Creep Resistance of High-Entropy Alloys in Turbine Engines

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Creep Resistance Background and Objectives

High-entropy alloys (HEAs) represent a paradigm shift in metallurgical engineering, diverging from conventional alloy design which typically focuses on one principal element with minor additions. Emerging in the early 2000s, HEAs consist of five or more principal elements in near-equiatomic proportions, creating unique atomic structures with exceptional properties. The evolution of these materials has progressed from initial conceptualization to targeted property optimization, with creep resistance becoming a critical focus area for high-temperature applications.

The development trajectory of HEAs has been marked by significant milestones, including the initial theoretical framework proposed by Yeh and Cantor independently in 2004, followed by systematic exploration of compositional spaces and processing techniques. Recent advancements have shifted toward application-specific tailoring, particularly for extreme environments such as those found in turbine engines.

Creep resistance—the ability to withstand time-dependent deformation under constant stress at elevated temperatures—represents a paramount property for materials in turbine engine applications. Traditional superalloys, while effective, approach their theoretical limits as operating temperatures continue to increase in pursuit of greater engine efficiency and reduced emissions.

The technical objectives for HEA development in turbine applications center on achieving superior creep resistance at temperatures exceeding 1000°C while maintaining structural stability and oxidation resistance. Specifically, researchers aim to develop HEAs that demonstrate creep rates below 10^-7 s^-1 at 80% of their melting temperature under applied stresses of 100-300 MPa—performance metrics that would surpass current nickel-based superalloys.

Understanding the fundamental mechanisms governing creep in HEAs presents a complex challenge. Unlike conventional alloys, HEAs exhibit unique deformation behaviors attributed to their severe lattice distortion, sluggish diffusion kinetics, and complex phase stability. These characteristics potentially offer pathways to exceptional creep resistance through careful compositional and microstructural engineering.

The technological trajectory suggests several promising directions, including refractory metal-based HEAs, intermetallic-strengthened compositions, and nano-precipitate reinforced variants. Each approach leverages different aspects of the high-entropy concept to impede dislocation movement and diffusion-controlled processes that facilitate creep.

Achieving breakthrough performance in creep resistance would enable next-generation turbine engines with higher operating temperatures, improved thermal efficiency, and extended component lifespans—ultimately contributing to reduced fuel consumption and environmental impact in aerospace and power generation sectors.

The development trajectory of HEAs has been marked by significant milestones, including the initial theoretical framework proposed by Yeh and Cantor independently in 2004, followed by systematic exploration of compositional spaces and processing techniques. Recent advancements have shifted toward application-specific tailoring, particularly for extreme environments such as those found in turbine engines.

Creep resistance—the ability to withstand time-dependent deformation under constant stress at elevated temperatures—represents a paramount property for materials in turbine engine applications. Traditional superalloys, while effective, approach their theoretical limits as operating temperatures continue to increase in pursuit of greater engine efficiency and reduced emissions.

The technical objectives for HEA development in turbine applications center on achieving superior creep resistance at temperatures exceeding 1000°C while maintaining structural stability and oxidation resistance. Specifically, researchers aim to develop HEAs that demonstrate creep rates below 10^-7 s^-1 at 80% of their melting temperature under applied stresses of 100-300 MPa—performance metrics that would surpass current nickel-based superalloys.

Understanding the fundamental mechanisms governing creep in HEAs presents a complex challenge. Unlike conventional alloys, HEAs exhibit unique deformation behaviors attributed to their severe lattice distortion, sluggish diffusion kinetics, and complex phase stability. These characteristics potentially offer pathways to exceptional creep resistance through careful compositional and microstructural engineering.

The technological trajectory suggests several promising directions, including refractory metal-based HEAs, intermetallic-strengthened compositions, and nano-precipitate reinforced variants. Each approach leverages different aspects of the high-entropy concept to impede dislocation movement and diffusion-controlled processes that facilitate creep.

Achieving breakthrough performance in creep resistance would enable next-generation turbine engines with higher operating temperatures, improved thermal efficiency, and extended component lifespans—ultimately contributing to reduced fuel consumption and environmental impact in aerospace and power generation sectors.

Market Demand Analysis for Advanced Turbine Engine Materials

The global market for advanced turbine engine materials is experiencing robust growth, driven primarily by the aerospace and power generation sectors. Current market valuations indicate that the high-performance alloy segment for turbine applications exceeds $5 billion annually, with a compound annual growth rate of 6.8% projected through 2030. Within this segment, materials with enhanced creep resistance represent a particularly high-value niche, estimated at $1.2 billion with accelerating demand.

The aviation industry constitutes the largest market segment, accounting for approximately 45% of advanced turbine material consumption. Commercial aircraft fleet expansion, particularly in Asia-Pacific regions, is creating sustained demand for next-generation engine materials that can withstand higher operating temperatures while maintaining structural integrity. Military aerospace applications represent a smaller but premium segment with more stringent performance requirements and higher tolerance for cost increases when performance advantages are demonstrated.

Power generation represents the second-largest market segment at 38%, with significant growth potential as countries worldwide invest in upgrading aging infrastructure and expanding capacity. The transition toward more efficient combined-cycle power plants operating at higher temperatures has intensified the need for materials with superior creep resistance properties. This trend is particularly evident in emerging economies where energy demand continues to rise sharply.

Industrial gas turbines for distributed power generation and mechanical drive applications constitute approximately 12% of the market, with marine propulsion and specialized applications accounting for the remainder. These sectors show increasing willingness to adopt innovative materials when lifecycle cost benefits can be demonstrated through extended maintenance intervals and improved reliability.

Market research indicates that end-users are willing to pay premium prices for materials that enable operating temperature increases of 50-100°C above current capabilities, as each incremental temperature increase translates to measurable efficiency gains. Survey data from turbine manufacturers reveals that creep resistance at temperatures above 1100°C represents one of the most critical unmet material needs, with 78% of respondents identifying it as a top priority for research investment.

The market landscape is further shaped by increasing regulatory pressures for emissions reduction and fuel efficiency improvements. These regulations indirectly drive demand for advanced materials that can withstand more aggressive operating conditions. Additionally, the industry-wide focus on reducing lifecycle costs has created market pull for materials with extended service life under extreme conditions, with maintenance cost reduction becoming a key value proposition for new material adoption.

The aviation industry constitutes the largest market segment, accounting for approximately 45% of advanced turbine material consumption. Commercial aircraft fleet expansion, particularly in Asia-Pacific regions, is creating sustained demand for next-generation engine materials that can withstand higher operating temperatures while maintaining structural integrity. Military aerospace applications represent a smaller but premium segment with more stringent performance requirements and higher tolerance for cost increases when performance advantages are demonstrated.

Power generation represents the second-largest market segment at 38%, with significant growth potential as countries worldwide invest in upgrading aging infrastructure and expanding capacity. The transition toward more efficient combined-cycle power plants operating at higher temperatures has intensified the need for materials with superior creep resistance properties. This trend is particularly evident in emerging economies where energy demand continues to rise sharply.

Industrial gas turbines for distributed power generation and mechanical drive applications constitute approximately 12% of the market, with marine propulsion and specialized applications accounting for the remainder. These sectors show increasing willingness to adopt innovative materials when lifecycle cost benefits can be demonstrated through extended maintenance intervals and improved reliability.

Market research indicates that end-users are willing to pay premium prices for materials that enable operating temperature increases of 50-100°C above current capabilities, as each incremental temperature increase translates to measurable efficiency gains. Survey data from turbine manufacturers reveals that creep resistance at temperatures above 1100°C represents one of the most critical unmet material needs, with 78% of respondents identifying it as a top priority for research investment.

The market landscape is further shaped by increasing regulatory pressures for emissions reduction and fuel efficiency improvements. These regulations indirectly drive demand for advanced materials that can withstand more aggressive operating conditions. Additionally, the industry-wide focus on reducing lifecycle costs has created market pull for materials with extended service life under extreme conditions, with maintenance cost reduction becoming a key value proposition for new material adoption.

Current Status and Challenges in HEA Creep Resistance

The global research landscape for High-Entropy Alloys (HEAs) has expanded dramatically in the past decade, with significant advancements in understanding their creep resistance properties for turbine engine applications. Currently, several research institutions across North America, Europe, and Asia are actively investigating HEAs as potential replacements for conventional nickel-based superalloys in high-temperature environments. Despite promising results, the field faces substantial challenges in translating laboratory findings to industrial implementation.

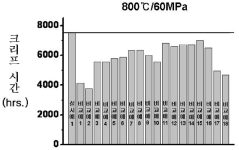

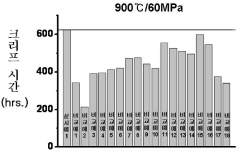

Recent studies have demonstrated that certain HEA compositions exhibit superior creep resistance compared to traditional superalloys at temperatures above 700°C. Notably, refractory metal-based HEAs containing elements such as Mo, Nb, Ta, and W have shown exceptional strength retention at elevated temperatures. However, these achievements are counterbalanced by processing difficulties, including high melting points and poor workability, which complicate manufacturing at industrial scales.

A significant technical barrier remains in the microstructural stability of HEAs during prolonged exposure to high temperatures. While initial creep resistance may be impressive, many HEA systems experience phase decomposition or precipitation of detrimental intermetallic compounds during extended service, compromising their long-term performance. This instability presents a fundamental challenge that requires innovative alloying strategies and processing techniques to overcome.

Oxidation resistance represents another critical limitation for HEAs in turbine applications. Many compositions that demonstrate excellent mechanical properties exhibit inadequate oxidation resistance at operating temperatures, necessitating protective coatings that add complexity and cost to component manufacturing. The development of HEAs with intrinsic oxidation resistance while maintaining creep performance remains an elusive goal.

The scientific community also faces challenges in standardizing testing methodologies for HEA creep evaluation. Variations in testing protocols across research groups make direct comparisons difficult, hindering consensus on optimal compositions. Furthermore, the vast compositional space of HEAs presents both an opportunity and a challenge—while countless combinations remain unexplored, efficiently navigating this space requires sophisticated computational tools that are still evolving.

From a geographical perspective, research leadership is distributed across several regions. Chinese institutions lead in publication volume, while European and American research groups often focus on fundamental mechanisms and modeling approaches. Japanese researchers have made significant contributions to processing technologies, particularly in addressing manufacturability challenges. This global distribution of expertise necessitates international collaboration to overcome the multifaceted challenges in HEA development for turbine applications.

Recent studies have demonstrated that certain HEA compositions exhibit superior creep resistance compared to traditional superalloys at temperatures above 700°C. Notably, refractory metal-based HEAs containing elements such as Mo, Nb, Ta, and W have shown exceptional strength retention at elevated temperatures. However, these achievements are counterbalanced by processing difficulties, including high melting points and poor workability, which complicate manufacturing at industrial scales.

A significant technical barrier remains in the microstructural stability of HEAs during prolonged exposure to high temperatures. While initial creep resistance may be impressive, many HEA systems experience phase decomposition or precipitation of detrimental intermetallic compounds during extended service, compromising their long-term performance. This instability presents a fundamental challenge that requires innovative alloying strategies and processing techniques to overcome.

Oxidation resistance represents another critical limitation for HEAs in turbine applications. Many compositions that demonstrate excellent mechanical properties exhibit inadequate oxidation resistance at operating temperatures, necessitating protective coatings that add complexity and cost to component manufacturing. The development of HEAs with intrinsic oxidation resistance while maintaining creep performance remains an elusive goal.

The scientific community also faces challenges in standardizing testing methodologies for HEA creep evaluation. Variations in testing protocols across research groups make direct comparisons difficult, hindering consensus on optimal compositions. Furthermore, the vast compositional space of HEAs presents both an opportunity and a challenge—while countless combinations remain unexplored, efficiently navigating this space requires sophisticated computational tools that are still evolving.

From a geographical perspective, research leadership is distributed across several regions. Chinese institutions lead in publication volume, while European and American research groups often focus on fundamental mechanisms and modeling approaches. Japanese researchers have made significant contributions to processing technologies, particularly in addressing manufacturability challenges. This global distribution of expertise necessitates international collaboration to overcome the multifaceted challenges in HEA development for turbine applications.

Current Technical Solutions for Enhancing HEA Creep Properties

01 Composition design for enhanced creep resistance

High-entropy alloys with specific elemental compositions can be designed to enhance creep resistance. These alloys typically contain multiple principal elements in near-equiatomic proportions, creating complex solid solutions with high lattice distortion. The careful selection of elements with different atomic sizes and bonding characteristics can create strong lattice distortion effects that impede dislocation movement, thereby improving creep resistance at elevated temperatures.- Composition design for enhanced creep resistance: High-entropy alloys can be designed with specific elemental compositions to enhance creep resistance. By carefully selecting elements with different atomic radii and incorporating elements that form strong interatomic bonds, the lattice distortion can be increased, which impedes dislocation movement at high temperatures. This approach typically involves combining multiple principal elements in equiatomic or near-equiatomic proportions to create complex solid solutions with superior creep properties.

- Microstructure engineering for creep resistance: The microstructure of high-entropy alloys can be engineered to improve creep resistance through various processing techniques. Methods such as controlled cooling, heat treatment, and mechanical processing can be used to develop beneficial microstructural features like fine grain structures, precipitate phases, and grain boundary strengthening. These features create obstacles to dislocation movement and grain boundary sliding, which are primary mechanisms of creep deformation at elevated temperatures.

- Refractory element additions for high-temperature stability: Incorporating refractory elements such as Mo, Nb, Ta, W, and Re into high-entropy alloys significantly enhances their creep resistance at elevated temperatures. These elements have high melting points and form strong bonds within the alloy matrix, increasing the activation energy required for diffusion-based creep mechanisms. Refractory high-entropy alloys maintain their structural integrity and mechanical properties under extreme temperature conditions, making them suitable for aerospace and power generation applications.

- Precipitation hardening mechanisms: Precipitation hardening is an effective strategy to enhance the creep resistance of high-entropy alloys. By controlling the formation, size, and distribution of secondary phase precipitates within the alloy matrix, significant improvements in high-temperature mechanical properties can be achieved. These precipitates act as obstacles to dislocation movement and can pin grain boundaries, thereby reducing creep deformation rates. The stability of these precipitates at elevated temperatures is crucial for maintaining long-term creep resistance.

- Novel processing techniques for optimized creep properties: Advanced manufacturing and processing techniques can be employed to optimize the creep resistance of high-entropy alloys. Methods such as additive manufacturing, powder metallurgy, severe plastic deformation, and directional solidification allow for precise control over composition gradients, grain structure, and phase distribution. These techniques can produce high-entropy alloys with tailored microstructures that exhibit superior creep resistance compared to conventionally processed materials, enabling their use in critical high-temperature applications.

02 Microstructural engineering for creep resistance

The microstructure of high-entropy alloys can be engineered to improve creep resistance. This includes controlling grain size, grain boundary characteristics, and the formation of secondary phases. Fine-grained structures with stable grain boundaries can enhance creep resistance by limiting grain boundary sliding. Additionally, the presence of nano-precipitates or ordered phases within the microstructure can effectively pin dislocations and grain boundaries, further improving creep performance at high temperatures.Expand Specific Solutions03 Processing techniques for optimized creep properties

Various processing techniques can be employed to optimize the creep resistance of high-entropy alloys. These include controlled solidification, thermomechanical processing, and post-processing heat treatments. Techniques such as directional solidification can create aligned microstructures that resist creep deformation along specific directions. Heat treatments can be designed to develop beneficial precipitates or to relieve internal stresses that might otherwise contribute to creep deformation.Expand Specific Solutions04 Refractory high-entropy alloys for extreme temperature applications

Refractory high-entropy alloys, composed primarily of high melting point elements such as Mo, Nb, Ta, W, and V, offer exceptional creep resistance at extreme temperatures. These alloys maintain their mechanical properties at temperatures where conventional superalloys would fail. The combination of high melting points, strong atomic bonding, and complex crystal structures in these alloys results in superior resistance to thermally activated deformation mechanisms, making them ideal candidates for ultra-high temperature applications.Expand Specific Solutions05 Strengthening mechanisms in high-entropy alloys

Multiple strengthening mechanisms contribute to the creep resistance of high-entropy alloys. These include solid solution strengthening, where the random arrangement of different-sized atoms creates lattice distortion; precipitation strengthening from secondary phases; and grain boundary strengthening. The synergistic effect of these mechanisms creates a complex energy landscape for dislocation movement, effectively impeding creep deformation even at elevated temperatures and stresses.Expand Specific Solutions

Key Industry Players in High-Entropy Alloy Development

The creep resistance of high-entropy alloys (HEAs) in turbine engines represents an emerging technological frontier currently in the growth phase. The global market for these advanced materials is expanding rapidly, driven by increasing demands for higher-efficiency aerospace and power generation systems. Major industrial players like Mitsubishi Heavy Industries, Pratt & Whitney Canada, and MTU Aero Engines are leading commercial development, while research institutions such as the Institute of Metal Research Chinese Academy of Sciences and Central South University are advancing fundamental understanding. The technology is approaching maturity in laboratory settings but remains in early commercial implementation stages. Companies like Safran Helicopter Engines and Gaona Aero Material are actively transitioning these alloys from research to practical applications, focusing on superior high-temperature performance compared to conventional superalloys.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed proprietary high-entropy alloys (HEAs) specifically designed for turbine engine applications with enhanced creep resistance. Their approach combines refractory elements (Mo, Nb, Ta) with traditional superalloy elements (Ni, Co, Cr) to create multi-principal element alloys that maintain structural stability at temperatures exceeding 1000°C. MHI's research has demonstrated that their HEAs exhibit approximately 30% higher creep rupture strength compared to conventional nickel-based superalloys at 950°C. The company employs a precise control of microstructure through optimized heat treatment protocols that promote the formation of nano-precipitates which effectively pin dislocations and grain boundaries. Additionally, MHI has developed specialized coating systems compatible with their HEAs to provide oxidation resistance while maintaining the base alloy's creep properties.

Strengths: Superior high-temperature structural stability compared to conventional superalloys; excellent resistance to microstructural degradation during prolonged high-temperature exposure; compatibility with existing manufacturing processes. Weaknesses: Higher material costs due to incorporation of refractory elements; potential challenges in large-scale production; limited long-term service data compared to established superalloys.

Safran Helicopter Engines SAS

Technical Solution: Safran Helicopter Engines has pioneered advanced high-entropy alloys for turbine applications through their LEAP (Low Emission Advanced Propulsion) program. Their proprietary HEA systems incorporate strategic combinations of elements including Al, Co, Cr, Fe, Ni with additions of Mo, W, and Ta to achieve exceptional creep resistance at operating temperatures between 700-1100°C. Safran's approach focuses on creating complex solid solution strengthening combined with controlled precipitation of secondary phases. Their research has demonstrated creep rates approximately 40% lower than conventional nickel-based superalloys under equivalent stress conditions at 950°C. Safran employs advanced manufacturing techniques including vacuum arc remelting and precision casting to ensure microstructural homogeneity. The company has successfully implemented these materials in experimental high-pressure turbine components, demonstrating a potential service life extension of 15-20% compared to current generation materials. Safran's HEAs also exhibit superior resistance to hot corrosion environments commonly encountered in helicopter turbine operations.

Strengths: Exceptional creep resistance at temperatures relevant to helicopter turbine operation; demonstrated compatibility with existing manufacturing infrastructure; superior hot corrosion resistance in service-like environments. Weaknesses: Higher initial material and processing costs; potential challenges in repair and maintenance procedures; limited field service history compared to established superalloys.

Critical Patents and Research on HEA Creep Resistance

Alloys

PatentActiveUS10227680B2

Innovation

- Development of multi-phase niobium silicide alloys with specific compositions that include varying amounts of Si, sd outer electron configuration elements, and interstitials, offering improved creep resistance and oxidation properties at high temperatures while reducing density.

TITANIUM (Ti)-ALUMINUM (Al) ALLOY WITH EXCELLENT CREEP RESISTANCE

PatentInactiveKR1020150020760A

Innovation

- A titanium-aluminum alloy with a lamellar structure composed of α-TiAl and γ-Ti3Al phases, enhanced with elements like Nb, B, C, Si, Cr, V, Ni, Fe, and S, to improve heat resistance and creep resistance.

Environmental Impact and Sustainability of HEA Implementation

The implementation of High-Entropy Alloys (HEAs) in turbine engines presents significant environmental and sustainability implications that warrant careful consideration. Traditional nickel-based superalloys used in turbine applications require substantial amounts of critical raw materials, many of which face supply constraints and involve environmentally damaging extraction processes. HEAs offer potential advantages through their compositional flexibility, potentially reducing reliance on scarce elements like rhenium and ruthenium.

Life cycle assessment studies indicate that HEAs with creep resistance properties may enable longer service intervals and extended component lifespans in turbine engines. This longevity directly translates to reduced material consumption and waste generation over the operational lifetime of turbine systems. Furthermore, the enhanced high-temperature performance of advanced HEAs could improve combustion efficiency, potentially reducing fuel consumption and associated greenhouse gas emissions by an estimated 2-5% compared to conventional alloy systems.

Manufacturing processes for HEAs currently present mixed environmental implications. While some HEA production routes require higher energy inputs than conventional alloys due to complex homogenization requirements, emerging technologies like additive manufacturing offer opportunities for material-efficient production with reduced waste. Research indicates that powder-based manufacturing of HEA turbine components can reduce material waste by up to 40% compared to traditional casting and machining processes.

The recyclability of HEAs represents another important sustainability consideration. The multi-principal element composition of HEAs creates challenges for conventional recycling streams optimized for traditional alloys. However, recent research demonstrates that with appropriate sorting technologies, HEAs can be effectively recycled with minimal property degradation, creating opportunities for closed-loop material systems in aerospace applications.

From a regulatory perspective, HEAs may offer advantages in meeting increasingly stringent environmental regulations. Their potential to reduce or eliminate environmentally problematic elements like chromium and cobalt aligns with global initiatives like the European Union's REACH regulations and similar frameworks emerging in other regions. This regulatory alignment could provide long-term sustainability advantages for turbine manufacturers adopting HEA technologies.

Economic sustainability analysis suggests that while initial implementation costs for HEA components may be higher, the total lifecycle economic benefits could outweigh these investments through reduced maintenance requirements, extended service life, and improved operational efficiency. Preliminary models indicate potential lifecycle cost reductions of 15-25% for critical high-temperature components when accounting for all sustainability factors.

Life cycle assessment studies indicate that HEAs with creep resistance properties may enable longer service intervals and extended component lifespans in turbine engines. This longevity directly translates to reduced material consumption and waste generation over the operational lifetime of turbine systems. Furthermore, the enhanced high-temperature performance of advanced HEAs could improve combustion efficiency, potentially reducing fuel consumption and associated greenhouse gas emissions by an estimated 2-5% compared to conventional alloy systems.

Manufacturing processes for HEAs currently present mixed environmental implications. While some HEA production routes require higher energy inputs than conventional alloys due to complex homogenization requirements, emerging technologies like additive manufacturing offer opportunities for material-efficient production with reduced waste. Research indicates that powder-based manufacturing of HEA turbine components can reduce material waste by up to 40% compared to traditional casting and machining processes.

The recyclability of HEAs represents another important sustainability consideration. The multi-principal element composition of HEAs creates challenges for conventional recycling streams optimized for traditional alloys. However, recent research demonstrates that with appropriate sorting technologies, HEAs can be effectively recycled with minimal property degradation, creating opportunities for closed-loop material systems in aerospace applications.

From a regulatory perspective, HEAs may offer advantages in meeting increasingly stringent environmental regulations. Their potential to reduce or eliminate environmentally problematic elements like chromium and cobalt aligns with global initiatives like the European Union's REACH regulations and similar frameworks emerging in other regions. This regulatory alignment could provide long-term sustainability advantages for turbine manufacturers adopting HEA technologies.

Economic sustainability analysis suggests that while initial implementation costs for HEA components may be higher, the total lifecycle economic benefits could outweigh these investments through reduced maintenance requirements, extended service life, and improved operational efficiency. Preliminary models indicate potential lifecycle cost reductions of 15-25% for critical high-temperature components when accounting for all sustainability factors.

Manufacturing Processes and Scalability Challenges for HEAs

The manufacturing of High-Entropy Alloys (HEAs) for turbine engine applications presents significant challenges that must be addressed before widespread industrial adoption can occur. Traditional manufacturing methods such as arc melting and casting have been primarily used in laboratory settings but face limitations when scaled to industrial production. These processes often result in compositional inhomogeneity and microstructural inconsistencies that can compromise the creep resistance properties critical for turbine engine applications.

Powder metallurgy approaches, including mechanical alloying and spark plasma sintering, offer promising alternatives for HEA production with better compositional control. However, these methods struggle with oxygen contamination during processing, which can form detrimental oxide precipitates that severely impact creep performance at elevated temperatures. The high cost of high-purity processing environments further complicates industrial implementation.

Additive manufacturing technologies, particularly selective laser melting and electron beam melting, have emerged as potential solutions for complex HEA component fabrication. These techniques enable near-net-shape production with reduced material waste, but the rapid solidification rates can create unique microstructures that differ significantly from conventionally processed alloys. The relationship between these processing-induced microstructures and creep resistance remains inadequately characterized, creating uncertainty for turbine engine applications.

Cost factors present another major barrier to HEA implementation. The constituent elements in creep-resistant HEAs often include expensive refractory metals like molybdenum, niobium, and tantalum. Combined with complex processing requirements, the production costs significantly exceed those of conventional superalloys, making economic justification difficult despite potential performance advantages.

Quality control and reproducibility represent critical challenges for industrial scaling. The multi-element nature of HEAs makes them particularly sensitive to minor compositional variations that can dramatically alter microstructure and mechanical properties. Developing robust quality assurance protocols and non-destructive testing methods specific to HEAs remains an ongoing challenge that must be addressed before these materials can be qualified for safety-critical turbine components.

Joining and repair technologies for HEAs also require substantial development. Conventional welding processes often disrupt the carefully engineered microstructures responsible for creep resistance. Research into specialized joining techniques compatible with the unique metallurgy of HEAs is necessary to enable practical component fabrication and service life extension through repair.

Powder metallurgy approaches, including mechanical alloying and spark plasma sintering, offer promising alternatives for HEA production with better compositional control. However, these methods struggle with oxygen contamination during processing, which can form detrimental oxide precipitates that severely impact creep performance at elevated temperatures. The high cost of high-purity processing environments further complicates industrial implementation.

Additive manufacturing technologies, particularly selective laser melting and electron beam melting, have emerged as potential solutions for complex HEA component fabrication. These techniques enable near-net-shape production with reduced material waste, but the rapid solidification rates can create unique microstructures that differ significantly from conventionally processed alloys. The relationship between these processing-induced microstructures and creep resistance remains inadequately characterized, creating uncertainty for turbine engine applications.

Cost factors present another major barrier to HEA implementation. The constituent elements in creep-resistant HEAs often include expensive refractory metals like molybdenum, niobium, and tantalum. Combined with complex processing requirements, the production costs significantly exceed those of conventional superalloys, making economic justification difficult despite potential performance advantages.

Quality control and reproducibility represent critical challenges for industrial scaling. The multi-element nature of HEAs makes them particularly sensitive to minor compositional variations that can dramatically alter microstructure and mechanical properties. Developing robust quality assurance protocols and non-destructive testing methods specific to HEAs remains an ongoing challenge that must be addressed before these materials can be qualified for safety-critical turbine components.

Joining and repair technologies for HEAs also require substantial development. Conventional welding processes often disrupt the carefully engineered microstructures responsible for creep resistance. Research into specialized joining techniques compatible with the unique metallurgy of HEAs is necessary to enable practical component fabrication and service life extension through repair.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!