Analyzing the CO2 Capture Efficiency of Carbon-negative Concrete

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Evolution

Carbon-negative concrete technology has evolved significantly over the past decades, transforming from a theoretical concept to a commercially viable solution for sustainable construction. The evolution began in the early 2000s when researchers first recognized the potential for concrete to sequester carbon dioxide rather than merely reducing emissions. This initial phase focused primarily on laboratory-scale experiments to understand the fundamental chemistry of carbon mineralization in cementitious materials.

By 2010, the technology had progressed to pilot projects, where various methodologies for incorporating CO2 into concrete were tested under real-world conditions. These early implementations demonstrated modest carbon sequestration capabilities, typically capturing 5-10% of the CO2 emissions associated with traditional concrete production. The primary approaches during this period involved post-production CO2 curing and the use of carbonated aggregates.

A significant breakthrough occurred around 2015 with the development of advanced carbon mineralization techniques that could be integrated directly into the concrete manufacturing process. This innovation allowed for higher carbon capture rates while maintaining or even enhancing concrete performance characteristics such as strength and durability. Companies like CarbonCure and Solidia Technologies emerged as pioneers, commercializing systems that could reduce the carbon footprint of concrete by up to 30%.

The period from 2018 to 2021 saw rapid acceleration in both technological sophistication and market adoption. Novel binder formulations incorporating supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume were optimized specifically for carbon sequestration. Simultaneously, direct air capture technologies began to be integrated with concrete production, creating truly carbon-negative solutions capable of removing more CO2 from the atmosphere than emitted during manufacturing.

Most recently (2021-2023), the technology has entered a phase of industrial scaling and standardization. Carbon-negative concrete has moved beyond niche applications to become increasingly mainstream in commercial construction projects. Current state-of-the-art solutions can achieve net carbon sequestration of 50-100 kg CO2 per cubic meter of concrete, representing a paradigm shift from concrete as a carbon source to a carbon sink.

The evolution has been accelerated by supportive policy frameworks, including carbon pricing mechanisms and green building standards that incentivize low-carbon construction materials. Looking forward, the technology trajectory suggests continued improvements in CO2 capture efficiency, with research focusing on novel catalysts, optimized curing conditions, and alternative calcium sources to maximize carbon mineralization potential.

By 2010, the technology had progressed to pilot projects, where various methodologies for incorporating CO2 into concrete were tested under real-world conditions. These early implementations demonstrated modest carbon sequestration capabilities, typically capturing 5-10% of the CO2 emissions associated with traditional concrete production. The primary approaches during this period involved post-production CO2 curing and the use of carbonated aggregates.

A significant breakthrough occurred around 2015 with the development of advanced carbon mineralization techniques that could be integrated directly into the concrete manufacturing process. This innovation allowed for higher carbon capture rates while maintaining or even enhancing concrete performance characteristics such as strength and durability. Companies like CarbonCure and Solidia Technologies emerged as pioneers, commercializing systems that could reduce the carbon footprint of concrete by up to 30%.

The period from 2018 to 2021 saw rapid acceleration in both technological sophistication and market adoption. Novel binder formulations incorporating supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume were optimized specifically for carbon sequestration. Simultaneously, direct air capture technologies began to be integrated with concrete production, creating truly carbon-negative solutions capable of removing more CO2 from the atmosphere than emitted during manufacturing.

Most recently (2021-2023), the technology has entered a phase of industrial scaling and standardization. Carbon-negative concrete has moved beyond niche applications to become increasingly mainstream in commercial construction projects. Current state-of-the-art solutions can achieve net carbon sequestration of 50-100 kg CO2 per cubic meter of concrete, representing a paradigm shift from concrete as a carbon source to a carbon sink.

The evolution has been accelerated by supportive policy frameworks, including carbon pricing mechanisms and green building standards that incentivize low-carbon construction materials. Looking forward, the technology trajectory suggests continued improvements in CO2 capture efficiency, with research focusing on novel catalysts, optimized curing conditions, and alternative calcium sources to maximize carbon mineralization potential.

Market Analysis for CO2 Capture Solutions

The global market for CO2 capture solutions has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions. The carbon capture, utilization, and storage (CCUS) market was valued at approximately $2.5 billion in 2022 and is projected to reach $7.0 billion by 2030, growing at a CAGR of 13.8% during the forecast period. This growth trajectory reflects the urgent need for effective carbon management strategies across various industries.

The construction sector, responsible for about 8% of global CO2 emissions, presents a substantial opportunity for carbon capture technologies. Carbon-negative concrete solutions specifically are gaining traction as they address emissions at one of the largest industrial sources. The market for green concrete, including carbon-negative variants, is expected to grow from $26.2 billion in 2021 to $43.4 billion by 2026, representing a CAGR of 10.6%.

Regional analysis reveals varying adoption rates and market potential. North America and Europe lead in terms of technology deployment and investment, with the United States allocating over $12 billion through the Infrastructure Investment and Jobs Act specifically for carbon capture initiatives. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid urbanization and construction activities coupled with increasing environmental regulations.

Customer segmentation within the CO2 capture market reveals three primary segments: large-scale industrial facilities (including cement manufacturers), government infrastructure projects, and commercial building developers. The cement industry, producing approximately 4 billion tons of cement annually and accounting for roughly 8% of global CO2 emissions, represents the most significant potential customer base for carbon-negative concrete technologies.

Pricing trends indicate that carbon-negative concrete solutions currently command a premium of 15-30% over traditional concrete. However, this premium is expected to decrease as technologies mature and economies of scale are achieved. The integration of carbon credits and regulatory incentives is increasingly influencing the economic viability of these solutions, with carbon credits trading at $30-85 per ton depending on the market and jurisdiction.

Demand drivers for CO2 capture in concrete include strengthening regulatory frameworks, corporate sustainability commitments, green building certification requirements, and increasing consumer awareness. The EU's Carbon Border Adjustment Mechanism and similar policies worldwide are creating financial incentives for low-carbon building materials, accelerating market adoption of carbon-negative concrete solutions.

The construction sector, responsible for about 8% of global CO2 emissions, presents a substantial opportunity for carbon capture technologies. Carbon-negative concrete solutions specifically are gaining traction as they address emissions at one of the largest industrial sources. The market for green concrete, including carbon-negative variants, is expected to grow from $26.2 billion in 2021 to $43.4 billion by 2026, representing a CAGR of 10.6%.

Regional analysis reveals varying adoption rates and market potential. North America and Europe lead in terms of technology deployment and investment, with the United States allocating over $12 billion through the Infrastructure Investment and Jobs Act specifically for carbon capture initiatives. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid urbanization and construction activities coupled with increasing environmental regulations.

Customer segmentation within the CO2 capture market reveals three primary segments: large-scale industrial facilities (including cement manufacturers), government infrastructure projects, and commercial building developers. The cement industry, producing approximately 4 billion tons of cement annually and accounting for roughly 8% of global CO2 emissions, represents the most significant potential customer base for carbon-negative concrete technologies.

Pricing trends indicate that carbon-negative concrete solutions currently command a premium of 15-30% over traditional concrete. However, this premium is expected to decrease as technologies mature and economies of scale are achieved. The integration of carbon credits and regulatory incentives is increasingly influencing the economic viability of these solutions, with carbon credits trading at $30-85 per ton depending on the market and jurisdiction.

Demand drivers for CO2 capture in concrete include strengthening regulatory frameworks, corporate sustainability commitments, green building certification requirements, and increasing consumer awareness. The EU's Carbon Border Adjustment Mechanism and similar policies worldwide are creating financial incentives for low-carbon building materials, accelerating market adoption of carbon-negative concrete solutions.

Current CO2 Capture Efficiency Challenges

Despite significant advancements in carbon-negative concrete technology, current CO2 capture efficiency faces several critical challenges that limit widespread implementation. The primary technical obstacle remains the relatively low CO2 absorption capacity of conventional carbonation processes, with most commercial solutions achieving only 5-20% of theoretical maximum capture rates. This efficiency gap stems from limitations in reaction kinetics and mass transfer barriers that prevent complete carbonation throughout the concrete matrix.

Material composition presents another significant challenge, as traditional supplementary cementitious materials (SCMs) like fly ash and slag demonstrate variable CO2 reactivity depending on their chemical makeup and physical properties. Research indicates that calcium content and specific surface area significantly influence carbonation potential, yet optimizing these parameters often compromises concrete's mechanical performance and durability characteristics.

Process conditions further complicate efficiency improvements, with temperature, pressure, and CO2 concentration all critically affecting capture rates. Current industrial applications struggle to maintain optimal conditions throughout the curing process, resulting in heterogeneous carbonation profiles and reduced overall efficiency. The energy requirements for maintaining ideal conditions also diminish the net carbon benefit, creating a technological paradox where increased capture may lead to higher operational emissions.

Measurement and verification methodologies represent another substantial challenge. Current techniques for quantifying captured CO2 lack standardization across the industry, making performance comparisons between different technologies difficult. Thermogravimetric analysis, X-ray diffraction, and mass balance calculations each present limitations in accuracy and applicability across varying concrete formulations and production scales.

Economic viability remains perhaps the most pressing challenge, as high-efficiency capture systems typically require significant capital investment and operational expenditure. The current cost premium for carbon-negative concrete ranges from 15-40% above conventional products, creating market resistance despite environmental benefits. Without carbon pricing mechanisms or regulatory incentives, manufacturers face limited economic motivation to maximize capture efficiency.

Scalability issues further compound these challenges, as laboratory-demonstrated high-efficiency capture methods often encounter significant performance degradation when implemented at industrial scale. Factors including mixing uniformity, curing time variations, and equipment limitations create substantial barriers to maintaining consistent capture rates in commercial production environments.

Material composition presents another significant challenge, as traditional supplementary cementitious materials (SCMs) like fly ash and slag demonstrate variable CO2 reactivity depending on their chemical makeup and physical properties. Research indicates that calcium content and specific surface area significantly influence carbonation potential, yet optimizing these parameters often compromises concrete's mechanical performance and durability characteristics.

Process conditions further complicate efficiency improvements, with temperature, pressure, and CO2 concentration all critically affecting capture rates. Current industrial applications struggle to maintain optimal conditions throughout the curing process, resulting in heterogeneous carbonation profiles and reduced overall efficiency. The energy requirements for maintaining ideal conditions also diminish the net carbon benefit, creating a technological paradox where increased capture may lead to higher operational emissions.

Measurement and verification methodologies represent another substantial challenge. Current techniques for quantifying captured CO2 lack standardization across the industry, making performance comparisons between different technologies difficult. Thermogravimetric analysis, X-ray diffraction, and mass balance calculations each present limitations in accuracy and applicability across varying concrete formulations and production scales.

Economic viability remains perhaps the most pressing challenge, as high-efficiency capture systems typically require significant capital investment and operational expenditure. The current cost premium for carbon-negative concrete ranges from 15-40% above conventional products, creating market resistance despite environmental benefits. Without carbon pricing mechanisms or regulatory incentives, manufacturers face limited economic motivation to maximize capture efficiency.

Scalability issues further compound these challenges, as laboratory-demonstrated high-efficiency capture methods often encounter significant performance degradation when implemented at industrial scale. Factors including mixing uniformity, curing time variations, and equipment limitations create substantial barriers to maintaining consistent capture rates in commercial production environments.

Current CO2 Capture Methodologies

01 CO2 mineralization in concrete production

Carbon dioxide can be captured and permanently stored in concrete through mineralization processes. This involves the reaction of CO2 with calcium or magnesium-rich materials to form stable carbonate minerals. The process not only sequesters carbon dioxide but also can improve concrete properties such as strength and durability. This approach allows concrete to become carbon-negative by storing more CO2 than is emitted during its production.- CO2 mineralization in concrete production: Carbon dioxide can be captured and permanently stored in concrete through mineralization processes. This involves the reaction of CO2 with calcium or magnesium-rich materials to form stable carbonate minerals. The process not only sequesters carbon dioxide but also can improve concrete properties such as strength and durability. This approach allows concrete to become carbon-negative by storing more CO2 than is emitted during its production.

- Accelerated carbonation techniques: Accelerated carbonation techniques enhance the CO2 capture efficiency in concrete by optimizing conditions such as pressure, temperature, and moisture content. These methods speed up the natural carbonation process, allowing concrete to absorb more carbon dioxide in a shorter time frame. The techniques can be applied during curing or post-production stages, significantly increasing the carbon sequestration potential of concrete products.

- Alternative binders and supplementary cementitious materials: The use of alternative binders and supplementary cementitious materials can significantly enhance the CO2 capture efficiency of concrete. Materials such as fly ash, slag, silica fume, and natural pozzolans can partially replace traditional Portland cement, reducing the carbon footprint of concrete production. These materials can also increase the concrete's capacity to absorb and store carbon dioxide through enhanced porosity and chemical reactivity.

- Monitoring and measurement systems for CO2 capture: Advanced monitoring and measurement systems are essential for quantifying the CO2 capture efficiency of carbon-negative concrete. These systems employ sensors, analytical techniques, and computational models to track carbon dioxide absorption in real-time or through periodic assessments. Accurate measurement is crucial for verifying carbon credits, optimizing production processes, and ensuring the concrete achieves its intended carbon sequestration goals.

- Integration with industrial carbon capture systems: Carbon-negative concrete production can be integrated with industrial carbon capture systems to maximize CO2 sequestration. This approach involves capturing carbon dioxide emissions from industrial processes such as cement kilns, power plants, or other manufacturing facilities, and then utilizing this captured CO2 in concrete production. The integration creates a closed-loop system that significantly enhances overall carbon capture efficiency and provides a practical use for captured industrial emissions.

02 Accelerated carbonation techniques

Accelerated carbonation techniques enhance the CO2 capture efficiency in concrete by optimizing conditions such as pressure, temperature, and moisture content. These methods speed up the natural carbonation process, allowing concrete to absorb more carbon dioxide in a shorter time frame. The techniques can be applied during curing or post-production stages, significantly increasing the carbon sequestration potential of concrete products.Expand Specific Solutions03 Alternative binders and supplementary cementitious materials

The use of alternative binders and supplementary cementitious materials can significantly enhance the CO2 capture efficiency of concrete. Materials such as fly ash, slag, silica fume, and natural pozzolans can partially replace traditional Portland cement, reducing the carbon footprint of concrete production. These materials can also increase the concrete's capacity to absorb CO2 during its lifetime, contributing to carbon-negative concrete solutions.Expand Specific Solutions04 Monitoring and measurement systems for CO2 capture

Advanced monitoring and measurement systems are essential for quantifying the CO2 capture efficiency in carbon-negative concrete. These systems employ sensors, analytical techniques, and computational models to accurately track carbon dioxide absorption throughout the concrete lifecycle. Real-time monitoring allows for optimization of the carbonation process and verification of carbon credits, ensuring the effectiveness of carbon-negative concrete solutions.Expand Specific Solutions05 Integration with carbon capture and utilization systems

Carbon-negative concrete can be integrated with broader carbon capture and utilization systems to maximize CO2 sequestration efficiency. This approach involves capturing CO2 from industrial emissions or directly from the air and utilizing it in concrete production. The integration creates a closed-loop system where carbon dioxide is continuously captured and converted into valuable construction materials, enhancing the overall carbon negativity of concrete products.Expand Specific Solutions

Leading Companies in Carbon-negative Concrete

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activity and commercial pilot projects. The market is expanding rapidly due to global decarbonization initiatives, with projections suggesting significant growth as construction industries seek sustainable alternatives. Technologically, carbon capture in concrete remains at varying maturity levels across players. Leading companies like Carbonbuilt and Carbon Limit have developed proprietary CO2 mineralization technologies that permanently sequester carbon while enhancing concrete properties. Academic institutions including University of California and Peking University are advancing fundamental research, while established industry players such as China National Building Material Group and CRH are scaling commercial applications. Concrete4Change and Shimizu Corporation represent innovative approaches to implementation across different markets.

Carbonbuilt, Inc.

Technical Solution: Carbonbuilt has developed a revolutionary concrete curing technology that directly absorbs CO2 from flue gas sources without requiring carbon capture or purification. Their Reversa™ process replaces traditional Portland cement with a proprietary low-carbon blend and injects CO2 during the concrete curing phase, permanently mineralizing it within the concrete matrix. This technology can achieve up to 70-100% reduction in carbon footprint compared to traditional concrete production methods. The process utilizes dilute CO2 streams (5-30% concentration) directly from industrial emissions, eliminating the need for expensive carbon capture equipment. Their concrete products meet or exceed industry performance standards while sequestering approximately 10-30 kg of CO2 per cubic meter of concrete produced.

Strengths: Direct utilization of flue gas without purification reduces costs; achieves high CO2 reduction percentages; produces market-ready concrete products. Weaknesses: Requires proximity to industrial CO2 sources; technology deployment still scaling up; may have limitations in certain specialized concrete applications requiring very specific performance characteristics.

China National Building Material Group Co., Ltd.

Technical Solution: China National Building Material Group (CNBM) has developed an integrated carbon-negative concrete technology platform that addresses the entire concrete production value chain. Their system combines low-clinker cement formulations with industrial waste utilization and direct CO2 mineralization. CNBM's approach incorporates captured CO2 from their own cement kilns, creating a closed-loop carbon utilization system. Their technology can achieve CO2 reductions of 40-60% compared to conventional concrete while maintaining equivalent performance characteristics. The process includes a specialized carbonation reactor that optimizes the CO2-cement reaction kinetics, achieving mineralization efficiencies of 70-90% of theoretical maximum. CNBM has implemented this technology at industrial scale across multiple facilities in China, with annual production capacity exceeding 1 million cubic meters of carbon-reduced concrete products.

Strengths: Vertically integrated approach from cement production to concrete manufacturing; large-scale implementation demonstrating commercial viability; closed-loop carbon utilization system. Weaknesses: Technology optimization heavily focused on materials available in Chinese market; complex implementation requiring significant capital investment; varying performance across different concrete applications.

Key Patents in Concrete CO2 Sequestration

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Cementitious materials and methods of making and using same

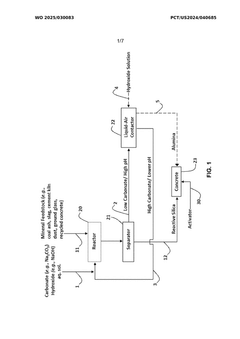

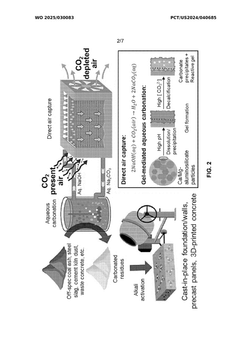

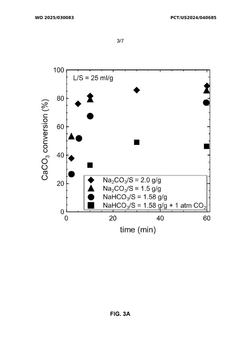

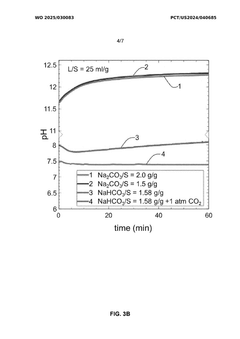

PatentWO2025030083A1

Innovation

- The method involves a carbon mineralization-based direct-air capture process using an aqueous carbonation cycle to capture CO2 from the air and enhance the pozzolanic reactivity of industrial mineral wastes, which are then used to produce carbon-negative cementitious materials that can replace or reduce Portland cement in concrete production.

Environmental Impact Assessment

The environmental impact assessment of carbon-negative concrete reveals significant potential for reducing greenhouse gas emissions across the construction industry lifecycle. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing processes that release carbon through limestone calcination and fossil fuel combustion.

Carbon-negative concrete technologies demonstrate promising CO2 capture efficiency metrics in laboratory settings, with some formulations achieving net carbon sequestration of 100-300 kg CO2 per cubic meter of concrete. This represents a dramatic improvement compared to conventional concrete, which typically emits 400-500 kg CO2 per cubic meter.

Life cycle assessment (LCA) studies indicate that carbon-negative concrete can reduce the carbon footprint of buildings by 10-25% when considering the entire construction process. The environmental benefits extend beyond carbon sequestration to include reduced water consumption and lower energy requirements during manufacturing, though these advantages vary significantly based on specific formulations and production methods.

Water usage analysis shows that certain carbon-negative concrete formulations require 15-30% less water than traditional concrete, contributing to conservation of this critical resource. However, some carbon capture processes may increase water demands, creating a complex environmental trade-off that requires careful regional assessment.

Land use impacts remain a concern, particularly regarding the sourcing of alternative cementitious materials and carbon capture substrates. Sustainable supply chains for materials like fly ash, slag, and novel carbon-absorbing aggregates must be established to prevent unintended environmental consequences such as habitat disruption or agricultural land conversion.

Air quality improvements represent another significant environmental benefit, as reduced cement clinker production decreases emissions of sulfur dioxide, nitrogen oxides, and particulate matter. Urban deployment of carbon-negative concrete may contribute to localized air quality improvements through continued carbon absorption during the material's service life.

Waste stream analysis indicates potential for circular economy integration, with carbon-negative concrete technologies capable of incorporating industrial byproducts and construction waste. This diverts materials from landfills while simultaneously reducing virgin resource extraction, creating a double environmental dividend.

The durability and longevity of carbon-negative concrete formulations remain under investigation, with preliminary studies suggesting comparable or potentially superior performance to conventional concrete in certain applications. Enhanced durability would further improve environmental outcomes through extended service life and reduced replacement frequency.

Carbon-negative concrete technologies demonstrate promising CO2 capture efficiency metrics in laboratory settings, with some formulations achieving net carbon sequestration of 100-300 kg CO2 per cubic meter of concrete. This represents a dramatic improvement compared to conventional concrete, which typically emits 400-500 kg CO2 per cubic meter.

Life cycle assessment (LCA) studies indicate that carbon-negative concrete can reduce the carbon footprint of buildings by 10-25% when considering the entire construction process. The environmental benefits extend beyond carbon sequestration to include reduced water consumption and lower energy requirements during manufacturing, though these advantages vary significantly based on specific formulations and production methods.

Water usage analysis shows that certain carbon-negative concrete formulations require 15-30% less water than traditional concrete, contributing to conservation of this critical resource. However, some carbon capture processes may increase water demands, creating a complex environmental trade-off that requires careful regional assessment.

Land use impacts remain a concern, particularly regarding the sourcing of alternative cementitious materials and carbon capture substrates. Sustainable supply chains for materials like fly ash, slag, and novel carbon-absorbing aggregates must be established to prevent unintended environmental consequences such as habitat disruption or agricultural land conversion.

Air quality improvements represent another significant environmental benefit, as reduced cement clinker production decreases emissions of sulfur dioxide, nitrogen oxides, and particulate matter. Urban deployment of carbon-negative concrete may contribute to localized air quality improvements through continued carbon absorption during the material's service life.

Waste stream analysis indicates potential for circular economy integration, with carbon-negative concrete technologies capable of incorporating industrial byproducts and construction waste. This diverts materials from landfills while simultaneously reducing virgin resource extraction, creating a double environmental dividend.

The durability and longevity of carbon-negative concrete formulations remain under investigation, with preliminary studies suggesting comparable or potentially superior performance to conventional concrete in certain applications. Enhanced durability would further improve environmental outcomes through extended service life and reduced replacement frequency.

Policy Frameworks for Carbon-negative Materials

Policy frameworks play a crucial role in accelerating the adoption of carbon-negative concrete technologies and materials across global markets. Currently, several jurisdictions have implemented progressive policies that incentivize carbon capture in building materials, with varying approaches and effectiveness.

The European Union leads with its Carbon Border Adjustment Mechanism (CBAM) and the Emissions Trading System (ETS), which create economic incentives for manufacturers to reduce embodied carbon in construction materials. These frameworks specifically recognize carbon-negative concrete as a pathway to meeting climate targets, offering preferential treatment in public procurement processes.

In North America, both the United States and Canada have developed complementary approaches. The U.S. Inflation Reduction Act allocates significant funding for carbon-negative material development, including tax credits of up to $85 per ton for permanently sequestered carbon. Meanwhile, Canada's Clean Concrete Standard establishes progressive carbon intensity limits for concrete used in federal projects.

The Asia-Pacific region demonstrates more varied policy implementation. While Singapore's Green Mark certification system rewards carbon-negative materials with premium certification levels, China has incorporated carbon-negative concrete into its national emissions reduction strategy with specific production targets by 2030.

Regulatory barriers remain significant challenges to widespread adoption. Current building codes and material standards in many countries lack provisions for innovative carbon-negative concrete formulations, creating approval hurdles. Additionally, the absence of standardized carbon accounting methodologies specifically for concrete creates market uncertainty.

Effective policy frameworks must address several key components to drive carbon-negative concrete adoption. First, they should establish clear carbon intensity metrics and verification protocols specific to concrete production. Second, they need to provide financial incentives through carbon pricing, tax benefits, or subsidies that recognize the climate value of carbon sequestration. Third, they should mandate carbon disclosure in public procurement to create market demand.

Future policy development trends indicate movement toward harmonized international standards for measuring embodied carbon in building materials. There is also growing momentum for lifecycle-based regulations that account for both operational and embodied carbon in buildings, potentially creating stronger market signals for carbon-negative materials.

The European Union leads with its Carbon Border Adjustment Mechanism (CBAM) and the Emissions Trading System (ETS), which create economic incentives for manufacturers to reduce embodied carbon in construction materials. These frameworks specifically recognize carbon-negative concrete as a pathway to meeting climate targets, offering preferential treatment in public procurement processes.

In North America, both the United States and Canada have developed complementary approaches. The U.S. Inflation Reduction Act allocates significant funding for carbon-negative material development, including tax credits of up to $85 per ton for permanently sequestered carbon. Meanwhile, Canada's Clean Concrete Standard establishes progressive carbon intensity limits for concrete used in federal projects.

The Asia-Pacific region demonstrates more varied policy implementation. While Singapore's Green Mark certification system rewards carbon-negative materials with premium certification levels, China has incorporated carbon-negative concrete into its national emissions reduction strategy with specific production targets by 2030.

Regulatory barriers remain significant challenges to widespread adoption. Current building codes and material standards in many countries lack provisions for innovative carbon-negative concrete formulations, creating approval hurdles. Additionally, the absence of standardized carbon accounting methodologies specifically for concrete creates market uncertainty.

Effective policy frameworks must address several key components to drive carbon-negative concrete adoption. First, they should establish clear carbon intensity metrics and verification protocols specific to concrete production. Second, they need to provide financial incentives through carbon pricing, tax benefits, or subsidies that recognize the climate value of carbon sequestration. Third, they should mandate carbon disclosure in public procurement to create market demand.

Future policy development trends indicate movement toward harmonized international standards for measuring embodied carbon in building materials. There is also growing momentum for lifecycle-based regulations that account for both operational and embodied carbon in buildings, potentially creating stronger market signals for carbon-negative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!