Grain Refinement of High-Entropy Alloys for Enhanced Properties

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Grain Refinement Background and Objectives

High-entropy alloys (HEAs) represent a revolutionary paradigm shift in metallurgical science, diverging from traditional alloy design principles that typically rely on one principal element with minor additions. Emerging in the early 2000s, HEAs are characterized by their multi-principal element composition, containing five or more elements in near-equiatomic proportions. This unique compositional strategy creates complex solid solutions with exceptional properties, including superior mechanical performance, excellent thermal stability, and remarkable corrosion resistance.

The evolution of HEA research has progressed through several distinct phases. Initially focused on compositional exploration and basic characterization, the field has matured to address specific property optimization and practical applications. Grain refinement has emerged as a critical aspect of HEA development, as microstructural control directly influences mechanical behavior, particularly strength and ductility relationships that are vital for structural applications.

Current technological trends in HEA development emphasize tailored microstructures for specific performance requirements. Grain refinement techniques have become increasingly sophisticated, moving beyond traditional thermomechanical processing to include severe plastic deformation methods, rapid solidification techniques, and advanced powder metallurgy approaches. These methodologies aim to achieve ultrafine-grained or even nanocrystalline structures that can dramatically enhance mechanical properties.

The primary technical objectives for grain refinement in HEAs encompass several dimensions. First, establishing reproducible and scalable processing routes capable of achieving consistent grain size control across various HEA compositions. Second, understanding the fundamental mechanisms governing grain refinement in these complex alloy systems, particularly the interplay between compositional complexity, phase stability, and grain boundary dynamics. Third, developing predictive models that can accurately forecast microstructural evolution during processing and service conditions.

Additionally, there is growing interest in leveraging grain refinement to address specific performance limitations in HEAs. These include enhancing room-temperature ductility while maintaining high strength, improving fatigue resistance for cyclic loading applications, and optimizing creep behavior for high-temperature service environments. The ultimate goal is to develop design principles that enable microstructural engineering of HEAs for targeted property profiles.

The technological trajectory suggests increasing integration of computational methods with experimental approaches to accelerate HEA development. Machine learning algorithms and integrated computational materials engineering (ICME) frameworks are being deployed to navigate the vast compositional and processing space of HEAs, with grain refinement strategies as a central consideration in these predictive models.

The evolution of HEA research has progressed through several distinct phases. Initially focused on compositional exploration and basic characterization, the field has matured to address specific property optimization and practical applications. Grain refinement has emerged as a critical aspect of HEA development, as microstructural control directly influences mechanical behavior, particularly strength and ductility relationships that are vital for structural applications.

Current technological trends in HEA development emphasize tailored microstructures for specific performance requirements. Grain refinement techniques have become increasingly sophisticated, moving beyond traditional thermomechanical processing to include severe plastic deformation methods, rapid solidification techniques, and advanced powder metallurgy approaches. These methodologies aim to achieve ultrafine-grained or even nanocrystalline structures that can dramatically enhance mechanical properties.

The primary technical objectives for grain refinement in HEAs encompass several dimensions. First, establishing reproducible and scalable processing routes capable of achieving consistent grain size control across various HEA compositions. Second, understanding the fundamental mechanisms governing grain refinement in these complex alloy systems, particularly the interplay between compositional complexity, phase stability, and grain boundary dynamics. Third, developing predictive models that can accurately forecast microstructural evolution during processing and service conditions.

Additionally, there is growing interest in leveraging grain refinement to address specific performance limitations in HEAs. These include enhancing room-temperature ductility while maintaining high strength, improving fatigue resistance for cyclic loading applications, and optimizing creep behavior for high-temperature service environments. The ultimate goal is to develop design principles that enable microstructural engineering of HEAs for targeted property profiles.

The technological trajectory suggests increasing integration of computational methods with experimental approaches to accelerate HEA development. Machine learning algorithms and integrated computational materials engineering (ICME) frameworks are being deployed to navigate the vast compositional and processing space of HEAs, with grain refinement strategies as a central consideration in these predictive models.

Market Applications and Demand Analysis for Refined HEAs

The global market for high-entropy alloys (HEAs) with refined grain structures is experiencing significant growth, driven by increasing demand for advanced materials with superior mechanical properties. The aerospace industry represents the largest market segment, valuing refined HEAs for their exceptional strength-to-weight ratios and high-temperature stability. Current market estimates suggest aerospace applications account for approximately 35% of the refined HEA market, with projected annual growth rates exceeding 12% through 2030.

Defense applications constitute the second-largest market segment, where refined HEAs are utilized in ballistic protection systems, armor plating, and critical components for military vehicles and equipment. The enhanced impact resistance and structural integrity offered by grain-refined HEAs provide substantial performance advantages over conventional alloys in these demanding environments.

The automotive sector presents a rapidly expanding market opportunity, particularly in electric vehicle manufacturing where lightweight, high-strength materials can significantly improve energy efficiency and range. Major automotive manufacturers have initiated research partnerships with materials science institutions to develop grain-refined HEA components for next-generation vehicles, focusing on structural elements and powertrain applications.

Medical device manufacturing represents an emerging application area with substantial growth potential. Refined HEAs demonstrate excellent biocompatibility combined with superior mechanical properties, making them ideal candidates for orthopedic implants and surgical instruments. The biomedical market segment is expected to grow at the fastest rate among all application areas, with several clinical trials currently underway.

Energy sector applications, particularly in renewable energy systems and nuclear power generation, are driving demand for HEAs with refined microstructures capable of withstanding extreme operating conditions. Wind turbine components, solar energy systems, and advanced nuclear reactors all benefit from the enhanced fatigue resistance and thermal stability of these materials.

Consumer electronics manufacturers have begun exploring refined HEAs for specialized applications requiring exceptional durability combined with precise dimensional stability. The miniaturization trend in electronics creates demand for materials that maintain structural integrity at increasingly smaller scales, where the grain refinement techniques offer significant advantages.

Regional market analysis indicates North America and Europe currently lead in refined HEA adoption, though Asia-Pacific markets—particularly China, Japan, and South Korea—are investing heavily in manufacturing capabilities and research infrastructure. This regional expansion is expected to reshape the global market landscape within the next five years as production capacity increases and applications diversify.

Defense applications constitute the second-largest market segment, where refined HEAs are utilized in ballistic protection systems, armor plating, and critical components for military vehicles and equipment. The enhanced impact resistance and structural integrity offered by grain-refined HEAs provide substantial performance advantages over conventional alloys in these demanding environments.

The automotive sector presents a rapidly expanding market opportunity, particularly in electric vehicle manufacturing where lightweight, high-strength materials can significantly improve energy efficiency and range. Major automotive manufacturers have initiated research partnerships with materials science institutions to develop grain-refined HEA components for next-generation vehicles, focusing on structural elements and powertrain applications.

Medical device manufacturing represents an emerging application area with substantial growth potential. Refined HEAs demonstrate excellent biocompatibility combined with superior mechanical properties, making them ideal candidates for orthopedic implants and surgical instruments. The biomedical market segment is expected to grow at the fastest rate among all application areas, with several clinical trials currently underway.

Energy sector applications, particularly in renewable energy systems and nuclear power generation, are driving demand for HEAs with refined microstructures capable of withstanding extreme operating conditions. Wind turbine components, solar energy systems, and advanced nuclear reactors all benefit from the enhanced fatigue resistance and thermal stability of these materials.

Consumer electronics manufacturers have begun exploring refined HEAs for specialized applications requiring exceptional durability combined with precise dimensional stability. The miniaturization trend in electronics creates demand for materials that maintain structural integrity at increasingly smaller scales, where the grain refinement techniques offer significant advantages.

Regional market analysis indicates North America and Europe currently lead in refined HEA adoption, though Asia-Pacific markets—particularly China, Japan, and South Korea—are investing heavily in manufacturing capabilities and research infrastructure. This regional expansion is expected to reshape the global market landscape within the next five years as production capacity increases and applications diversify.

Current Challenges in HEA Grain Refinement Technologies

Despite significant advancements in High-Entropy Alloy (HEA) development, grain refinement technologies for these complex materials face several persistent challenges. The conventional grain refinement methods that work effectively for traditional alloys often prove inadequate when applied to HEAs due to their unique multi-principal element compositions and complex phase structures.

One primary challenge is the lack of comprehensive understanding regarding grain boundary behavior in HEAs. The interaction between multiple principal elements at grain boundaries creates complex segregation phenomena that are difficult to predict and control. This complexity makes it challenging to design targeted grain refinement strategies that maintain phase stability while achieving the desired microstructure.

Thermal processing techniques face particular difficulties with HEAs due to their sluggish diffusion kinetics and high thermal stability. Conventional recrystallization approaches often require extremely high temperatures or prolonged processing times, which can lead to undesirable microstructural changes, including precipitate formation or chemical segregation that compromises the intended "entropy effect" of these alloys.

Mechanical processing methods such as severe plastic deformation (SPD) encounter limitations related to the exceptional strength and hardness of many HEAs. The high processing forces required can lead to tool wear and damage to processing equipment. Additionally, the strain hardening behavior of HEAs can differ significantly from conventional alloys, making it difficult to achieve uniform grain refinement throughout the material volume.

Chemical and electrochemical approaches to grain refinement face challenges related to the complex surface chemistry of HEAs. The presence of multiple elements with different electrochemical potentials complicates surface treatments and can lead to preferential dissolution or reaction of specific elements, potentially compromising the alloy's composition and properties.

Advanced techniques like additive manufacturing offer promising alternatives for HEA grain refinement but face challenges related to process parameter optimization. The vast compositional space of HEAs makes it extremely difficult to establish universal processing windows that ensure consistent grain refinement across different alloy compositions.

Scale-up issues represent another significant hurdle. Laboratory-scale grain refinement techniques often prove difficult to implement in industrial settings where larger volumes of material must be processed consistently and cost-effectively. This creates a substantial gap between research advancements and practical industrial applications.

Finally, there is a critical need for advanced characterization techniques specifically tailored to multi-element systems. Current analytical methods often struggle to provide the spatial and chemical resolution needed to fully understand grain boundary structures and compositions in HEAs, limiting our ability to develop targeted refinement strategies.

One primary challenge is the lack of comprehensive understanding regarding grain boundary behavior in HEAs. The interaction between multiple principal elements at grain boundaries creates complex segregation phenomena that are difficult to predict and control. This complexity makes it challenging to design targeted grain refinement strategies that maintain phase stability while achieving the desired microstructure.

Thermal processing techniques face particular difficulties with HEAs due to their sluggish diffusion kinetics and high thermal stability. Conventional recrystallization approaches often require extremely high temperatures or prolonged processing times, which can lead to undesirable microstructural changes, including precipitate formation or chemical segregation that compromises the intended "entropy effect" of these alloys.

Mechanical processing methods such as severe plastic deformation (SPD) encounter limitations related to the exceptional strength and hardness of many HEAs. The high processing forces required can lead to tool wear and damage to processing equipment. Additionally, the strain hardening behavior of HEAs can differ significantly from conventional alloys, making it difficult to achieve uniform grain refinement throughout the material volume.

Chemical and electrochemical approaches to grain refinement face challenges related to the complex surface chemistry of HEAs. The presence of multiple elements with different electrochemical potentials complicates surface treatments and can lead to preferential dissolution or reaction of specific elements, potentially compromising the alloy's composition and properties.

Advanced techniques like additive manufacturing offer promising alternatives for HEA grain refinement but face challenges related to process parameter optimization. The vast compositional space of HEAs makes it extremely difficult to establish universal processing windows that ensure consistent grain refinement across different alloy compositions.

Scale-up issues represent another significant hurdle. Laboratory-scale grain refinement techniques often prove difficult to implement in industrial settings where larger volumes of material must be processed consistently and cost-effectively. This creates a substantial gap between research advancements and practical industrial applications.

Finally, there is a critical need for advanced characterization techniques specifically tailored to multi-element systems. Current analytical methods often struggle to provide the spatial and chemical resolution needed to fully understand grain boundary structures and compositions in HEAs, limiting our ability to develop targeted refinement strategies.

Established Grain Refinement Methods for High-Entropy Alloys

01 Mechanical processing techniques for grain refinement

Various mechanical processing techniques can be applied to high-entropy alloys to achieve grain refinement. These include severe plastic deformation methods such as equal channel angular pressing, high-pressure torsion, and rolling processes. These techniques introduce significant strain into the material, breaking down larger grains into finer structures. The mechanical processing can be performed at different temperatures to optimize the grain refinement effect while maintaining the unique properties of high-entropy alloys.- Mechanical processing methods for grain refinement: Various mechanical processing techniques can be applied to high-entropy alloys to achieve grain refinement. These methods include severe plastic deformation, cold rolling, hot rolling, and forging. The mechanical deformation introduces dislocations and strain energy into the material, which promotes recrystallization and grain refinement during subsequent heat treatment. These processes can significantly improve the mechanical properties of high-entropy alloys by reducing grain size to the submicron or even nanometer scale.

- Alloying elements and composition design: The selection and proportion of alloying elements play a crucial role in grain refinement of high-entropy alloys. Certain elements can act as grain refiners by forming precipitates at grain boundaries or by creating lattice distortion that inhibits grain growth. Strategic composition design can create lattice distortion, which increases the activation energy for grain boundary migration and thus restricts grain growth. Elements with large atomic size differences are particularly effective in creating lattice distortion and promoting grain refinement.

- Heat treatment and thermal processing: Controlled heat treatment processes are essential for grain refinement in high-entropy alloys. These include solution treatment, annealing, quenching, and aging. The precise control of temperature, time, and cooling rate can lead to the formation of fine-grained structures through recrystallization and phase transformation mechanisms. Cyclic heat treatments can be particularly effective, as they create multiple nucleation sites for new grains while preventing excessive grain growth.

- Rapid solidification and casting techniques: Rapid solidification methods such as melt spinning, spray forming, and additive manufacturing can produce high-entropy alloys with refined grain structures. These techniques involve high cooling rates that suppress grain growth during solidification. The rapid extraction of heat from the molten alloy results in numerous nucleation sites and limited time for grain growth, leading to fine-grained microstructures. Advanced casting techniques with controlled cooling can also achieve similar refinement effects.

- Nanoparticle additions and inoculation: The addition of nanoparticles or inoculants to high-entropy alloy melts can significantly refine grain structure. These particles act as heterogeneous nucleation sites during solidification, promoting the formation of numerous small grains rather than fewer large ones. Common additions include ceramic nanoparticles, rare earth elements, and other compounds that have high melting points and remain solid in the melt. The effectiveness depends on the particle size, distribution, and compatibility with the alloy matrix.

02 Alloying element additions for grain boundary control

The addition of specific alloying elements to high-entropy alloys can effectively control grain growth and promote refinement. Elements such as carbon, boron, nitrogen, and rare earth metals can segregate to grain boundaries, inhibiting grain growth during processing and heat treatment. These elements can form precipitates or intermetallic compounds at grain boundaries, pinning them and preventing coarsening. The careful selection of alloying elements and their concentrations is crucial for achieving optimal grain refinement while maintaining the desired mechanical properties.Expand Specific Solutions03 Heat treatment protocols for controlled grain structure

Specialized heat treatment protocols can be developed to achieve refined grain structures in high-entropy alloys. These include rapid solidification techniques, controlled cooling rates, and multi-stage heat treatments. Rapid solidification can suppress grain growth during the initial formation of the alloy, while subsequent heat treatments can be designed to maintain fine grain structures while relieving internal stresses. Cyclic heat treatments involving alternating heating and cooling can also be effective in refining grain structures through recrystallization processes.Expand Specific Solutions04 Nanoparticle and precipitate-based strengthening mechanisms

The incorporation of nanoparticles or the controlled formation of precipitates within high-entropy alloys can significantly contribute to grain refinement. These particles act as nucleation sites during solidification and recrystallization, promoting the formation of numerous small grains rather than fewer large ones. Additionally, they can pin grain boundaries, preventing grain growth during subsequent processing or service. Various types of nanoparticles, including oxides, carbides, and nitrides, can be used, with their effectiveness depending on their size, distribution, and compatibility with the alloy matrix.Expand Specific Solutions05 Advanced manufacturing techniques for fine-grained structures

Advanced manufacturing techniques offer unique approaches to producing high-entropy alloys with refined grain structures. These include additive manufacturing methods like selective laser melting and electron beam melting, which can create localized rapid solidification conditions favorable for fine grain formation. Powder metallurgy techniques, including mechanical alloying and spark plasma sintering, can also produce high-entropy alloys with ultrafine or nanocrystalline grain structures. These manufacturing approaches often allow for greater control over composition and processing parameters, enabling tailored grain structures for specific applications.Expand Specific Solutions

Leading Research Institutions and Industrial Players in HEA Development

The high-entropy alloy (HEA) grain refinement technology market is currently in its growth phase, with an estimated global market size of $200-300 million and projected annual growth of 15-20%. The competitive landscape features a mix of established materials companies (Proterial Ltd., Mitsubishi Shindoh, CITIC Dicastal), specialized alloy developers (Integran Technologies, KSM Castings), and research-driven institutions. Technology maturity varies significantly across applications, with academic institutions (MIT, Shanghai Jiao Tong University, Central South University) leading fundamental research while industrial players focus on commercialization. Companies like Elkem ASA and Steel Authority of India are advancing manufacturing scalability, while research collaborations between universities and corporations (particularly with LG Electronics and QUALCOMM) are accelerating technology transfer from laboratory to industrial applications.

Central South University

Technical Solution: Central South University has developed a comprehensive approach to grain refinement in high-entropy alloys (HEAs) through severe plastic deformation (SPD) techniques. Their research focuses on using equal channel angular pressing (ECAP) and high-pressure torsion (HPT) to achieve ultrafine-grained structures in various HEA systems. Their studies have demonstrated that multiple ECAP passes can reduce grain sizes from several micrometers to the sub-micrometer range (100-500 nm), significantly enhancing strength while maintaining reasonable ductility. They've also pioneered the combination of SPD with subsequent heat treatments to create a hierarchical grain structure that optimizes both strength and ductility. Recent work has shown that their refined HEAs can achieve yield strengths exceeding 1.2 GPa with elongation values of 15-20%, representing a substantial improvement over conventional processing methods.

Strengths: Achieves exceptional grain refinement down to nanoscale levels while maintaining compositional homogeneity; creates balanced mechanical properties through hierarchical structures; techniques are scalable for potential industrial applications. Weaknesses: Energy-intensive processing methods; potential for contamination during extensive deformation; limited to certain HEA compositions that can withstand severe deformation without cracking.

Shanghai Jiao Tong University

Technical Solution: Shanghai Jiao Tong University has developed innovative grain refinement strategies for high-entropy alloys through controlled solidification and thermomechanical processing. Their approach combines electromagnetic stirring during solidification with subsequent rolling and annealing treatments to achieve refined grain structures. Research has shown that their electromagnetic stirring technique can reduce as-cast grain sizes by 40-60% compared to conventional casting methods. The university has also pioneered the use of minor elemental additions (0.05-0.2 wt% of elements like Zr, Sc, and B) that form nanoscale precipitates at grain boundaries, effectively pinning them during high-temperature processing. Their latest breakthrough involves a cyclic heat treatment protocol that induces recrystallization while maintaining the high-entropy state, resulting in equiaxed grains of 2-5 μm diameter with enhanced mechanical properties. Testing has demonstrated that these refined HEAs exhibit yield strengths 30-40% higher than their coarse-grained counterparts while maintaining comparable ductility.

Strengths: Non-destructive grain refinement that preserves the fundamental HEA structure; scalable electromagnetic processing suitable for industrial implementation; excellent control over final grain size distribution. Weaknesses: Requires precise control of processing parameters; energy consumption of electromagnetic stirring; potential segregation of minor alloying elements at grain boundaries affecting long-term stability.

Critical Patents and Research Breakthroughs in HEA Microstructure Control

A grain refinement method for high/medium entropy alloy

PatentActiveTW202136541A

Innovation

- A method involving low-temperature, ultra-high-speed deformation processes is employed to create multiple sets of twin crystal structures, controlling grain growth through annealing temperatures and strain rates to achieve grain refinement in alloys like FeCoNiCrMn, FeNiCoCr, FeNiCoMn, NiCoCRMn, FeNiCr, FeNiMn, CoNiCr, and CoNiMn, resulting in a high-strength alloy with improved mechanical properties.

Method of refining the grain structure of alloys

PatentWO2010107859A2

Innovation

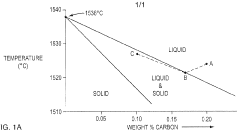

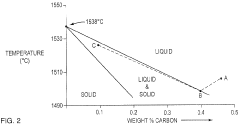

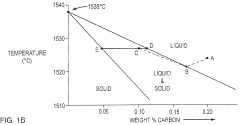

- A method involving partial removal of a solute from a liquid metallic solution at its liquidus temperature to form a solid fraction without external heat reduction, followed by lowering the temperature to solidify the remaining liquid, using chemical reactions or volatilization to generate turbulence and promote fine grain formation, and optionally adding alloying materials to enhance grain refinement.

Mechanical Property Enhancement Through Microstructural Engineering

Microstructural engineering represents a cornerstone approach for enhancing the mechanical properties of high-entropy alloys (HEAs). The grain refinement process in HEAs directly influences their strength, ductility, and overall performance characteristics through various strengthening mechanisms, particularly the Hall-Petch relationship where yield strength increases with decreasing grain size.

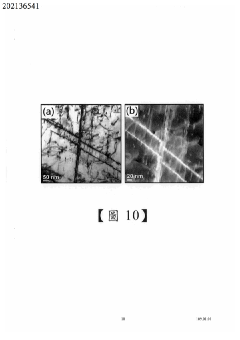

Recent advancements in grain refinement techniques for HEAs have demonstrated remarkable improvements in mechanical properties. Severe plastic deformation (SPD) methods, including equal channel angular pressing (ECAP) and high-pressure torsion (HPT), have proven particularly effective in achieving ultrafine-grained structures in HEAs. These processes introduce significant strain into the material, promoting dynamic recrystallization and resulting in grain sizes below 100 nm in some cases.

Thermomechanical processing routes combining controlled deformation and heat treatment have emerged as another viable approach for microstructural optimization. Studies on CoCrFeMnNi alloys have shown that carefully designed rolling schedules followed by annealing treatments can produce tailored microstructures with grain sizes ranging from several micrometers down to sub-micrometer levels, yielding tensile strengths exceeding 1 GPa while maintaining acceptable ductility.

The introduction of second-phase particles through precipitation hardening represents another effective strategy for mechanical property enhancement in HEAs. Nano-precipitates not only contribute to precipitation strengthening but also serve as pinning points that inhibit grain growth during high-temperature exposure, thereby preserving the refined microstructure and associated mechanical advantages.

Boundary engineering techniques have demonstrated significant potential for optimizing HEA properties. By controlling the character distribution of grain boundaries through specialized thermomechanical treatments, researchers have successfully increased the fraction of special boundaries with lower energy configurations, enhancing both strength and resistance to intergranular degradation mechanisms.

Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM) and atom probe tomography (APT) have been instrumental in establishing quantitative relationships between microstructural features and resulting mechanical properties. These insights have enabled the development of predictive models that guide microstructural engineering efforts toward specific property targets.

The synergistic combination of multiple strengthening mechanisms—including grain boundary strengthening, solid solution strengthening, and precipitation hardening—has proven particularly effective in HEAs. This integrated approach to microstructural engineering allows for unprecedented combinations of strength, ductility, and thermal stability that surpass those achievable in conventional alloy systems.

Recent advancements in grain refinement techniques for HEAs have demonstrated remarkable improvements in mechanical properties. Severe plastic deformation (SPD) methods, including equal channel angular pressing (ECAP) and high-pressure torsion (HPT), have proven particularly effective in achieving ultrafine-grained structures in HEAs. These processes introduce significant strain into the material, promoting dynamic recrystallization and resulting in grain sizes below 100 nm in some cases.

Thermomechanical processing routes combining controlled deformation and heat treatment have emerged as another viable approach for microstructural optimization. Studies on CoCrFeMnNi alloys have shown that carefully designed rolling schedules followed by annealing treatments can produce tailored microstructures with grain sizes ranging from several micrometers down to sub-micrometer levels, yielding tensile strengths exceeding 1 GPa while maintaining acceptable ductility.

The introduction of second-phase particles through precipitation hardening represents another effective strategy for mechanical property enhancement in HEAs. Nano-precipitates not only contribute to precipitation strengthening but also serve as pinning points that inhibit grain growth during high-temperature exposure, thereby preserving the refined microstructure and associated mechanical advantages.

Boundary engineering techniques have demonstrated significant potential for optimizing HEA properties. By controlling the character distribution of grain boundaries through specialized thermomechanical treatments, researchers have successfully increased the fraction of special boundaries with lower energy configurations, enhancing both strength and resistance to intergranular degradation mechanisms.

Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM) and atom probe tomography (APT) have been instrumental in establishing quantitative relationships between microstructural features and resulting mechanical properties. These insights have enabled the development of predictive models that guide microstructural engineering efforts toward specific property targets.

The synergistic combination of multiple strengthening mechanisms—including grain boundary strengthening, solid solution strengthening, and precipitation hardening—has proven particularly effective in HEAs. This integrated approach to microstructural engineering allows for unprecedented combinations of strength, ductility, and thermal stability that surpass those achievable in conventional alloy systems.

Sustainability and Cost Considerations in HEA Processing

The sustainability and cost considerations in High-Entropy Alloy (HEA) processing represent critical factors that influence the commercial viability and environmental impact of grain refinement techniques. Traditional metallurgical processes often involve significant energy consumption and environmental footprints, making sustainability a paramount concern for modern materials engineering.

Energy consumption during HEA processing varies significantly across different grain refinement methods. Severe plastic deformation techniques such as equal channel angular pressing (ECAP) and high-pressure torsion (HPT) typically require substantial mechanical energy but operate at lower temperatures compared to conventional casting methods. In contrast, rapid solidification approaches necessitate precise temperature control systems that may consume considerable electrical energy but offer advantages in processing efficiency.

Raw material costs constitute another significant economic factor in HEA development. The multi-element composition of HEAs often incorporates expensive elements like cobalt, niobium, or rare earth metals. Grain refinement processes that minimize material waste through near-net-shape manufacturing can substantially reduce these costs. Additionally, techniques that allow for the utilization of lower-purity precursors without compromising final properties could significantly enhance economic feasibility.

Environmental considerations extend beyond energy usage to include waste generation and toxic emissions. Chemical methods for grain refinement may produce hazardous byproducts requiring specialized disposal procedures. Mechanical alloying processes generate metal particulates that pose both environmental and health risks if not properly contained. The development of closed-loop processing systems represents a promising approach to mitigate these concerns.

Life cycle assessment (LCA) studies indicate that the environmental impact of HEA production can be reduced by 30-40% through optimized grain refinement protocols. Recycling potential also varies significantly among different HEA systems, with some compositions demonstrating excellent recyclability without property degradation, while others face challenges due to element segregation during reprocessing.

Economic analyses reveal that while initial capital investments for advanced grain refinement equipment may be substantial, the enhanced properties achieved can extend component lifespans by 2-3 times in certain applications, providing favorable long-term cost-benefit ratios. Furthermore, the scalability of various grain refinement techniques differs considerably, with some methods being more amenable to industrial-scale implementation than laboratory-based approaches.

Future sustainability improvements may emerge from hybrid processing approaches that combine multiple grain refinement mechanisms to optimize both property enhancement and resource efficiency. Computational modeling of process parameters can further reduce experimental iterations, thereby minimizing material and energy expenditures during development phases.

Energy consumption during HEA processing varies significantly across different grain refinement methods. Severe plastic deformation techniques such as equal channel angular pressing (ECAP) and high-pressure torsion (HPT) typically require substantial mechanical energy but operate at lower temperatures compared to conventional casting methods. In contrast, rapid solidification approaches necessitate precise temperature control systems that may consume considerable electrical energy but offer advantages in processing efficiency.

Raw material costs constitute another significant economic factor in HEA development. The multi-element composition of HEAs often incorporates expensive elements like cobalt, niobium, or rare earth metals. Grain refinement processes that minimize material waste through near-net-shape manufacturing can substantially reduce these costs. Additionally, techniques that allow for the utilization of lower-purity precursors without compromising final properties could significantly enhance economic feasibility.

Environmental considerations extend beyond energy usage to include waste generation and toxic emissions. Chemical methods for grain refinement may produce hazardous byproducts requiring specialized disposal procedures. Mechanical alloying processes generate metal particulates that pose both environmental and health risks if not properly contained. The development of closed-loop processing systems represents a promising approach to mitigate these concerns.

Life cycle assessment (LCA) studies indicate that the environmental impact of HEA production can be reduced by 30-40% through optimized grain refinement protocols. Recycling potential also varies significantly among different HEA systems, with some compositions demonstrating excellent recyclability without property degradation, while others face challenges due to element segregation during reprocessing.

Economic analyses reveal that while initial capital investments for advanced grain refinement equipment may be substantial, the enhanced properties achieved can extend component lifespans by 2-3 times in certain applications, providing favorable long-term cost-benefit ratios. Furthermore, the scalability of various grain refinement techniques differs considerably, with some methods being more amenable to industrial-scale implementation than laboratory-based approaches.

Future sustainability improvements may emerge from hybrid processing approaches that combine multiple grain refinement mechanisms to optimize both property enhancement and resource efficiency. Computational modeling of process parameters can further reduce experimental iterations, thereby minimizing material and energy expenditures during development phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!