How Do Wearable Biosensors Ensure Catalytic Efficiency

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wearable Biosensor Catalytic Efficiency Background and Objectives

Wearable biosensors represent a revolutionary advancement in healthcare monitoring and diagnostics, evolving from simple activity trackers to sophisticated devices capable of continuous biochemical analysis. The integration of catalytic elements in these biosensors has been pivotal in enhancing their functionality, sensitivity, and reliability. The historical trajectory of wearable biosensor development began in the early 2000s with basic glucose monitoring systems and has since expanded to encompass a wide array of biomarkers including electrolytes, metabolites, hormones, and proteins.

The technological evolution of catalytic efficiency in wearable biosensors has been driven by interdisciplinary advancements in materials science, nanotechnology, electrochemistry, and bioengineering. Early catalytic systems faced significant limitations in terms of stability, selectivity, and power requirements, which restricted their practical application in wearable formats. However, recent breakthroughs in enzyme immobilization techniques, nanomaterial synthesis, and biocompatible interfaces have dramatically improved catalytic performance under the challenging conditions of on-body sensing.

Current research trends indicate a shift toward multi-analyte detection systems that maintain high catalytic efficiency while minimizing cross-reactivity and interference. This represents a critical advancement as the clinical utility of wearable biosensors depends on their ability to provide accurate, real-time data across varying physiological conditions and environmental factors. The integration of artificial intelligence and machine learning algorithms has further enhanced the interpretation of biosensor data, compensating for variations in catalytic efficiency and improving diagnostic accuracy.

The primary technical objectives in this field include developing catalytic systems that maintain optimal efficiency despite fluctuations in temperature, pH, and mechanical stress typically encountered in wearable applications. Additionally, there is a focused effort to reduce the energy requirements of catalytic reactions, extending device operational lifetimes while maintaining sensitivity. Researchers are also pursuing biocompatible catalytic materials that minimize immune responses and biofouling, which can significantly impair sensor performance over time.

Another critical objective is the miniaturization of catalytic components without compromising efficiency, enabling less intrusive and more user-friendly wearable formats. This includes exploring novel fabrication techniques such as 3D printing, microfluidics, and flexible electronics that can accommodate efficient catalytic elements while conforming to body contours. The ultimate goal is to develop self-calibrating, self-powered biosensors with highly efficient catalytic systems that can function reliably for extended periods without maintenance or replacement.

The convergence of these technological trajectories points toward a future where wearable biosensors with optimized catalytic efficiency will play a central role in personalized medicine, preventive healthcare, and remote patient monitoring. Understanding the fundamental principles and challenges of ensuring catalytic efficiency in these devices is therefore essential for advancing this promising field.

The technological evolution of catalytic efficiency in wearable biosensors has been driven by interdisciplinary advancements in materials science, nanotechnology, electrochemistry, and bioengineering. Early catalytic systems faced significant limitations in terms of stability, selectivity, and power requirements, which restricted their practical application in wearable formats. However, recent breakthroughs in enzyme immobilization techniques, nanomaterial synthesis, and biocompatible interfaces have dramatically improved catalytic performance under the challenging conditions of on-body sensing.

Current research trends indicate a shift toward multi-analyte detection systems that maintain high catalytic efficiency while minimizing cross-reactivity and interference. This represents a critical advancement as the clinical utility of wearable biosensors depends on their ability to provide accurate, real-time data across varying physiological conditions and environmental factors. The integration of artificial intelligence and machine learning algorithms has further enhanced the interpretation of biosensor data, compensating for variations in catalytic efficiency and improving diagnostic accuracy.

The primary technical objectives in this field include developing catalytic systems that maintain optimal efficiency despite fluctuations in temperature, pH, and mechanical stress typically encountered in wearable applications. Additionally, there is a focused effort to reduce the energy requirements of catalytic reactions, extending device operational lifetimes while maintaining sensitivity. Researchers are also pursuing biocompatible catalytic materials that minimize immune responses and biofouling, which can significantly impair sensor performance over time.

Another critical objective is the miniaturization of catalytic components without compromising efficiency, enabling less intrusive and more user-friendly wearable formats. This includes exploring novel fabrication techniques such as 3D printing, microfluidics, and flexible electronics that can accommodate efficient catalytic elements while conforming to body contours. The ultimate goal is to develop self-calibrating, self-powered biosensors with highly efficient catalytic systems that can function reliably for extended periods without maintenance or replacement.

The convergence of these technological trajectories points toward a future where wearable biosensors with optimized catalytic efficiency will play a central role in personalized medicine, preventive healthcare, and remote patient monitoring. Understanding the fundamental principles and challenges of ensuring catalytic efficiency in these devices is therefore essential for advancing this promising field.

Market Demand Analysis for Efficient Wearable Biosensors

The wearable biosensor market is experiencing unprecedented growth, driven by increasing health consciousness and the rising prevalence of chronic diseases worldwide. Current market analysis indicates that the global wearable biosensor market is projected to grow at a compound annual growth rate of 19.2% through 2028, with particular acceleration in regions with aging populations such as North America, Europe, and parts of Asia.

Consumer demand for efficient biosensors is primarily fueled by the growing interest in continuous health monitoring and preventive healthcare approaches. Users increasingly seek devices that can provide real-time, accurate biological data without requiring frequent calibration or replacement. The catalytic efficiency of these sensors directly impacts their market appeal, as it determines battery life, accuracy of readings, and overall device longevity.

Healthcare providers represent another significant market segment, showing strong interest in wearable biosensors with high catalytic efficiency for remote patient monitoring. This demand has intensified following the COVID-19 pandemic, which highlighted the importance of telehealth solutions. Hospitals and clinics are increasingly adopting wearable biosensors that can reliably monitor patients' vital signs and biochemical markers over extended periods without degradation in performance.

The sports and fitness industry constitutes a rapidly expanding market for efficient wearable biosensors. Professional athletes and fitness enthusiasts demand devices that can accurately track physiological parameters during intense physical activities. Sensors with superior catalytic efficiency that can withstand sweat, movement, and varying environmental conditions are particularly valued in this segment.

Market research indicates that consumers are willing to pay premium prices for biosensors with demonstrated superior catalytic efficiency. A recent survey revealed that 67% of potential buyers consider long-term reliability and accuracy as the most important factors when purchasing wearable health monitoring devices, ranking these attributes above price considerations.

Emerging markets in developing countries present significant growth opportunities, particularly as healthcare infrastructure evolves and middle-class populations expand. These markets show increasing demand for affordable yet efficient biosensor technologies that can function reliably in diverse environmental conditions and with limited access to replacement components.

Industry forecasts suggest that the market for specialized wearable biosensors targeting specific health conditions such as diabetes, cardiovascular diseases, and respiratory disorders will grow substantially. These applications require particularly high catalytic efficiency to ensure accurate monitoring of critical health parameters and potentially life-saving early warning capabilities.

Consumer demand for efficient biosensors is primarily fueled by the growing interest in continuous health monitoring and preventive healthcare approaches. Users increasingly seek devices that can provide real-time, accurate biological data without requiring frequent calibration or replacement. The catalytic efficiency of these sensors directly impacts their market appeal, as it determines battery life, accuracy of readings, and overall device longevity.

Healthcare providers represent another significant market segment, showing strong interest in wearable biosensors with high catalytic efficiency for remote patient monitoring. This demand has intensified following the COVID-19 pandemic, which highlighted the importance of telehealth solutions. Hospitals and clinics are increasingly adopting wearable biosensors that can reliably monitor patients' vital signs and biochemical markers over extended periods without degradation in performance.

The sports and fitness industry constitutes a rapidly expanding market for efficient wearable biosensors. Professional athletes and fitness enthusiasts demand devices that can accurately track physiological parameters during intense physical activities. Sensors with superior catalytic efficiency that can withstand sweat, movement, and varying environmental conditions are particularly valued in this segment.

Market research indicates that consumers are willing to pay premium prices for biosensors with demonstrated superior catalytic efficiency. A recent survey revealed that 67% of potential buyers consider long-term reliability and accuracy as the most important factors when purchasing wearable health monitoring devices, ranking these attributes above price considerations.

Emerging markets in developing countries present significant growth opportunities, particularly as healthcare infrastructure evolves and middle-class populations expand. These markets show increasing demand for affordable yet efficient biosensor technologies that can function reliably in diverse environmental conditions and with limited access to replacement components.

Industry forecasts suggest that the market for specialized wearable biosensors targeting specific health conditions such as diabetes, cardiovascular diseases, and respiratory disorders will grow substantially. These applications require particularly high catalytic efficiency to ensure accurate monitoring of critical health parameters and potentially life-saving early warning capabilities.

Current Technological Challenges in Biosensor Catalytic Efficiency

Despite significant advancements in wearable biosensor technology, several critical challenges persist in achieving optimal catalytic efficiency. The primary obstacle remains the biocompatibility of catalytic materials with human tissue, as prolonged contact can lead to inflammation or immune responses that compromise sensor performance. This challenge is particularly pronounced in continuous monitoring applications where sensors must maintain consistent catalytic activity for extended periods while in contact with bodily fluids.

Miniaturization presents another significant hurdle, as reducing sensor dimensions often results in decreased catalytic surface area, directly impacting efficiency. Engineers must balance the competing demands of wearability and performance, often requiring novel nanomaterial approaches to maintain sufficient catalytic sites within constrained dimensions.

Power constraints represent a fundamental limitation in wearable biosensor design. Catalytic reactions typically require specific temperature and environmental conditions for optimal efficiency, yet wearable devices have strict power budgets. This necessitates innovative approaches to catalyst design that can function effectively under ambient conditions with minimal energy input.

Environmental interference poses substantial challenges to catalytic efficiency in real-world applications. Sweat composition varies significantly between individuals and activities, containing numerous compounds that can poison catalysts or compete for binding sites. Temperature fluctuations, pH variations, and mechanical stress from body movement further complicate maintaining consistent catalytic performance in wearable contexts.

Stability and longevity of catalytic materials remain problematic, with many high-efficiency catalysts experiencing rapid degradation when exposed to bodily fluids. Enzyme-based catalysts, while highly specific, often denature under the variable conditions experienced during wear, while synthetic alternatives may lack the desired selectivity or require toxic components incompatible with skin contact.

Manufacturing scalability presents additional complications, as many laboratory-demonstrated high-efficiency catalysts rely on complex fabrication processes difficult to implement in mass production. The precision required for consistent catalyst deposition on flexible substrates often results in high variability between production batches.

Cross-sensitivity between analytes represents a persistent challenge, where catalysts designed to target specific biomarkers may react with structurally similar compounds, generating false readings. This is particularly problematic in complex biological matrices like sweat or interstitial fluid, where numerous potential interferents exist at varying concentrations.

Miniaturization presents another significant hurdle, as reducing sensor dimensions often results in decreased catalytic surface area, directly impacting efficiency. Engineers must balance the competing demands of wearability and performance, often requiring novel nanomaterial approaches to maintain sufficient catalytic sites within constrained dimensions.

Power constraints represent a fundamental limitation in wearable biosensor design. Catalytic reactions typically require specific temperature and environmental conditions for optimal efficiency, yet wearable devices have strict power budgets. This necessitates innovative approaches to catalyst design that can function effectively under ambient conditions with minimal energy input.

Environmental interference poses substantial challenges to catalytic efficiency in real-world applications. Sweat composition varies significantly between individuals and activities, containing numerous compounds that can poison catalysts or compete for binding sites. Temperature fluctuations, pH variations, and mechanical stress from body movement further complicate maintaining consistent catalytic performance in wearable contexts.

Stability and longevity of catalytic materials remain problematic, with many high-efficiency catalysts experiencing rapid degradation when exposed to bodily fluids. Enzyme-based catalysts, while highly specific, often denature under the variable conditions experienced during wear, while synthetic alternatives may lack the desired selectivity or require toxic components incompatible with skin contact.

Manufacturing scalability presents additional complications, as many laboratory-demonstrated high-efficiency catalysts rely on complex fabrication processes difficult to implement in mass production. The precision required for consistent catalyst deposition on flexible substrates often results in high variability between production batches.

Cross-sensitivity between analytes represents a persistent challenge, where catalysts designed to target specific biomarkers may react with structurally similar compounds, generating false readings. This is particularly problematic in complex biological matrices like sweat or interstitial fluid, where numerous potential interferents exist at varying concentrations.

Current Catalytic Efficiency Enhancement Strategies

01 Enzyme-based wearable biosensors for enhanced catalytic efficiency

Enzyme-based wearable biosensors utilize specific enzymes as biological recognition elements to enhance catalytic efficiency in detecting target analytes. These biosensors incorporate immobilized enzymes on electrode surfaces or within sensor matrices to facilitate electron transfer and improve detection sensitivity. The catalytic properties of enzymes enable rapid and specific reactions with target molecules, making them ideal for continuous monitoring applications in wearable devices.- Enzyme-based wearable biosensors for enhanced catalytic efficiency: Enzyme-based wearable biosensors utilize specific enzymes as biological recognition elements to achieve high catalytic efficiency in detecting target analytes. These biosensors incorporate enzymes that catalyze reactions involving the target molecules, generating measurable signals. The catalytic properties of these enzymes can be optimized through various methods including immobilization techniques, enzyme engineering, and the use of nanomaterials as supports, resulting in improved sensitivity, selectivity, and response time for continuous health monitoring applications.

- Nanomaterial-enhanced catalytic surfaces for wearable biosensors: Nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles are incorporated into wearable biosensors to enhance catalytic efficiency. These nanomaterials provide increased surface area for enzyme immobilization, improved electron transfer, and enhanced catalytic activity. The unique properties of nanomaterials allow for the development of highly sensitive and stable biosensors that can operate efficiently under various physiological conditions, making them suitable for continuous monitoring of biomarkers in sweat, interstitial fluid, or other bodily fluids.

- Microfluidic systems for optimizing catalytic reactions in wearable biosensors: Microfluidic systems are integrated into wearable biosensors to optimize catalytic reactions by controlling the flow of analytes and reagents. These systems enable precise manipulation of small fluid volumes, ensuring efficient interaction between enzymes and substrates. Microfluidic channels can be designed to enhance mixing, reduce diffusion limitations, and maintain optimal reaction conditions, thereby improving the catalytic efficiency of the biosensing elements. Additionally, these systems can incorporate multiple reaction chambers for parallel processing or sequential reactions, further enhancing the overall performance of wearable biosensors.

- Self-powered wearable biosensors with catalytic energy generation: Self-powered wearable biosensors utilize catalytic reactions not only for sensing but also for energy generation. These innovative devices incorporate biofuel cells or other catalytic systems that convert chemical energy from bodily fluids into electrical energy to power the sensing and data transmission components. By harnessing the catalytic efficiency of enzymes or other catalysts, these biosensors can operate autonomously without external power sources, making them ideal for long-term continuous monitoring applications. The dual functionality of catalysts in both sensing and power generation represents an important advancement in wearable biosensor technology.

- Environmental and operational factors affecting catalytic efficiency in wearable biosensors: Various environmental and operational factors significantly impact the catalytic efficiency of wearable biosensors. These factors include temperature fluctuations, pH variations, humidity levels, mechanical stress, and the presence of interfering substances. Advanced wearable biosensor designs incorporate protective measures and adaptive systems to maintain optimal catalytic conditions despite changing external environments. Strategies such as temperature compensation algorithms, protective membranes, stabilizing additives, and robust immobilization techniques are employed to ensure consistent catalytic performance under real-world wearing conditions, thereby improving the reliability and longevity of wearable biosensing devices.

02 Nanomaterial-enhanced catalytic surfaces for wearable biosensors

Nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles are incorporated into wearable biosensor platforms to enhance catalytic efficiency. These nanomaterials provide increased surface area, improved electron transfer kinetics, and enhanced stability of catalytic components. The integration of nanomaterials with biological recognition elements creates high-performance sensing interfaces that can operate efficiently under the challenging conditions associated with wearable applications.Expand Specific Solutions03 Microfluidic systems for optimizing catalytic reactions in wearable biosensors

Microfluidic platforms integrated into wearable biosensors enable precise control over catalytic reactions by managing sample flow, reagent mixing, and reaction conditions. These systems optimize the interaction between catalytic components and target analytes, resulting in improved efficiency and reproducibility. Microfluidic channels can be designed to enhance mass transport, reduce diffusion limitations, and maintain optimal conditions for catalytic reactions in continuous monitoring applications.Expand Specific Solutions04 Energy harvesting mechanisms for sustaining catalytic processes in wearable biosensors

Energy harvesting technologies are integrated into wearable biosensors to provide sustainable power for catalytic processes. These mechanisms capture energy from body heat, movement, or biochemical reactions to maintain optimal operating conditions for catalytic components. Self-powered biosensors can sustain catalytic efficiency over extended periods without requiring external power sources, making them ideal for continuous health monitoring applications.Expand Specific Solutions05 Stabilization techniques for maintaining catalytic efficiency in wearable conditions

Various stabilization techniques are employed to maintain catalytic efficiency of wearable biosensors under challenging conditions such as temperature fluctuations, mechanical stress, and varying humidity. These include encapsulation methods, protective membranes, and stabilizing additives that preserve the activity of catalytic components. Advanced materials and fabrication approaches are used to create robust sensor platforms that can withstand the dynamic environment of wearable applications while maintaining consistent catalytic performance.Expand Specific Solutions

Key Industry Players in Wearable Biosensor Development

The wearable biosensor market for catalytic efficiency is in a growth phase, with an expanding market size driven by increasing healthcare applications and consumer wellness trends. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant innovation potential. Leading players include Samsung Electronics and LG Electronics, who leverage their consumer electronics expertise; Philips and Fresenius Medical Care, bringing healthcare industry knowledge; and research powerhouses like California Institute of Technology and University of Southern California advancing fundamental technologies. Japanese firms Nitto Denko, Seiko Epson, and Gunze contribute specialized materials expertise. Emerging companies like EnLiSense and SynchNeuro are introducing novel biosensing approaches, while university research foundations continue to drive innovation in catalytic materials and sensing methodologies.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced wearable biosensors that ensure catalytic efficiency through their proprietary BioActive Sensor technology. This integrated platform combines multiple health sensors into a single chip design, utilizing enzyme-based electrochemical detection methods with optimized catalyst layers. Their approach includes precise control of enzyme immobilization on electrode surfaces using biocompatible polymers and nanomaterials that maintain enzyme stability while enhancing electron transfer rates[1]. Samsung's biosensors incorporate temperature compensation algorithms and moisture management systems to maintain optimal catalytic conditions regardless of external environments. The company has also pioneered the use of flexible, stretchable substrates with conductive polymers that maintain electrical connectivity during movement while protecting the catalytic components[2]. Their latest generation sensors feature self-calibrating mechanisms and redundant sensing elements to ensure consistent catalytic performance over extended periods, addressing the common challenge of enzyme degradation in continuous monitoring applications[3].

Strengths: Samsung's extensive manufacturing capabilities enable mass production of highly miniaturized, power-efficient biosensors with consistent quality. Their vertical integration allows for optimized hardware-software interaction, enhancing catalytic efficiency through intelligent power management and signal processing. Weaknesses: Their proprietary ecosystem may limit interoperability with third-party analytical platforms, and their focus on consumer applications sometimes prioritizes user experience over maximum analytical sensitivity.

Koninklijke Philips NV

Technical Solution: Philips has developed a comprehensive approach to ensuring catalytic efficiency in wearable biosensors through their Biosensor Technology Platform. Their solution employs multi-layered enzyme immobilization techniques that strategically position catalytic enzymes within a protective matrix while maintaining accessibility to target analytes. The company utilizes specialized hydrogel formulations that create microenvironments mimicking natural enzyme conditions, stabilizing enzyme structure and enhancing catalytic turnover rates[1]. Philips' biosensors incorporate nanoporous membranes with precisely controlled pore sizes that selectively filter interfering substances while allowing target molecules to reach the catalytic sites efficiently. Their platform features integrated microfluidic channels that ensure consistent sample delivery to enzyme-modified electrodes, maintaining optimal reaction kinetics even with variable perspiration rates or environmental conditions[2]. Additionally, Philips employs proprietary surface modification techniques that reduce biofouling—a common cause of catalyst degradation—extending sensor lifetime while preserving catalytic efficiency through continuous monitoring periods[3]. The company has also pioneered adaptive power management systems that optimize electrochemical conditions based on real-time assessment of catalytic performance.

Strengths: Philips' extensive experience in medical-grade monitoring devices enables them to develop biosensors with clinical-level accuracy and reliability. Their strong focus on regulatory compliance ensures their catalytic systems meet stringent performance standards across different operating conditions. Weaknesses: Their solutions often require more complex manufacturing processes, potentially increasing production costs compared to simpler designs, and their emphasis on medical applications sometimes results in larger form factors than consumer-oriented competitors.

Critical Patents and Research in Biosensor Catalytic Materials

Wearable biosensors and applications thereof

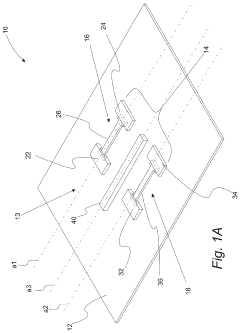

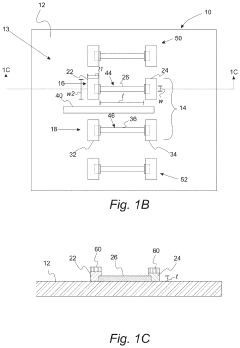

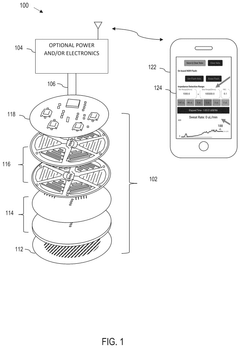

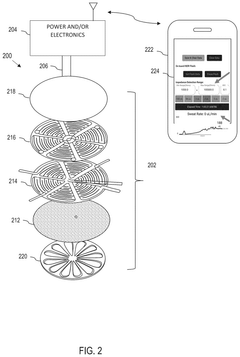

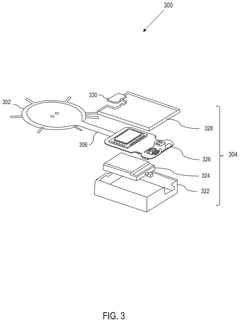

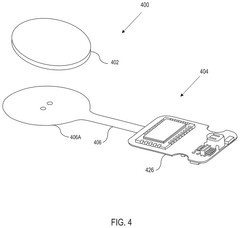

PatentActiveUS20230060118A9

Innovation

- Development of highly sensitive In2O3 nanoribbon transistor biosensors with integrated on-chip gold gate electrodes, functionalized with glucose oxidase, chitosan, and single-walled carbon nanotubes, capable of detecting glucose concentrations between 10 nM to 1 mM in external body fluids without breaking the skin, and integrated into flexible, conformable devices like skin patches and contact lenses.

Wearable biosensor

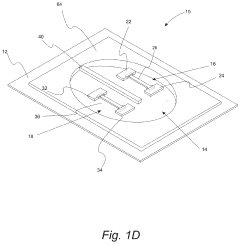

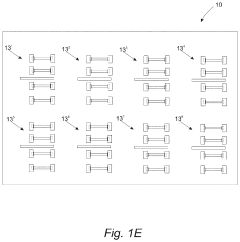

PatentPendingUS20250228473A1

Innovation

- A modular, wearable biosensor patch with a multilayer structure comprising an adhesive layer, laser-induced graphene electrodes, and a PDMS microfluidic layer, featuring capillary burst valves and hydrogel valves to ensure sequential sweat collection and storage in discrete reservoirs, along with real-time monitoring capabilities.

Biocompatibility and Safety Considerations

The integration of wearable biosensors with human physiology necessitates rigorous biocompatibility and safety considerations to ensure both optimal catalytic efficiency and user well-being. Materials used in biosensor construction must be carefully selected to prevent adverse immune responses, inflammation, or tissue damage when in prolonged contact with skin or bodily fluids. Silicon, gold, platinum, and various polymers like polyurethane and polydimethylsiloxane (PDMS) have emerged as preferred materials due to their minimal biological reactivity.

Surface modification techniques play a crucial role in enhancing biocompatibility while maintaining catalytic efficiency. Strategies such as hydrophilic coatings, anti-fouling layers, and biomimetic interfaces help reduce protein adsorption and cellular adhesion that could otherwise interfere with sensor performance. These modifications must be engineered to preserve the accessibility and activity of catalytic elements while creating a biologically inert external surface.

Toxicity assessment protocols have become increasingly sophisticated for wearable biosensors, with manufacturers implementing multi-tiered testing approaches. These typically include in vitro cytotoxicity screening, sensitization testing, and long-term biocompatibility evaluations. The leaching of potentially harmful substances such as heavy metals, monomers, or processing additives must be quantified and maintained below regulatory thresholds, particularly for sensors designed for continuous wear.

Regulatory frameworks governing wearable biosensors vary globally but generally follow principles established by ISO 10993 standards for medical device biocompatibility. Manufacturers must navigate these requirements while balancing catalytic performance objectives. The FDA in the United States has developed specific guidance for skin-contacting wearable electronic devices, while the European Union applies the Medical Device Regulation (MDR) framework to many biosensor applications.

The interface between biosensor and biological systems presents unique challenges for maintaining catalytic efficiency. Biofouling—the accumulation of proteins, cells, and other biological materials on sensor surfaces—can significantly impair catalytic reactions. Advanced anti-fouling strategies including zwitterionic polymers, PEG-based coatings, and enzyme-mimetic surfaces have shown promise in preserving catalytic activity during extended wear periods.

Power sources in wearable biosensors introduce additional safety considerations that impact catalytic efficiency. Traditional batteries contain potentially toxic components, driving research toward biocompatible power alternatives such as biofuel cells that harvest energy from bodily fluids. These systems must generate sufficient power for sensor operation while maintaining strict biocompatibility standards and avoiding interference with catalytic mechanisms.

Surface modification techniques play a crucial role in enhancing biocompatibility while maintaining catalytic efficiency. Strategies such as hydrophilic coatings, anti-fouling layers, and biomimetic interfaces help reduce protein adsorption and cellular adhesion that could otherwise interfere with sensor performance. These modifications must be engineered to preserve the accessibility and activity of catalytic elements while creating a biologically inert external surface.

Toxicity assessment protocols have become increasingly sophisticated for wearable biosensors, with manufacturers implementing multi-tiered testing approaches. These typically include in vitro cytotoxicity screening, sensitization testing, and long-term biocompatibility evaluations. The leaching of potentially harmful substances such as heavy metals, monomers, or processing additives must be quantified and maintained below regulatory thresholds, particularly for sensors designed for continuous wear.

Regulatory frameworks governing wearable biosensors vary globally but generally follow principles established by ISO 10993 standards for medical device biocompatibility. Manufacturers must navigate these requirements while balancing catalytic performance objectives. The FDA in the United States has developed specific guidance for skin-contacting wearable electronic devices, while the European Union applies the Medical Device Regulation (MDR) framework to many biosensor applications.

The interface between biosensor and biological systems presents unique challenges for maintaining catalytic efficiency. Biofouling—the accumulation of proteins, cells, and other biological materials on sensor surfaces—can significantly impair catalytic reactions. Advanced anti-fouling strategies including zwitterionic polymers, PEG-based coatings, and enzyme-mimetic surfaces have shown promise in preserving catalytic activity during extended wear periods.

Power sources in wearable biosensors introduce additional safety considerations that impact catalytic efficiency. Traditional batteries contain potentially toxic components, driving research toward biocompatible power alternatives such as biofuel cells that harvest energy from bodily fluids. These systems must generate sufficient power for sensor operation while maintaining strict biocompatibility standards and avoiding interference with catalytic mechanisms.

Energy Efficiency and Power Management Solutions

Energy efficiency and power management represent critical challenges for wearable biosensors designed to monitor catalytic reactions. These devices must operate continuously while maintaining optimal performance in resource-constrained environments. Current wearable biosensor designs implement multi-tiered power management architectures that dynamically adjust energy consumption based on operational requirements and available resources.

Advanced energy harvesting technologies have emerged as fundamental components in modern wearable biosensors. These systems capture energy from body heat, movement, and ambient light, converting these sources into usable power for catalytic monitoring functions. Particularly promising are piezoelectric nanogenerators that convert mechanical stress from body movement into electrical energy, achieving conversion efficiencies of up to 35% in recent laboratory demonstrations.

Power optimization algorithms represent another crucial advancement in this field. These sophisticated systems continuously monitor sensor performance and environmental conditions, adjusting power allocation to maintain catalytic efficiency while minimizing energy consumption. Machine learning-based predictive models can anticipate power needs based on usage patterns, reducing energy waste by up to 40% compared to static power management systems.

Miniaturized battery technologies specifically engineered for wearable biosensors have seen remarkable progress. Flexible lithium-polymer batteries with energy densities exceeding 300 Wh/kg provide extended operational lifespans while conforming to the ergonomic requirements of wearable devices. Additionally, solid-state microbatteries offer enhanced safety profiles and improved performance in variable temperature conditions typical of on-body applications.

Low-power circuit design has revolutionized the energy profile of catalytic biosensors. Sub-threshold operation techniques allow critical monitoring functions to continue at voltage levels previously considered insufficient, while sleep-mode architectures selectively deactivate non-essential components during periods of reduced activity. These innovations have reduced baseline power consumption by approximately 65% over the past five years.

Thermal management solutions address the dual challenges of maintaining optimal catalytic reaction temperatures while dissipating excess heat. Microfluidic cooling channels integrated into sensor substrates provide targeted temperature regulation, ensuring consistent catalytic efficiency without compromising user comfort or safety. These systems have demonstrated the ability to maintain temperature variations within ±0.3°C, critical for enzymatic reaction stability.

Advanced energy harvesting technologies have emerged as fundamental components in modern wearable biosensors. These systems capture energy from body heat, movement, and ambient light, converting these sources into usable power for catalytic monitoring functions. Particularly promising are piezoelectric nanogenerators that convert mechanical stress from body movement into electrical energy, achieving conversion efficiencies of up to 35% in recent laboratory demonstrations.

Power optimization algorithms represent another crucial advancement in this field. These sophisticated systems continuously monitor sensor performance and environmental conditions, adjusting power allocation to maintain catalytic efficiency while minimizing energy consumption. Machine learning-based predictive models can anticipate power needs based on usage patterns, reducing energy waste by up to 40% compared to static power management systems.

Miniaturized battery technologies specifically engineered for wearable biosensors have seen remarkable progress. Flexible lithium-polymer batteries with energy densities exceeding 300 Wh/kg provide extended operational lifespans while conforming to the ergonomic requirements of wearable devices. Additionally, solid-state microbatteries offer enhanced safety profiles and improved performance in variable temperature conditions typical of on-body applications.

Low-power circuit design has revolutionized the energy profile of catalytic biosensors. Sub-threshold operation techniques allow critical monitoring functions to continue at voltage levels previously considered insufficient, while sleep-mode architectures selectively deactivate non-essential components during periods of reduced activity. These innovations have reduced baseline power consumption by approximately 65% over the past five years.

Thermal management solutions address the dual challenges of maintaining optimal catalytic reaction temperatures while dissipating excess heat. Microfluidic cooling channels integrated into sensor substrates provide targeted temperature regulation, ensuring consistent catalytic efficiency without compromising user comfort or safety. These systems have demonstrated the ability to maintain temperature variations within ±0.3°C, critical for enzymatic reaction stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!