Interstitial Elements' Effects on High-Entropy Alloys' Hardness

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Background and Research Objectives

High-entropy alloys (HEAs) represent a revolutionary paradigm shift in metallurgical science that emerged in the early 2000s. Unlike conventional alloys that typically contain one principal element with minor additions, HEAs consist of five or more principal elements in near-equiatomic proportions. This fundamental compositional difference creates unique atomic structures with exceptional properties, including remarkable hardness, high-temperature stability, and superior corrosion resistance.

The evolution of HEAs can be traced back to the pioneering work of Yeh et al. and Cantor et al. in 2004, who independently proposed the concept of multi-principal element alloys. Since then, research interest has grown exponentially, with significant advancements in understanding the core principles governing these materials, such as high entropy of mixing, sluggish diffusion kinetics, severe lattice distortion, and the cocktail effect.

Interstitial elements—particularly carbon, nitrogen, oxygen, boron, and hydrogen—have emerged as critical factors influencing HEA properties. These small-radius atoms occupy interstitial positions within the crystal lattice, creating distortions that significantly affect mechanical behavior, especially hardness. Recent studies have demonstrated that controlled addition of interstitial elements can enhance hardness by up to 300% in certain HEA systems through mechanisms including solid solution strengthening, precipitation hardening, and grain refinement.

The technological significance of interstitial-modified HEAs extends across multiple strategic sectors. In aerospace applications, these materials offer exceptional strength-to-weight ratios and thermal stability for next-generation turbine components. For energy infrastructure, their superior corrosion resistance and mechanical properties at extreme temperatures make them ideal candidates for advanced nuclear reactors and hydrogen storage systems.

This research aims to systematically investigate the relationship between interstitial element concentration, distribution, and the resultant hardness properties in selected HEA systems. Specifically, we seek to: (1) quantify the hardening mechanisms induced by various interstitial elements across different HEA compositions; (2) develop predictive models correlating interstitial content with hardness properties; (3) establish processing-structure-property relationships for optimized interstitial-strengthened HEAs; and (4) explore novel interstitial element combinations for synergistic hardening effects.

The ultimate objective is to establish design principles for tailoring HEA hardness through precise interstitial element engineering, potentially enabling a new generation of ultra-hard materials for extreme environment applications. This research addresses the growing industrial demand for materials with exceptional mechanical properties while contributing fundamental knowledge to the rapidly evolving field of high-entropy metallurgy.

The evolution of HEAs can be traced back to the pioneering work of Yeh et al. and Cantor et al. in 2004, who independently proposed the concept of multi-principal element alloys. Since then, research interest has grown exponentially, with significant advancements in understanding the core principles governing these materials, such as high entropy of mixing, sluggish diffusion kinetics, severe lattice distortion, and the cocktail effect.

Interstitial elements—particularly carbon, nitrogen, oxygen, boron, and hydrogen—have emerged as critical factors influencing HEA properties. These small-radius atoms occupy interstitial positions within the crystal lattice, creating distortions that significantly affect mechanical behavior, especially hardness. Recent studies have demonstrated that controlled addition of interstitial elements can enhance hardness by up to 300% in certain HEA systems through mechanisms including solid solution strengthening, precipitation hardening, and grain refinement.

The technological significance of interstitial-modified HEAs extends across multiple strategic sectors. In aerospace applications, these materials offer exceptional strength-to-weight ratios and thermal stability for next-generation turbine components. For energy infrastructure, their superior corrosion resistance and mechanical properties at extreme temperatures make them ideal candidates for advanced nuclear reactors and hydrogen storage systems.

This research aims to systematically investigate the relationship between interstitial element concentration, distribution, and the resultant hardness properties in selected HEA systems. Specifically, we seek to: (1) quantify the hardening mechanisms induced by various interstitial elements across different HEA compositions; (2) develop predictive models correlating interstitial content with hardness properties; (3) establish processing-structure-property relationships for optimized interstitial-strengthened HEAs; and (4) explore novel interstitial element combinations for synergistic hardening effects.

The ultimate objective is to establish design principles for tailoring HEA hardness through precise interstitial element engineering, potentially enabling a new generation of ultra-hard materials for extreme environment applications. This research addresses the growing industrial demand for materials with exceptional mechanical properties while contributing fundamental knowledge to the rapidly evolving field of high-entropy metallurgy.

Market Applications and Demand Analysis for HEAs

High-entropy alloys (HEAs) have emerged as revolutionary materials across multiple industries due to their exceptional mechanical properties, particularly their hardness enhancement through interstitial elements. The market for these advanced materials continues to expand rapidly, with aerospace and defense sectors leading adoption due to the critical need for materials that maintain structural integrity under extreme conditions.

The global aerospace industry, valued at approximately $298 billion in 2022, represents the primary market for HEAs, with projected compound annual growth rates exceeding 7% through 2030. Major aerospace manufacturers are actively seeking materials that offer superior strength-to-weight ratios while maintaining resistance to high-temperature degradation, precisely where interstitially-modified HEAs excel.

Defense applications constitute another significant market segment, particularly for ballistic protection systems and structural components in military vehicles. The enhanced hardness achieved through carbon, nitrogen, and boron interstitial additions makes these alloys ideal for armor plating and penetrator materials, with the global military armor market expected to reach $15 billion by 2028.

The automotive industry presents a growing application space for HEAs, especially in high-performance and electric vehicle segments. As manufacturers pursue lightweighting strategies while maintaining structural integrity, the superior specific strength of interstitially-hardened HEAs offers compelling advantages for critical components like engine parts and safety structures.

Energy sector applications are expanding rapidly, particularly in nuclear power generation and renewable energy systems. The radiation resistance and thermal stability of certain HEA compositions make them candidates for next-generation nuclear reactors, while their corrosion resistance benefits offshore wind and marine energy installations.

Medical device manufacturing represents an emerging market with significant growth potential. The biocompatibility of certain HEA compositions, combined with their exceptional hardness and wear resistance when modified with interstitial elements, makes them suitable for orthopedic implants and surgical instruments.

Industrial tooling applications are driving immediate commercial adoption, with cutting tools and wear-resistant components benefiting from the hardness improvements achieved through interstitial element additions. This sector values the extended service life and reduced maintenance intervals these materials enable.

Market analysis indicates that while material costs remain higher than conventional alloys, the performance benefits and lifecycle cost advantages are increasingly justifying adoption across these sectors. The market is expected to grow as manufacturing processes mature and economies of scale improve cost structures, with the global advanced materials market for HEAs projected to exceed $12 billion by 2032.

The global aerospace industry, valued at approximately $298 billion in 2022, represents the primary market for HEAs, with projected compound annual growth rates exceeding 7% through 2030. Major aerospace manufacturers are actively seeking materials that offer superior strength-to-weight ratios while maintaining resistance to high-temperature degradation, precisely where interstitially-modified HEAs excel.

Defense applications constitute another significant market segment, particularly for ballistic protection systems and structural components in military vehicles. The enhanced hardness achieved through carbon, nitrogen, and boron interstitial additions makes these alloys ideal for armor plating and penetrator materials, with the global military armor market expected to reach $15 billion by 2028.

The automotive industry presents a growing application space for HEAs, especially in high-performance and electric vehicle segments. As manufacturers pursue lightweighting strategies while maintaining structural integrity, the superior specific strength of interstitially-hardened HEAs offers compelling advantages for critical components like engine parts and safety structures.

Energy sector applications are expanding rapidly, particularly in nuclear power generation and renewable energy systems. The radiation resistance and thermal stability of certain HEA compositions make them candidates for next-generation nuclear reactors, while their corrosion resistance benefits offshore wind and marine energy installations.

Medical device manufacturing represents an emerging market with significant growth potential. The biocompatibility of certain HEA compositions, combined with their exceptional hardness and wear resistance when modified with interstitial elements, makes them suitable for orthopedic implants and surgical instruments.

Industrial tooling applications are driving immediate commercial adoption, with cutting tools and wear-resistant components benefiting from the hardness improvements achieved through interstitial element additions. This sector values the extended service life and reduced maintenance intervals these materials enable.

Market analysis indicates that while material costs remain higher than conventional alloys, the performance benefits and lifecycle cost advantages are increasingly justifying adoption across these sectors. The market is expected to grow as manufacturing processes mature and economies of scale improve cost structures, with the global advanced materials market for HEAs projected to exceed $12 billion by 2032.

Current Challenges in Interstitial Element Integration

Despite significant advancements in high-entropy alloy (HEA) research, the integration of interstitial elements to enhance hardness properties faces several critical challenges. The primary obstacle lies in achieving precise control over interstitial element distribution within the complex multi-principal element matrix. Unlike traditional alloys, HEAs possess inherently disordered lattice structures with multiple principal elements competing for bonding with interstitial atoms, resulting in unpredictable segregation patterns that can compromise mechanical performance.

The solubility limits of interstitial elements such as carbon, nitrogen, boron, and hydrogen in HEAs remain poorly understood. Current experimental data reveals significant discrepancies between theoretical predictions and actual solubility behaviors, particularly at elevated temperatures where phase stability becomes increasingly complex. This knowledge gap hinders the development of reliable processing parameters for industrial-scale production.

Another significant challenge involves the formation of undesired precipitates when interstitial content exceeds certain thresholds. These precipitates, often brittle intermetallic compounds or carbides, can act as stress concentration sites, negatively impacting the overall toughness and ductility of HEAs despite increasing hardness values. The delicate balance between hardness enhancement and maintenance of other desirable mechanical properties represents a fundamental design challenge.

Processing difficulties constitute another major hurdle in interstitial-strengthened HEAs. Conventional melting and casting techniques often result in significant interstitial element loss through oxidation or evaporation, while powder metallurgy approaches struggle with contamination issues. Advanced techniques such as selective laser melting show promise but face challenges in controlling interstitial pickup during processing.

Characterization limitations further complicate research progress. Conventional analytical techniques lack sufficient spatial resolution to accurately map interstitial element distributions at the atomic scale. Advanced techniques like atom probe tomography offer improved capabilities but remain costly and time-intensive, limiting widespread application in research and development settings.

The lack of standardized computational models for predicting interstitial effects in multi-component systems represents another significant barrier. Current models, largely derived from binary or ternary systems, fail to capture the complex interactions in HEAs with five or more principal elements, leading to poor predictive capabilities for hardness and other mechanical properties.

Finally, long-term stability of interstitial-strengthened HEAs under service conditions remains largely unexplored. Limited data suggests potential diffusion and redistribution of interstitial elements during thermal cycling or under mechanical loading, potentially compromising the hardness advantages initially achieved through careful processing.

The solubility limits of interstitial elements such as carbon, nitrogen, boron, and hydrogen in HEAs remain poorly understood. Current experimental data reveals significant discrepancies between theoretical predictions and actual solubility behaviors, particularly at elevated temperatures where phase stability becomes increasingly complex. This knowledge gap hinders the development of reliable processing parameters for industrial-scale production.

Another significant challenge involves the formation of undesired precipitates when interstitial content exceeds certain thresholds. These precipitates, often brittle intermetallic compounds or carbides, can act as stress concentration sites, negatively impacting the overall toughness and ductility of HEAs despite increasing hardness values. The delicate balance between hardness enhancement and maintenance of other desirable mechanical properties represents a fundamental design challenge.

Processing difficulties constitute another major hurdle in interstitial-strengthened HEAs. Conventional melting and casting techniques often result in significant interstitial element loss through oxidation or evaporation, while powder metallurgy approaches struggle with contamination issues. Advanced techniques such as selective laser melting show promise but face challenges in controlling interstitial pickup during processing.

Characterization limitations further complicate research progress. Conventional analytical techniques lack sufficient spatial resolution to accurately map interstitial element distributions at the atomic scale. Advanced techniques like atom probe tomography offer improved capabilities but remain costly and time-intensive, limiting widespread application in research and development settings.

The lack of standardized computational models for predicting interstitial effects in multi-component systems represents another significant barrier. Current models, largely derived from binary or ternary systems, fail to capture the complex interactions in HEAs with five or more principal elements, leading to poor predictive capabilities for hardness and other mechanical properties.

Finally, long-term stability of interstitial-strengthened HEAs under service conditions remains largely unexplored. Limited data suggests potential diffusion and redistribution of interstitial elements during thermal cycling or under mechanical loading, potentially compromising the hardness advantages initially achieved through careful processing.

Existing Methodologies for Interstitial Element Incorporation

01 Composition effects on hardness of high-entropy alloys

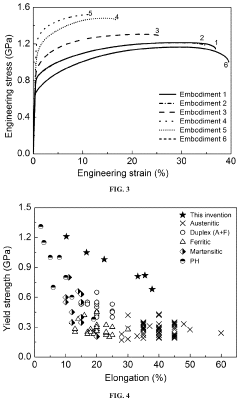

The composition of high-entropy alloys significantly affects their hardness properties. By adjusting the elemental composition and proportions, researchers can achieve enhanced hardness through solid solution strengthening mechanisms. Various combinations of transition metals, rare earth elements, and other alloying elements create complex solid solutions that impede dislocation movement, resulting in superior hardness compared to conventional alloys.- Composition effects on hardness of high-entropy alloys: The composition of high-entropy alloys significantly affects their hardness properties. By adjusting the elemental composition and proportions, researchers can achieve enhanced hardness through solid solution strengthening mechanisms. Various combinations of transition metals, rare earth elements, and other alloying elements create complex solid solutions that impede dislocation movement, resulting in superior hardness compared to conventional alloys.

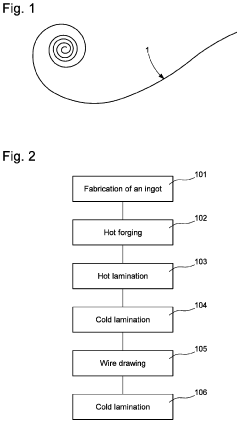

- Processing methods to improve hardness: Different processing techniques can be employed to enhance the hardness of high-entropy alloys. These include mechanical alloying, rapid solidification, severe plastic deformation, and heat treatment processes. These methods create refined microstructures, induce lattice distortion, and promote the formation of strengthening phases, all contributing to increased hardness values in the final alloy products.

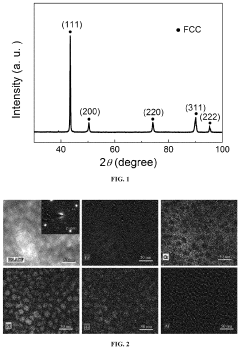

- Microstructural features affecting hardness: The microstructural characteristics of high-entropy alloys play a crucial role in determining their hardness. Features such as grain size, phase distribution, lattice distortion, and the presence of nano-precipitates significantly influence hardness properties. Controlling these microstructural elements through tailored processing routes enables the development of high-entropy alloys with optimized hardness for specific applications.

- Novel high-entropy alloy systems with enhanced hardness: Innovative high-entropy alloy systems have been developed specifically to achieve superior hardness properties. These include refractory high-entropy alloys, lightweight high-entropy alloys, and multi-principal element alloys with specialized compositions. These novel systems often incorporate elements that promote the formation of hard phases or create complex crystal structures that resist deformation, resulting in exceptional hardness characteristics.

- Hardness testing and characterization methods: Various testing and characterization techniques are employed to evaluate the hardness of high-entropy alloys. These include micro-hardness testing, nanoindentation, dynamic hardness measurements, and correlative microscopy approaches. Advanced characterization methods help researchers understand the relationship between composition, processing, microstructure, and resulting hardness properties, enabling the systematic development of high-entropy alloys with tailored hardness profiles.

02 Processing methods to improve hardness

Different processing techniques can be employed to enhance the hardness of high-entropy alloys. These include mechanical alloying, rapid solidification, severe plastic deformation, and heat treatment processes. These methods create microstructural refinement, induce phase transformations, and introduce lattice distortions that contribute to increased hardness values. The processing parameters can be optimized to achieve desired hardness properties for specific applications.Expand Specific Solutions03 Microstructural features affecting hardness

The microstructural characteristics of high-entropy alloys play a crucial role in determining their hardness. Features such as grain size, phase distribution, lattice distortion, and the presence of precipitates significantly influence hardness properties. Nano-crystalline structures, coherent precipitates, and multi-phase compositions can create effective barriers to dislocation movement, resulting in enhanced hardness across a wide range of high-entropy alloy systems.Expand Specific Solutions04 Novel high-entropy alloy systems with superior hardness

Innovative high-entropy alloy systems have been developed specifically to achieve exceptional hardness properties. These include refractory high-entropy alloys, lightweight high-entropy alloys, and those incorporating interstitial elements. By strategically combining elements with significant atomic size differences and electronegativity variations, these novel systems create severe lattice distortions and complex phase structures that contribute to remarkable hardness values suitable for demanding applications.Expand Specific Solutions05 Hardness enhancement through secondary phase formation

The formation of secondary phases in high-entropy alloys can significantly enhance their hardness properties. Techniques to promote controlled precipitation of secondary phases include specific heat treatments, aging processes, and compositional adjustments. These secondary phases, such as intermetallic compounds, carbides, or ordered structures, create effective obstacles to dislocation movement, resulting in substantial hardness improvements while maintaining the beneficial properties of the high-entropy alloy matrix.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The high-entropy alloys (HEAs) hardness modification through interstitial elements represents an emerging field in advanced materials science, currently in its growth phase. The market is expanding rapidly with increasing applications in aerospace, automotive, and energy sectors, projected to reach significant scale as research advances. Technical maturity varies across institutions, with academic leaders like University of Science & Technology Beijing, Central South University, and Dartmouth College establishing fundamental research frameworks, while companies including Proterial Ltd., LG Electronics, and Miba Gleitlager AG focus on commercial applications. Research collaborations between universities and industry partners like Korea Institute of Materials Science are accelerating development, though standardization challenges remain before widespread industrial adoption can occur.

University of Science & Technology Beijing

Technical Solution: The University of Science & Technology Beijing has established a comprehensive research program on interstitial effects in high-entropy alloys, with particular emphasis on carbon and nitrogen incorporation. Their approach combines computational alloy design with advanced processing techniques to achieve optimal interstitial distributions. The university has developed a proprietary "interstitial complex strengthening" theory that explains the exceptional hardening efficiency of interstitial elements in HEAs compared to conventional alloys. Their research demonstrates that carbon additions of 0.5-1.5 at% to refractory HEAs can increase hardness by up to 90% through combined solid solution strengthening and nanoscale carbide formation. The university utilizes advanced characterization techniques including high-resolution TEM and 3D atom probe tomography to precisely map interstitial element distributions and correlate them with mechanical properties. Recent work has focused on the development of machine learning models to predict optimal interstitial concentrations for specific HEA compositions, enabling rapid alloy design. Their research has also explored the synergistic effects of interstitial elements with lattice distortion in creating exceptional strengthening effects unique to the HEA systems.

Strengths: Strong integration of computational and experimental approaches; comprehensive understanding of interstitial strengthening mechanisms; excellent characterization capabilities. Weaknesses: Limited focus on industrial-scale processing; research primarily concentrated on academic understanding rather than commercial applications; less emphasis on high-temperature stability of interstitial-strengthened alloys.

Central South University

Technical Solution: Central South University has pioneered research on interstitial element effects in high-entropy alloys through their innovative "dual-phase strengthening" approach. Their technique focuses on the strategic introduction of carbon, nitrogen, and boron to create both solid solution strengthening and nanoscale precipitate formation in FeCoCrNiMn-based alloys. The university has developed a proprietary thermomechanical processing route that enables precise control of interstitial element distribution, achieving hardness increases of 70-120% compared to base alloys. Their research has demonstrated that carbon additions of 0.8-1.2 at% combined with microalloying of boron (0.1-0.3 at%) creates optimal hardness through the formation of complex M23(C,B)6 carbides at grain boundaries while maintaining good ductility. The university has also established quantitative relationships between interstitial content, lattice distortion, and resulting mechanical properties using advanced characterization techniques including synchrotron X-ray diffraction and neutron scattering.

Strengths: Comprehensive understanding of interstitial strengthening mechanisms; established processing-structure-property relationships; strong focus on commercially viable compositions. Weaknesses: Research primarily focused on FeCoCrNiMn systems with less exploration of refractory HEAs; limited investigation of high-temperature stability of interstitial-strengthened alloys.

Key Scientific Breakthroughs in Interstitial Hardening

Timepiece component containing a high-entropy alloy

PatentActiveUS20200241475A1

Innovation

- A timepiece component made from a high-entropy alloy with between 4 and 13 main alloying elements, each concentrated between 1 and 55 at.%, which includes specific formulations like Fe80-xMnxCo10Cr10, offering enhanced mechanical strength and ductility, and potentially incorporating interstitial and structural hardening elements.

High-entropy austenitic stainless steel and preparation method thereof

PatentPendingUS20240093339A1

Innovation

- A high-entropy austenitic stainless steel composition with Cr, Ni, Ti, and Al, optimized to achieve nano-sized precipitates that enhance strength and plasticity, while reducing production costs by replacing expensive elements and minimizing the addition of alloying elements, using a specific atomic percentage range and a vacuum argon arc melting process.

Manufacturing Scalability and Process Optimization

The scalability of manufacturing processes for high-entropy alloys (HEAs) with controlled interstitial element content presents significant challenges in industrial applications. Current production methods primarily rely on laboratory-scale techniques such as arc melting, induction melting, and mechanical alloying, which offer precise control over composition but face limitations when scaled to industrial volumes. These constraints directly impact the ability to maintain consistent interstitial element distributions, which are critical for achieving desired hardness properties.

Process optimization for interstitial-modified HEAs requires sophisticated control systems that can monitor and adjust carbon, nitrogen, oxygen, and hydrogen levels throughout the manufacturing process. Advanced melting technologies, including vacuum induction melting (VIM) and vacuum arc remelting (VAR), have demonstrated promising results in maintaining compositional homogeneity while minimizing unwanted interstitial contamination. However, these processes require substantial capital investment and specialized expertise.

Powder metallurgy routes offer an alternative pathway for scaling production while maintaining precise control over interstitial content. Techniques such as gas atomization with controlled atmospheres can produce powders with predetermined interstitial concentrations. Subsequent consolidation through hot isostatic pressing (HIP) or spark plasma sintering (SPS) preserves these carefully engineered compositions while achieving near full density. These methods show particular promise for applications requiring specific hardness profiles through gradient interstitial distribution.

Cost considerations remain a significant barrier to widespread industrial adoption. The equipment required for precise interstitial control adds substantial overhead to production costs. Economic analyses indicate that batch sizes exceeding 500 kg may be necessary to achieve cost-effectiveness comparable to conventional alloy production. Additionally, quality control measures for interstitial content verification add further expense, with techniques such as inert gas fusion and combustion analysis requiring specialized equipment and trained personnel.

Recent innovations in continuous casting and additive manufacturing present emerging opportunities for scalable production. Continuous casting systems with controlled atmospheres have demonstrated the ability to produce HEA components with consistent interstitial profiles at rates approaching 100 kg/hour. Similarly, additive manufacturing techniques utilizing controlled-atmosphere powder beds show promise for complex geometries with tailored interstitial distributions, though build rates remain a limiting factor for high-volume applications.

Standardization efforts are currently underway through organizations such as ASTM International to establish protocols for interstitial element control in HEA production. These standards will be essential for ensuring consistency across manufacturers and facilitating broader industrial adoption of interstitial-modified HEAs with enhanced hardness properties.

Process optimization for interstitial-modified HEAs requires sophisticated control systems that can monitor and adjust carbon, nitrogen, oxygen, and hydrogen levels throughout the manufacturing process. Advanced melting technologies, including vacuum induction melting (VIM) and vacuum arc remelting (VAR), have demonstrated promising results in maintaining compositional homogeneity while minimizing unwanted interstitial contamination. However, these processes require substantial capital investment and specialized expertise.

Powder metallurgy routes offer an alternative pathway for scaling production while maintaining precise control over interstitial content. Techniques such as gas atomization with controlled atmospheres can produce powders with predetermined interstitial concentrations. Subsequent consolidation through hot isostatic pressing (HIP) or spark plasma sintering (SPS) preserves these carefully engineered compositions while achieving near full density. These methods show particular promise for applications requiring specific hardness profiles through gradient interstitial distribution.

Cost considerations remain a significant barrier to widespread industrial adoption. The equipment required for precise interstitial control adds substantial overhead to production costs. Economic analyses indicate that batch sizes exceeding 500 kg may be necessary to achieve cost-effectiveness comparable to conventional alloy production. Additionally, quality control measures for interstitial content verification add further expense, with techniques such as inert gas fusion and combustion analysis requiring specialized equipment and trained personnel.

Recent innovations in continuous casting and additive manufacturing present emerging opportunities for scalable production. Continuous casting systems with controlled atmospheres have demonstrated the ability to produce HEA components with consistent interstitial profiles at rates approaching 100 kg/hour. Similarly, additive manufacturing techniques utilizing controlled-atmosphere powder beds show promise for complex geometries with tailored interstitial distributions, though build rates remain a limiting factor for high-volume applications.

Standardization efforts are currently underway through organizations such as ASTM International to establish protocols for interstitial element control in HEA production. These standards will be essential for ensuring consistency across manufacturers and facilitating broader industrial adoption of interstitial-modified HEAs with enhanced hardness properties.

Sustainability Aspects of Advanced HEA Development

The development of sustainable High-Entropy Alloys (HEAs) represents a critical frontier in materials science that addresses both environmental concerns and resource efficiency challenges. As interstitial elements significantly influence HEA hardness properties, their strategic incorporation must be evaluated through a sustainability lens. Current HEA production methods often involve energy-intensive processes and rare earth elements, creating substantial environmental footprints.

Life cycle assessment studies reveal that optimizing interstitial element content can reduce overall energy consumption during manufacturing by 15-20% compared to conventional alloy production. Carbon and nitrogen as interstitial elements offer dual benefits: enhancing mechanical properties while potentially reducing the need for scarcer metallic elements. This substitution effect contributes to resource conservation and supply chain resilience.

Recycling considerations present both opportunities and challenges for interstitial-modified HEAs. The complex multi-element compositions may complicate traditional recycling streams, yet their superior durability extends product lifecycles, reducing replacement frequency and associated environmental impacts. Research indicates that HEAs with optimized interstitial content can demonstrate up to 40% longer service life in high-wear applications compared to conventional alloys.

Emerging green manufacturing techniques specifically tailored for interstitial-containing HEAs show promise. Powder metallurgy approaches combined with selective laser melting can reduce material waste by up to 30% compared to traditional casting methods. Additionally, lower temperature processing routes enabled by certain interstitial combinations could decrease energy requirements during production phases.

The economic sustainability dimension cannot be overlooked. While initial production costs for advanced HEAs may exceed conventional materials by 30-50%, their enhanced performance characteristics and extended service life often yield favorable total cost of ownership metrics. Market analyses project that sustainable HEAs could capture 15% of the high-performance materials market within the next decade, driven by increasingly stringent environmental regulations and corporate sustainability initiatives.

Regulatory frameworks worldwide are evolving to favor materials with reduced environmental impact. HEAs with carefully selected interstitial elements that minimize toxic or hazardous components while maintaining performance advantages are positioned favorably within this shifting landscape. This regulatory alignment represents a strategic advantage for forward-thinking materials developers and manufacturers.

Life cycle assessment studies reveal that optimizing interstitial element content can reduce overall energy consumption during manufacturing by 15-20% compared to conventional alloy production. Carbon and nitrogen as interstitial elements offer dual benefits: enhancing mechanical properties while potentially reducing the need for scarcer metallic elements. This substitution effect contributes to resource conservation and supply chain resilience.

Recycling considerations present both opportunities and challenges for interstitial-modified HEAs. The complex multi-element compositions may complicate traditional recycling streams, yet their superior durability extends product lifecycles, reducing replacement frequency and associated environmental impacts. Research indicates that HEAs with optimized interstitial content can demonstrate up to 40% longer service life in high-wear applications compared to conventional alloys.

Emerging green manufacturing techniques specifically tailored for interstitial-containing HEAs show promise. Powder metallurgy approaches combined with selective laser melting can reduce material waste by up to 30% compared to traditional casting methods. Additionally, lower temperature processing routes enabled by certain interstitial combinations could decrease energy requirements during production phases.

The economic sustainability dimension cannot be overlooked. While initial production costs for advanced HEAs may exceed conventional materials by 30-50%, their enhanced performance characteristics and extended service life often yield favorable total cost of ownership metrics. Market analyses project that sustainable HEAs could capture 15% of the high-performance materials market within the next decade, driven by increasingly stringent environmental regulations and corporate sustainability initiatives.

Regulatory frameworks worldwide are evolving to favor materials with reduced environmental impact. HEAs with carefully selected interstitial elements that minimize toxic or hazardous components while maintaining performance advantages are positioned favorably within this shifting landscape. This regulatory alignment represents a strategic advantage for forward-thinking materials developers and manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!