Applications of High-Entropy Alloys in Fusion Energy Systems

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys in Fusion Energy: Background and Objectives

High-entropy alloys (HEAs) represent a paradigm shift in materials science, emerging as a revolutionary concept in the early 2000s. Unlike conventional alloys that primarily consist of one principal element with minor additions, HEAs incorporate multiple principal elements in near-equiatomic proportions, typically five or more. This fundamental departure from traditional alloy design has opened new avenues for developing materials with exceptional combinations of properties that were previously unattainable.

The evolution of HEAs has been marked by significant milestones, from initial theoretical frameworks to experimental validations demonstrating their unique characteristics. These alloys exhibit remarkable structural stability at high temperatures, excellent mechanical properties, superior radiation resistance, and exceptional corrosion resistance—attributes that make them particularly promising for extreme environments such as fusion energy systems.

Fusion energy represents one of humanity's most ambitious technological pursuits, offering the potential for abundant, clean energy production. However, the harsh operating conditions within fusion reactors—including intense neutron irradiation, high thermal loads, and plasma interactions—pose extraordinary challenges for materials. Conventional materials often degrade rapidly under these conditions, limiting reactor efficiency and operational lifespan.

The convergence of HEA development and fusion energy requirements creates a compelling technological synergy. The inherent properties of HEAs, particularly their radiation damage tolerance and thermal stability, align remarkably well with the demands of fusion reactor environments. This alignment has catalyzed growing interest in exploring HEAs as structural materials, plasma-facing components, and functional elements within fusion systems.

Current technological trends indicate accelerating research in tailoring HEAs specifically for fusion applications. This includes compositional optimization to enhance neutron irradiation resistance, development of manufacturing techniques for complex HEA components, and integration of computational modeling to predict long-term material behavior under fusion-relevant conditions.

The primary technical objectives for HEAs in fusion energy applications include: developing alloy compositions that maintain structural integrity under neutron fluences exceeding 200 dpa (displacements per atom); creating HEAs with operating temperature capabilities spanning from cryogenic conditions to above 1000°C; engineering compositions with minimal neutron activation for reduced radioactive waste; and establishing cost-effective, scalable manufacturing processes for complex fusion components.

As fusion energy progresses toward commercial viability with projects like ITER, DEMO, and various private ventures, the development of enabling materials becomes increasingly critical. HEAs stand at the forefront of this materials revolution, potentially offering solutions to longstanding challenges that have hindered fusion energy realization.

The evolution of HEAs has been marked by significant milestones, from initial theoretical frameworks to experimental validations demonstrating their unique characteristics. These alloys exhibit remarkable structural stability at high temperatures, excellent mechanical properties, superior radiation resistance, and exceptional corrosion resistance—attributes that make them particularly promising for extreme environments such as fusion energy systems.

Fusion energy represents one of humanity's most ambitious technological pursuits, offering the potential for abundant, clean energy production. However, the harsh operating conditions within fusion reactors—including intense neutron irradiation, high thermal loads, and plasma interactions—pose extraordinary challenges for materials. Conventional materials often degrade rapidly under these conditions, limiting reactor efficiency and operational lifespan.

The convergence of HEA development and fusion energy requirements creates a compelling technological synergy. The inherent properties of HEAs, particularly their radiation damage tolerance and thermal stability, align remarkably well with the demands of fusion reactor environments. This alignment has catalyzed growing interest in exploring HEAs as structural materials, plasma-facing components, and functional elements within fusion systems.

Current technological trends indicate accelerating research in tailoring HEAs specifically for fusion applications. This includes compositional optimization to enhance neutron irradiation resistance, development of manufacturing techniques for complex HEA components, and integration of computational modeling to predict long-term material behavior under fusion-relevant conditions.

The primary technical objectives for HEAs in fusion energy applications include: developing alloy compositions that maintain structural integrity under neutron fluences exceeding 200 dpa (displacements per atom); creating HEAs with operating temperature capabilities spanning from cryogenic conditions to above 1000°C; engineering compositions with minimal neutron activation for reduced radioactive waste; and establishing cost-effective, scalable manufacturing processes for complex fusion components.

As fusion energy progresses toward commercial viability with projects like ITER, DEMO, and various private ventures, the development of enabling materials becomes increasingly critical. HEAs stand at the forefront of this materials revolution, potentially offering solutions to longstanding challenges that have hindered fusion energy realization.

Market Analysis for Advanced Materials in Fusion Energy

The fusion energy materials market is experiencing significant growth, driven by global initiatives to develop commercial fusion power as a clean, sustainable energy source. Current market estimates value advanced materials for fusion at approximately $2.5 billion, with projections indicating a compound annual growth rate of 8-12% through 2035 as fusion energy approaches commercial viability.

High-entropy alloys (HEAs) represent an emerging segment within this market, currently accounting for a relatively small but rapidly growing share. Their unique properties—including exceptional radiation resistance, thermal stability, and mechanical strength at high temperatures—position them as critical materials for next-generation fusion reactors.

Demand analysis reveals several key market drivers for HEAs in fusion applications. Primary among these is the intensifying global race to achieve commercial fusion energy, with major projects like ITER, Commonwealth Fusion Systems, and China's EAST accelerating material requirements. Additionally, increasing public and private investment in fusion startups has created new market opportunities, with over $4.7 billion invested in private fusion ventures since 2021.

Market segmentation shows potential applications across multiple fusion reactor components, including first wall materials, blanket structures, divertor components, and magnet systems. The divertor segment currently represents the largest market opportunity due to extreme operating conditions requiring advanced material solutions.

Regional analysis indicates North America leads in HEA research investment, while Europe dominates in terms of fusion infrastructure development. The Asia-Pacific region, particularly China and Japan, is rapidly expanding both research capabilities and manufacturing capacity for advanced fusion materials.

Customer analysis identifies national laboratories, government-funded fusion programs, and private fusion startups as the primary current customers. However, as fusion technology matures, the customer base is expected to expand to include energy utilities and industrial power users seeking to incorporate fusion into their energy portfolios.

Pricing trends remain volatile due to the experimental nature of many HEAs and limited production scales. Current manufacturing costs are high, reflecting specialized production requirements and limited economies of scale. However, analysis suggests costs could decrease by 30-45% with increased production volumes and manufacturing optimization.

Market barriers include high material development costs, lengthy qualification processes for nuclear applications, and competition from established materials like reduced-activation ferritic-martensitic steels. Despite these challenges, the market outlook remains highly positive, with HEAs positioned to capture an increasing share of the fusion materials market as the industry progresses toward commercial deployment.

High-entropy alloys (HEAs) represent an emerging segment within this market, currently accounting for a relatively small but rapidly growing share. Their unique properties—including exceptional radiation resistance, thermal stability, and mechanical strength at high temperatures—position them as critical materials for next-generation fusion reactors.

Demand analysis reveals several key market drivers for HEAs in fusion applications. Primary among these is the intensifying global race to achieve commercial fusion energy, with major projects like ITER, Commonwealth Fusion Systems, and China's EAST accelerating material requirements. Additionally, increasing public and private investment in fusion startups has created new market opportunities, with over $4.7 billion invested in private fusion ventures since 2021.

Market segmentation shows potential applications across multiple fusion reactor components, including first wall materials, blanket structures, divertor components, and magnet systems. The divertor segment currently represents the largest market opportunity due to extreme operating conditions requiring advanced material solutions.

Regional analysis indicates North America leads in HEA research investment, while Europe dominates in terms of fusion infrastructure development. The Asia-Pacific region, particularly China and Japan, is rapidly expanding both research capabilities and manufacturing capacity for advanced fusion materials.

Customer analysis identifies national laboratories, government-funded fusion programs, and private fusion startups as the primary current customers. However, as fusion technology matures, the customer base is expected to expand to include energy utilities and industrial power users seeking to incorporate fusion into their energy portfolios.

Pricing trends remain volatile due to the experimental nature of many HEAs and limited production scales. Current manufacturing costs are high, reflecting specialized production requirements and limited economies of scale. However, analysis suggests costs could decrease by 30-45% with increased production volumes and manufacturing optimization.

Market barriers include high material development costs, lengthy qualification processes for nuclear applications, and competition from established materials like reduced-activation ferritic-martensitic steels. Despite these challenges, the market outlook remains highly positive, with HEAs positioned to capture an increasing share of the fusion materials market as the industry progresses toward commercial deployment.

Current Status and Challenges of HEAs in Extreme Environments

High-entropy alloys (HEAs) have emerged as promising materials for extreme environments, particularly in fusion energy systems. Currently, research institutions worldwide are investigating HEAs for fusion applications, with significant progress in the United States, Europe, China, and Japan. The development of these materials has reached laboratory-scale testing phases, with some advanced compositions undergoing simulated fusion environment testing.

The primary technical challenges facing HEAs in fusion environments stem from the extreme conditions these materials must withstand. Fusion reactors present a unique combination of high temperatures (exceeding 1000°C), intense neutron radiation (up to 200 dpa), strong magnetic fields, and plasma exposure. Conventional materials typically fail under these combined stresses, creating a critical need for advanced materials solutions.

Radiation damage represents perhaps the most significant challenge, as neutron bombardment causes transmutation, void formation, and embrittlement in materials. Current HEA research focuses on designing compositions with enhanced radiation resistance through careful selection of constituent elements and microstructural engineering. Early results show promising radiation tolerance in certain HEA systems, particularly those containing elements with similar atomic radii that create distorted lattice structures capable of better accommodating radiation-induced defects.

Thermal stability presents another major hurdle. While many HEAs exhibit excellent high-temperature strength, maintaining phase stability during thermal cycling remains problematic. Some compositions experience unwanted phase transformations or segregation during prolonged exposure to temperature gradients typical in fusion systems. Research efforts are directed toward developing thermally stable compositions through additions of refractory elements and optimized processing techniques.

Compatibility with hydrogen isotopes (deuterium and tritium) represents a fusion-specific challenge for HEAs. Current data on hydrogen permeation, retention, and embrittlement in HEAs remains limited, creating a significant knowledge gap. Initial studies suggest that certain HEA compositions may offer improved resistance to hydrogen embrittlement compared to conventional alloys, but comprehensive testing under fusion-relevant conditions is still needed.

Manufacturing scalability constitutes a practical constraint on HEA implementation. Most current HEA research utilizes small-scale laboratory production methods, while fusion components require industrial-scale manufacturing with consistent properties. Powder metallurgy, additive manufacturing, and advanced casting techniques show promise for scaling HEA production, though significant process optimization is still required.

Geographically, HEA research for fusion applications shows distinct regional specializations. North American institutions focus primarily on fundamental mechanisms of radiation resistance, European programs emphasize integration with existing fusion projects like ITER, and Asian research centers lead in high-throughput computational screening of novel compositions.

The primary technical challenges facing HEAs in fusion environments stem from the extreme conditions these materials must withstand. Fusion reactors present a unique combination of high temperatures (exceeding 1000°C), intense neutron radiation (up to 200 dpa), strong magnetic fields, and plasma exposure. Conventional materials typically fail under these combined stresses, creating a critical need for advanced materials solutions.

Radiation damage represents perhaps the most significant challenge, as neutron bombardment causes transmutation, void formation, and embrittlement in materials. Current HEA research focuses on designing compositions with enhanced radiation resistance through careful selection of constituent elements and microstructural engineering. Early results show promising radiation tolerance in certain HEA systems, particularly those containing elements with similar atomic radii that create distorted lattice structures capable of better accommodating radiation-induced defects.

Thermal stability presents another major hurdle. While many HEAs exhibit excellent high-temperature strength, maintaining phase stability during thermal cycling remains problematic. Some compositions experience unwanted phase transformations or segregation during prolonged exposure to temperature gradients typical in fusion systems. Research efforts are directed toward developing thermally stable compositions through additions of refractory elements and optimized processing techniques.

Compatibility with hydrogen isotopes (deuterium and tritium) represents a fusion-specific challenge for HEAs. Current data on hydrogen permeation, retention, and embrittlement in HEAs remains limited, creating a significant knowledge gap. Initial studies suggest that certain HEA compositions may offer improved resistance to hydrogen embrittlement compared to conventional alloys, but comprehensive testing under fusion-relevant conditions is still needed.

Manufacturing scalability constitutes a practical constraint on HEA implementation. Most current HEA research utilizes small-scale laboratory production methods, while fusion components require industrial-scale manufacturing with consistent properties. Powder metallurgy, additive manufacturing, and advanced casting techniques show promise for scaling HEA production, though significant process optimization is still required.

Geographically, HEA research for fusion applications shows distinct regional specializations. North American institutions focus primarily on fundamental mechanisms of radiation resistance, European programs emphasize integration with existing fusion projects like ITER, and Asian research centers lead in high-throughput computational screening of novel compositions.

Current HEA Solutions for Fusion Reactor Components

01 Composition and design of high-entropy alloys

High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. The design of these alloys focuses on achieving a single-phase solid solution with high configurational entropy. Various element combinations can be used to create HEAs with specific properties, including transition metals, refractory metals, and rare earth elements. The composition design often involves consideration of atomic size differences, mixing enthalpy, and valence electron concentration to predict phase stability.- Composition and design of high-entropy alloys: High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. The design of these alloys focuses on achieving a single-phase solid solution with high configurational entropy. Various element combinations can be used to create HEAs with specific properties, including transition metals, refractory elements, and rare earth metals. The composition design often involves consideration of atomic size differences, mixing enthalpy, and valence electron concentration to predict phase stability.

- Manufacturing methods for high-entropy alloys: Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, scalability, and final properties. Arc melting is commonly used for laboratory-scale production, while mechanical alloying allows for solid-state synthesis. Powder metallurgy techniques enable near-net-shape manufacturing, and additive manufacturing offers design flexibility and reduced material waste.

- Mechanical properties and structural applications: High-entropy alloys exhibit exceptional mechanical properties, including high strength, excellent ductility, superior fracture toughness, and good fatigue resistance. These properties make them suitable for structural applications in aerospace, automotive, and energy sectors. The unique combination of strength and ductility is attributed to their complex microstructure and multiple strengthening mechanisms. Some HEAs also maintain their mechanical properties at elevated temperatures, making them potential candidates for high-temperature applications.

- Functional properties and specialized applications: Beyond mechanical properties, high-entropy alloys demonstrate various functional properties including corrosion resistance, radiation resistance, magnetic properties, and catalytic activity. These functional characteristics expand their application range to include biomedical implants, nuclear reactor components, magnetic devices, and catalysts. Some HEAs exhibit superparamagnetism, while others show promising hydrogen storage capabilities or superior oxidation resistance at high temperatures.

- Surface treatments and coatings of high-entropy alloys: Surface modification techniques for high-entropy alloys include laser surface treatment, plasma nitriding, and deposition of HEA coatings. These treatments can enhance surface hardness, wear resistance, and corrosion protection. HEA coatings applied through thermal spraying, physical vapor deposition, or electrodeposition provide protective layers for conventional materials. The multi-principal element nature of HEAs allows for tailored surface properties to meet specific environmental challenges while maintaining the bulk material's integrity.

02 Manufacturing methods for high-entropy alloys

Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, scalability, and final properties. Arc melting is commonly used for laboratory-scale production, while powder metallurgy enables better control of grain size and porosity. Additive manufacturing techniques allow for complex geometries and compositional gradients in high-entropy alloys.Expand Specific Solutions03 Mechanical properties and structural applications

High-entropy alloys exhibit exceptional mechanical properties, including high strength, excellent ductility, superior fracture toughness, and good fatigue resistance. These properties make them suitable for structural applications in aerospace, automotive, and energy sectors. The unique combination of strength and ductility is attributed to their complex microstructure and multiple strengthening mechanisms. Some high-entropy alloys also demonstrate excellent performance at elevated temperatures, making them potential candidates for high-temperature structural applications.Expand Specific Solutions04 Functional properties and specialized applications

Beyond mechanical properties, high-entropy alloys exhibit various functional properties including corrosion resistance, radiation resistance, magnetic properties, and catalytic activity. These functional properties enable applications in harsh environments, nuclear reactors, electronic devices, and chemical processing. Some high-entropy alloys show superparamagnetic behavior, while others demonstrate superior hydrogen storage capacity or biocompatibility for medical applications. The multifunctionality of these alloys opens up possibilities for smart materials and sensors.Expand Specific Solutions05 Surface treatments and coatings of high-entropy alloys

Surface modification techniques for high-entropy alloys include the development of high-entropy ceramic coatings, nitrides, and carbides. These surface treatments enhance wear resistance, oxidation resistance, and tribological properties. High-entropy alloy coatings can be applied using techniques such as physical vapor deposition, laser cladding, and thermal spraying. The multi-element nature of these coatings provides superior protection against various degradation mechanisms compared to conventional coating systems.Expand Specific Solutions

Leading Organizations in HEA Research and Fusion Energy

High-entropy alloys (HEAs) in fusion energy systems represent an emerging field at the intersection of advanced materials science and clean energy technology. The market is in its early growth stage, with research institutions like Chungnam National University, University of Science & Technology Beijing, and Dartmouth College leading fundamental research. Commercial development is being pursued by established industrial players including Hitachi, LG Electronics, and Proterial Ltd., who are leveraging their materials expertise to develop HEAs with superior radiation resistance and thermal stability. The technology maturity remains at TRL 3-5, with significant R&D investment from both academic institutions and national laboratories like Korea Institute of Materials Science and UT-Battelle. While current market size is modest, projected growth is substantial as fusion energy approaches commercial viability, with HEAs positioned as critical enabling materials for extreme operating environments.

Hitachi Ltd.

Technical Solution: Hitachi has developed a comprehensive technical approach to high-entropy alloys (HEAs) for fusion energy applications, focusing on plasma-facing components and structural materials. Their solution centers on CrMnFeCoNi-based HEAs with controlled additions of refractory elements (W, Mo) to enhance high-temperature stability while maintaining fabricability. Hitachi's proprietary manufacturing process combines vacuum induction melting with subsequent thermomechanical treatments to optimize microstructure. Their HEAs demonstrate exceptional resistance to helium embrittlement—a critical concern in fusion environments—through engineered grain boundary structures that trap helium bubbles without compromising mechanical integrity. Hitachi has successfully produced prototype first wall panels using their HEA technology, demonstrating thermal cycling resistance up to 10 MW/m² heat loads while maintaining structural integrity after simulated neutron damage. Their integrated approach includes joining technologies specifically developed for connecting HEAs to conventional structural materials in fusion systems.

Strengths: Extensive industrial manufacturing capabilities enable scaling from laboratory concepts to full-size components. Strong integration with existing nuclear industry supply chains facilitates technology transfer. Weaknesses: Relatively higher production costs compared to conventional alloys may limit widespread adoption, and some compositions contain elements that could become activated under neutron irradiation.

Korea Institute of Materials Science

Technical Solution: The Korea Institute of Materials Science (KIMS) has developed advanced high-entropy alloys specifically engineered for fusion energy applications, with a focus on plasma-facing components and structural materials for tokamak designs. Their technical approach centers on refractory high-entropy alloys (RHEAs) based on the W-Ta-V-Cr-Mo system, modified with minor additions of Y₂O₃ nanoparticles for enhanced radiation resistance. KIMS employs a proprietary powder metallurgy process combined with spark plasma sintering to create materials with controlled porosity and grain structure optimized for both thermal conductivity and mechanical stability under irradiation. Their HEAs have demonstrated exceptional resistance to neutron-induced swelling (<0.5% after 5 dpa) while maintaining thermal conductivity above 80 W/m·K at operating temperatures. A key innovation in their approach is the development of functionally graded HEAs where composition gradually transitions from heat-resistant surfaces to tough structural bases, addressing the competing requirements of plasma-facing components. KIMS has successfully manufactured and tested prototype divertor tiles using these materials in collaboration with Korea's KSTAR tokamak facility.

Strengths: Excellent balance between radiation resistance, thermal properties, and mechanical stability. Strong integration with active fusion research programs provides realistic testing environments. Weaknesses: Complex manufacturing process increases production costs, and long-term activation behavior under fusion neutron spectrum requires further validation.

Critical Patents and Research on Radiation-Resistant HEAs

High-entropy alloy for high-temperature applications and process for preparing the same

PatentUndeterminedRO134838A2

Innovation

- Development of a novel CrFeNiAlNbZr high-entropy alloy system with specific composition ranges that maintains hardness up to 400 HV at extreme temperatures (1000°C).

- Integration of Nb and Zr elements in specific proportions (2.5-2.8% and 2.6-2.8% respectively) to achieve high oxidation resistance while maintaining reduced density.

- Development of a specialized vacuum induction melting process with double re-melting and subsequent heat treatment protocol (1000°C for 100h) to ensure homogenization and optimal properties.

High-entropy alloy, and method for producing the same

PatentActiveUS20200392613A1

Innovation

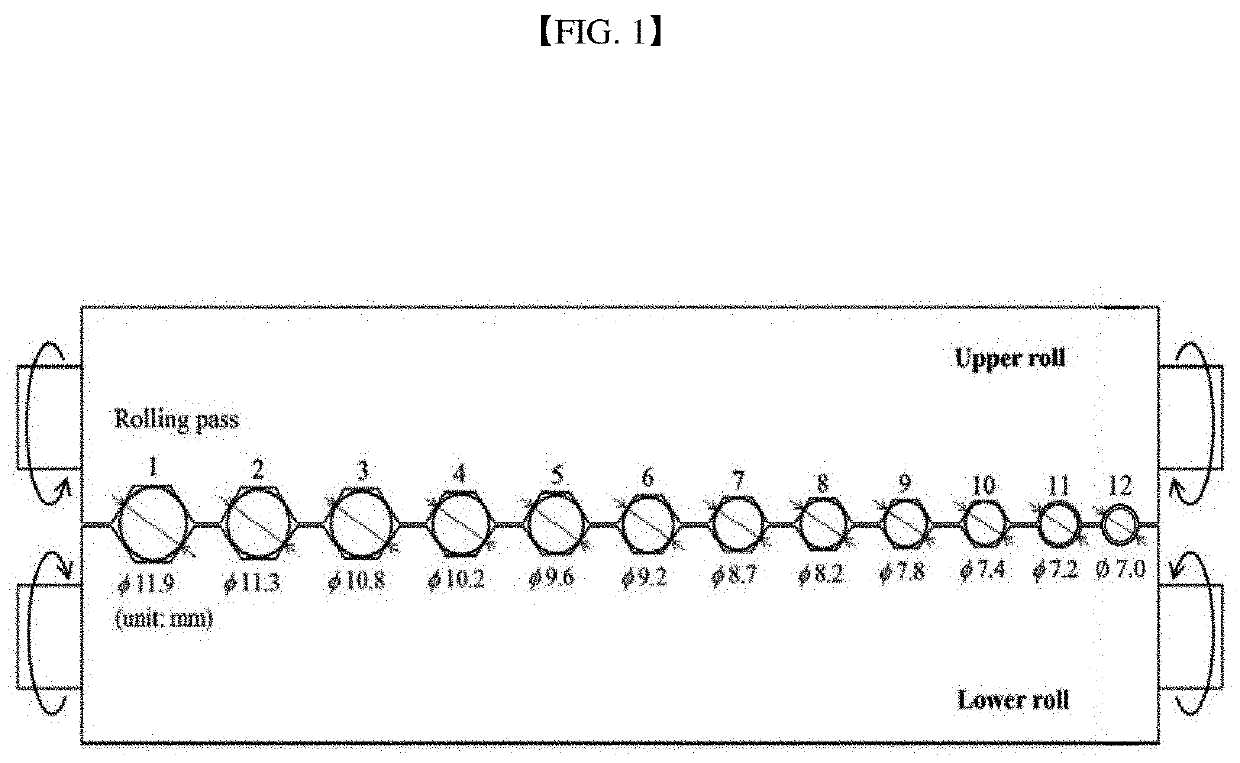

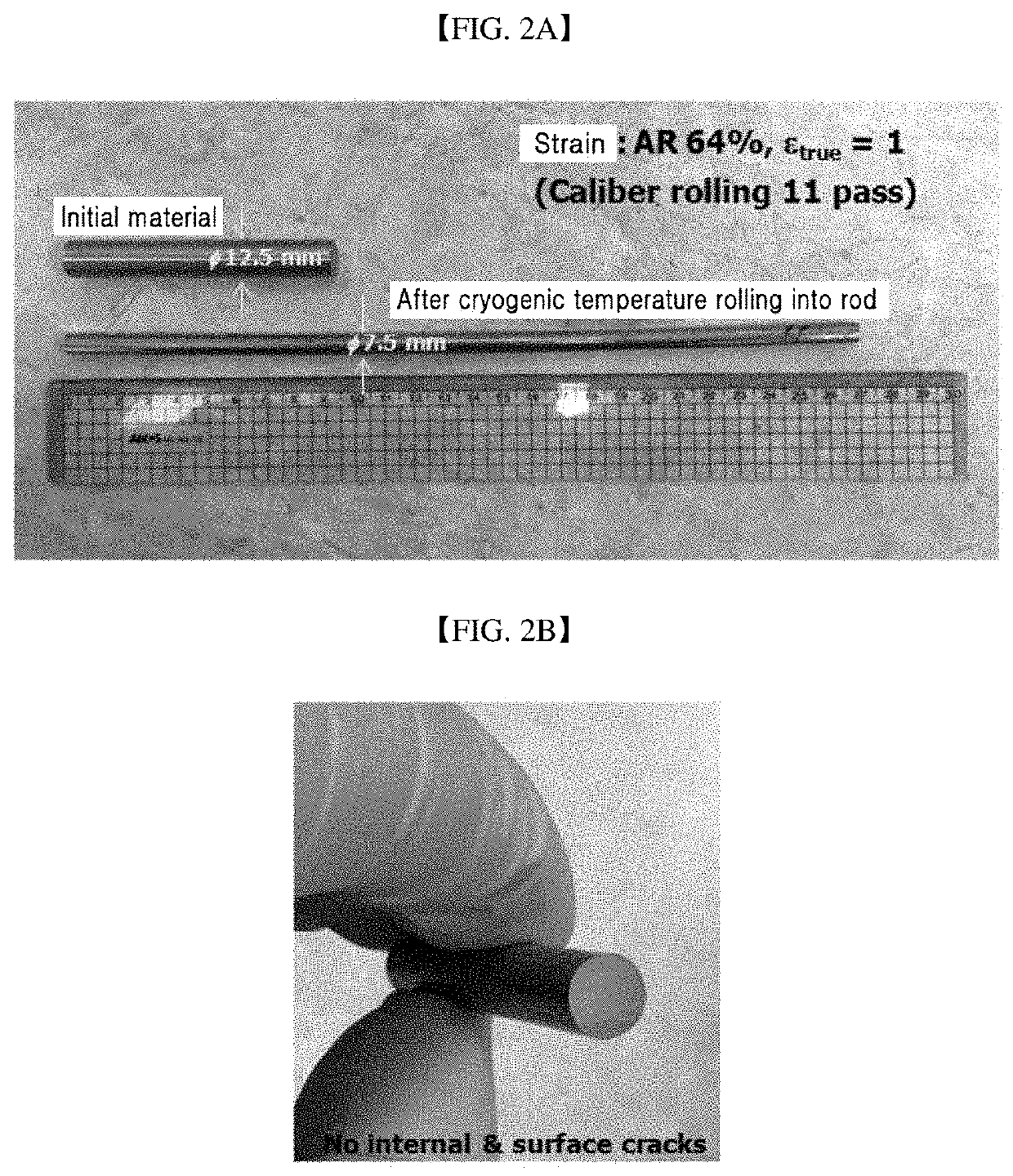

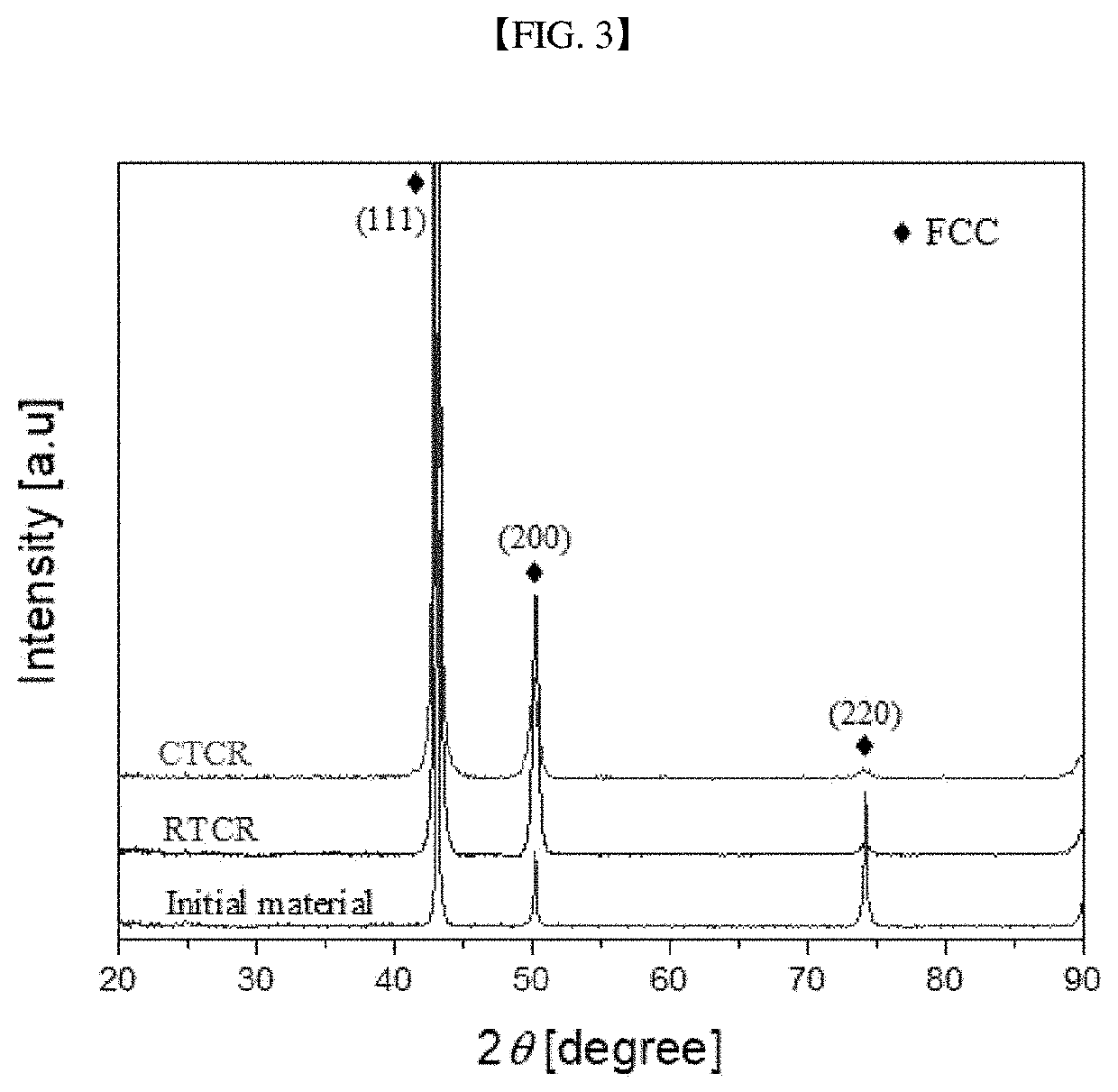

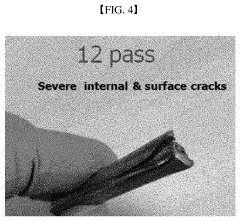

- A method involving annealing and homogenizing an initial alloy containing Co, Cr, Fe, Mn, and Ni, followed by cryogenic temperature rolling with a multi-pass caliber roller to form intersecting twins and secondary fine twins, enhancing grain refinement and hydrogen embrittlement resistance without severe plastic deformation.

Regulatory Framework for Nuclear Materials Qualification

The regulatory landscape for qualifying high-entropy alloys (HEAs) for fusion energy systems presents unique challenges due to the novel nature of these materials and the stringent safety requirements of nuclear environments. Current regulatory frameworks primarily address traditional nuclear materials like steel alloys and zirconium-based composites, creating a significant gap for innovative materials such as HEAs.

The International Atomic Energy Agency (IAEA) provides overarching guidelines for nuclear material qualification, which must be adapted for fusion-specific applications of HEAs. These guidelines emphasize radiation resistance, structural integrity under extreme conditions, and minimal activation properties—all areas where HEAs show promising characteristics.

In the United States, the Nuclear Regulatory Commission (NRC) maintains specific protocols for qualifying materials for nuclear service through 10 CFR Part 50. For HEAs to gain regulatory approval, comprehensive testing regimes must demonstrate their performance under neutron irradiation, thermal cycling, and plasma-facing conditions. The ASME Boiler and Pressure Vessel Code Section III, which governs nuclear components, requires extensive validation before new materials can be included.

The European Union follows the EURATOM framework, which has recently begun developing specialized protocols for fusion materials through the EUROfusion consortium. Their Materials Research Program specifically addresses qualification pathways for advanced materials including HEAs, focusing on their behavior under fusion-relevant conditions.

Japan's Nuclear Regulation Authority and China's National Nuclear Safety Administration have also initiated specialized programs for fusion materials qualification, with particular interest in HEAs for their potential radiation resistance properties. These regulatory bodies are actively developing testing standards that address the unique compositional complexity of HEAs.

A critical regulatory challenge is the lack of long-term irradiation data for HEAs. Regulatory acceptance requires accelerated testing protocols that can reliably predict material behavior over the operational lifetime of fusion components. Several international facilities, including the Materials Test Station at Los Alamos and the IFMIF-DONES project in Europe, are being developed to provide the necessary neutron irradiation testing capabilities.

Harmonization of international standards represents another significant challenge. The ITER project has established the ITER Materials Properties Handbook, which could serve as a foundation for standardizing HEA qualification across different regulatory jurisdictions, facilitating global collaboration in fusion energy development.

The International Atomic Energy Agency (IAEA) provides overarching guidelines for nuclear material qualification, which must be adapted for fusion-specific applications of HEAs. These guidelines emphasize radiation resistance, structural integrity under extreme conditions, and minimal activation properties—all areas where HEAs show promising characteristics.

In the United States, the Nuclear Regulatory Commission (NRC) maintains specific protocols for qualifying materials for nuclear service through 10 CFR Part 50. For HEAs to gain regulatory approval, comprehensive testing regimes must demonstrate their performance under neutron irradiation, thermal cycling, and plasma-facing conditions. The ASME Boiler and Pressure Vessel Code Section III, which governs nuclear components, requires extensive validation before new materials can be included.

The European Union follows the EURATOM framework, which has recently begun developing specialized protocols for fusion materials through the EUROfusion consortium. Their Materials Research Program specifically addresses qualification pathways for advanced materials including HEAs, focusing on their behavior under fusion-relevant conditions.

Japan's Nuclear Regulation Authority and China's National Nuclear Safety Administration have also initiated specialized programs for fusion materials qualification, with particular interest in HEAs for their potential radiation resistance properties. These regulatory bodies are actively developing testing standards that address the unique compositional complexity of HEAs.

A critical regulatory challenge is the lack of long-term irradiation data for HEAs. Regulatory acceptance requires accelerated testing protocols that can reliably predict material behavior over the operational lifetime of fusion components. Several international facilities, including the Materials Test Station at Los Alamos and the IFMIF-DONES project in Europe, are being developed to provide the necessary neutron irradiation testing capabilities.

Harmonization of international standards represents another significant challenge. The ITER project has established the ITER Materials Properties Handbook, which could serve as a foundation for standardizing HEA qualification across different regulatory jurisdictions, facilitating global collaboration in fusion energy development.

Sustainability and Resource Considerations for HEA Production

The sustainability of High-Entropy Alloy (HEA) production for fusion energy applications represents a critical consideration as these materials move toward commercial implementation. Current manufacturing processes for HEAs often involve energy-intensive methods such as arc melting, induction melting, and mechanical alloying, which contribute significantly to their environmental footprint. The multi-element composition of HEAs, while beneficial for their unique properties, presents challenges for resource efficiency and sustainable production.

Raw material sourcing for HEAs introduces complex supply chain considerations, particularly when incorporating elements like niobium, tantalum, and rare earth metals that face geopolitical supply constraints or environmental concerns during extraction. The fusion energy sector must carefully balance the performance benefits of these elements against their availability and environmental impact. Several HEA compositions under development for fusion applications deliberately utilize more abundant elements to mitigate these concerns.

Life cycle assessment (LCA) studies of HEA production reveal opportunities for process optimization to reduce environmental impact. Emerging manufacturing techniques such as additive manufacturing and powder metallurgy offer promising pathways to reduce material waste and energy consumption compared to traditional casting methods. These approaches enable near-net-shape production, minimizing the need for subsequent machining and material removal steps.

Recycling and circular economy principles present significant opportunities for HEA sustainability. The multi-element nature of HEAs creates both challenges and advantages for recycling efforts. While separating individual elements can be complex, the inherent compositional flexibility of HEAs potentially allows for direct recycling without complete elemental separation, provided tight control of impurities can be maintained.

Energy consumption during HEA production remains a significant concern, with estimates suggesting that manufacturing processes account for 60-70% of the total environmental impact across the material's lifecycle. Research initiatives are exploring alternative processing routes, including non-equilibrium processing techniques and lower-temperature synthesis methods, to reduce this energy burden.

Water usage and emissions control in HEA production facilities represent additional sustainability considerations. Advanced filtration systems and closed-loop water recycling technologies are being implemented to minimize environmental impact, particularly important for production scaling to meet potential fusion industry demands.

As fusion energy systems themselves aim to provide sustainable power generation, ensuring that the materials enabling these systems are produced sustainably creates an important alignment of values and practical outcomes. Future research directions should prioritize developing HEA compositions and manufacturing processes that balance exceptional performance requirements with environmental sustainability considerations.

Raw material sourcing for HEAs introduces complex supply chain considerations, particularly when incorporating elements like niobium, tantalum, and rare earth metals that face geopolitical supply constraints or environmental concerns during extraction. The fusion energy sector must carefully balance the performance benefits of these elements against their availability and environmental impact. Several HEA compositions under development for fusion applications deliberately utilize more abundant elements to mitigate these concerns.

Life cycle assessment (LCA) studies of HEA production reveal opportunities for process optimization to reduce environmental impact. Emerging manufacturing techniques such as additive manufacturing and powder metallurgy offer promising pathways to reduce material waste and energy consumption compared to traditional casting methods. These approaches enable near-net-shape production, minimizing the need for subsequent machining and material removal steps.

Recycling and circular economy principles present significant opportunities for HEA sustainability. The multi-element nature of HEAs creates both challenges and advantages for recycling efforts. While separating individual elements can be complex, the inherent compositional flexibility of HEAs potentially allows for direct recycling without complete elemental separation, provided tight control of impurities can be maintained.

Energy consumption during HEA production remains a significant concern, with estimates suggesting that manufacturing processes account for 60-70% of the total environmental impact across the material's lifecycle. Research initiatives are exploring alternative processing routes, including non-equilibrium processing techniques and lower-temperature synthesis methods, to reduce this energy burden.

Water usage and emissions control in HEA production facilities represent additional sustainability considerations. Advanced filtration systems and closed-loop water recycling technologies are being implemented to minimize environmental impact, particularly important for production scaling to meet potential fusion industry demands.

As fusion energy systems themselves aim to provide sustainable power generation, ensuring that the materials enabling these systems are produced sustainably creates an important alignment of values and practical outcomes. Future research directions should prioritize developing HEA compositions and manufacturing processes that balance exceptional performance requirements with environmental sustainability considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!