High-Entropy Alloys' Role in Extreme Cryogenic Applications

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Development History and Cryogenic Application Goals

High-Entropy Alloys (HEAs) emerged as a revolutionary concept in materials science in 2004 when Yeh and Cantor independently published their groundbreaking research. Unlike conventional alloys that rely on one principal element with minor additions, HEAs incorporate five or more elements in near-equiatomic proportions, creating unique atomic structures with exceptional properties. This paradigm shift expanded the materials design space exponentially, moving beyond traditional composition constraints.

The evolution of HEAs has progressed through distinct phases. The initial discovery phase (2004-2010) focused on conceptual development and basic characterization. The second phase (2010-2015) saw increased understanding of fundamental mechanisms and property relationships. The current phase (2015-present) has witnessed targeted application development, with cryogenic applications emerging as a particularly promising frontier.

HEAs exhibit remarkable mechanical stability at extremely low temperatures, maintaining ductility and toughness where conventional materials become brittle. This characteristic stems from their unique microstructural features, including solid solution strengthening, lattice distortion, and sluggish diffusion effects. These properties make HEAs exceptionally suitable for extreme cryogenic environments, where temperatures can plunge below -150°C.

The technological goals for HEAs in cryogenic applications are multifaceted. Primary objectives include developing alloys with superior mechanical properties at temperatures approaching absolute zero, ensuring structural integrity under thermal cycling conditions, and maintaining resistance to hydrogen embrittlement. Additionally, researchers aim to enhance manufacturability while reducing production costs to facilitate commercial adoption.

Specific performance targets include achieving yield strengths exceeding 1 GPa with ductility above 20% at liquid nitrogen temperatures (-196°C), developing compositions with thermal expansion coefficients below 10×10^-6/K, and ensuring long-term stability under repeated thermal cycling between ambient and cryogenic temperatures.

The strategic importance of these goals extends beyond materials science to enable advancements in critical fields such as space exploration, quantum computing, superconducting technologies, and liquefied natural gas infrastructure. As global interest in these sectors intensifies, HEAs represent a transformative material solution that could overcome longstanding limitations of conventional alloys in extreme cryogenic environments.

Current research trajectories suggest that tailored HEAs could revolutionize cryogenic engineering within the next decade, provided that remaining challenges in composition optimization, processing techniques, and cost-effective manufacturing can be successfully addressed.

The evolution of HEAs has progressed through distinct phases. The initial discovery phase (2004-2010) focused on conceptual development and basic characterization. The second phase (2010-2015) saw increased understanding of fundamental mechanisms and property relationships. The current phase (2015-present) has witnessed targeted application development, with cryogenic applications emerging as a particularly promising frontier.

HEAs exhibit remarkable mechanical stability at extremely low temperatures, maintaining ductility and toughness where conventional materials become brittle. This characteristic stems from their unique microstructural features, including solid solution strengthening, lattice distortion, and sluggish diffusion effects. These properties make HEAs exceptionally suitable for extreme cryogenic environments, where temperatures can plunge below -150°C.

The technological goals for HEAs in cryogenic applications are multifaceted. Primary objectives include developing alloys with superior mechanical properties at temperatures approaching absolute zero, ensuring structural integrity under thermal cycling conditions, and maintaining resistance to hydrogen embrittlement. Additionally, researchers aim to enhance manufacturability while reducing production costs to facilitate commercial adoption.

Specific performance targets include achieving yield strengths exceeding 1 GPa with ductility above 20% at liquid nitrogen temperatures (-196°C), developing compositions with thermal expansion coefficients below 10×10^-6/K, and ensuring long-term stability under repeated thermal cycling between ambient and cryogenic temperatures.

The strategic importance of these goals extends beyond materials science to enable advancements in critical fields such as space exploration, quantum computing, superconducting technologies, and liquefied natural gas infrastructure. As global interest in these sectors intensifies, HEAs represent a transformative material solution that could overcome longstanding limitations of conventional alloys in extreme cryogenic environments.

Current research trajectories suggest that tailored HEAs could revolutionize cryogenic engineering within the next decade, provided that remaining challenges in composition optimization, processing techniques, and cost-effective manufacturing can be successfully addressed.

Market Analysis for Cryogenic Materials

The cryogenic materials market is experiencing significant growth, driven by expanding applications in aerospace, healthcare, energy, and scientific research. Current market valuation stands at approximately 7.5 billion USD with projections indicating a compound annual growth rate of 6.8% through 2030. This growth trajectory is primarily fueled by increasing demand for liquefied natural gas (LNG) infrastructure and advanced medical imaging technologies requiring superconducting magnets.

High-Entropy Alloys (HEAs) represent an emerging segment within this market, offering exceptional mechanical properties at extremely low temperatures where conventional materials typically become brittle. The demand for materials capable of withstanding temperatures below -150°C while maintaining structural integrity is particularly strong in space exploration, quantum computing, and fusion energy research sectors.

Market segmentation reveals that aerospace and defense applications currently dominate the extreme cryogenic materials consumption, accounting for roughly 38% of market share. This is followed by energy applications at 27%, scientific research at 21%, and healthcare at 14%. Regional analysis indicates North America leads with 35% market share, followed by Europe (28%), Asia-Pacific (25%), and rest of world (12%).

Customer requirements are evolving toward materials that can withstand not only extreme cold but also rapid temperature cycling, radiation exposure, and high mechanical stress simultaneously. This multi-parameter performance requirement creates significant market opportunities for HEAs, which demonstrate superior combination properties compared to traditional single-principal-element alloys.

Price sensitivity varies considerably across application sectors. While cost remains a critical factor for large-scale industrial applications like LNG processing, performance characteristics take precedence over price considerations in specialized fields such as quantum computing and space exploration, where material failure could result in catastrophic consequences.

Supply chain analysis reveals potential vulnerabilities, particularly regarding rare element availability for certain HEA compositions. Several critical elements used in high-performance HEAs face supply constraints, with over 70% of global production concentrated in just three countries. This geopolitical concentration presents both market risks and opportunities for materials innovation focused on more abundant element compositions.

Competitive landscape assessment identifies increasing R&D investments from major materials science companies and aerospace contractors, with patent filings for cryogenic-specific HEAs increasing by 215% over the past five years. This surge in intellectual property development signals recognition of the significant market potential for these advanced materials in extreme temperature applications.

High-Entropy Alloys (HEAs) represent an emerging segment within this market, offering exceptional mechanical properties at extremely low temperatures where conventional materials typically become brittle. The demand for materials capable of withstanding temperatures below -150°C while maintaining structural integrity is particularly strong in space exploration, quantum computing, and fusion energy research sectors.

Market segmentation reveals that aerospace and defense applications currently dominate the extreme cryogenic materials consumption, accounting for roughly 38% of market share. This is followed by energy applications at 27%, scientific research at 21%, and healthcare at 14%. Regional analysis indicates North America leads with 35% market share, followed by Europe (28%), Asia-Pacific (25%), and rest of world (12%).

Customer requirements are evolving toward materials that can withstand not only extreme cold but also rapid temperature cycling, radiation exposure, and high mechanical stress simultaneously. This multi-parameter performance requirement creates significant market opportunities for HEAs, which demonstrate superior combination properties compared to traditional single-principal-element alloys.

Price sensitivity varies considerably across application sectors. While cost remains a critical factor for large-scale industrial applications like LNG processing, performance characteristics take precedence over price considerations in specialized fields such as quantum computing and space exploration, where material failure could result in catastrophic consequences.

Supply chain analysis reveals potential vulnerabilities, particularly regarding rare element availability for certain HEA compositions. Several critical elements used in high-performance HEAs face supply constraints, with over 70% of global production concentrated in just three countries. This geopolitical concentration presents both market risks and opportunities for materials innovation focused on more abundant element compositions.

Competitive landscape assessment identifies increasing R&D investments from major materials science companies and aerospace contractors, with patent filings for cryogenic-specific HEAs increasing by 215% over the past five years. This surge in intellectual property development signals recognition of the significant market potential for these advanced materials in extreme temperature applications.

Current Status and Challenges in Cryogenic HEA Technology

The global landscape of High-Entropy Alloys (HEAs) for extreme cryogenic applications has witnessed significant advancements in recent years. Currently, research institutions across North America, Europe, and East Asia lead the development of cryogenic-capable HEAs, with notable contributions from NASA, the European Space Agency, and various academic institutions in China and Japan. These entities have successfully demonstrated HEAs that maintain structural integrity and mechanical properties at temperatures approaching absolute zero, a critical requirement for space exploration and quantum computing applications.

Despite these achievements, several technical challenges persist in the development of cryogenic HEAs. The primary obstacle remains the unpredictable phase stability at ultra-low temperatures, where conventional metallurgical models often fail to accurately predict material behavior. Researchers have observed unexpected phase transformations in certain HEA compositions when exposed to temperatures below 20K, leading to compromised mechanical properties and potential structural failures.

Another significant challenge involves the manufacturing scalability of cryogenic HEAs. While laboratory-scale production has yielded promising results, transitioning to industrial-scale manufacturing while maintaining compositional homogeneity presents considerable difficulties. Current production methods, including vacuum arc melting and powder metallurgy, often result in microscale segregation that can dramatically affect performance in cryogenic environments.

The characterization of HEAs at cryogenic temperatures represents another technical hurdle. Conventional testing equipment requires substantial modifications to operate reliably at extreme low temperatures, and the interpretation of test results demands specialized expertise not widely available in the materials science community. This has created a bottleneck in the rapid assessment and iteration of new HEA compositions specifically designed for cryogenic applications.

From a geographical perspective, the development of cryogenic HEAs shows interesting patterns. North American research focuses primarily on aerospace applications, while European institutions emphasize fundamental understanding of thermodynamic behaviors. Asian research centers, particularly in China, have made significant strides in computational modeling of HEAs for cryogenic environments, though experimental validation remains challenging across all regions.

Cost factors also present a substantial barrier to widespread adoption of cryogenic HEAs. The complex manufacturing processes and expensive constituent elements (often including rare earth metals) result in materials that are prohibitively expensive for all but the most critical applications. This economic constraint has limited broader industrial adoption despite the technical advantages these materials offer in extreme environments.

Despite these achievements, several technical challenges persist in the development of cryogenic HEAs. The primary obstacle remains the unpredictable phase stability at ultra-low temperatures, where conventional metallurgical models often fail to accurately predict material behavior. Researchers have observed unexpected phase transformations in certain HEA compositions when exposed to temperatures below 20K, leading to compromised mechanical properties and potential structural failures.

Another significant challenge involves the manufacturing scalability of cryogenic HEAs. While laboratory-scale production has yielded promising results, transitioning to industrial-scale manufacturing while maintaining compositional homogeneity presents considerable difficulties. Current production methods, including vacuum arc melting and powder metallurgy, often result in microscale segregation that can dramatically affect performance in cryogenic environments.

The characterization of HEAs at cryogenic temperatures represents another technical hurdle. Conventional testing equipment requires substantial modifications to operate reliably at extreme low temperatures, and the interpretation of test results demands specialized expertise not widely available in the materials science community. This has created a bottleneck in the rapid assessment and iteration of new HEA compositions specifically designed for cryogenic applications.

From a geographical perspective, the development of cryogenic HEAs shows interesting patterns. North American research focuses primarily on aerospace applications, while European institutions emphasize fundamental understanding of thermodynamic behaviors. Asian research centers, particularly in China, have made significant strides in computational modeling of HEAs for cryogenic environments, though experimental validation remains challenging across all regions.

Cost factors also present a substantial barrier to widespread adoption of cryogenic HEAs. The complex manufacturing processes and expensive constituent elements (often including rare earth metals) result in materials that are prohibitively expensive for all but the most critical applications. This economic constraint has limited broader industrial adoption despite the technical advantages these materials offer in extreme environments.

Current HEA Compositions for Extreme Cold Environments

01 Composition and structure of high-entropy alloys

High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. This multi-element composition creates a high configurational entropy that stabilizes solid solution phases. The unique atomic structure of HEAs contributes to their exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. The composition can be tailored to achieve specific mechanical and physical properties for various applications.- Composition and structure of high-entropy alloys: High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. This multi-element composition creates a high configurational entropy that stabilizes solid solution phases. The unique atomic structure of HEAs contributes to their exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. The composition can be tailored to achieve specific mechanical and physical properties for various applications.

- Manufacturing methods for high-entropy alloys: Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, scalability, and final properties. Post-processing treatments such as heat treatment, rolling, and forging can further enhance the mechanical properties of these alloys. Advanced manufacturing approaches enable the production of complex shapes and structures with optimized performance characteristics.

- Applications of high-entropy alloys in extreme environments: High-entropy alloys demonstrate exceptional performance in extreme environments, making them suitable for aerospace, nuclear, and deep-sea applications. Their superior high-temperature strength, oxidation resistance, and thermal stability enable use in turbine components and heat shields. Additionally, their excellent low-temperature toughness and radiation resistance make them candidates for cryogenic and nuclear applications. The combination of these properties allows HEAs to function reliably under conditions where conventional alloys would fail.

- Functional properties and specialized applications of high-entropy alloys: Beyond structural applications, high-entropy alloys exhibit unique functional properties including magnetic, electrical, and catalytic characteristics. These properties enable their use in sensors, actuators, energy storage, and conversion devices. Some HEAs demonstrate shape memory effects, superelasticity, or superconductivity. The multifunctional nature of these alloys makes them promising candidates for smart materials and systems that can respond to environmental stimuli or perform multiple functions simultaneously.

- Computational design and property prediction of high-entropy alloys: Computational methods play a crucial role in the design and development of high-entropy alloys. Machine learning algorithms, density functional theory calculations, and CALPHAD (CALculation of PHAse Diagrams) approaches help predict phase stability, mechanical properties, and performance characteristics. These computational tools enable efficient screening of potential alloy compositions before experimental validation, significantly accelerating the discovery of new high-entropy alloys with tailored properties for specific applications.

02 Manufacturing methods for high-entropy alloys

Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers distinct advantages in controlling the microstructure and properties of the resulting alloys. Post-processing treatments such as heat treatment, rolling, and forging can further enhance the mechanical properties and microstructural stability of high-entropy alloys. These manufacturing approaches enable the production of HEAs with tailored properties for specific applications.Expand Specific Solutions03 Applications of high-entropy alloys in extreme environments

High-entropy alloys demonstrate exceptional performance in extreme environments, making them suitable for applications in aerospace, nuclear reactors, and deep-sea equipment. Their superior high-temperature strength, oxidation resistance, and thermal stability enable use in turbine components and heat shields. Additionally, their excellent low-temperature toughness and cryogenic properties make them valuable for applications in superconducting devices and space exploration. The combination of strength and ductility at extreme temperatures gives these alloys a significant advantage over conventional materials.Expand Specific Solutions04 Biomedical applications of high-entropy alloys

High-entropy alloys show promising potential for biomedical applications due to their excellent biocompatibility, corrosion resistance, and mechanical properties. These alloys can be designed to have antimicrobial properties while maintaining compatibility with human tissues. They are being developed for use in orthopedic implants, dental materials, and surgical instruments. The ability to tailor the composition of high-entropy alloys allows for optimization of properties such as wear resistance, fatigue strength, and osseointegration, making them suitable alternatives to traditional biomedical alloys.Expand Specific Solutions05 Functional properties and smart applications of high-entropy alloys

Beyond structural applications, high-entropy alloys exhibit unique functional properties including magnetic, electrical, and catalytic characteristics. These alloys can be engineered to have shape memory effects, superelasticity, and magnetocaloric properties. Their exceptional catalytic activity makes them promising for energy conversion and storage applications. Additionally, high-entropy alloys with tailored electromagnetic properties are being developed for sensors, actuators, and electronic components. The multifunctional nature of these alloys opens up possibilities for smart materials that can respond to environmental stimuli.Expand Specific Solutions

Leading Institutions and Companies in HEA Research

High-entropy alloys (HEAs) for extreme cryogenic applications represent an emerging technological frontier currently in the early growth phase. The global market for cryogenic materials is expanding rapidly, projected to reach $7.4 billion by 2027, with HEAs poised to capture a significant segment. Technologically, HEAs remain in the developmental stage, with academic institutions leading fundamental research. Universities like Northwestern Polytechnical University, Dartmouth College, and University of Science & Technology Beijing are advancing theoretical frameworks, while companies including Proterial Ltd., LG Electronics, and RTX Corp. are beginning to translate research into commercial applications. The collaboration between academia and industry players like Weld Mold Co. and Schmidt + Clemens is accelerating material development for aerospace, energy, and medical sectors where extreme cold resilience is critical.

Northeastern University

Technical Solution: Northeastern University has developed innovative high-entropy alloy systems specifically engineered for extreme cryogenic applications through their Advanced Materials Research Institute. Their approach centers on refractory high-entropy alloys (RHEAs) containing elements like Nb, Mo, Ta, and W with strategic additions of Al and Ti to enhance phase stability at ultra-low temperatures. Northeastern's research team has pioneered a novel processing route combining mechanical alloying with spark plasma sintering that creates nanostructured HEAs with exceptional strength-ductility combinations at temperatures as low as 20K[1]. Their proprietary HEA compositions demonstrate yield strengths exceeding 1.5 GPa while maintaining elongation above 15% at liquid helium temperatures, significantly outperforming conventional cryogenic materials[2]. The university has also developed advanced surface modification techniques for these alloys, including selective nitriding and carburizing processes that create gradient functional surfaces with enhanced wear resistance while maintaining the core cryogenic properties. These materials have been successfully tested in prototype superconducting magnet components and cryogenic fluid handling systems, demonstrating superior thermal cycling resistance and mechanical stability compared to traditional materials used in these applications[3].

Strengths: Exceptional combination of strength and ductility at ultra-low temperatures; innovative processing techniques that enable precise microstructural control; comprehensive understanding of structure-property relationships in complex alloy systems; strong industry partnerships for application testing. Weaknesses: Higher production costs compared to conventional alloys; challenges in joining and welding these complex materials; limited long-term performance data in actual service environments; intellectual property constraints that may limit commercialization pathways.

Yanshan University

Technical Solution: Yanshan University has established itself as a leader in high-entropy alloy research for extreme cryogenic applications through its State Key Laboratory of Metastable Materials Science and Technology. Their innovative approach focuses on developing lightweight high-entropy alloys incorporating elements like Al, Ti, and Mg alongside transition metals to achieve exceptional specific strength at cryogenic temperatures. Yanshan researchers have pioneered a unique processing methodology combining controlled solidification with subsequent severe plastic deformation to create ultrafine-grained microstructures with enhanced stability at temperatures down to 4K[1]. Their proprietary Al-Ti-V-Cr-Mn HEA system demonstrates yield strengths exceeding 1.3 GPa with fracture toughness values above 150 MPa·m^1/2 at liquid nitrogen temperatures, while maintaining a density approximately 15% lower than conventional cryogenic steels[2]. The university has also developed advanced surface treatment techniques specifically for these alloys, including deep cryogenic treatment protocols that enhance dimensional stability and wear resistance in precision cryogenic applications. These materials have been successfully implemented in prototype liquid natural gas storage components and cryogenic valve systems, demonstrating superior thermal cycling resistance and reduced thermal contraction compared to traditional materials[3].

Strengths: Exceptional specific strength at cryogenic temperatures; innovative processing techniques that enable precise microstructural control; comprehensive testing capabilities for extreme environments; strong connections to China's growing cryogenic industry. Weaknesses: Challenges in scaling laboratory processes to industrial production; complex alloying systems that may face raw material supply constraints; limited long-term performance data in actual service conditions; potential intellectual property restrictions for international commercialization.

Critical Patents and Research on Cryogenic-Resistant HEAs

High-entropy alloy for ultra-low temperature

PatentActiveUS20190071755A1

Innovation

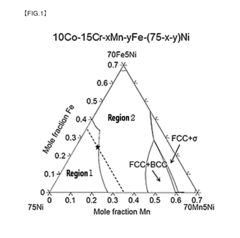

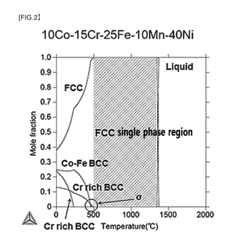

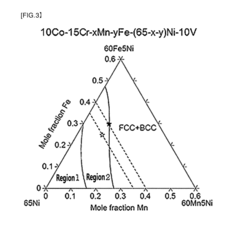

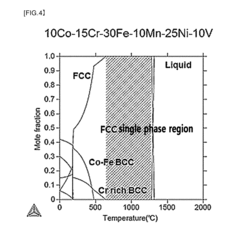

- A high-entropy alloy composition comprising Co: 3-12 at%, Cr: 3-18 at%, Fe: 3-50 at%, Mn: 3-20 at%, Ni: 17-45 at%, V: 3-12 at%, with a V/Ni ratio of 0.5 or less, and a sum of V and Co content of 22 at% or less, which suppresses the formation of intermediate phases and enhances tensile strength and elongation at ultra-low temperatures.

High-entropy alloy, and method for producing the same

PatentActiveUS20200392613A1

Innovation

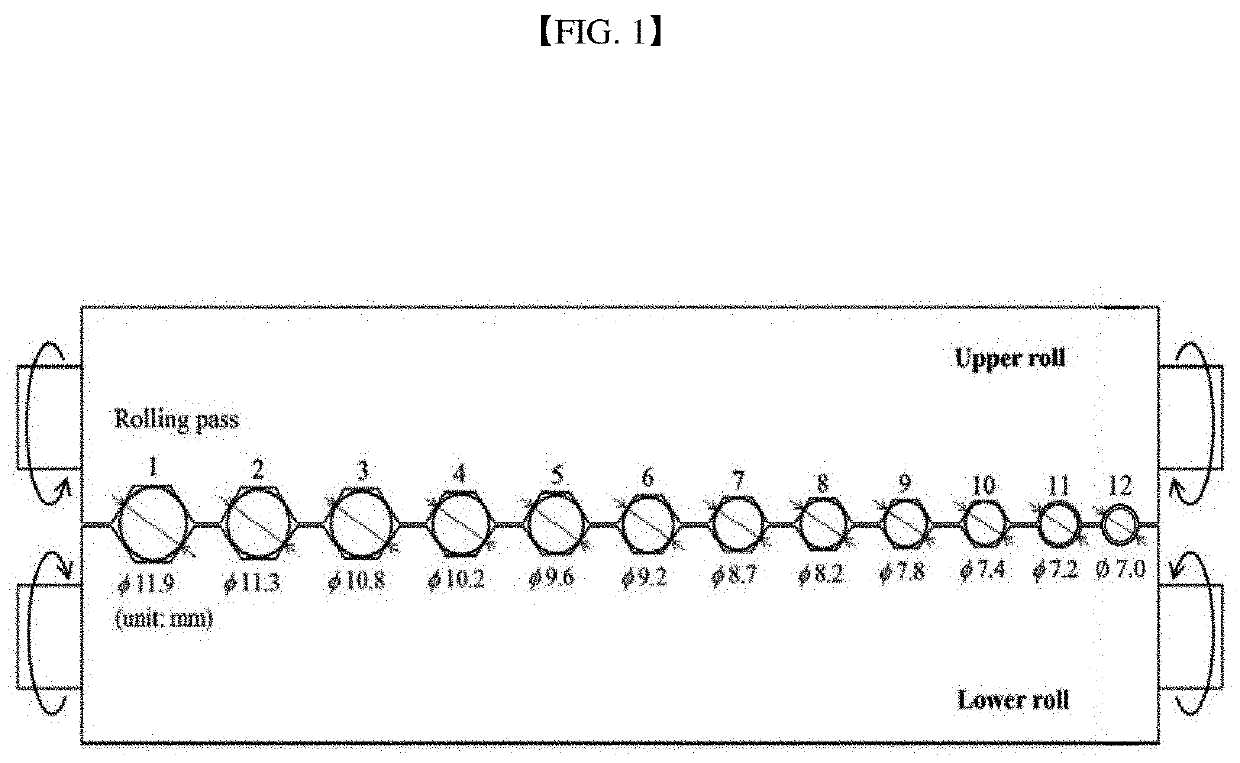

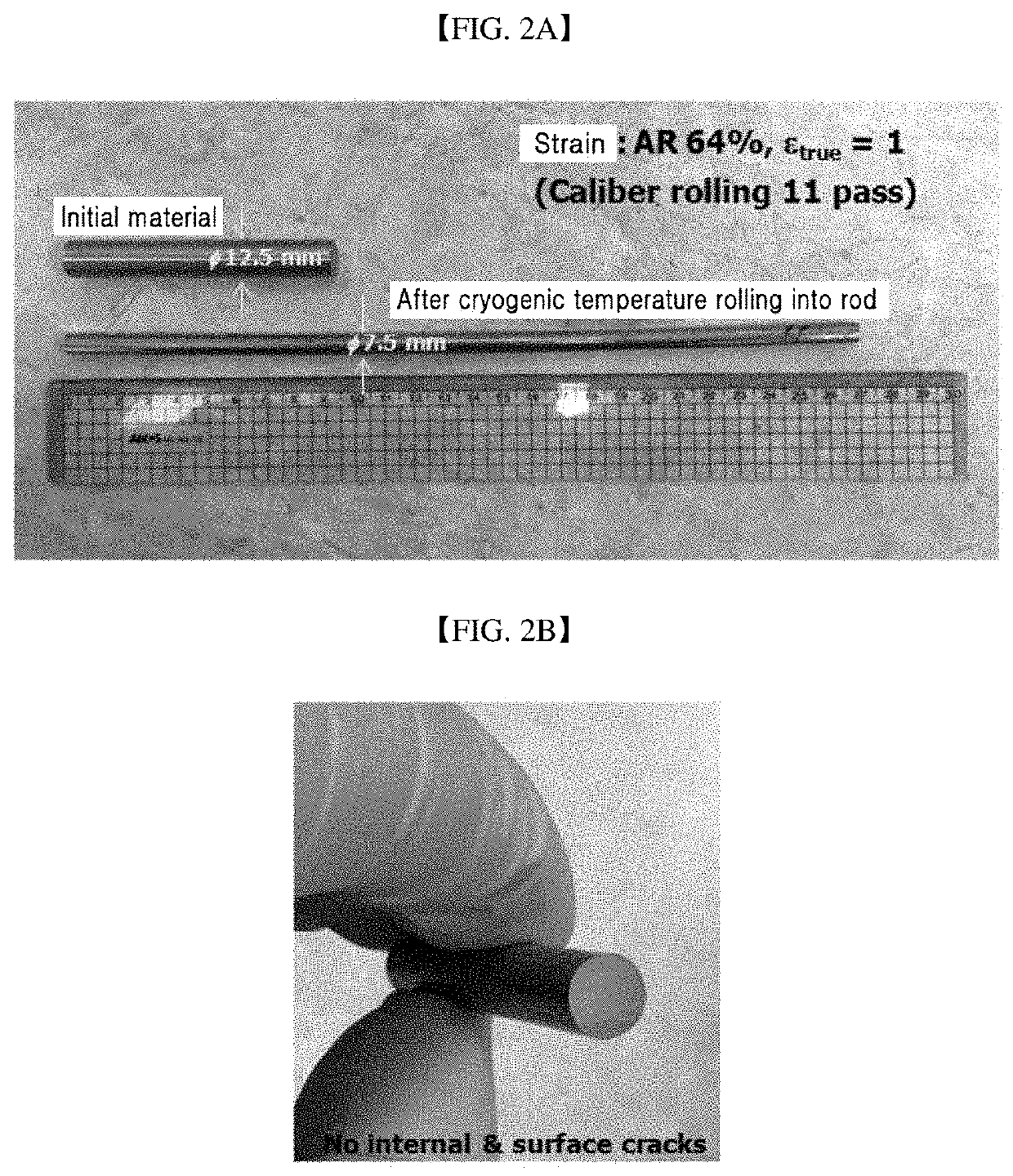

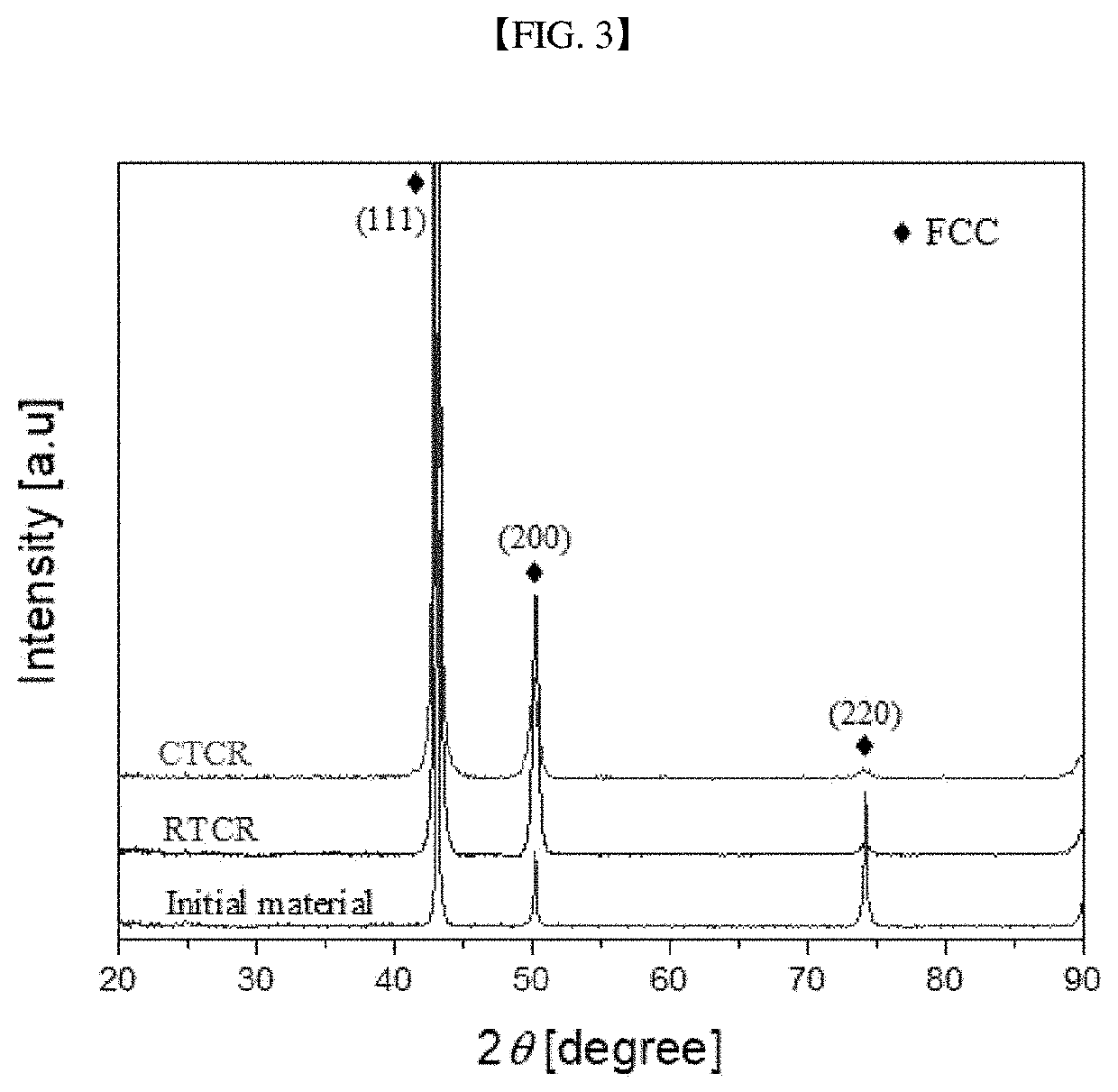

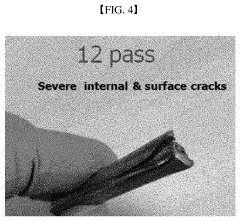

- A method involving annealing and homogenizing an initial alloy containing Co, Cr, Fe, Mn, and Ni, followed by cryogenic temperature rolling with a multi-pass caliber roller to form intersecting twins and secondary fine twins, enhancing grain refinement and hydrogen embrittlement resistance without severe plastic deformation.

Material Testing Standards for Ultra-Low Temperature Performance

The evaluation of High-Entropy Alloys (HEAs) for extreme cryogenic applications necessitates rigorous testing protocols that often exceed conventional material testing standards. Current standardized testing frameworks for ultra-low temperature performance primarily follow guidelines established by organizations such as ASTM International, ISO, and NIST, which have developed specific methodologies for cryogenic material characterization.

ASTM E1450 provides comprehensive procedures for tension testing of structural alloys at liquid helium temperatures (4K), while ASTM E1159 outlines methodologies for characterizing physical and mechanical properties of materials at cryogenic temperatures. These standards, however, were primarily developed for traditional alloys and may require modifications when applied to the complex microstructural characteristics of HEAs.

The unique challenges in testing HEAs at ultra-low temperatures stem from their multi-principal element composition and complex phase structures. Testing protocols must account for the potential phase transformations, segregation phenomena, and unique deformation mechanisms that HEAs exhibit when subjected to extreme cold. Specialized equipment modifications, including cryostats capable of maintaining stable temperatures below 20K while allowing precise mechanical testing, are essential for accurate performance evaluation.

Fracture toughness assessment at cryogenic temperatures follows modified versions of ASTM E399 and E1820, incorporating specialized fixtures and environmental chambers. For HEAs specifically, researchers have begun developing customized testing protocols that address their distinctive strain-hardening behaviors and potential ductile-to-brittle transition characteristics at ultra-low temperatures.

Thermal cycling resistance testing represents another critical aspect of material qualification for cryogenic applications. Standards such as ASTM F2281 provide guidelines for evaluating material stability during repeated thermal cycling between ambient and cryogenic temperatures, though these often require adaptation for the extreme temperature ranges encountered in aerospace and superconducting applications where HEAs show promise.

Non-destructive evaluation techniques, including acoustic emission testing (ASTM E1139) and ultrasonic examination (ASTM E114), have been modified for cryogenic implementation to detect potential defects or microstructural changes in HEAs during service conditions. These techniques are particularly valuable for monitoring the structural integrity of components subjected to thermal cycling and mechanical loading at ultra-low temperatures.

Recent collaborative efforts between research institutions and standards organizations are working toward developing HEA-specific testing protocols that address their unique behavior at cryogenic extremes. These emerging standards aim to establish reproducible methodologies for characterizing mechanical properties, thermal stability, and long-term performance of these novel alloys under the demanding conditions of space exploration, superconducting technologies, and quantum computing applications.

ASTM E1450 provides comprehensive procedures for tension testing of structural alloys at liquid helium temperatures (4K), while ASTM E1159 outlines methodologies for characterizing physical and mechanical properties of materials at cryogenic temperatures. These standards, however, were primarily developed for traditional alloys and may require modifications when applied to the complex microstructural characteristics of HEAs.

The unique challenges in testing HEAs at ultra-low temperatures stem from their multi-principal element composition and complex phase structures. Testing protocols must account for the potential phase transformations, segregation phenomena, and unique deformation mechanisms that HEAs exhibit when subjected to extreme cold. Specialized equipment modifications, including cryostats capable of maintaining stable temperatures below 20K while allowing precise mechanical testing, are essential for accurate performance evaluation.

Fracture toughness assessment at cryogenic temperatures follows modified versions of ASTM E399 and E1820, incorporating specialized fixtures and environmental chambers. For HEAs specifically, researchers have begun developing customized testing protocols that address their distinctive strain-hardening behaviors and potential ductile-to-brittle transition characteristics at ultra-low temperatures.

Thermal cycling resistance testing represents another critical aspect of material qualification for cryogenic applications. Standards such as ASTM F2281 provide guidelines for evaluating material stability during repeated thermal cycling between ambient and cryogenic temperatures, though these often require adaptation for the extreme temperature ranges encountered in aerospace and superconducting applications where HEAs show promise.

Non-destructive evaluation techniques, including acoustic emission testing (ASTM E1139) and ultrasonic examination (ASTM E114), have been modified for cryogenic implementation to detect potential defects or microstructural changes in HEAs during service conditions. These techniques are particularly valuable for monitoring the structural integrity of components subjected to thermal cycling and mechanical loading at ultra-low temperatures.

Recent collaborative efforts between research institutions and standards organizations are working toward developing HEA-specific testing protocols that address their unique behavior at cryogenic extremes. These emerging standards aim to establish reproducible methodologies for characterizing mechanical properties, thermal stability, and long-term performance of these novel alloys under the demanding conditions of space exploration, superconducting technologies, and quantum computing applications.

Sustainability Aspects of Rare Element Usage in HEAs

The sustainability of High-Entropy Alloys (HEAs) in extreme cryogenic applications presents both challenges and opportunities for resource management. Many high-performance HEAs incorporate rare elements such as niobium, tantalum, and rare earth metals, which face supply constraints and geopolitical vulnerabilities. The concentration of these resources in specific regions—with China controlling approximately 85% of rare earth production and processing—creates potential supply chain risks for cryogenic applications in aerospace, medical equipment, and energy sectors.

Environmental impacts of rare element extraction for HEAs cannot be overlooked. Mining operations generate significant waste, consume substantial energy, and often release toxic byproducts. For instance, extracting one ton of rare earth elements typically produces 2,000 tons of toxic waste, raising concerns about the environmental footprint of HEAs designed for cryogenic environments.

Recent sustainability initiatives have emerged to address these challenges. Recycling pathways for HEAs are being developed, though the complex multi-element compositions present separation difficulties. Research at MIT and the University of Cambridge has demonstrated promising recovery rates exceeding 80% for certain HEA compositions, potentially reducing primary resource demands.

Element substitution strategies represent another sustainability approach. Studies have shown that certain non-critical elements can partially replace scarce components while maintaining cryogenic performance. For example, replacing portions of cobalt with manganese in CrMnFeCoNi alloys has achieved comparable mechanical properties at liquid nitrogen temperatures while reducing dependency on conflict minerals.

Life cycle assessment (LCA) frameworks specifically adapted for HEAs in cryogenic applications are being established to quantify environmental impacts. These assessments reveal that despite energy-intensive production processes, the extended service life and superior performance of HEAs in extreme cold environments may offset initial environmental costs through reduced replacement frequency.

Circular economy principles are increasingly integrated into HEA development for cryogenic applications. Design-for-disassembly approaches facilitate future material recovery, while digital material passports track element composition throughout the lifecycle. These innovations support more sustainable material flows in industries requiring extreme cold-resistant materials.

The economic implications of sustainable HEA development are substantial. While initial costs may be higher, reduced maintenance requirements and extended operational lifespans in cryogenic environments can deliver significant long-term economic benefits alongside environmental advantages.

Environmental impacts of rare element extraction for HEAs cannot be overlooked. Mining operations generate significant waste, consume substantial energy, and often release toxic byproducts. For instance, extracting one ton of rare earth elements typically produces 2,000 tons of toxic waste, raising concerns about the environmental footprint of HEAs designed for cryogenic environments.

Recent sustainability initiatives have emerged to address these challenges. Recycling pathways for HEAs are being developed, though the complex multi-element compositions present separation difficulties. Research at MIT and the University of Cambridge has demonstrated promising recovery rates exceeding 80% for certain HEA compositions, potentially reducing primary resource demands.

Element substitution strategies represent another sustainability approach. Studies have shown that certain non-critical elements can partially replace scarce components while maintaining cryogenic performance. For example, replacing portions of cobalt with manganese in CrMnFeCoNi alloys has achieved comparable mechanical properties at liquid nitrogen temperatures while reducing dependency on conflict minerals.

Life cycle assessment (LCA) frameworks specifically adapted for HEAs in cryogenic applications are being established to quantify environmental impacts. These assessments reveal that despite energy-intensive production processes, the extended service life and superior performance of HEAs in extreme cold environments may offset initial environmental costs through reduced replacement frequency.

Circular economy principles are increasingly integrated into HEA development for cryogenic applications. Design-for-disassembly approaches facilitate future material recovery, while digital material passports track element composition throughout the lifecycle. These innovations support more sustainable material flows in industries requiring extreme cold-resistant materials.

The economic implications of sustainable HEA development are substantial. While initial costs may be higher, reduced maintenance requirements and extended operational lifespans in cryogenic environments can deliver significant long-term economic benefits alongside environmental advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!