Application of Zirconia in Modern Electronic Devices

Zirconia in Electronics: Background and Objectives

Zirconia, a versatile ceramic material, has emerged as a significant player in the field of modern electronics. Its journey from traditional applications to cutting-edge electronic devices marks a fascinating evolution in materials science. The development of zirconia-based technologies has been driven by the increasing demand for high-performance, miniaturized, and reliable electronic components.

The primary objective of exploring zirconia in electronics is to harness its unique properties to address the limitations of conventional materials. Zirconia's exceptional thermal stability, mechanical strength, and electrical characteristics make it an attractive candidate for various electronic applications. As the electronics industry continues to push the boundaries of device performance and efficiency, zirconia offers potential solutions to overcome existing technological barriers.

One of the key trends in zirconia's technological evolution is its application in semiconductor manufacturing. The material's high dielectric constant and thermal stability have led to its incorporation in advanced gate dielectrics for metal-oxide-semiconductor field-effect transistors (MOSFETs). This development aims to mitigate the challenges associated with gate leakage and power consumption in nanoscale devices.

Another significant trend is the utilization of zirconia in solid-state electrolytes for next-generation batteries and fuel cells. The material's ionic conductivity and chemical stability contribute to enhanced energy storage and conversion capabilities, aligning with the growing focus on sustainable and efficient energy solutions in the electronics sector.

The integration of zirconia in electronic packaging and thermal management systems represents another evolving application. As electronic devices become more compact and powerful, the need for effective heat dissipation becomes crucial. Zirconia's low thermal conductivity and high thermal expansion coefficient make it suitable for addressing thermal challenges in advanced electronic systems.

Furthermore, the exploration of zirconia-based sensors and actuators has gained momentum in recent years. The material's piezoelectric properties and chemical stability open up possibilities for developing robust and sensitive devices for various sensing applications, including pressure sensors, gas detectors, and biosensors.

As research in this field progresses, the ultimate goal is to leverage zirconia's properties to create more efficient, durable, and high-performance electronic devices. This includes improving the reliability of semiconductor components, enhancing energy storage and conversion technologies, and developing novel sensing and actuation mechanisms. The ongoing exploration of zirconia in electronics aims to contribute to the advancement of next-generation technologies, ranging from consumer electronics to industrial applications and beyond.

Market Demand Analysis for Zirconia-based Components

The market demand for zirconia-based components in modern electronic devices has been experiencing significant growth in recent years. This surge is primarily driven by the unique properties of zirconia, including its high strength, excellent thermal insulation, and superior chemical resistance. These characteristics make zirconia an ideal material for various applications in the electronics industry.

In the semiconductor sector, zirconia is increasingly used in the manufacturing of advanced chips and integrated circuits. The material's high dielectric constant and thermal stability make it suitable for gate dielectrics in transistors, helping to reduce leakage current and improve overall device performance. As the demand for smaller, more powerful, and energy-efficient electronic devices continues to rise, the market for zirconia-based components in semiconductor manufacturing is expected to expand further.

The telecommunications industry is another key driver of demand for zirconia-based components. With the ongoing rollout of 5G networks and the development of 6G technology, there is a growing need for high-performance materials that can withstand the increased frequencies and power requirements of these advanced communication systems. Zirconia's excellent electrical insulation properties and low dielectric loss make it an attractive option for various components in telecommunications infrastructure.

In the consumer electronics market, zirconia is finding applications in smartphones, tablets, and wearable devices. Its durability and scratch resistance make it an ideal material for protective coatings on screens and device casings. Additionally, zirconia's biocompatibility has led to its use in medical electronic devices, such as implantable sensors and hearing aids.

The automotive industry is also contributing to the increasing demand for zirconia-based components in electronic systems. As vehicles become more electrified and autonomous, the need for reliable, high-performance materials in sensors, actuators, and control units grows. Zirconia's ability to withstand harsh environments and maintain stability under varying temperatures makes it well-suited for these applications.

Market analysts project that the global demand for zirconia in electronic applications will continue to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is expected to be driven by advancements in semiconductor technology, the expansion of 5G and future wireless networks, and the increasing integration of electronic systems in various industries.

However, challenges such as the high cost of production and limited availability of high-purity zirconia may impact market growth. Manufacturers and researchers are actively working on developing more cost-effective production methods and exploring alternative sources of zirconia to meet the growing demand. As these challenges are addressed, the market for zirconia-based components in modern electronic devices is poised for continued expansion and innovation.

Current State and Challenges in Zirconia Application

Zirconia has emerged as a crucial material in modern electronic devices, with its applications spanning various sectors due to its unique properties. Currently, zirconia is widely used in semiconductor manufacturing, particularly as a gate dielectric material in advanced transistors. Its high dielectric constant and thermal stability make it an excellent alternative to traditional silicon dioxide in metal-oxide-semiconductor field-effect transistors (MOSFETs).

In the field of solid oxide fuel cells (SOFCs), yttria-stabilized zirconia (YSZ) serves as a popular electrolyte material due to its high ionic conductivity at elevated temperatures. This application has gained significant attention in the pursuit of clean energy solutions. However, challenges remain in reducing the operating temperature of SOFCs to improve their long-term stability and reduce manufacturing costs.

The use of zirconia in electronic packaging has also seen considerable growth. Its low thermal conductivity and high mechanical strength make it an ideal material for thermal barrier coatings in electronic components, helping to protect sensitive devices from extreme temperatures and environmental conditions.

Despite these advancements, several challenges persist in the application of zirconia in modern electronic devices. One major issue is the difficulty in achieving uniform and defect-free thin films of zirconia on various substrates. This is particularly crucial in semiconductor manufacturing, where even minor imperfections can significantly impact device performance.

Another challenge lies in the control of zirconia's crystal structure during deposition processes. The material can exist in different phases (monoclinic, tetragonal, and cubic), each with distinct properties. Ensuring the formation of the desired phase for specific applications remains a complex task, often requiring precise control of temperature, pressure, and other processing parameters.

The integration of zirconia with other materials in complex device structures also presents challenges. Issues such as interfacial reactions, thermal expansion mismatches, and adhesion problems need to be addressed to ensure the reliability and longevity of zirconia-based electronic components.

Furthermore, as electronic devices continue to miniaturize, there is a growing need to develop methods for depositing ultra-thin zirconia films with precise thickness control and minimal defects. This is particularly important in the development of next-generation transistors and memory devices.

Lastly, the cost-effective production of high-purity zirconia remains a challenge, especially for large-scale industrial applications. Developing more efficient and economical synthesis methods is crucial for the widespread adoption of zirconia in various electronic applications.

Existing Zirconia Solutions in Electronic Devices

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are described, including sol-gel techniques, hydrothermal synthesis, and chemical vapor deposition. These methods aim to control the particle size, crystalline structure, and purity of zirconia for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.

- Zirconia-based composites and coatings: Development of zirconia-based composites and coatings for enhanced mechanical, thermal, and chemical properties. These materials often combine zirconia with other ceramics, metals, or polymers to create advanced materials with improved performance in various industrial and technological applications.

- Dental and biomedical applications of zirconia: Utilization of zirconia in dental and biomedical fields, including dental implants, crowns, and orthopedic implants. The material's biocompatibility, strength, and aesthetic properties make it suitable for these applications, with ongoing research focusing on improving its performance and integration with biological tissues.

- Zirconia in fuel cells and energy applications: Application of zirconia in solid oxide fuel cells and other energy-related technologies. Its unique properties, such as high ionic conductivity when doped with certain elements, make it valuable for electrochemical devices and energy conversion systems.

- Stabilization and phase transformation of zirconia: Research on stabilizing zirconia in its various crystalline phases and controlling phase transformations. This includes the use of dopants and specific processing techniques to achieve desired crystal structures and properties for different applications, such as improving the material's mechanical strength and thermal stability.

02 Zirconia-based dental materials

Zirconia is widely used in dental applications due to its biocompatibility, strength, and aesthetic properties. Innovations in this field include improved formulations for dental prosthetics, crowns, and implants, as well as techniques for enhancing the material's translucency and color matching capabilities.Expand Specific Solutions03 Zirconia in advanced ceramics and composites

Zirconia is incorporated into advanced ceramic materials and composites to enhance mechanical properties, thermal resistance, and wear resistance. Applications include cutting tools, thermal barrier coatings, and structural components for aerospace and automotive industries.Expand Specific Solutions04 Stabilized zirconia and phase transformation

Research focuses on stabilizing zirconia in its various crystalline phases, particularly the tetragonal and cubic forms, through doping with other elements. This stabilization is crucial for maintaining desired properties in high-temperature and high-stress applications.Expand Specific Solutions05 Zirconia in fuel cells and sensors

Zirconia, particularly yttria-stabilized zirconia, is utilized in solid oxide fuel cells and oxygen sensors. Developments in this area include improving ionic conductivity, reducing operating temperatures, and enhancing durability for more efficient energy conversion and sensing applications.Expand Specific Solutions

Key Players in Zirconia-based Electronic Components

The application of zirconia in modern electronic devices is in a growth phase, with an expanding market driven by increasing demand for high-performance components. The global zirconia market size is projected to reach significant figures, fueled by its unique properties and versatility. Technologically, zirconia applications are advancing rapidly, with companies like Kyocera Corp., Tosoh Corp., and Saint-Gobain Ceramics & Plastics leading innovation. These firms, along with others like Taiyo Yuden Co., Ltd. and Apple, Inc., are pushing the boundaries of zirconia's capabilities in electronics, focusing on miniaturization, thermal management, and durability. The competitive landscape is diverse, featuring both established materials giants and specialized electronic component manufacturers, indicating a mature yet still evolving technological field.

Kyocera Corp.

Tosoh Corp.

Core Innovations in Zirconia Material Science

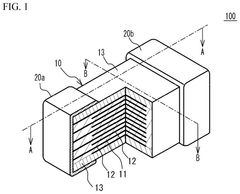

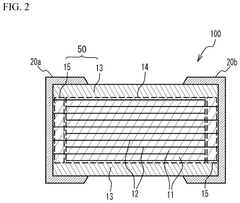

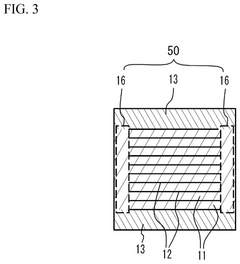

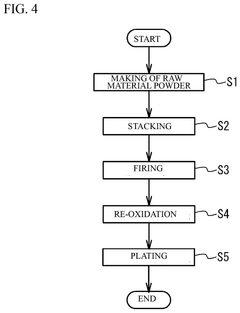

- A ceramic electronic device with a dielectric layer containing yttria-stabilized zirconia and (Cax1Bax2Sr1-x1-x2)(TiyZr1-y)O3 as the main component, where the concentration of yttria-stabilized zirconia is between 0.5 mol% and 5.0 mol% when the total amount of Ti and Zr is 100 mol%, allowing for increased mechanical strength and suppression of cracking even at lower firing temperatures.

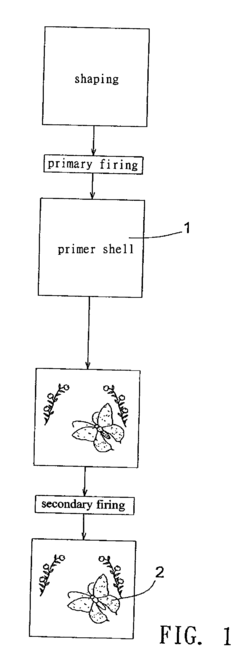

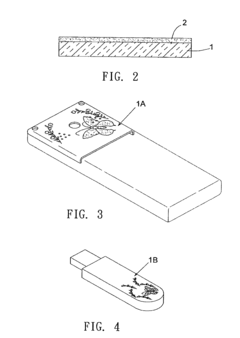

- A zirconia-based color shell structure is developed, comprising a primer shell made of 92-98% zirconia and 2-8% yttrium, subjected to primary firing at 1200-1700°C, with a color layer formed by applying or attaching glaze and subjecting it to secondary firing, creating a hard and aesthetically appealing glazed coating.

Environmental Impact of Zirconia in Electronics

The environmental impact of zirconia in electronics is a crucial consideration as the material gains prominence in modern electronic devices. Zirconia's unique properties, such as high thermal stability and excellent electrical insulation, make it an attractive option for various electronic applications. However, its increasing use also raises concerns about potential environmental consequences throughout its lifecycle.

During the production phase, zirconia mining and processing can lead to habitat disruption and soil erosion. The extraction process often involves open-pit mining, which can significantly alter landscapes and ecosystems. Additionally, the refining of zirconium ore into zirconia requires substantial energy input, contributing to greenhouse gas emissions and potentially exacerbating climate change if not managed sustainably.

In the manufacturing stage of electronic components, the integration of zirconia may involve the use of hazardous chemicals and generate waste products. While zirconia itself is generally considered inert and non-toxic, the production processes for electronic devices incorporating zirconia may still pose environmental risks if not properly controlled. This includes the potential release of particulate matter and the generation of electronic waste containing zirconia-based components.

During the use phase, zirconia-containing electronic devices generally have a positive environmental impact due to their enhanced durability and efficiency. The material's thermal stability and resistance to wear can extend the lifespan of electronic components, potentially reducing electronic waste generation. Moreover, zirconia's excellent insulating properties can contribute to improved energy efficiency in certain applications, indirectly reducing the carbon footprint associated with device operation.

End-of-life management of zirconia-containing electronics presents both challenges and opportunities. While zirconia is not inherently toxic, its presence in electronic waste can complicate recycling processes. The material's high melting point and chemical stability make it difficult to separate from other components, potentially hindering the recovery of valuable materials. However, advancements in recycling technologies may eventually allow for more efficient recovery and reuse of zirconia from electronic waste.

To mitigate the environmental impact of zirconia in electronics, several strategies can be employed. These include developing more sustainable mining and processing techniques, implementing closed-loop manufacturing systems to minimize waste, designing products for easier disassembly and recycling, and investing in advanced recycling technologies capable of handling zirconia-containing electronic waste. Additionally, promoting the use of recycled zirconia in new electronic components could help reduce the demand for virgin materials and associated environmental impacts.

Zirconia's Role in Miniaturization of Electronics

Zirconia has emerged as a crucial material in the miniaturization of electronic devices, playing a significant role in advancing the capabilities of modern technology. As electronic components continue to shrink in size while increasing in performance, zirconia's unique properties make it an ideal candidate for various applications in the electronics industry.

One of the primary contributions of zirconia to miniaturization is its use as a high-k dielectric material in semiconductor devices. As transistors become smaller, traditional silicon dioxide gate dielectrics reach their physical limits, leading to increased leakage current and power consumption. Zirconia, with its high dielectric constant, allows for thinner gate oxide layers while maintaining excellent insulating properties, enabling the production of smaller and more efficient transistors.

In the realm of microelectromechanical systems (MEMS), zirconia's exceptional mechanical properties and chemical stability make it an attractive material for miniaturized sensors and actuators. Its high strength and wear resistance allow for the creation of durable, compact components that can withstand harsh operating conditions. This is particularly valuable in the development of miniaturized accelerometers, gyroscopes, and pressure sensors used in smartphones, wearables, and other portable electronic devices.

Zirconia's thermal properties also contribute to the miniaturization of electronic devices. Its low thermal conductivity helps in thermal management, allowing for the design of more compact cooling solutions. This is crucial in densely packed electronic systems where heat dissipation is a significant challenge. Additionally, zirconia's thermal stability enables its use in high-temperature applications, such as in miniaturized sensors for automotive and industrial environments.

The material's biocompatibility has opened up new possibilities for miniaturized medical devices. Zirconia-based components are being used in implantable electronics, such as pacemakers and cochlear implants, where size reduction is critical for patient comfort and device longevity. The material's inertness and resistance to corrosion ensure long-term stability in biological environments.

In the field of optical devices, zirconia's high refractive index and transparency in the visible and near-infrared regions make it valuable for miniaturized optical components. This property is exploited in the development of compact laser diodes, waveguides, and optical sensors, contributing to the miniaturization of photonic devices and optical communication systems.

As the demand for smaller, more powerful electronic devices continues to grow, zirconia's role in miniaturization is expected to expand further. Ongoing research into nanostructured zirconia and zirconia-based composites promises to unlock even greater potential for size reduction and performance enhancement in future electronic applications.