Anticipating supply chain elasticity improvements in V16 engine logistics

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Logistics Evolution and Objectives

The V16 engine, a pinnacle of automotive engineering, has undergone significant evolution in its logistics and supply chain management. This evolution has been driven by the need for increased efficiency, cost-effectiveness, and adaptability in an ever-changing global market. The primary objective in V16 engine logistics is to create a seamless, responsive, and resilient supply chain that can meet the demands of high-performance vehicle production while minimizing costs and environmental impact.

Historically, V16 engine logistics were characterized by rigid, linear supply chains with limited flexibility. These traditional models often struggled to adapt to sudden changes in demand or supply disruptions, leading to inefficiencies and increased costs. As the automotive industry has become more globalized and competitive, there has been a shift towards more agile and elastic supply chain strategies.

The evolution of V16 engine logistics has been marked by several key milestones. The introduction of just-in-time (JIT) manufacturing principles in the 1980s revolutionized inventory management, reducing storage costs and improving production efficiency. The 1990s saw the rise of enterprise resource planning (ERP) systems, which integrated various aspects of the supply chain, from procurement to distribution, enhancing visibility and coordination.

In recent years, the focus has shifted towards creating more resilient and adaptive supply chains. This has been driven by factors such as increasing market volatility, geopolitical uncertainties, and the need for greater sustainability. Advanced analytics and artificial intelligence have played a crucial role in this evolution, enabling more accurate demand forecasting and real-time supply chain optimization.

The current objectives in V16 engine logistics center around achieving greater supply chain elasticity. This involves developing the capability to rapidly scale production up or down in response to market demands, while maintaining cost-effectiveness and quality. Key goals include reducing lead times, minimizing inventory holding costs, and improving overall supply chain visibility and traceability.

Another critical objective is to enhance the sustainability of V16 engine logistics. This includes optimizing transportation routes to reduce carbon emissions, implementing circular economy principles in the supply chain, and sourcing materials from environmentally responsible suppliers. These efforts align with broader industry trends towards more sustainable and socially responsible manufacturing practices.

Looking ahead, the future of V16 engine logistics will likely be shaped by emerging technologies such as blockchain for enhanced traceability, Internet of Things (IoT) for real-time monitoring, and advanced robotics for more flexible manufacturing processes. The ultimate aim is to create a highly responsive, efficient, and sustainable supply chain ecosystem that can adapt to the rapidly changing landscape of the automotive industry.

Historically, V16 engine logistics were characterized by rigid, linear supply chains with limited flexibility. These traditional models often struggled to adapt to sudden changes in demand or supply disruptions, leading to inefficiencies and increased costs. As the automotive industry has become more globalized and competitive, there has been a shift towards more agile and elastic supply chain strategies.

The evolution of V16 engine logistics has been marked by several key milestones. The introduction of just-in-time (JIT) manufacturing principles in the 1980s revolutionized inventory management, reducing storage costs and improving production efficiency. The 1990s saw the rise of enterprise resource planning (ERP) systems, which integrated various aspects of the supply chain, from procurement to distribution, enhancing visibility and coordination.

In recent years, the focus has shifted towards creating more resilient and adaptive supply chains. This has been driven by factors such as increasing market volatility, geopolitical uncertainties, and the need for greater sustainability. Advanced analytics and artificial intelligence have played a crucial role in this evolution, enabling more accurate demand forecasting and real-time supply chain optimization.

The current objectives in V16 engine logistics center around achieving greater supply chain elasticity. This involves developing the capability to rapidly scale production up or down in response to market demands, while maintaining cost-effectiveness and quality. Key goals include reducing lead times, minimizing inventory holding costs, and improving overall supply chain visibility and traceability.

Another critical objective is to enhance the sustainability of V16 engine logistics. This includes optimizing transportation routes to reduce carbon emissions, implementing circular economy principles in the supply chain, and sourcing materials from environmentally responsible suppliers. These efforts align with broader industry trends towards more sustainable and socially responsible manufacturing practices.

Looking ahead, the future of V16 engine logistics will likely be shaped by emerging technologies such as blockchain for enhanced traceability, Internet of Things (IoT) for real-time monitoring, and advanced robotics for more flexible manufacturing processes. The ultimate aim is to create a highly responsive, efficient, and sustainable supply chain ecosystem that can adapt to the rapidly changing landscape of the automotive industry.

Market Demand Analysis for V16 Engines

The market demand for V16 engines has been experiencing a significant shift in recent years, driven by various factors including environmental regulations, technological advancements, and changing consumer preferences. While traditionally associated with high-performance luxury vehicles and marine applications, the V16 engine market has seen a contraction in the automotive sector due to stringent emission standards and the push towards electrification.

In the automotive industry, V16 engines are now primarily limited to ultra-luxury and collector vehicles, with a very niche market. Manufacturers like Cadillac and Bugatti have historically produced V16-powered cars, but current production is extremely limited. The demand in this sector is driven by enthusiasts and collectors who value the unique characteristics and prestige of V16 engines, rather than practical considerations.

However, the marine sector continues to show steady demand for V16 engines, particularly in large yachts and commercial vessels. These engines are valued for their power output, smoothness, and reliability in marine applications. The luxury yacht market, which has shown resilience even during economic downturns, remains a key driver for V16 engine demand.

In industrial applications, V16 engines find use in power generation, particularly for standby and emergency power systems in critical infrastructure such as hospitals, data centers, and industrial facilities. This sector shows potential for growth as the need for reliable backup power increases globally.

The aerospace industry, while a smaller market segment, also utilizes V16 engines in certain specialized aircraft and military applications. This niche market is characterized by high-value, low-volume demand with stringent performance and reliability requirements.

Looking at market trends, there is a growing emphasis on improving the efficiency and environmental performance of V16 engines. Manufacturers are investing in technologies such as advanced fuel injection systems, turbocharging, and hybrid integration to meet evolving regulatory standards while maintaining the performance characteristics that V16 engines are known for.

The global market size for V16 engines, while difficult to quantify precisely due to the niche nature of the product, is estimated to be in the range of hundreds of millions of dollars annually. Growth projections vary by sector, with the marine and industrial segments showing more promising outlooks compared to the automotive sector.

In conclusion, while the overall market for V16 engines has contracted in certain traditional sectors, it continues to evolve and find new applications. The future market demand will likely be shaped by advancements in engine technology, regulatory pressures, and the ability of manufacturers to adapt these powerful engines to meet changing environmental and performance requirements across various industries.

In the automotive industry, V16 engines are now primarily limited to ultra-luxury and collector vehicles, with a very niche market. Manufacturers like Cadillac and Bugatti have historically produced V16-powered cars, but current production is extremely limited. The demand in this sector is driven by enthusiasts and collectors who value the unique characteristics and prestige of V16 engines, rather than practical considerations.

However, the marine sector continues to show steady demand for V16 engines, particularly in large yachts and commercial vessels. These engines are valued for their power output, smoothness, and reliability in marine applications. The luxury yacht market, which has shown resilience even during economic downturns, remains a key driver for V16 engine demand.

In industrial applications, V16 engines find use in power generation, particularly for standby and emergency power systems in critical infrastructure such as hospitals, data centers, and industrial facilities. This sector shows potential for growth as the need for reliable backup power increases globally.

The aerospace industry, while a smaller market segment, also utilizes V16 engines in certain specialized aircraft and military applications. This niche market is characterized by high-value, low-volume demand with stringent performance and reliability requirements.

Looking at market trends, there is a growing emphasis on improving the efficiency and environmental performance of V16 engines. Manufacturers are investing in technologies such as advanced fuel injection systems, turbocharging, and hybrid integration to meet evolving regulatory standards while maintaining the performance characteristics that V16 engines are known for.

The global market size for V16 engines, while difficult to quantify precisely due to the niche nature of the product, is estimated to be in the range of hundreds of millions of dollars annually. Growth projections vary by sector, with the marine and industrial segments showing more promising outlooks compared to the automotive sector.

In conclusion, while the overall market for V16 engines has contracted in certain traditional sectors, it continues to evolve and find new applications. The future market demand will likely be shaped by advancements in engine technology, regulatory pressures, and the ability of manufacturers to adapt these powerful engines to meet changing environmental and performance requirements across various industries.

Current Challenges in V16 Engine Supply Chain

The V16 engine supply chain faces several significant challenges in the current landscape. One of the primary issues is the complexity of the engine itself, which requires a vast array of specialized components. This complexity leads to a higher risk of supply disruptions, as even a single missing part can halt the entire production process.

Another major challenge is the limited number of suppliers capable of producing the high-precision parts required for V16 engines. This scarcity creates a dependency on a small pool of vendors, increasing vulnerability to supply shortages and price fluctuations. The situation is further exacerbated by the global nature of the supply chain, which exposes it to geopolitical risks and trade uncertainties.

The high cost of V16 engine components also presents a significant challenge. These specialized parts often require advanced manufacturing techniques and materials, driving up production costs. This cost factor makes it difficult to maintain optimal inventory levels, as holding excess stock ties up significant capital, while insufficient inventory can lead to production delays.

Forecasting demand for V16 engines is another critical challenge. The market for these high-performance engines is relatively niche and can be influenced by various factors such as economic conditions, regulatory changes, and shifts in consumer preferences. Inaccurate demand forecasts can result in either overproduction or shortages, both of which can have severe financial implications.

Quality control presents an ongoing challenge in the V16 engine supply chain. The precision required in these engines means that even minor defects in components can lead to significant performance issues or failures. Implementing rigorous quality assurance processes across a global supply network is both complex and costly.

Transportation and logistics pose additional challenges, particularly for international supply chains. V16 engine components often require specialized handling and transportation methods to ensure their integrity. This necessity increases shipping costs and extends lead times, making it difficult to respond quickly to changes in demand or supply disruptions.

Lastly, the V16 engine supply chain faces increasing pressure to improve sustainability and reduce environmental impact. This challenge involves not only the manufacturing processes but also the sourcing of raw materials and the logistics of transportation. Balancing these environmental concerns with the high-performance requirements of V16 engines adds another layer of complexity to supply chain management.

Another major challenge is the limited number of suppliers capable of producing the high-precision parts required for V16 engines. This scarcity creates a dependency on a small pool of vendors, increasing vulnerability to supply shortages and price fluctuations. The situation is further exacerbated by the global nature of the supply chain, which exposes it to geopolitical risks and trade uncertainties.

The high cost of V16 engine components also presents a significant challenge. These specialized parts often require advanced manufacturing techniques and materials, driving up production costs. This cost factor makes it difficult to maintain optimal inventory levels, as holding excess stock ties up significant capital, while insufficient inventory can lead to production delays.

Forecasting demand for V16 engines is another critical challenge. The market for these high-performance engines is relatively niche and can be influenced by various factors such as economic conditions, regulatory changes, and shifts in consumer preferences. Inaccurate demand forecasts can result in either overproduction or shortages, both of which can have severe financial implications.

Quality control presents an ongoing challenge in the V16 engine supply chain. The precision required in these engines means that even minor defects in components can lead to significant performance issues or failures. Implementing rigorous quality assurance processes across a global supply network is both complex and costly.

Transportation and logistics pose additional challenges, particularly for international supply chains. V16 engine components often require specialized handling and transportation methods to ensure their integrity. This necessity increases shipping costs and extends lead times, making it difficult to respond quickly to changes in demand or supply disruptions.

Lastly, the V16 engine supply chain faces increasing pressure to improve sustainability and reduce environmental impact. This challenge involves not only the manufacturing processes but also the sourcing of raw materials and the logistics of transportation. Balancing these environmental concerns with the high-performance requirements of V16 engines adds another layer of complexity to supply chain management.

Existing Supply Chain Elasticity Solutions

01 V16 engine design and optimization

This category focuses on the design and optimization of V16 engines, including improvements in performance, efficiency, and power output. It covers advancements in engine architecture, combustion processes, and component integration to enhance overall engine functionality and reliability.- V16 engine design and optimization: This category focuses on the design and optimization of V16 engines, including improvements in performance, efficiency, and power output. It covers advancements in engine architecture, combustion processes, and component integration to enhance overall engine functionality and reliability.

- Logistics management for V16 engine production: This area addresses the logistics and supply chain management aspects of V16 engine production. It includes inventory control, production scheduling, and resource allocation to ensure efficient manufacturing and distribution of V16 engines and related components.

- Elasticity in V16 engine systems: This category explores the concept of elasticity in V16 engine systems, focusing on the ability to adapt to changing demands and conditions. It covers flexible manufacturing processes, scalable production systems, and adaptive engine control mechanisms to improve responsiveness and efficiency.

- Data analytics and AI for V16 engine optimization: This area involves the application of data analytics and artificial intelligence techniques to optimize V16 engine performance and logistics. It includes predictive maintenance, real-time monitoring, and intelligent decision-making systems to enhance engine efficiency and reliability.

- Sustainable and eco-friendly V16 engine solutions: This category focuses on developing sustainable and environmentally friendly solutions for V16 engines. It covers innovations in fuel efficiency, emissions reduction, and the integration of alternative energy sources to minimize the environmental impact of V16 engine operations.

02 Logistics management for V16 engine production

This point addresses the logistics and supply chain management aspects of V16 engine production. It includes inventory control, production scheduling, and resource allocation to ensure efficient manufacturing processes and timely delivery of engines and components.Expand Specific Solutions03 Elasticity in V16 engine systems

This category explores the concept of elasticity in V16 engine systems, focusing on the ability to adapt to varying loads and operating conditions. It covers technologies that enhance engine responsiveness, flexibility, and performance across different power demands and environmental factors.Expand Specific Solutions04 Data analytics and AI for V16 engine optimization

This point emphasizes the use of data analytics and artificial intelligence in optimizing V16 engine performance and logistics. It includes predictive maintenance, real-time monitoring, and intelligent decision-making systems to enhance engine efficiency and reliability.Expand Specific Solutions05 Sustainable and eco-friendly V16 engine solutions

This category focuses on developing sustainable and environmentally friendly solutions for V16 engines. It covers innovations in fuel efficiency, emissions reduction, and the integration of alternative energy sources to minimize the environmental impact of these powerful engines.Expand Specific Solutions

Key Players in V16 Engine Manufacturing

The V16 engine logistics market is in a mature phase, characterized by established players and steady demand. The global market size for V16 engine components and logistics is estimated to be in the billions, driven by applications in luxury vehicles, marine vessels, and power generation. Technologically, the field is advancing towards improved efficiency and reduced emissions. Key players like Toyota, Nissan, BMW, and Mercedes-Benz are investing in supply chain innovations to enhance elasticity. Emerging technologies in predictive analytics and IoT are being adopted by companies such as Siemens and Honda to optimize logistics operations. The competitive landscape is intense, with both traditional automakers and specialized engineering firms like Schaeffler and IAV contributing to advancements in V16 engine supply chain management.

Toyota Motor Corp.

Technical Solution: Toyota has developed a "Just-In-Time" (JIT) inventory management system specifically tailored for V16 engine logistics, which aims to minimize inventory holding costs while maintaining high responsiveness to demand changes[5]. This system is supported by advanced analytics and machine learning algorithms that continuously optimize order quantities and timing based on historical data and real-time market signals. Toyota has also implemented a supplier development program to improve the capabilities and responsiveness of their tier 1 and tier 2 suppliers, ensuring that the entire supply chain can adapt quickly to changes in demand or supply disruptions[6].

Strengths: Reduced inventory costs, improved cash flow, and enhanced supplier relationships. Weaknesses: Potential vulnerability to sudden supply disruptions and reliance on consistent supplier performance.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has focused on developing a flexible manufacturing system for V16 engines that allows for rapid adjustments in production volume and mix. This system incorporates modular production lines and advanced robotics that can be quickly reconfigured to accommodate changes in demand or product specifications[7]. To support this flexible manufacturing approach, Nissan has implemented a dynamic sourcing strategy that includes multi-sourcing for critical components and the use of regional supply hubs to reduce lead times and improve responsiveness[8]. The company has also invested in predictive analytics tools to forecast demand more accurately and adjust production plans in real-time.

Strengths: High adaptability to market changes, reduced lead times, and improved capacity utilization. Weaknesses: Higher capital investment required for flexible manufacturing equipment and potential complexity in managing multiple suppliers.

Innovative Approaches in V16 Logistics

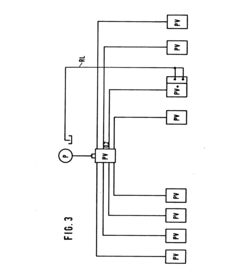

Logistics device and method for operating same

PatentInactiveEP2207135A1

Innovation

- A logistics device with an adjustable electric drive and control unit that records utilization parameters to dynamically adjust operating parameters, such as speed and torque, to optimize energy efficiency by reducing energy consumption during low-order periods and protecting mechanical components, while allowing for energy recovery during braking.

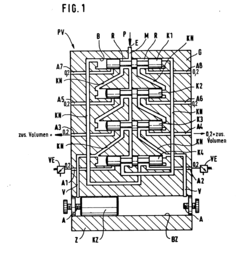

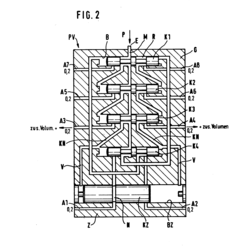

Progressive distributor

PatentInactiveEP0152901A2

Innovation

- The integration of an additional cylinder with a movable piston and connecting channels allows for controlled lubricant release, creating a hydraulic timing element that delays the continuation of the displacement cycle based on the additional cylinder's volume, ensuring pistons are only displaced when the additional lubricant volume is released, thus managing higher outlet pressures and adjusting for different lubrication frequencies.

Environmental Impact of V16 Engine Logistics

The environmental impact of V16 engine logistics is a critical consideration in the automotive industry's pursuit of sustainability and regulatory compliance. V16 engines, known for their high performance and power output, present unique challenges in terms of their ecological footprint throughout the supply chain.

Transportation of V16 engines and their components contributes significantly to carbon emissions. The sheer size and weight of these engines necessitate specialized transportation methods, often requiring larger vehicles or more frequent shipments, thereby increasing fuel consumption and greenhouse gas emissions. To mitigate this impact, logistics companies are exploring alternative fuel options, such as biodiesel or hydrogen-powered trucks, for long-haul transportation.

Manufacturing processes for V16 engines also pose environmental concerns. The production of these complex engines involves energy-intensive processes and the use of various materials, including rare earth metals and petroleum-based products. Efforts to reduce the environmental impact in this area focus on implementing more efficient manufacturing techniques, such as additive manufacturing, which can reduce material waste and energy consumption.

Packaging and storage of V16 engines and their components present additional environmental challenges. The need for robust packaging to protect these high-value items often results in the use of non-biodegradable materials. Innovations in eco-friendly packaging solutions, such as reusable containers and biodegradable protective materials, are being developed to address this issue.

End-of-life considerations for V16 engines are becoming increasingly important as the automotive industry shifts towards more sustainable practices. Recycling and proper disposal of these engines and their components are crucial to minimizing environmental impact. Advanced recycling technologies are being developed to recover valuable materials from used engines, reducing the need for raw material extraction and associated environmental degradation.

Water usage in V16 engine production and maintenance is another significant environmental factor. The manufacturing process and engine cleaning procedures consume substantial amounts of water, potentially leading to water stress in production regions. Implementation of water recycling systems and development of waterless cleaning technologies are being explored to reduce this impact.

Noise pollution associated with V16 engine logistics is an often-overlooked environmental concern. The transportation and testing of these powerful engines can contribute to noise pollution in urban areas and along transportation routes. Acoustic engineering solutions and strategic routing are being employed to minimize this impact on local communities and wildlife.

As the automotive industry continues to evolve, balancing the performance demands of V16 engines with environmental sustainability remains a complex challenge. Ongoing research and development in green technologies and sustainable logistics practices are essential to reducing the ecological footprint of V16 engine logistics while maintaining the high performance standards expected from these powerful engines.

Transportation of V16 engines and their components contributes significantly to carbon emissions. The sheer size and weight of these engines necessitate specialized transportation methods, often requiring larger vehicles or more frequent shipments, thereby increasing fuel consumption and greenhouse gas emissions. To mitigate this impact, logistics companies are exploring alternative fuel options, such as biodiesel or hydrogen-powered trucks, for long-haul transportation.

Manufacturing processes for V16 engines also pose environmental concerns. The production of these complex engines involves energy-intensive processes and the use of various materials, including rare earth metals and petroleum-based products. Efforts to reduce the environmental impact in this area focus on implementing more efficient manufacturing techniques, such as additive manufacturing, which can reduce material waste and energy consumption.

Packaging and storage of V16 engines and their components present additional environmental challenges. The need for robust packaging to protect these high-value items often results in the use of non-biodegradable materials. Innovations in eco-friendly packaging solutions, such as reusable containers and biodegradable protective materials, are being developed to address this issue.

End-of-life considerations for V16 engines are becoming increasingly important as the automotive industry shifts towards more sustainable practices. Recycling and proper disposal of these engines and their components are crucial to minimizing environmental impact. Advanced recycling technologies are being developed to recover valuable materials from used engines, reducing the need for raw material extraction and associated environmental degradation.

Water usage in V16 engine production and maintenance is another significant environmental factor. The manufacturing process and engine cleaning procedures consume substantial amounts of water, potentially leading to water stress in production regions. Implementation of water recycling systems and development of waterless cleaning technologies are being explored to reduce this impact.

Noise pollution associated with V16 engine logistics is an often-overlooked environmental concern. The transportation and testing of these powerful engines can contribute to noise pollution in urban areas and along transportation routes. Acoustic engineering solutions and strategic routing are being employed to minimize this impact on local communities and wildlife.

As the automotive industry continues to evolve, balancing the performance demands of V16 engines with environmental sustainability remains a complex challenge. Ongoing research and development in green technologies and sustainable logistics practices are essential to reducing the ecological footprint of V16 engine logistics while maintaining the high performance standards expected from these powerful engines.

Risk Management in V16 Supply Chain

Risk management is a critical aspect of V16 engine supply chain logistics, particularly when anticipating improvements in supply chain elasticity. The complex nature of V16 engines, with their high-performance specifications and intricate components, necessitates a robust risk management strategy to ensure smooth operations and minimize disruptions.

One of the primary risks in the V16 supply chain is the potential for supply shortages or delays in critical components. Given the specialized nature of V16 engine parts, many suppliers may be single-source or have limited alternatives. To mitigate this risk, implementing a multi-tiered supplier network and maintaining strategic inventory buffers can enhance supply chain resilience. Additionally, developing long-term partnerships with key suppliers and investing in their capabilities can help secure a more stable supply base.

Another significant risk lies in the volatility of demand for V16 engines, which are often used in luxury or high-performance vehicles. Market fluctuations can lead to sudden changes in production requirements, potentially causing overstock or understock situations. To address this, implementing advanced forecasting techniques and developing flexible production schedules can help align supply with demand more effectively.

Quality control presents another critical risk area in V16 engine logistics. The high-precision nature of these engines means that even minor defects can have significant consequences. Implementing rigorous quality assurance processes throughout the supply chain, including at supplier facilities, can help mitigate this risk. Additionally, leveraging technologies such as IoT sensors and blockchain for traceability can enhance quality control measures and facilitate rapid issue identification and resolution.

Transportation and logistics risks are also paramount in the V16 supply chain. The high value and sensitivity of engine components require specialized handling and secure transportation methods. Developing contingency plans for transportation disruptions, diversifying logistics partners, and utilizing real-time tracking systems can help manage these risks effectively.

Lastly, geopolitical and economic risks can significantly impact the V16 supply chain. Trade tensions, currency fluctuations, and regulatory changes can disrupt supply flows and increase costs. Developing a geographically diverse supplier base and maintaining awareness of global economic trends can help mitigate these risks. Additionally, scenario planning and stress testing the supply chain against various geopolitical events can improve overall preparedness and resilience.

One of the primary risks in the V16 supply chain is the potential for supply shortages or delays in critical components. Given the specialized nature of V16 engine parts, many suppliers may be single-source or have limited alternatives. To mitigate this risk, implementing a multi-tiered supplier network and maintaining strategic inventory buffers can enhance supply chain resilience. Additionally, developing long-term partnerships with key suppliers and investing in their capabilities can help secure a more stable supply base.

Another significant risk lies in the volatility of demand for V16 engines, which are often used in luxury or high-performance vehicles. Market fluctuations can lead to sudden changes in production requirements, potentially causing overstock or understock situations. To address this, implementing advanced forecasting techniques and developing flexible production schedules can help align supply with demand more effectively.

Quality control presents another critical risk area in V16 engine logistics. The high-precision nature of these engines means that even minor defects can have significant consequences. Implementing rigorous quality assurance processes throughout the supply chain, including at supplier facilities, can help mitigate this risk. Additionally, leveraging technologies such as IoT sensors and blockchain for traceability can enhance quality control measures and facilitate rapid issue identification and resolution.

Transportation and logistics risks are also paramount in the V16 supply chain. The high value and sensitivity of engine components require specialized handling and secure transportation methods. Developing contingency plans for transportation disruptions, diversifying logistics partners, and utilizing real-time tracking systems can help manage these risks effectively.

Lastly, geopolitical and economic risks can significantly impact the V16 supply chain. Trade tensions, currency fluctuations, and regulatory changes can disrupt supply flows and increase costs. Developing a geographically diverse supplier base and maintaining awareness of global economic trends can help mitigate these risks. Additionally, scenario planning and stress testing the supply chain against various geopolitical events can improve overall preparedness and resilience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!