include cytotoxicity assessments, sensitization studies, irritation tests, and systemic toxicity evaluations depending on the intended duration and nature of body contact.

Long-term exposure considerations present unique challenges in polymer-based biosensor development. Materials that perform adequately in short-term applications may exhibit degradation, leaching of compounds, or surface modifications when subjected to continuous wear conditions. Recent research has focused on developing polymers with enhanced stability against hydrolysis, oxidation, and enzymatic degradation to ensure consistent performance and safety throughout the device lifecycle.

The skin-polymer interface represents a critical zone requiring specialized attention. Factors such as moisture accumulation, microbial colonization, and mechanical friction can compromise skin integrity and create conditions for irritation or infection. Advanced polymer formulations incorporating antimicrobial properties, moisture-wicking capabilities, or microporous structures that allow skin respiration have emerged as promising solutions to these challenges.

Allergenicity remains a significant concern, particularly with synthetic polymers containing residual monomers, catalysts, or processing additives. Manufacturers increasingly employ purification techniques to minimize these potential allergens and implement hypoallergenic design principles. Additionally, the development of biopolymer alternatives derived from natural sources such as cellulose, chitosan, and alginate offers potentially reduced allergenicity profiles while maintaining functional properties.

Environmental and disposal considerations have gained prominence as the wearable biosensor market expands. Biodegradable polymers that maintain stability during use but decompose safely after disposal represent an emerging research direction. These materials aim to balance the competing demands of durability during application and environmental responsibility at end-of-life, addressing growing concerns about electronic waste accumulation from disposable medical devices.

Regulatory frameworks worldwide impose stringent requirements on wearable biosensor materials. The FDA in the United States, the European Medicines Agency, and similar bodies in Asia have established comprehensive guidelines for biocompatibility testing according to ISO 10993 standards. These protocols typically include cytotoxicity assessments, sensitization studies, irritation tests, and systemic toxicity evaluations depending on the intended duration and nature of body contact.

Long-term exposure considerations present unique challenges in polymer-based biosensor development. Materials that perform adequately in short-term applications may exhibit degradation, leaching of compounds, or surface modifications when subjected to continuous wear conditions. Recent research has focused on developing polymers with enhanced stability against hydrolysis, oxidation, and enzymatic degradation to ensure consistent performance and safety throughout the device lifecycle.

The skin-polymer interface represents a critical zone requiring specialized attention. Factors such as moisture accumulation, microbial colonization, and mechanical friction can compromise skin integrity and create conditions for irritation or infection. Advanced polymer formulations incorporating antimicrobial properties, moisture-wicking capabilities, or microporous structures that allow skin respiration have emerged as promising solutions to these challenges.

Allergenicity remains a significant concern, particularly with synthetic polymers containing residual monomers, catalysts, or processing additives. Manufacturers increasingly employ purification techniques to minimize these potential allergens and implement hypoallergenic design principles. Additionally, the development of biopolymer alternatives derived from natural sources such as cellulose, chitosan, and alginate offers potentially reduced allergenicity profiles while maintaining functional properties.

Environmental and disposal considerations have gained prominence as the wearable biosensor market expands. Biodegradable polymers that maintain stability during use but decompose safely after disposal represent an emerging research direction. These materials aim to balance the competing demands of durability during application and environmental responsibility at end-of-life, addressing growing concerns about electronic waste accumulation from disposable medical devices.

Manufacturing Scalability of Polymer Biosensors

The scalability of polymer biosensor manufacturing represents a critical factor in the widespread adoption of wearable health monitoring technologies. Current production methods for polymer-based biosensors face significant challenges when transitioning from laboratory-scale prototypes to mass production. Traditional manufacturing approaches often involve complex multi-step processes including substrate preparation, polymer deposition, patterning, and functionalization with biorecognition elements, creating bottlenecks in high-volume production scenarios.

Injection molding and roll-to-roll (R2R) processing have emerged as promising techniques for scaling polymer biosensor production. R2R manufacturing, in particular, offers continuous production capabilities with throughput rates exceeding 100 meters per minute for certain polymer films. This approach has demonstrated up to 60% reduction in production costs compared to batch processing methods while maintaining sensor performance specifications.

Material consistency presents another manufacturing challenge, as polymer properties can vary between batches, affecting sensor reliability. Advanced quality control systems incorporating in-line spectroscopic analysis have been implemented by leading manufacturers to ensure uniformity, reducing defect rates from approximately 15% to below 5% in large-scale production environments.

Integration of automated assembly processes has significantly improved manufacturing efficiency. Recent innovations in robotic placement systems have achieved precision alignment of polymer sensing elements with tolerances of ±10 micrometers at assembly rates of up to 1,200 units per hour. These systems have been particularly effective for multi-layer polymer sensor constructions requiring precise alignment of sensing elements.

Environmentally controlled manufacturing facilities have proven essential for maintaining polymer stability during production. Temperature fluctuations of even ±2°C can significantly impact polymer crosslinking reactions and sensor performance. Leading manufacturers have implemented cleanroom environments with tightly regulated temperature (±0.5°C) and humidity (±3% RH) controls to ensure consistent sensor performance.

Scalable functionalization methods represent perhaps the most significant manufacturing challenge. Traditional techniques for attaching biorecognition elements often involve time-consuming chemical processes unsuitable for mass production. Recent innovations in UV-initiated grafting methods have reduced functionalization times from hours to minutes, enabling continuous production workflows and improving throughput by approximately 300% compared to conventional methods.

Economic viability ultimately depends on achieving economies of scale. Industry analysis indicates that polymer biosensor production becomes economically competitive with traditional medical sensors when annual production volumes exceed approximately 500,000 units. At this scale, per-unit manufacturing costs typically decrease by 40-60% compared to small-batch production, making widespread adoption of wearable polymer biosensors increasingly feasible.

Injection molding and roll-to-roll (R2R) processing have emerged as promising techniques for scaling polymer biosensor production. R2R manufacturing, in particular, offers continuous production capabilities with throughput rates exceeding 100 meters per minute for certain polymer films. This approach has demonstrated up to 60% reduction in production costs compared to batch processing methods while maintaining sensor performance specifications.

Material consistency presents another manufacturing challenge, as polymer properties can vary between batches, affecting sensor reliability. Advanced quality control systems incorporating in-line spectroscopic analysis have been implemented by leading manufacturers to ensure uniformity, reducing defect rates from approximately 15% to below 5% in large-scale production environments.

Integration of automated assembly processes has significantly improved manufacturing efficiency. Recent innovations in robotic placement systems have achieved precision alignment of polymer sensing elements with tolerances of ±10 micrometers at assembly rates of up to 1,200 units per hour. These systems have been particularly effective for multi-layer polymer sensor constructions requiring precise alignment of sensing elements.

Environmentally controlled manufacturing facilities have proven essential for maintaining polymer stability during production. Temperature fluctuations of even ±2°C can significantly impact polymer crosslinking reactions and sensor performance. Leading manufacturers have implemented cleanroom environments with tightly regulated temperature (±0.5°C) and humidity (±3% RH) controls to ensure consistent sensor performance.

Scalable functionalization methods represent perhaps the most significant manufacturing challenge. Traditional techniques for attaching biorecognition elements often involve time-consuming chemical processes unsuitable for mass production. Recent innovations in UV-initiated grafting methods have reduced functionalization times from hours to minutes, enabling continuous production workflows and improving throughput by approximately 300% compared to conventional methods.

Economic viability ultimately depends on achieving economies of scale. Industry analysis indicates that polymer biosensor production becomes economically competitive with traditional medical sensors when annual production volumes exceed approximately 500,000 units. At this scale, per-unit manufacturing costs typically decrease by 40-60% compared to small-batch production, making widespread adoption of wearable polymer biosensors increasingly feasible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!