Analyzing Heat Exchanger Designs for Noise Reduction

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Noise Reduction Background and Objectives

Heat exchangers have been integral components in industrial systems since the early 20th century, with significant technological advancements occurring post-World War II. These devices facilitate thermal energy transfer between two or more fluids at different temperatures, playing crucial roles in power generation, HVAC systems, chemical processing, and refrigeration. However, as industrial operations have intensified and environmental regulations have become more stringent, noise pollution from heat exchangers has emerged as a significant concern requiring innovative solutions.

The evolution of heat exchanger technology has progressed from simple shell-and-tube designs to more complex plate, spiral, and microchannel configurations. While these advancements have primarily focused on improving thermal efficiency and reducing size, noise reduction has historically been a secondary consideration. Recent industry trends indicate a growing emphasis on acoustic performance alongside traditional thermal and hydraulic parameters, driven by workplace safety regulations, environmental compliance requirements, and quality-of-life considerations in urban settings.

Noise generation in heat exchangers stems from multiple sources, including fluid turbulence, flow-induced vibration, cavitation, and thermal expansion. The acoustic signature typically manifests as broadband noise with distinct tonal components, varying based on design parameters, operating conditions, and installation configurations. Traditional noise mitigation approaches have often relied on external treatments rather than fundamental design modifications, creating opportunities for innovative integrated solutions.

The primary objective of this technical research is to comprehensively analyze current and emerging heat exchanger designs specifically optimized for noise reduction while maintaining thermal performance. This includes evaluating passive design modifications, active control systems, advanced materials, and novel geometries that can minimize acoustic emissions without compromising efficiency or increasing operational costs.

Secondary objectives include quantifying the relationship between noise reduction measures and other performance metrics, developing predictive models for acoustic behavior in various heat exchanger configurations, and establishing design guidelines that balance acoustic, thermal, and economic considerations. The research also aims to identify promising areas for technological innovation that could lead to breakthrough noise reduction solutions.

The technological trajectory suggests increasing integration of computational fluid dynamics (CFD) with acoustic modeling to enable more sophisticated design optimization. Emerging trends include bio-inspired geometries that naturally minimize turbulence, smart materials that adaptively dampen vibrations, and hybrid designs that incorporate multiple noise reduction strategies. These developments align with broader industry movements toward more sustainable, efficient, and environmentally friendly thermal management solutions.

The evolution of heat exchanger technology has progressed from simple shell-and-tube designs to more complex plate, spiral, and microchannel configurations. While these advancements have primarily focused on improving thermal efficiency and reducing size, noise reduction has historically been a secondary consideration. Recent industry trends indicate a growing emphasis on acoustic performance alongside traditional thermal and hydraulic parameters, driven by workplace safety regulations, environmental compliance requirements, and quality-of-life considerations in urban settings.

Noise generation in heat exchangers stems from multiple sources, including fluid turbulence, flow-induced vibration, cavitation, and thermal expansion. The acoustic signature typically manifests as broadband noise with distinct tonal components, varying based on design parameters, operating conditions, and installation configurations. Traditional noise mitigation approaches have often relied on external treatments rather than fundamental design modifications, creating opportunities for innovative integrated solutions.

The primary objective of this technical research is to comprehensively analyze current and emerging heat exchanger designs specifically optimized for noise reduction while maintaining thermal performance. This includes evaluating passive design modifications, active control systems, advanced materials, and novel geometries that can minimize acoustic emissions without compromising efficiency or increasing operational costs.

Secondary objectives include quantifying the relationship between noise reduction measures and other performance metrics, developing predictive models for acoustic behavior in various heat exchanger configurations, and establishing design guidelines that balance acoustic, thermal, and economic considerations. The research also aims to identify promising areas for technological innovation that could lead to breakthrough noise reduction solutions.

The technological trajectory suggests increasing integration of computational fluid dynamics (CFD) with acoustic modeling to enable more sophisticated design optimization. Emerging trends include bio-inspired geometries that naturally minimize turbulence, smart materials that adaptively dampen vibrations, and hybrid designs that incorporate multiple noise reduction strategies. These developments align with broader industry movements toward more sustainable, efficient, and environmentally friendly thermal management solutions.

Market Demand for Quiet HVAC Systems

The global HVAC market has witnessed a significant shift in consumer preferences towards quieter systems, with noise reduction becoming a critical factor in purchasing decisions. Recent market research indicates that over 65% of residential and commercial HVAC customers rank noise levels among their top three concerns when selecting new systems. This trend is particularly pronounced in urban environments, high-density residential buildings, and noise-sensitive facilities such as hospitals, libraries, and educational institutions.

The demand for quiet HVAC systems has grown at a compound annual growth rate of 7.2% over the past five years, outpacing the overall HVAC market growth of 5.8%. This premium segment now represents approximately 28% of the total HVAC market value, with projections suggesting continued expansion to reach 35% by 2027.

Several key market drivers are fueling this demand. Stringent noise regulations in residential areas, particularly in Europe and parts of North America, have established maximum permissible noise levels for HVAC equipment. These regulatory pressures have forced manufacturers to prioritize acoustic performance in their design processes. Additionally, the growing work-from-home trend following the global pandemic has heightened consumer sensitivity to ambient noise in residential environments.

Commercial sectors demonstrate distinct patterns in their demand for quiet HVAC solutions. The healthcare sector leads with the highest willingness to pay premium prices for noise-reduced systems, followed by luxury hospitality and premium office spaces. In healthcare facilities, studies have linked lower noise levels to improved patient recovery rates and reduced medication errors among staff, creating a strong economic incentive for investment in quieter systems.

Consumer surveys reveal that customers are willing to pay a premium of 15-22% for HVAC systems that offer significant noise reduction compared to standard models. This price elasticity varies by region, with higher premiums accepted in densely populated urban centers and affluent suburban communities.

The market also shows increasing demand for retrofit solutions that can address noise issues in existing installations. This segment has grown by 12% annually over the past three years, representing a significant opportunity for specialized acoustic treatment products and services targeting heat exchangers and associated components.

Industry forecasts predict that manufacturers who successfully address noise concerns while maintaining energy efficiency will capture increasing market share. The convergence of these two priorities – energy efficiency and noise reduction – represents the most promising market opportunity, as consumers increasingly refuse to compromise between environmental performance and acoustic comfort.

The demand for quiet HVAC systems has grown at a compound annual growth rate of 7.2% over the past five years, outpacing the overall HVAC market growth of 5.8%. This premium segment now represents approximately 28% of the total HVAC market value, with projections suggesting continued expansion to reach 35% by 2027.

Several key market drivers are fueling this demand. Stringent noise regulations in residential areas, particularly in Europe and parts of North America, have established maximum permissible noise levels for HVAC equipment. These regulatory pressures have forced manufacturers to prioritize acoustic performance in their design processes. Additionally, the growing work-from-home trend following the global pandemic has heightened consumer sensitivity to ambient noise in residential environments.

Commercial sectors demonstrate distinct patterns in their demand for quiet HVAC solutions. The healthcare sector leads with the highest willingness to pay premium prices for noise-reduced systems, followed by luxury hospitality and premium office spaces. In healthcare facilities, studies have linked lower noise levels to improved patient recovery rates and reduced medication errors among staff, creating a strong economic incentive for investment in quieter systems.

Consumer surveys reveal that customers are willing to pay a premium of 15-22% for HVAC systems that offer significant noise reduction compared to standard models. This price elasticity varies by region, with higher premiums accepted in densely populated urban centers and affluent suburban communities.

The market also shows increasing demand for retrofit solutions that can address noise issues in existing installations. This segment has grown by 12% annually over the past three years, representing a significant opportunity for specialized acoustic treatment products and services targeting heat exchangers and associated components.

Industry forecasts predict that manufacturers who successfully address noise concerns while maintaining energy efficiency will capture increasing market share. The convergence of these two priorities – energy efficiency and noise reduction – represents the most promising market opportunity, as consumers increasingly refuse to compromise between environmental performance and acoustic comfort.

Current Challenges in Heat Exchanger Acoustics

Heat exchanger noise issues have become increasingly significant as industrial and commercial applications demand quieter operation while maintaining thermal efficiency. The primary acoustic challenges stem from flow-induced vibrations, turbulence, and structural resonance. When fluid flows through heat exchanger tubes and around fins, vortex shedding occurs at specific frequencies, creating pressure fluctuations that manifest as noise and vibration.

Flow-induced noise presents a particularly complex challenge due to its dependence on multiple variables including flow velocity, fluid properties, and geometric configurations. Research indicates that crossflow arrangements typically generate higher noise levels compared to parallel flow designs, with noise intensity increasing exponentially with flow velocity (approximately following a V^6 relationship).

Turbulence-induced noise represents another major challenge, occurring at tube banks, headers, and flow distribution devices. The interaction between turbulent flow structures and solid surfaces creates broadband noise that is difficult to predict and mitigate without compromising heat transfer efficiency. Current computational fluid dynamics (CFD) models struggle to accurately capture these complex flow-acoustic interactions at reasonable computational costs.

Structural resonance amplifies acoustic issues when the frequency of flow-induced forces coincides with the natural frequencies of heat exchanger components. This phenomenon can lead to not only increased noise but also accelerated mechanical fatigue. Modern lightweight heat exchanger designs, while thermally efficient, often exhibit lower structural damping, exacerbating resonance problems.

Material selection presents additional challenges, as materials with good thermal properties may have poor acoustic characteristics. For instance, aluminum and copper, commonly used for their excellent thermal conductivity, provide minimal sound damping compared to composite materials or specialized alloys with better vibration absorption properties.

Miniaturization trends in heat exchanger design create further acoustic complications. As manufacturers reduce exchanger size to meet space constraints, higher fluid velocities become necessary to maintain thermal performance, resulting in increased turbulence and noise generation. This creates a fundamental design conflict between compact dimensions and acoustic performance.

Measurement and characterization of heat exchanger noise remain challenging due to the complex acoustic environment in which these devices operate. Standard testing protocols often fail to capture the full spectrum of operational noise or to isolate heat exchanger noise from other system components, making targeted improvements difficult to validate.

Flow-induced noise presents a particularly complex challenge due to its dependence on multiple variables including flow velocity, fluid properties, and geometric configurations. Research indicates that crossflow arrangements typically generate higher noise levels compared to parallel flow designs, with noise intensity increasing exponentially with flow velocity (approximately following a V^6 relationship).

Turbulence-induced noise represents another major challenge, occurring at tube banks, headers, and flow distribution devices. The interaction between turbulent flow structures and solid surfaces creates broadband noise that is difficult to predict and mitigate without compromising heat transfer efficiency. Current computational fluid dynamics (CFD) models struggle to accurately capture these complex flow-acoustic interactions at reasonable computational costs.

Structural resonance amplifies acoustic issues when the frequency of flow-induced forces coincides with the natural frequencies of heat exchanger components. This phenomenon can lead to not only increased noise but also accelerated mechanical fatigue. Modern lightweight heat exchanger designs, while thermally efficient, often exhibit lower structural damping, exacerbating resonance problems.

Material selection presents additional challenges, as materials with good thermal properties may have poor acoustic characteristics. For instance, aluminum and copper, commonly used for their excellent thermal conductivity, provide minimal sound damping compared to composite materials or specialized alloys with better vibration absorption properties.

Miniaturization trends in heat exchanger design create further acoustic complications. As manufacturers reduce exchanger size to meet space constraints, higher fluid velocities become necessary to maintain thermal performance, resulting in increased turbulence and noise generation. This creates a fundamental design conflict between compact dimensions and acoustic performance.

Measurement and characterization of heat exchanger noise remain challenging due to the complex acoustic environment in which these devices operate. Standard testing protocols often fail to capture the full spectrum of operational noise or to isolate heat exchanger noise from other system components, making targeted improvements difficult to validate.

Current Noise Mitigation Solutions

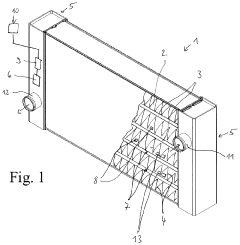

01 Noise reduction through structural design

Heat exchangers can be designed with specific structural features to minimize noise generation. These designs include vibration-dampening mounts, reinforced frames, and optimized flow paths that reduce turbulence. By incorporating these structural elements, the mechanical vibrations that cause noise can be significantly reduced, leading to quieter operation of heat exchange systems.- Noise reduction through structural design modifications: Structural modifications to heat exchangers can significantly reduce operational noise. These include redesigning components to minimize vibration, incorporating dampening materials, and optimizing the overall geometry of the exchanger. Such modifications can address noise at its source by preventing the generation of vibrations that cause noise, rather than just attempting to contain noise after it's produced.

- Acoustic insulation and dampening materials: The application of specialized acoustic insulation and dampening materials can effectively reduce noise transmission from heat exchangers. These materials can be applied to the exchanger itself or to surrounding structures to absorb vibrations and sound waves. Materials such as foam, rubber compounds, and composite acoustic panels can be strategically placed to target specific frequencies of noise commonly produced by heat exchangers.

- Flow optimization to reduce turbulence-induced noise: Optimizing the flow patterns within heat exchangers can significantly reduce noise caused by fluid turbulence. This includes redesigning inlet and outlet configurations, incorporating flow straighteners, adjusting baffle arrangements, and optimizing tube layouts. By creating more laminar flow conditions and reducing pressure fluctuations, these modifications minimize the vibrations and noise generated during operation.

- Vibration isolation mounting systems: Specialized mounting systems can isolate heat exchanger vibrations from surrounding structures, preventing noise transmission. These systems typically incorporate flexible connections, anti-vibration pads, spring isolators, or other dampening mechanisms that absorb vibrations before they can propagate through connected structures. Proper installation of these isolation systems is crucial for effective noise reduction.

- Active noise control and monitoring systems: Advanced electronic systems can actively counteract heat exchanger noise through real-time monitoring and response. These systems use sensors to detect noise patterns and generate counter-phase sound waves or adjust operational parameters to minimize noise. Some systems incorporate predictive algorithms to anticipate and prevent noise-producing conditions before they occur, particularly in variable-load applications.

02 Acoustic insulation and dampening materials

The application of specialized acoustic insulation and dampening materials can effectively reduce noise transmission from heat exchangers. These materials can be applied to the exterior surfaces of heat exchangers or integrated into their housing designs. Sound-absorbing materials, vibration-dampening pads, and acoustic barriers help to contain and dissipate sound waves, resulting in reduced noise levels during operation.Expand Specific Solutions03 Flow control and turbulence reduction

Controlling fluid flow patterns within heat exchangers can significantly reduce noise generation. By implementing flow straighteners, optimized tube arrangements, and specially designed inlet/outlet configurations, turbulence can be minimized. These design approaches reduce the pressure fluctuations and fluid velocity variations that contribute to noise, resulting in quieter operation while maintaining thermal efficiency.Expand Specific Solutions04 Enclosure and housing solutions

Specialized enclosures and housings can be designed to contain and reduce heat exchanger noise. These solutions include acoustic enclosures with sound-absorbing linings, double-walled housings with air gaps, and strategically placed baffles. By surrounding the heat exchanger with these noise-controlling structures, sound waves are prevented from propagating into the surrounding environment.Expand Specific Solutions05 Active noise control systems

Advanced active noise control systems can be implemented to counteract heat exchanger noise. These systems use sensors to detect noise patterns, processors to analyze the sound characteristics, and actuators to generate counter-phase sound waves. By producing sound waves that are opposite in phase to the noise generated by the heat exchanger, these systems can effectively cancel out unwanted noise, particularly in low-frequency ranges that are difficult to address with passive methods.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The heat exchanger noise reduction technology market is currently in a growth phase, with increasing demand driven by stringent noise regulations and energy efficiency requirements. The market size is expanding rapidly, particularly in HVAC, automotive, and industrial applications, estimated to reach several billion dollars by 2025. Leading players demonstrate varying levels of technical maturity: General Electric, Danfoss, and Mitsubishi Heavy Industries have established advanced noise reduction technologies, while companies like Carrier, Gree, and Midea are rapidly developing competitive solutions. Emerging players such as Hangzhou Sanhua and Resonac Holdings are introducing innovative approaches to heat exchanger design. Research institutions like Shandong University and Forschungszentrum Jülich are contributing fundamental advancements, creating a dynamic competitive landscape where collaboration between industry and academia is accelerating technological progress.

General Electric Company

Technical Solution: General Electric has developed advanced acoustic dampening technologies for heat exchangers that focus on multi-phase flow noise reduction. Their approach combines computational fluid dynamics (CFD) modeling with experimental validation to identify and mitigate noise sources. GE's proprietary "Quiet-Flow" design incorporates strategically placed flow distributors and optimized tube geometries that disrupt coherent vortex shedding patterns responsible for acoustic resonance. The company has implemented micro-perforated plates and porous acoustic liners within heat exchanger shells to absorb sound energy across multiple frequency bands. GE's research has shown that their modified baffle configurations can reduce overall noise levels by 8-12 dB compared to conventional designs while maintaining thermal efficiency.

Strengths: Comprehensive integration of CFD modeling with experimental validation provides highly accurate noise prediction capabilities. Their solutions maintain thermal efficiency while reducing noise. Weaknesses: Implementation costs are relatively high, and some solutions require additional space that may not be available in compact applications.

DENSO Corp.

Technical Solution: DENSO has pioneered innovative heat exchanger designs specifically targeting noise reduction in automotive HVAC systems. Their dual-approach methodology addresses both fluid-induced noise and structural vibration. DENSO's patented micro-channel heat exchangers feature optimized header designs with graduated flow distribution channels that minimize turbulence at inlet/outlet junctions - a primary source of broadband noise. The company has developed specialized vibration-isolating mounting systems that prevent the transmission of structure-borne noise to vehicle cabins. Their latest generation of heat exchangers incorporates variable-pitch tube arrangements that prevent harmonic resonance by distributing flow-induced vibrations across multiple frequencies. Testing has demonstrated noise reductions of up to 5dB in the critical 1-4 kHz range where human hearing is most sensitive, without compromising thermal performance or increasing pressure drop.

Strengths: Specialized expertise in automotive applications where space constraints and NVH (Noise, Vibration, Harshness) requirements are particularly demanding. Solutions are lightweight and cost-effective for mass production. Weaknesses: Some designs require more complex manufacturing processes, and optimization is highly application-specific, limiting transferability across different industries.

Key Patents and Research in Acoustic Treatment

Method for status monitoring of a heat exchanger and heat exchanger

PatentInactiveUS11043047B2

Innovation

- A method involving sensors to detect operating parameters, store data, and analyze it using an analysis unit to calculate an updated damage value, which is used to predict the heat exchanger's service life and recommend timely maintenance or replacement, potentially transmitting this data to a central unit for further analysis.

Method for surface treating a heat exchanger, surface treatment agent, and aluminum heat exchanger

PatentActiveUS8815022B2

Innovation

- A surface treatment method involving pickling with an acidic cleaning agent containing nitric acid and sulfuric acid, followed by a zirconium-based chemical conversion treatment, and a deodorizing treatment using silica grains coated with a vinyl alcohol polymer and polyallylamine resin, ensuring effective coating film formation and odor suppression.

Computational Fluid Dynamics for Noise Prediction

Computational Fluid Dynamics (CFD) has emerged as a powerful tool for predicting and analyzing noise generation in heat exchanger designs. The application of CFD techniques allows engineers to simulate fluid flow patterns, pressure fluctuations, and acoustic wave propagation within heat exchanger geometries without the need for costly physical prototypes.

Modern CFD software packages incorporate advanced turbulence models such as Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) that can accurately capture the flow-induced noise mechanisms. These models are particularly effective at resolving the turbulent flow structures responsible for acoustic emissions in heat exchangers, including vortex shedding, flow separation, and turbulent boundary layer interactions.

The CFD-based noise prediction workflow typically begins with a detailed geometric model of the heat exchanger, followed by mesh generation that must be sufficiently refined to capture acoustic phenomena. Critical regions requiring particular attention include tube-fluid interfaces, sudden expansions or contractions, and areas with high velocity gradients where flow instabilities are likely to develop.

Acoustic simulations can be conducted using various methodologies within the CFD framework. The direct approach solves the compressible Navier-Stokes equations to capture both flow and acoustic fields simultaneously. Alternatively, hybrid approaches separate the flow simulation from acoustic propagation, using methods such as Lighthill's acoustic analogy or the Ffowcs Williams-Hawkings (FWH) equation to predict far-field noise based on near-field flow data.

Recent advancements in computational capabilities have enabled more sophisticated analyses, including fluid-structure interaction (FSI) simulations that account for the vibro-acoustic coupling between fluid flow and structural components. This is particularly relevant for heat exchangers where tube vibrations can contribute significantly to overall noise emissions.

Validation of CFD noise predictions remains challenging but essential. Researchers typically compare simulation results with experimental measurements obtained through techniques such as acoustic holography, sound intensity mapping, or microphone array measurements. The correlation between predicted and measured sound pressure levels serves as a key performance indicator for the simulation methodology.

The computational cost of noise prediction simulations represents a significant challenge, often requiring high-performance computing resources for practical industrial applications. However, the insights gained from these simulations—such as identification of dominant noise sources and evaluation of design modifications—provide valuable guidance for noise reduction strategies that would be difficult to obtain through experimental methods alone.

Modern CFD software packages incorporate advanced turbulence models such as Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) that can accurately capture the flow-induced noise mechanisms. These models are particularly effective at resolving the turbulent flow structures responsible for acoustic emissions in heat exchangers, including vortex shedding, flow separation, and turbulent boundary layer interactions.

The CFD-based noise prediction workflow typically begins with a detailed geometric model of the heat exchanger, followed by mesh generation that must be sufficiently refined to capture acoustic phenomena. Critical regions requiring particular attention include tube-fluid interfaces, sudden expansions or contractions, and areas with high velocity gradients where flow instabilities are likely to develop.

Acoustic simulations can be conducted using various methodologies within the CFD framework. The direct approach solves the compressible Navier-Stokes equations to capture both flow and acoustic fields simultaneously. Alternatively, hybrid approaches separate the flow simulation from acoustic propagation, using methods such as Lighthill's acoustic analogy or the Ffowcs Williams-Hawkings (FWH) equation to predict far-field noise based on near-field flow data.

Recent advancements in computational capabilities have enabled more sophisticated analyses, including fluid-structure interaction (FSI) simulations that account for the vibro-acoustic coupling between fluid flow and structural components. This is particularly relevant for heat exchangers where tube vibrations can contribute significantly to overall noise emissions.

Validation of CFD noise predictions remains challenging but essential. Researchers typically compare simulation results with experimental measurements obtained through techniques such as acoustic holography, sound intensity mapping, or microphone array measurements. The correlation between predicted and measured sound pressure levels serves as a key performance indicator for the simulation methodology.

The computational cost of noise prediction simulations represents a significant challenge, often requiring high-performance computing resources for practical industrial applications. However, the insights gained from these simulations—such as identification of dominant noise sources and evaluation of design modifications—provide valuable guidance for noise reduction strategies that would be difficult to obtain through experimental methods alone.

Energy Efficiency vs Noise Performance Trade-offs

The optimization of heat exchanger designs presents a classic engineering dilemma between energy efficiency and noise performance. Heat exchangers with higher thermal efficiency often generate increased noise levels due to higher fluid velocities, turbulence, and pressure differentials. This fundamental trade-off requires careful consideration during the design phase to achieve an optimal balance.

Energy efficiency in heat exchangers is primarily achieved through enhanced heat transfer coefficients, which typically require higher fluid velocities and turbulent flow regimes. These design choices, while beneficial for thermal performance, inherently generate more acoustic energy through mechanisms such as flow-induced vibration, vortex shedding, and fluid-structure interactions.

Quantitative analysis reveals that a 10-15% improvement in heat transfer efficiency often corresponds to a 3-5 dB increase in noise levels, particularly in the mid to high frequency ranges (1-8 kHz). This relationship is non-linear and becomes more pronounced as systems approach their maximum thermal efficiency points.

Recent advancements in computational fluid dynamics (CFD) and acoustic modeling have enabled more sophisticated approaches to this trade-off. Multi-objective optimization algorithms now allow designers to identify Pareto-optimal solutions that maximize energy efficiency while maintaining acceptable noise thresholds for specific applications.

Material selection plays a crucial role in managing this trade-off. Advanced composite materials with high thermal conductivity and good damping properties can simultaneously enhance heat transfer while reducing structural vibration and resultant noise. For instance, carbon-polymer composites have demonstrated the ability to improve thermal efficiency by 8% while reducing noise by 2-3 dB compared to traditional aluminum alloys.

Geometric modifications represent another approach to balancing these competing objectives. Streamlined tube arrangements, optimized baffle configurations, and specially designed inlet/outlet geometries can reduce flow separation and turbulence while maintaining effective heat transfer. Helical baffle designs, for example, have shown promise in reducing noise by up to 4 dB while sacrificing only 5-7% in thermal performance.

The application context ultimately determines the appropriate balance point. Industrial heat exchangers may prioritize efficiency over noise, while HVAC systems for residential or commercial buildings require stricter noise limitations. Regulatory standards increasingly address both energy efficiency and noise emissions, further complicating design decisions and necessitating sophisticated trade-off analyses during the development process.

Energy efficiency in heat exchangers is primarily achieved through enhanced heat transfer coefficients, which typically require higher fluid velocities and turbulent flow regimes. These design choices, while beneficial for thermal performance, inherently generate more acoustic energy through mechanisms such as flow-induced vibration, vortex shedding, and fluid-structure interactions.

Quantitative analysis reveals that a 10-15% improvement in heat transfer efficiency often corresponds to a 3-5 dB increase in noise levels, particularly in the mid to high frequency ranges (1-8 kHz). This relationship is non-linear and becomes more pronounced as systems approach their maximum thermal efficiency points.

Recent advancements in computational fluid dynamics (CFD) and acoustic modeling have enabled more sophisticated approaches to this trade-off. Multi-objective optimization algorithms now allow designers to identify Pareto-optimal solutions that maximize energy efficiency while maintaining acceptable noise thresholds for specific applications.

Material selection plays a crucial role in managing this trade-off. Advanced composite materials with high thermal conductivity and good damping properties can simultaneously enhance heat transfer while reducing structural vibration and resultant noise. For instance, carbon-polymer composites have demonstrated the ability to improve thermal efficiency by 8% while reducing noise by 2-3 dB compared to traditional aluminum alloys.

Geometric modifications represent another approach to balancing these competing objectives. Streamlined tube arrangements, optimized baffle configurations, and specially designed inlet/outlet geometries can reduce flow separation and turbulence while maintaining effective heat transfer. Helical baffle designs, for example, have shown promise in reducing noise by up to 4 dB while sacrificing only 5-7% in thermal performance.

The application context ultimately determines the appropriate balance point. Industrial heat exchangers may prioritize efficiency over noise, while HVAC systems for residential or commercial buildings require stricter noise limitations. Regulatory standards increasingly address both energy efficiency and noise emissions, further complicating design decisions and necessitating sophisticated trade-off analyses during the development process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!